3D printing 60 minutes

3D printed houses are leading a revolution in real estate

MoneyWatch

By Anne Marie Lee

/ MoneyWatch

3D-printed homes go on the market

3D-printed homes could lead to a revolution in real estate 01:43Prices for new homes are on the rise. But there's a new kind of home going on the market that some say could change that trend, reports CBS News' Michael George in Calverton, New York.

3D printed houses —partially built by a robotic construction system that stacks layers upon layers of concrete from the ground up to create the framework for a new home — are transforming the speed and cost at which houses are being developed and sold.

While the 3D printer can't do all the work, it can build about 40% of the structure before workers come in to finish the rest, according to Kirk Andersen, director of operations for SQ4D Inc., a 3D house printing company based in Patchogue on New York's Long Island.

"We should be able to do our part of the build in eight days or less," Anderson told CBS News, referring to a 1,900-square-foot structure currently being printed and soon to be turned into a model Long Island home.

SQ4D is developing a similar residence in Riverhead, New York, that is the first 3D printed house to be placed for sale in the U.S., according to 3Dnatives. The three-bedroom, 1,400 square-foot house is listed for $299,000, about 80% the median cost of comparable homes in the area, which is around $370,000 according to Redfin real estate brokerage.

SQ4D claims they have already received more than 1,000 offers to purchase this 3D printed three-bedroom home for sale in Riverhead, New York. It is the first 3D printed house to be placed on the market in the U.S. Asking price: $299.000. 3D Natives

It is the first 3D printed house to be placed on the market in the U.S. Asking price: $299.000. 3D Natives "This process can save you about 20 percent to 30 percent on an overall bill," Anderson said.

Other homebuilders are also using 3D printers. Icon, a construction technology startup in Austin, Texas, in 2019 built the first-ever 3D printed neighborhood in Mexico.

The Texas company, which is committed to "affordable, dignified housing available to everyone throughout the world," is working with nonprofits to build low-income housing using its own proprietary construction technology.

Mighty Buildings in California offers a range of customizable homes also using its own 3D printing equipment.

"We've developed a unique technology — we can print geometry, we can do curves, we can do free-form," Sam Reuben, one of Mighty Buildings' cofounders, told CBS News.

Construction is a $1. 3 trillion industry in the U.S., according to the Associated General Contractors of America, an industry that 3D construction companies, with their radical new technology and equally radical ideas, seem poised to disrupt.

3 trillion industry in the U.S., according to the Associated General Contractors of America, an industry that 3D construction companies, with their radical new technology and equally radical ideas, seem poised to disrupt.

SQ4D claims it has already received more than a thousand offers to purchase the 3D printed home in Riverhead — an indication that if you print it, they will come.

Trending News

First published on March 16, 2021 / 2:55 PM

© 2021 CBS Interactive Inc. All Rights Reserved.

Thanks for reading CBS NEWS.

Create your free account or log in

for more features.

Please enter email address to continue

Please enter valid email address to continue

Sliced 3D printer file (60 min, RIC) – Prototype Now!

- Assignment Type: Individual

- For RIC students only

- Estimated time required: 60 minutes

- Due by second week of class

- Typical Points Possible: 10

- U.

C. Berkeley Students: Find specific due dates and times in Bcourses.

C. Berkeley Students: Find specific due dates and times in Bcourses.

Preparing a 3D CAD file for 3D Printing. “Build Prep”.

Why is this assignment valuable for my career?

A: There are two main reasons:

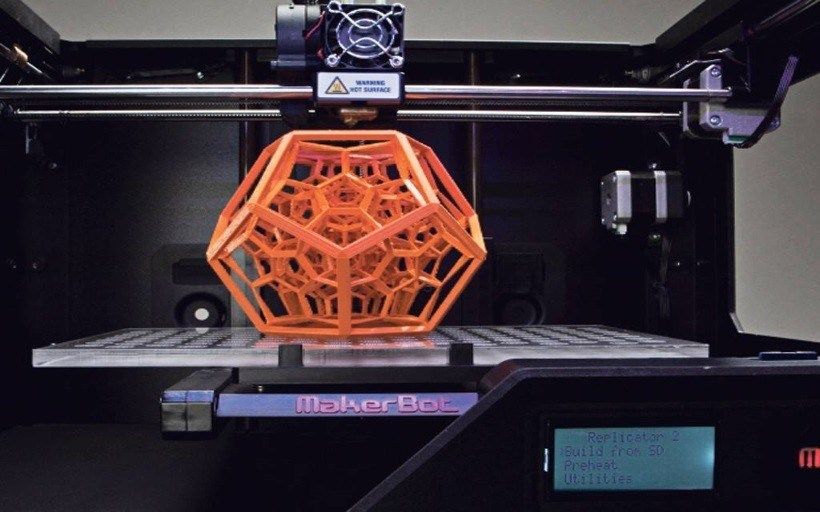

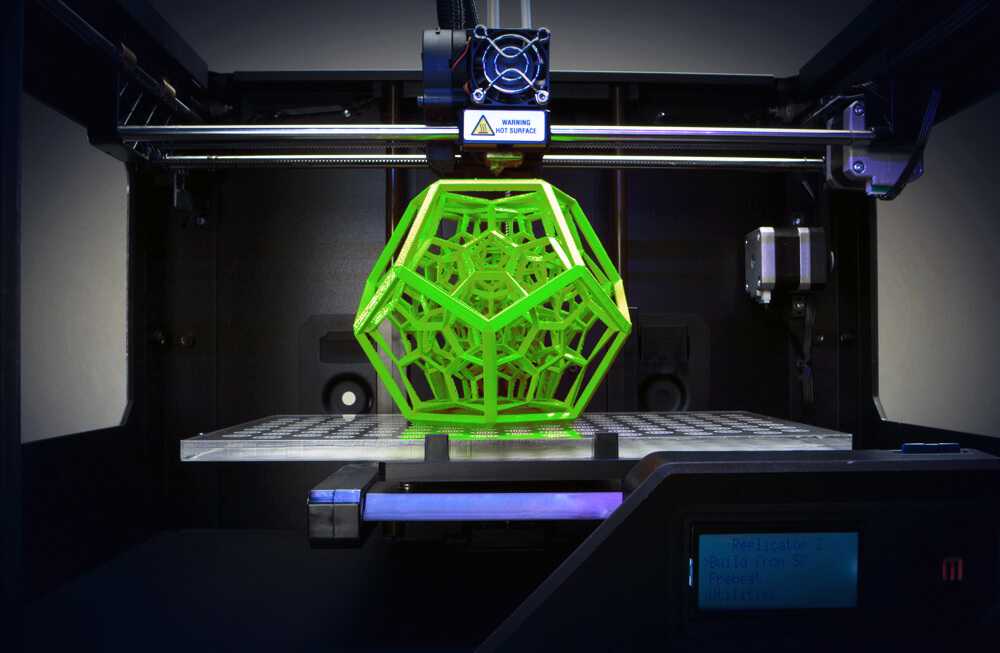

- Hardware prototyping has been dramatically improved by access to low-cost 3D printing, you should understand its limits and capabilities. Your ability to understand how they work and manage others in their strategic use will be key to your prototyping success. Understanding the workflow of desktop extrusion 3D printing (namely Fused Filament Fabrication, FFF or Fused Deposition Modeling, FDM) will give you a taste of understanding additive manufacturing more broadly.

- Troubleshooting skills are a must for entrepreneurs. Your ability to stay persistent, find workarounds, ask for help, find answers is key to your success as a technical entrepreneur / intrapreneur. Nothing like using open source software and a low-cost desktop 3D printer to test your troubleshooting abilities.

Review this 1-page workflow: http://bit.ly/3DPOverview

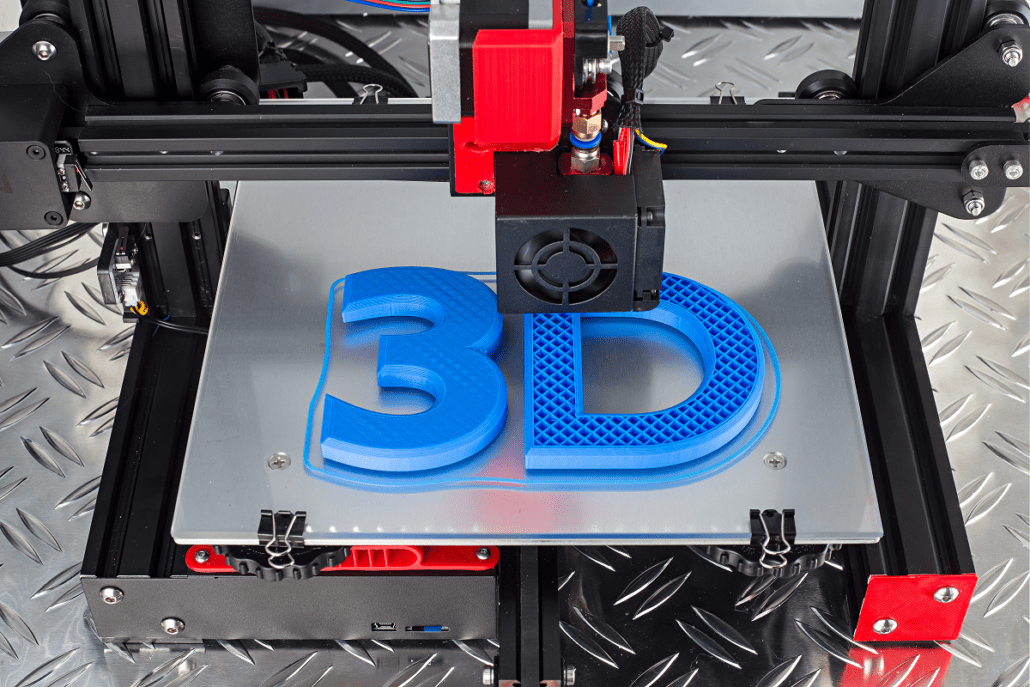

1) Find a model on Thingiverse.com to 3D Print and scale the object so it will print in less than 15 minutes.

