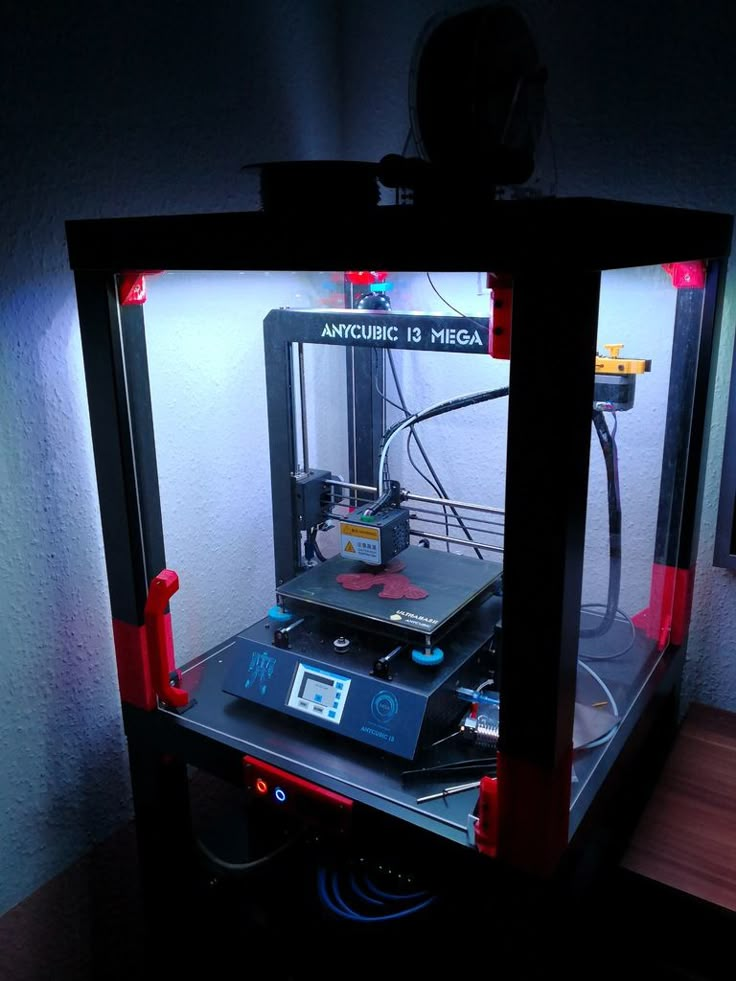

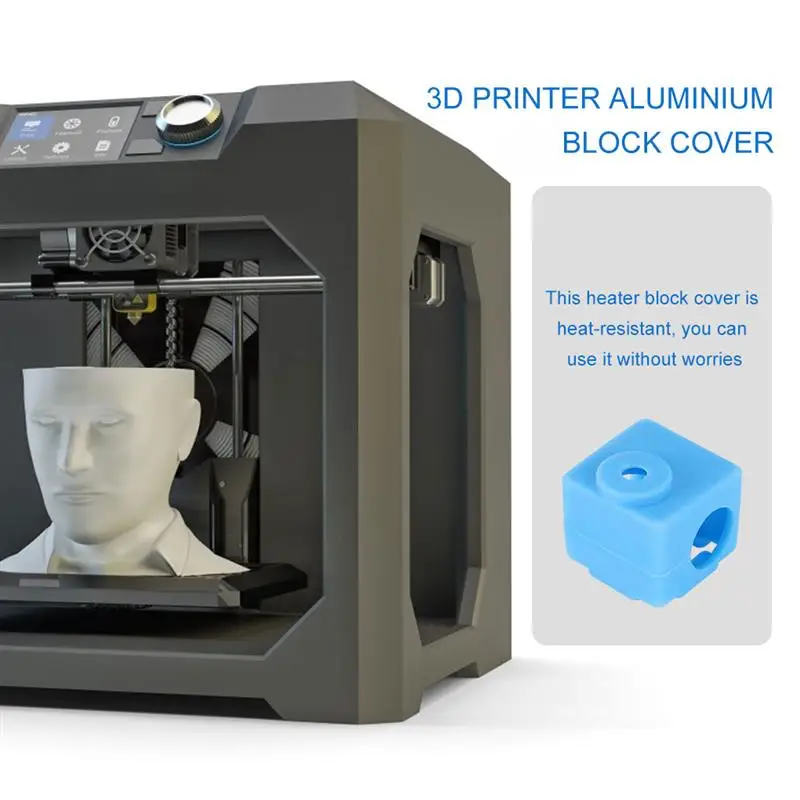

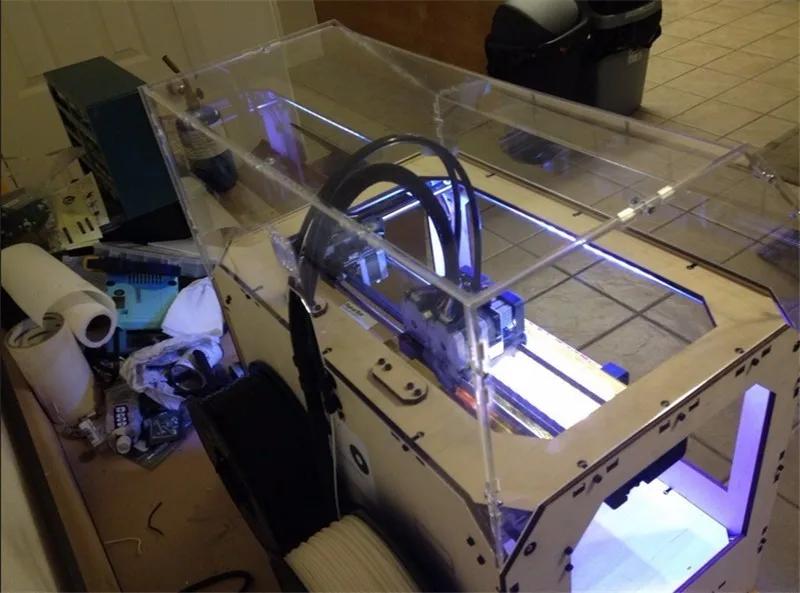

3D printer cover

3D Printer Enclosures, Boxes, Cases and Covers from 3DUPfitters – 3D UP Fitters

3D Printer Enclosures

Remove dangerous plastic fumes, suppress fires, reduce noise, and manage temperature to consistently print high quality parts

Buy Now

Thousands of 3D Upfitters customers have found that our enclosures help 3D printer owners to manage temperatures and consistently manufacture high-quality parts, remove dangerous plastic fumes, reduce noise, and automatically suppress fires.

Customers include not only the top tier in the technology, transportation, and education sectors, but small schools, small businesses, libraries, and hobbyists all over the world.

We sell top quality products Made in America on using materials from American factories.

We don't make 3D printers; we make 3D printers work better.

Advanced Engineering

Heat and airflow analysis enable the best placement for vents and fansAdvanced Testing

Each enclosure is thoroughly tested in our labDual Channel 3D Printer Temperature and Air Quality Meter

Changes of season, with the thermostat ping-ponging between heat and A/C can be a challenging time to get consistent 3D prints. This dual channel temperature logger helps you track temperature changes over time to determine the optimal settings for your prints while monitoring air quality.

Product Details

I do really love this enclosure, the quality is amazing, and the results with ABS have been exactly what I was looking for! Saved me a bunch of money upgrading to a more commercial-grade printer to do what I need!

Ted M.

