3D printing boise

3D Printing Service for Boise, Idaho

CapabilitiesCustom Online 3D Printing ServiceIdahoBoise

High Quality Boise, Idaho 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Boise, Idaho 3D Printing Service: 3D Prototypes and Production Parts

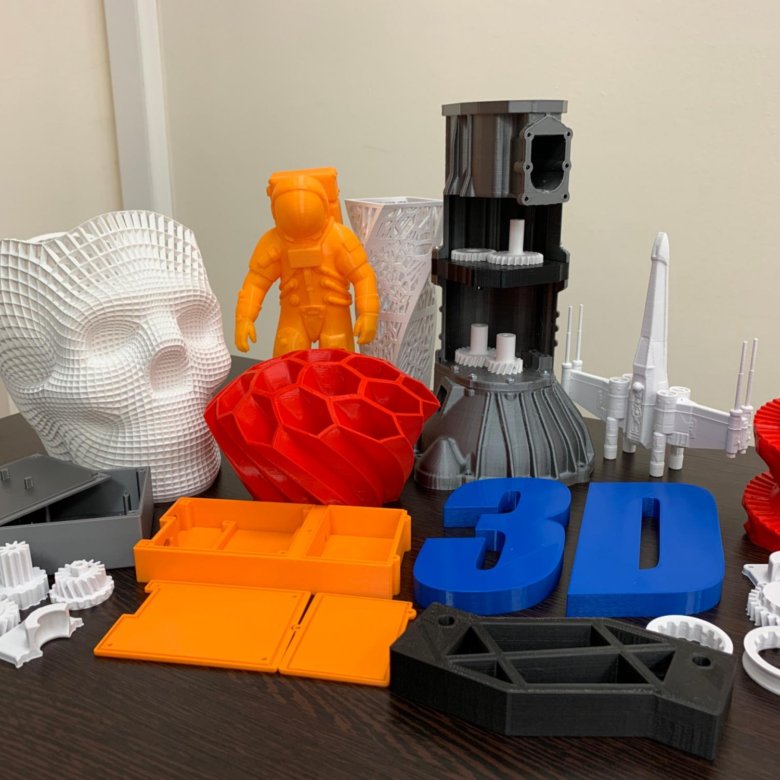

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

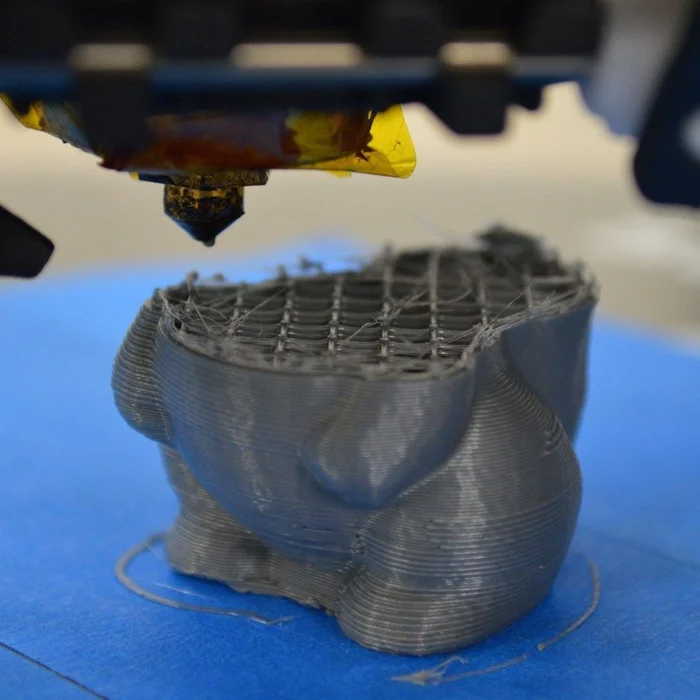

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Boise, Idaho

Meridian

IdahoSpokane

WashingtonHelena

MontanaBozeman

MontanaYakima

WashingtonSalt Lake City

UtahProvo

UtahSparks

NevadaReno

NevadaEugene

OregonPortland

OregonSalem

OregonCorvallis

OregonCarson City

NevadaTacoma

WashingtonBellevue

WashingtonRedmond

WashingtonSeattle

WashingtonBillings

MontanaSacramento

California

Ready to start making custom 3D printed parts?

