3D printed beating heart

Boston University's new 3D printed mini human heart beats on its own

0Shares

A research team led by Boston University has used 3D printing technology to develop a miniature replica of a human heart – and it beats like the real thing.

Named the cardiac miniaturized Precision-enabled Unidirectional Microfluidic Pump, aka the miniPUMP, the device was created using a combination of stem cell-derived human heart cells and micro-scale 3D printed acrylic parts. Designed to behave like a real heart chamber, the miniPUMP doesn’t rely on any external sources of power, instead beating by itself thanks to its live tissue.

The researchers believe their heart chamber replica could serve as a testbed to study how the organ works in the human body. It can be used to track how the heart grows in an embryo, how heart tissue is affected by diseases, and how effective new medications are in treating said diseases, all without the need for human testing.

“We can study disease progression in a way that hasn’t been possible before,” says Alice White, a Boston University College of Engineering professor. “We chose to work on heart tissue because of its particularly complicated mechanics, but we showed that, when you take nanotechnology and marry it with tissue engineering, there’s potential for replicating this for multiple organs.”

The challenge of studying the heart

According to the Centers for Disease Control and Prevention, heart disease is the leading cause of death for both men and women in the US, with around 659,000 mortalities every year. That’s one in four deaths. As such, there’s an urgent need to study the vital organ.

However, due to its inaccessible location in the human body, the heart is a tricky thing to study as it can’t just be removed, examined, and replaced on a whim. To address this, researchers have tried several alternative approaches: they’ve manually pumped blood through cadaver hearts and they’ve spring-loaded lab-grown heart tissues to make them expand and contract. Unfortunately, we’re yet to find a suitable lifelike proxy as reanimated hearts can’t beat indefinitely and springs don’t contract like real muscle fibers.

Unfortunately, we’re yet to find a suitable lifelike proxy as reanimated hearts can’t beat indefinitely and springs don’t contract like real muscle fibers.

With innovations like the miniPUMP, researchers could eventually mimic and study diseases such as hypertension and valve disease in a more accurate manner. The device is also expected to streamline the drug development process for upcoming medicines, enabling lab-based testing in lieu of costly and tedious human trials.

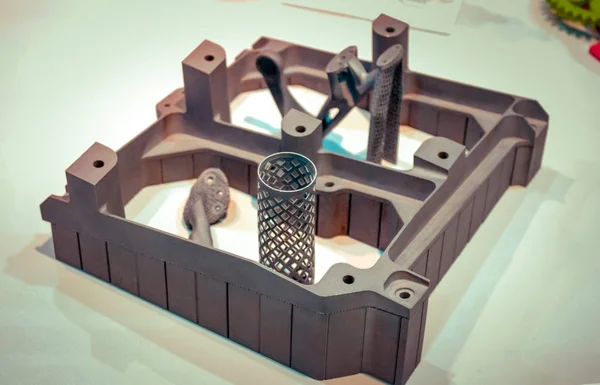

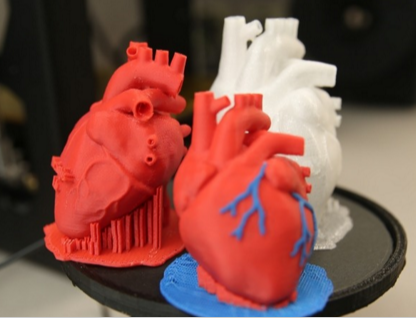

A large-scale replica of the 3D printed scaffold that supports the heart tissue. Photo via Christos Michas.How was the miniPUMP developed?

The miniPUMP measures just three square centimeters and features an acrylic scaffold 3D printed using two-photon direct laser writing, a very precise form of micro-SLA. The tiny acrylic valves within open and close to control the flow of fluid, while the miniature tubes serve as arteries and veins. To make the device beat, the researchers also integrated heart muscle cells called cardiomyocytes, which were differentiated from pluripotent stem cells.

The decision to make the miniPUMP so small was a deliberate one, as the 3D printed acrylic scaffolds had to be strong enough to support the structure but thin enough to bend and move with the contracting heart tissue.

“The structural elements are so fine that things that would ordinarily be stiff are flexible,” adds White. “By analogy, think about optical fiber: a glass window is very stiff, but you can wrap a glass optical fiber around your finger. Acrylic can be very stiff, but at the scale involved in the miniPUMP, the acrylic scaffold is able to be compressed by the beating cardiomyocytes.”

As far as next steps go, the miniPUMP research team aims to refine the technology and find ways of manufacturing it reliably. The work can also eventually be applied to implantable patches that may fix defects in the heart, as well as other organs such as livers.