I wanted to send a note to you folks about how happy and impressed I am with the quality and design of your enclosure for our new Makergear M3-SE. We at Tandemloc, Inc. just purchased our first printer to manufacture some peripheral plastic components for our new automated lifter designs and the enclosure enables us to use the printer right in the engineering office, with no smell and no audible sound while printing.

William D.As a mechanical engineer I realize the amount of work that goes in to making something that works well and is simple to build. The fit and look is fantastic.

I just wanted to let you know how much I like my Prusa Mk3 enclosure. I’m not that handy but the videos and the instructions were first rate. The fit and finish of your product is really outstanding and I would highly recommend it to anyone. I was concerned about air quality. By having the enclosure venting outside, this has freed my mind to concentrate on the printing. Glorious!

James H.

I would like to commend you on the professionalism, great attention to detail, and pride each step of the way.

Chris C.

I was so pleased with the Prusa Mk3S+ and your enclosure so I went and bought another Prusa.

Jonas I.

The IKEA "Lack" table has reached legendary status among 3D printing enthusiasts. It’s amazing they can sell a table for $9 even if it is made out...

- Read more

If you've been active in the online 3D printing forums, it won't take long to come across a picture of someone's printer after a fire. But does th...

- Read more

A lot of 3D printer enthusiasts start out putting a cardboard box over the printer, but there’s a lot more to it than that! This article will expl. ..

..

- Read more

3D Printer Enclosures from 3DUPfitters – 3D UP Fitters

by Michael Czeiszperger

Seth Fowler is a typical 3DUPFitters customer, using his collection of 3D printers and enclosures to create something cool: shoes made of flexible...