Fee-Based Services - Makerlab

The MakerLab offers current students (actively enrolled), staff, and faculty at Boise State University the following services:

- Access to and assistance with emerging technology

- Instruction for Boise State University courses

Other services provided by the MakerLab are beyond the scope of the MakerLab services and therefore have fees associated with them.

3D Printing

Any student, staff, and faculty may use the LulzBot and other Fused Deposition Modeling 3D Printers to print themselves with some coaching from the MakerLab employees. Simply walk in any time the MakerLab is open and request help getting started.

Resin Printing

All resin prints on Form 2 are available for students, staff, and faculty for assignments and research purposes only. There is no charge for using the resin printers.

FDM 3D Printing Flat Rate

Boise State students, staff, and faculty who need to protect their own intellectual property needs, or who would like the MakerLab team to 3D print on their behalf there is a fee. There is no fee for Boise State students, staff, and faculty who learn to 3D print themselves, manage their prints, and schedule their time to fit within the open hours of the MakerLab.

The MakerLab cannot encumber mass production of 3d prints and recommends that if your project requires mass production that you consider two options:

- Working with a company such as Slant 3D to obtain a quote on mass production

- Have a student researcher or employee manage their own prints in the MakerLab

For those 3D prints you’d like the MakerLab to 3D print, there is a charge and a process.

- The rate is calculated based on the number of grams, including support material if support material is deemed to be necessary.

- The invoice must be paid before we start work.

- The size must be correct. The customer is responsible for size accuracy.

- The fee is $1.00 per gram plus Idaho sales tax of 6% plus a one-time set up fee of $10.00.

- Each part or file must be submitted separately and encumbers its own setup fees per part.

- Requesters must meet with the MakerLab team to consult on the 3D print. Email [email protected] to set up a time.

- Not all requests are possible given time, resource, and staffing constraints.

Other Services

- Occasionally, we may not be able to meet your needs. If that is the case we recommend reaching out to these organizations.

- Shapeways

- Hubs

- Little Shop of Laser

- UnBound

- Slant 3D

- Tech Help

- Woodcraft of Boise

Open the MakerLab for Special Events

- To open the MakerLab beyond regular hours for special events requires additional staffing, as well as cleanup and set up.

This includes training on one piece of equipment per hour per 10 students

This includes training on one piece of equipment per hour per 10 students - Cost is $150 per hour

- To open the MakerLab beyond this for additional students $150 per hour base, plus $15 per additional student

- $100 each additional hour per each technology

MakerLab: Tours and Instruction for Non-Boise State School Groups

- $7.00 per student – base rate instruction

- Includes:

- 1 3D printed Boise State B per attendee

- One half-hour Tinkercad instruction

- Gain creative confidence

- Acquire digital skills

- Discuss making and tinkering with available emerging technology

Ed Boys 3D File・3D Printer Model Download・Cults

Leopard Gecko

2.36 €

Lord Boxman

Free

Best 3D Printer Files in the Miscellaneous Category

Pudsey Bear

Free

nine0003 Smartphone holder for Peugeot 308 1. 80 €

80 €

N scale Southern Pacific 3/4 Dome car

1.42 €

Mk Ultra - 3D printed 1/10 4wd buggy

Free

Ant farm formicarium horizontal doublecolor

14 €

eGull 9 outboard motor0004

4.57 €

Hermione Granger wand - Harry Potter films 3D print model

3,14 €

Sequoia and King's Canyon Park Maps

Free

Bestsellers in Miscellaneous category

Speeder-Pad support on FLSUN V400 and FLSUN SuperRacer

3 €

nine0003 HAND OF THE ADDAMS FAMILY5 €

4th planet Fighting pre-Olympic god

12 €

Gremlin rail 640 mm FPV

0,94 €

hinged shenron

3 €

Predator-inspired movable mask

€6. 20 nine0075 -fifteen% 5.27 €

20 nine0075 -fifteen% 5.27 €

ItsLitho "Creamy" personalized Lithophane Christmas ball

1,90 €

Key holder for middle finger

1 €

Item

8 €

Wednesday item

€3.82 -twenty% 3.05 €

Christmas Park

4.57 €

Articulated Raykuaza Flexible Dragon Pokémon

1 €

MMPR Dragon Dagger

4.72 €

nine0003 Gengar - pokemon with flexible articulation (seal in place, without supports)2 €