The project is being conducted as part of CELL-MET, a joint National Science Foundation Engineering Research Center in Cellular Metamaterials led by Boston University. The center’s ultimate goal is to create devices capable of regenerating diseased human heart tissue.

The center’s ultimate goal is to create devices capable of regenerating diseased human heart tissue.

The 3D printing of human heart replicas and models is something we’ve seen before. Just last month, researchers from the Technical University of Munich (TUM) and the University of Western Australia developed 3D printed artificial heart valves made from a patient’s own cells that grow as the individual ages. The approach hopes to overcome the drawbacks of conventional prosthetic heart valves, which only last a limited number of years and therefore require multiple replacement surgeries.

Elsewhere, researchers from the Chinese Academy of Sciences (CAS) recently converted a six-axis robotic arm into a 3D bioprinter and used it to fabricate a complex-shaped blood vessel scaffold. The 3D printed vascularized heart tissue remained alive and beating for six months, and could demonstrate a feasible method of bioprinting functional tissues and organs in the future.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

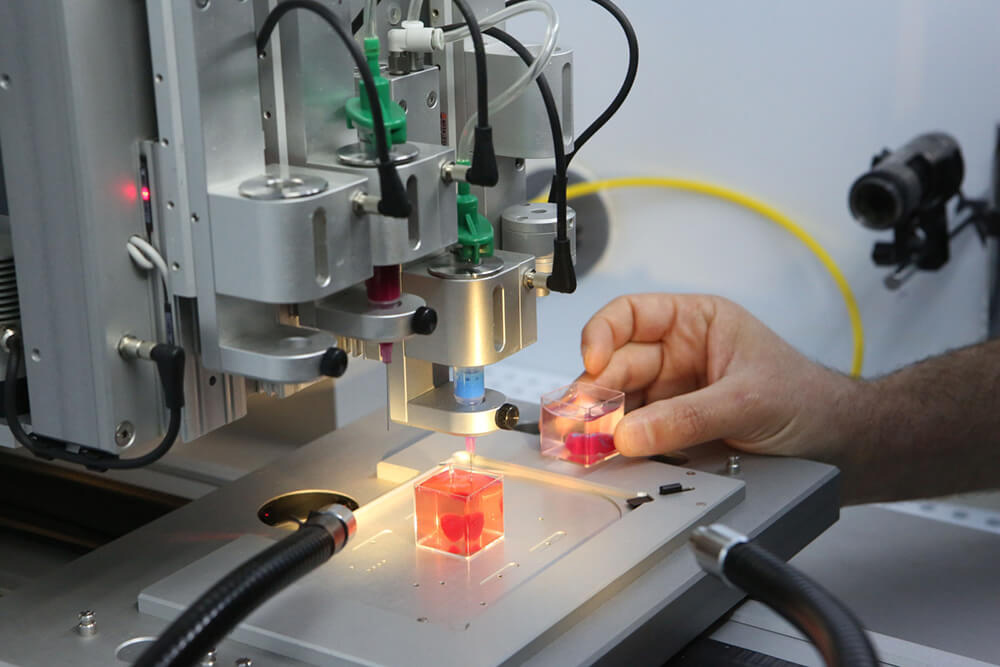

Featured image shows a side view image of the miniPUMP being taken in the lab. Photo via Jackie Ricciardi.

Tags Alice White Boston University CELL-MET miniPUMP

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Israeli scientists create world's first 3D-printed heart using human cells

Innovation

The team created a cell-containing "bioink" and used it to 3D print the organ layer by layer.

By David Freeman

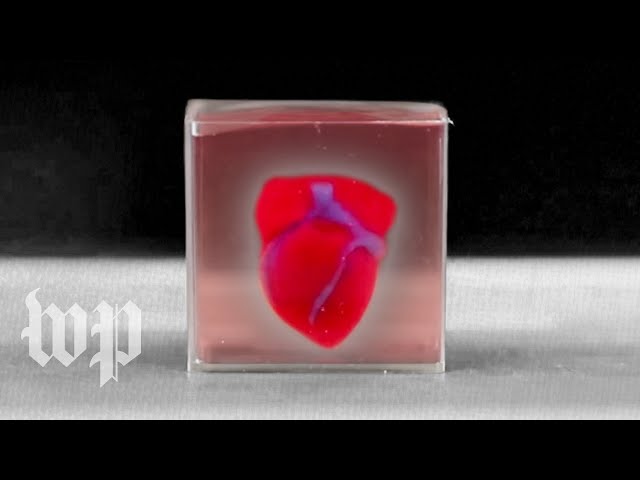

Israeli researchers have created an entire 3D-printed heart made from human cells in what they say is a world first.