- Read more

by Michael Czeiszperger

"I've sold hundreds of 3D-printed license plate mounts for various Porsche models. These feature heat-set metal threads and 3M Molding Tape to hold them in place. Demand got to be so high, that I now have the standard black mounts CNC'd out of solid ABS, but still print them in special colors for people who want color-matched mounts."

These feature heat-set metal threads and 3M Molding Tape to hold them in place. Demand got to be so high, that I now have the standard black mounts CNC'd out of solid ABS, but still print them in special colors for people who want color-matched mounts."

- Read more

by Michael Czeiszperger

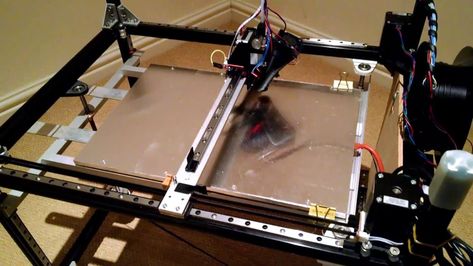

The 3DUPfitters enclosures work by carefully aligning vents to bring cool air from outside of the enclosure to electronics and power supplies. Thi...

- Read more

by Jon Powell

The IKEA "Lack" table has reached legendary status among 3D printing enthusiasts. It’s amazing they can sell a table for $9 even if it is made out...

It’s amazing they can sell a table for $9 even if it is made out...

Sticky

- Read more

by Jon Powell

Normally we pick fan CFM to be allow of balance of heat vs air quality control. The problem is airflow that recirculates every few minutes isn’t a...

- Read more

by Jon Powell

We've got 4 Prusa MINIs running 24/7 at 3D Upfitters, and the only thing keeping them from being a perfect print farm machine was the side loading . ..

..

- Read more

by Jon Powell

I recently tried out some cheap filament on a 1Kg spool on one of our super-smooth spool holders on a Prusa MK3S+. Since these printers are direct ...

- Read more

by Jon Powell

It's the 1950s. Leo Fender had popularized the electric guitar, which of course, required an amplifier. Like his guitars, he picked the cheapest co...

Leo Fender had popularized the electric guitar, which of course, required an amplifier. Like his guitars, he picked the cheapest co...

- Read more

by Jon Powell

One of the more common ideas customers have had was adding skate bearings to our acrylic spool holder, so when the supply of acrylic rods ran low, it was a no-brainer to convert the spool holder to use skate bearings instead. Keep in mind everything we design has to work in our print farm. The spool holders are specifically designed to require no adjustment or maintenance and just work day after day and month after month. Any changes to add skate bearings couldn't affect the practical functionality.

acrylic spool holder

- Read more

by Michael Czeiszperger

Prusa MK3 owners have it made: the rubber feet on the Prusa MK3S+ printers don't slip and they make the Prusa MK3 one of the quietest on the market...

- Read more

by Jon Powell

The grass is always greener, etc. , etc. I once bought a printer with a direct drive hot end design and then read online that the smart thing to d...

, etc. I once bought a printer with a direct drive hot end design and then read online that the smart thing to d...