Mickey Christmas night light Litophane

3,50 €

flexible volute

2 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are is a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

How 3D printing helps fight the coronavirus

Protective mask designs, door handle designs, medical supplies blueprints are donated by companies and enthusiasts who work with 3D printing. Volunteer 3D makers from all over the world have joined the fight against coronavirus. nine0006

Hospitals in Italy, which ranks second in the world in terms of the number of victims of COVID-19 (more than 25 thousand people died there), are sorely lacking medicines and equipment. In March, a clinic in the city of Brescia in Lombardy ran out of valves for ventilators. The manufacturer could not organize an emergency supply of components. Enthusiasts from the startup Isinnova came to the rescue. They independently made drawings according to the model, printed consumables on a 3D printer and handed them over to the hospital for free. Ventilators could be used again, and this helped save the lives of ten people. nine0006

In March, a clinic in the city of Brescia in Lombardy ran out of valves for ventilators. The manufacturer could not organize an emergency supply of components. Enthusiasts from the startup Isinnova came to the rescue. They independently made drawings according to the model, printed consumables on a 3D printer and handed them over to the hospital for free. Ventilators could be used again, and this helped save the lives of ten people. nine0006

Later, fakes began to spread on the Web that the valve manufacturer sued the startup for patent infringement. Subsequently, this information was refuted.

Participants of the Chilean project Copper3D also contributed to the fight against coronavirus. They have posted a 3D design of a protective mask in the public domain. In the first two days alone, the file was downloaded 3 million times.

Czech Prusa Research has published a drawing of a face shield. The company printed and donated more than 65,000 shields to the country's medical institutions. nine0006

nine0006

Large companies are not left out. In the US, 3D manufacturer SmileDirectClub, a manufacturer of orthodontic accessories, has lent its capacity to print medical consumables needed to treat COVID-19. The company manufactures protective screens. The first batch of 1,000 shields has already arrived at St. Luke's Medical Center in Boise, Idaho.

CadCrowd, an international portal for 3D creators, is holding a competition to develop accessories that will help you avoid touching surfaces in common areas with your hands. “Examples of such products are touchless door handles, door handle attachments and faucets,” the briefing notes. The most successful ideas with all the technical documentation will be posted online. nine0006

Such developments already exist. Belgium-based Materialize posted on their website a drawing of a doorknob escutcheon that can be used to open the door with your elbow.

There are enthusiasts who are not afraid to take on more complex tasks. Thus, on the platform of the web service for hosting and joint development of IT projects Github, within the framework of the OpenRespirator project, a list of verified drawings of ventilators and their components is presented, according to which products can be printed on a 3D printer. nine0006

Thus, on the platform of the web service for hosting and joint development of IT projects Github, within the framework of the OpenRespirator project, a list of verified drawings of ventilators and their components is presented, according to which products can be printed on a 3D printer. nine0006

The Russian community of 3D printer owners has also joined the global trend. Participants of the “Makers against COVID-19” initiatives, volunteers from different cities of the Russian Federation, produce and donate personal protective equipment to medical institutions.

Another example is the initiative of the residents of the Technopolis Moscow special economic zone. Companies are ready to set up the production of scarce components for medical equipment using 3D printing.

Ordinary people who have a 3D printer are also actively involved in the common cause.

“Gentlemen, in case everything stops working at all, how can our printers help in the fight against this infection? Can some kind of respiratory filters be printed or are there simplest ventilation systems? - a subscriber of the 3DToday website addresses like-minded people (the spelling of the author is preserved - ed.