The heart doesn't beat and is too small for use in people — it's only about the size of a rabbit's heart. But the little organ is considered a big advance in the ongoing effort to find new treatments for heart disease, the leading cause of death in the United States.

Heart transplantation is currently the only good option for people with severe heart failure. But donor organs are in such short supply that, on average, 18 Americans die each day before one becomes available. Being able to 3D-print a human heart when needed could conceivably help save many lives that are now lost.

"Maybe, in 10 years, there will be organ printers in the finest hospitals around the world, and these procedures will be conducted routinely," Tal Dvir, a researcher with Tel Aviv University's School of Molecular Cell Biology and Biotechnology and the leader of the team of scientists who created the heart, told NBC News MACH in an email.

A 3D printer builds a heart with human tissue during a presentation at the University of Tel Aviv on April 15.Oded Balilty / APA paper describing the research was published Monday in the journal Advanced Science.

Previously, scientists were able to 3D-print heart structures that lacked cells or blood vessels. But the new 3D-printed heart contains cells, blood vessels, chambers and other structures a heart needs to function normally. To make it, Dvir and his team took fatty tissue from patients and converted the fat cells into stem cells. These were added to a gel and then further processed until they turned into heart cells. The cell-containing "bioink" was added to a 3D printer and used to build the experimental organ layer by layer.

Tal said the next step for his team would be to explore ways to "teach" 3D-printed hearts to function normally and then transplant them into rats to see how well they work. The scientists will also explore the feasibility of 3D-printing larger hearts, with the ultimate goal of building functional human hearts.

That might be even harder than it sounds.

"There are many questions and technical hurdles that need to be addressed," James Yoo, a professor at the Institute for Regenerative Medicine at the Wake Forest School of Medicine in Winston-Salem, North Carolina, said in an email.

Yoo said it's not clear that a printed heart of this sort could withstand the flow of blood under high pressure or that the printed structures would remain stable after implantation in the body. And he expressed concerns over the real-world feasibility of the "complex" process of cellular manipulation used to create the bioink — though he called the heart "a great advance in the field of bioprinting. "

"

Doris Taylor, director of regenerative medicine research at the Texas Heart Institute in Houston, said in an email that the Israeli scientists had "pushed the envelope" of regenerative medicine but declined to call the 3D-printed heart a major breakthrough.

"A successful bioartificial organ that is implanted in a human will be a major medical breakthrough," she said in the email. "This is certainly a step that could lead to a breakthrough, but we aren’t there yet.”

WANT MORE STORIES ABOUT SCIENCE?

- Scientist create artificial blood vessels that come to life

- These tiny robots could be disease-fighting machines inside your body

- Scientists say brain implant may be key to fighting addiction

FOLLOW NBC NEWS MACH ON TWITTER, FACEBOOK, AND INSTAGRAM.

Living heart printed on a 3D printer - Kommersant FM - Kommersant

In Israel, for the first time in the world, a living heart was created on a 3D printer, which consists of tissues and blood vessels, and also has cameras. True, at the moment it can only suit a rabbit because of its small size. But scientists from the University of Tel Aviv are confident that in the future they will be able to print a heart for a person. How did you manage to create an organ on the printer? And can we talk about a revolution in medicine? Anna Nikitina and Gleb Silko will tell. nine0003

True, at the moment it can only suit a rabbit because of its small size. But scientists from the University of Tel Aviv are confident that in the future they will be able to print a heart for a person. How did you manage to create an organ on the printer? And can we talk about a revolution in medicine? Anna Nikitina and Gleb Silko will tell. nine0003

Photo: Yaroslav Chingaev, Kommersant / buy photo

The world's first 3D-printed heart resembles a berry: its size is about 2.5 cm, although it took more than three hours to print. However, even now the achievement of Israeli scientists is called a medical breakthrough. The heart is made from human fat cells and connective tissue. Previously, synthetic substances were used for this.