- Read more

by Jon Powell

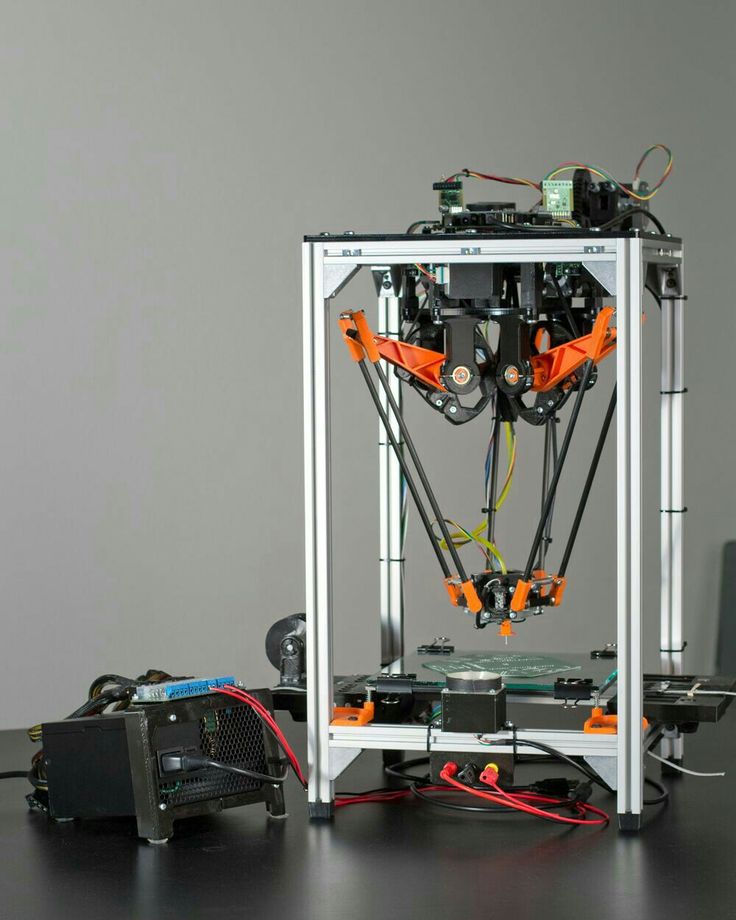

Most people don't customize their 3D printers, and thus 3D UP Fitters enclosures are designed to work with the stock configuration and as few modif...

3d printer 3D Printer Enclosure 3d printing

- Read more

An ordinary plastic lid can become an innovative material

An ordinary plastic lid can become an innovative material

As part of the Ecotechnologies for Children environmental campaign in Krasnodar, plastic lids become a material for a 3D printer.

An ordinary plastic cap from a PET bottle made from water, milk and even yogurt can become a material for 3D modeling. This became possible within the framework of the environmental campaign "Ecotechnologies for Children", which was launched at the Krasnodar Center for Children's and Youth Technical Creativity with the support of the Ministry of Education, Science and Youth Policy of the Krasnodar Territory and OOO Lukoil-Kubanenergo.

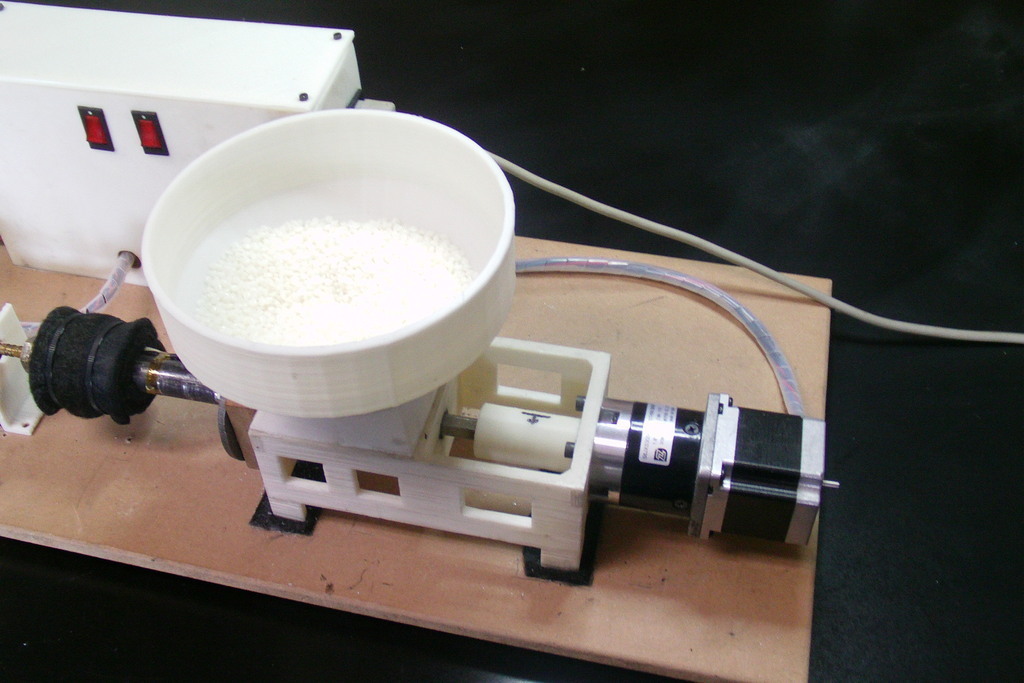

Assembled plastic caps, according to project manager Artem Sobolev, must go through several

stages of processing before becoming a material for a 3D printer.

First, the colored caps are crushed in a special grinder. Then the multi-colored crumb enters a softening machine called an "extruder" - there the material becomes plastic and can be given any shape by forcing through a profiling tool. The temperature inside such a machine reaches 220 degrees. The finished thread for the printing printer appears after an hour.

Not only plastic caps can be used, but also PET bottles themselves, however, due to their large size, they take much longer to cut and grind, and the pressure temperature in the extruder must be higher - the training machine does not allow such experiments.