In the future, this new technology will not only solve the problem of the shortage of organs for transplantation, but will also facilitate the transplantation process as much as possible, says Israeli journalist Sasha Vilensky: “The most global problem is the rejection of a transplanted organ by the body. There is always such a danger. But the whole point of interest is that in the case of a 3D printer, we are dealing with what is grown and printed from the cells of the patient himself, thus simply removing the issue of rejection. This is genius". nine0003

There is always such a danger. But the whole point of interest is that in the case of a 3D printer, we are dealing with what is grown and printed from the cells of the patient himself, thus simply removing the issue of rejection. This is genius". nine0003

The problem of organ shortages around the world is really acute. In Russia, for example, in 2017, there were only 900 donors per 6 million people. And the most complex organ - the heart - was transplanted 250 times in a year, while it required almost 2 million people. The experience of Israeli scientists in printing hearts is impressive, and it can be used in other countries, says Yousef Hesuani, executive director of the 3D Bioprinting Solutions laboratory. True, according to him, it is still too early to talk about a revolution in medicine: “Scientists have used a very interesting material based on collagen - this is a protein in the body of mammals. In addition, it is from the point of view of creating a complex three-dimensional structure that the researchers are great, they did a really good job. However, the form does not yet determine the function, especially if we are talking about such a complex organ as the heart. nine0003

However, the form does not yet determine the function, especially if we are talking about such a complex organ as the heart. nine0003

New approaches have been used, but unfortunately it is too early to say that there has been an incredible breakthrough in this area.

When, for example, the native organ is removed and a new one is transplanted, and the function is fully restored, this will become an unconditional revolution.”

Tel Aviv University itself, where the heart was printed, says that in the future the necessary organs can be printed directly in hospitals. Now similar developments are being carried out all over the world. Russian companies, for example, are trying to create an artificial liver and kidneys. True, this process is too expensive, and it is unlikely that in the near future the technology will be introduced on a mass level, says the director of the National Medical Center for Transplantation and Artificial Organs. Shumakova Sergei Gauthier: “What the Israeli doctors did is just great. This proves that these possibilities can really be used to create some kind of anatomical structures. As for other organs, such as the kidney and liver, our institute is also working on this. We also have bioprinters, but frankly, growing such tissue complexes is a rather complicated and expensive technology, which is very different from the traditional method of organ transplantation.” nine0003

This proves that these possibilities can really be used to create some kind of anatomical structures. As for other organs, such as the kidney and liver, our institute is also working on this. We also have bioprinters, but frankly, growing such tissue complexes is a rather complicated and expensive technology, which is very different from the traditional method of organ transplantation.” nine0003

There are already examples in the world when doctors managed not only to create artificial organs on a 3D printer, but also successfully transplant them, for example, a few years ago in Russia a thyroid gland was printed, which took root in a patient. And last year, scientists from Jerusalem implanted a prosthesis for the skull on a patient, and it was also created using three-dimensional technologies.

During this year, Israeli scientists plan to test printed hearts on rabbits and rats, and then start working on creating a human heart. nine0023

Free STL file Heartbeat・3D printer model to download・Cults

Poly Heart

0. 75 €

75 €

Love Heart Flip

0,50 €

Ramadan Crescent 2

1.50 €

UAE 51 - Name flip

3 €

nine0028 Ramadan Crescent1.50 €

Crescent minaret

0.50 €

Shade

Free

Toolbox

Free

Best 3D Printer Files in the Miscellaneous Category

Key ring Jasmin

Free

RETRO CASSETTE DOCUMENT HOLDER

1,32 €

Silicone rubber hookah mouthpiece / silicone rubber hookah mouthpiece

1 €

American truck (can roll)

Free

Glow Stick Saber

Free

Mini Table for Solo Camping

Free

STAR WARS VINTAGE MINIONS HALLOWEEN SPECIAL R2-D2, CUSTOM UNPRODUCED KENNER, HASBRO ACTION FIGURE, 3.

75", 1/18, 5POA

75", 1/18, 5POA 1,88 €

Eren Jaeger Attack on Titan Shingeki no Kyojin

6,60 €

Bestsellers in Miscellaneous category nine0062

Charizard - pokemon with flexible articulation (seal in place, without supports)

3 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2,50 €

ItsLitho "Pure" personalized Lithophane Christmas ball

1,90 €

THING Addams

€8.49

Chop Fernet World Cup

10.56 €

Gremlin rail 640 mm FPV

0,94 €

Mickey Christmas night light Litophane

3,50 €

MMPR Dragon Dagger

4. 72 €

72 €

Christmas House

6.81 €

THING-ENVIRONMENT-COMPANY-HD-PRINT

1,30 €

ItsLitho "Drop" personalized lithophane Christmas ball

1,90 €

Bunch of Christmas balls ItsLitho

5,70 €

4th planet Fighting pre-Olympic god

12 €

nine0028 Adderini - 3D printed repeating slingbow / crossbow pistol€12.50

Addams Thing

1.99 €

Articulated Gyarados

1.99 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.