Recycled plastic can become not only a material for a 3D printer, but also the basis for furniture, stationery, clothing, household products and many other things that we use in everyday life.

“Today, in addition to the humanities, there is an applied search science - the creation of new technologies. Therefore, it is symbolic that within the walls of this center for children's and youth technical creativity, schoolchildren at the age of 7-14 are already involved in cognitive activities,” said Mikhail Sharafan, head of the department of the Ministry of Education, Science and Youth Policy of the Krasnodar Territory.

In parallel with the 3D modeling experiments, the children are told why it is important to collect plastic. Vacationers often leave PET bottles and other plastic packaging in nature, which negatively affects the environment, as they decompose for at least a hundred years. And plastic bottle caps often attract gulls and terns: when corks accumulate in the bird's stomach, they cause death. The action "Ecotechnologies for Children" is designed to give garbage a second life, demonstrate the idea of waste-free production and thereby save nature. Recycled plastic can become not only a material for a 3D printer, but also the basis for furniture, stationery, clothing, household products and many other things that we use in everyday life.

Vacationers often leave PET bottles and other plastic packaging in nature, which negatively affects the environment, as they decompose for at least a hundred years. And plastic bottle caps often attract gulls and terns: when corks accumulate in the bird's stomach, they cause death. The action "Ecotechnologies for Children" is designed to give garbage a second life, demonstrate the idea of waste-free production and thereby save nature. Recycled plastic can become not only a material for a 3D printer, but also the basis for furniture, stationery, clothing, household products and many other things that we use in everyday life.

“Participation in such events allows you to change the way a child thinks, makes you think more about how waste can be reused. And who knows what ideas of environmental projects they will have when they grow up,” says Artem Sobolev.

The future is in plastic recycling technology, organizers of the action are sure. They plan to hold presentation events in sponsored orphanages and stations for young technicians throughout the Kuban. The environmental campaign will continue from October 16 to October 25 in the cities and regions of the Krasnodar, Stavropol Territories, as well as in the Rostov Region.

They plan to hold presentation events in sponsored orphanages and stations for young technicians throughout the Kuban. The environmental campaign will continue from October 16 to October 25 in the cities and regions of the Krasnodar, Stavropol Territories, as well as in the Rostov Region.

Read more

Russia and exports: new data on an old question!

Plastic packaging in Russia: import substitution in action

Surprising facts about the plastic bottle that you did not know

Reincarnation of the plastic bottle

How PET bottles are made: blowing, cooling and a little magic

Stakeholders

3D printed lid - for determining the degree of freshness of milk

Feb32016

3D printing cover

In addition to the global use of 3D printing, there are more and more 3D models designed to simplify our daily lives. Most are still in development or at the initial stage of implementation. However, this niche is gradually being filled with new devices, because there is no limit to the human desire to reduce everyday problems to a minimum.

At the moment, almost every new invention is a breakthrough, but it is planned that one day people will be able to simply download a 3D model file of suitable function and design from the Internet and print useful devices at home on their own 3D printer. This trend is gradually gaining momentum, and in the future, no doubt, it will become commonplace for everyone.

Sometimes inventions are quite useful, but very funny and non-standard. Scientists in Berkeley, California, working with National Taiwan University, have finally recognized the importance of meeting the needs of the millions of consumers who rely on less-than-perfect usability systems every day. The team succeeded in creating a wireless smart lid with built-in sensors for determining the degree of freshness of milk.

3D printing cover

The invention was started by a group of researchers who were interested in working with polymers to create electronic devices. Polymers have a very high degree of flexibility, which allows them to take any desired shape and makes them the most suitable material for 3D printing. However, they are not of interest for creating printed electronics, since they are very poor conductors of electricity. After much research, a very practical decision was made to use a flexible polymer shell interspersed with special printing wax, which can then be removed and replaced with a metal, in this case silver. By manipulating the shape of the metal, the researchers were able to achieve the functions of various electrical components.

However, they are not of interest for creating printed electronics, since they are very poor conductors of electricity. After much research, a very practical decision was made to use a flexible polymer shell interspersed with special printing wax, which can then be removed and replaced with a metal, in this case silver. By manipulating the shape of the metal, the researchers were able to achieve the functions of various electrical components.

3D printed lid

The developers have integrated electronic elements into the plastic lid of the milk bag in order to be able to control the amount of bacteria inside. The device was equipped with a capacitor and an inductor to form a resonant circuit. Then the package was filled with milk so that a small amount of it fell on the condenser, the container was closed and left at room temperature for 36 hours. As the level of bacteria increased, the electrical signals changed, and these changes were tracked using a special program.