2) Download Cura and install the Printrbot Simple Metal machine profile.

Note: there are many versions of Cura out there. The latest version *should* still work, however, Cura version 15.04.6 is known to work. Here are some YouTube videos which may help:

There are also more relevant setup videos in the Pages area (flipped-class content) of this course.

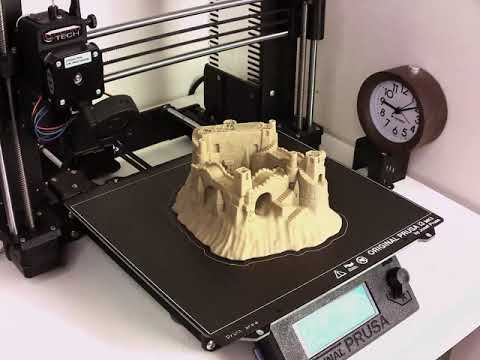

The 3D Printers we have in the Innovation Lab are:

- Make: Printrbot

- Model: Simple Metal

3) Using Cura, “slice” your Thingiverse object (*. STL file) and scale your model so it prints in LESS THAN 10 minutes. The object will be small.

STL file) and scale your model so it prints in LESS THAN 10 minutes. The object will be small.

4) Submit the *.gcode file to this Bcourses assignment.

Use YouTube, Google and other online references to help you get started / trouble shoot issues. Goal here is to familiarize yourself with the high-level FFF 3D printing workflow, build software (Cura environment), so you can come to class prepared to 3D print.

What will I have achieved if I fully engage in this assignment?

- You will have downloaded, installed and used a modern 3D printing, build prep (slicing) software used by millions of avid hardware prototyping experts.

- You will have ultimately troubleshooted the basics of this program and through this painful and annoying process, fully learned the ins and outs of the program itself.

- By importing a *.STL file to the build prep software, slicing the file and then exporting to *.gcode, you’re one step closer to enabling your use of the 3D printers located in the lab and MANY OTHER machines that utilize gcode to operate.

It’s like learning a little bit of HTML, you establish some street cred in the 3D printing world having created such files.

It’s like learning a little bit of HTML, you establish some street cred in the 3D printing world having created such files.

3D printing. What are we breathing?

Hello dear. In this article, I will try to tell you about what and in what quantities can be released from plastics during the FDM 3D printing process. The issue will be considered not from the side of global environmental pollution, but from the side of possible pollution of the room or workshop in which the FDM 3D printer directly operates.

I recommend that you read at least the fourth and fifth sections. Link to the video version of the article at the end. Here is the content of the article:

1 What and how much is released from plastics?

2 At what point in time is the emission of suspended particles maximum?

3 Effect of print settings

4 Particulate matter and VOC control methods

5 Pins

I must say right away that all the data is again for foreign plastics. In the comments, you write to me that it would be interesting to read about our materials, and not about foreign ones. Yes, I agree, perhaps the conclusions drawn from my work may not be applicable to "our" plastics. But in defense, I note that, firstly: the conditional foreign ABS should not radically differ from “our” ABS. Secondly, our major producers say that they buy raw materials from European firms. In this regard, I believe that the voiced data should be relevant for domestic filaments.

In the comments, you write to me that it would be interesting to read about our materials, and not about foreign ones. Yes, I agree, perhaps the conclusions drawn from my work may not be applicable to "our" plastics. But in defense, I note that, firstly: the conditional foreign ABS should not radically differ from “our” ABS. Secondly, our major producers say that they buy raw materials from European firms. In this regard, I believe that the voiced data should be relevant for domestic filaments.

1 What and how much is released from plastics?

Two types of air pollutants are emitted from any plastic during operation of a 3D printer. Firstly, these are ultra- and finely dispersed (or suspended) particles, the size of which ranges from several nanometers to several micrometers. The second is volatile organic compounds.

In fact, the first group is micro dust, consisting of fragments of plastic, as well as fragments of fillers. In [1], an analysis was made of the release of suspended particles from various plastics during printing of a cylindrical sample with a duration of 60 minutes. Plastics PLA, PVA, ABS, PC, ASA, nylon were analyzed. An analysis of the results showed an interesting regularity in the intensity of the release of suspended particles during the operation of a 3D printer. Look at this graph:

Plastics PLA, PVA, ABS, PC, ASA, nylon were analyzed. An analysis of the results showed an interesting regularity in the intensity of the release of suspended particles during the operation of a 3D printer. Look at this graph:

Zero is the start of printing. It is clearly seen that it is at the very beginning of printing that there is a sharp increase in the concentration of suspended particles, then the concentration gradually decreases. The researchers attribute the initial peak to the nozzle's heating period to operating temperature. At this point, the plastic, which is motionless inside the nozzle, is subjected to prolonged heating and, consequently, thermal degradation. It can be seen from the graphs that such a picture is typical for absolutely all plastics. In support of this, the researchers from [2] come to similar conclusions.

Now let's look at each plastic separately. I think it will be most interesting for you to find out which plastics are leaders in terms of the number of emitted particles. ASA took first place, followed by nylon, PC and ABS, respectively. PLA and PVA turned out to be the most environmentally friendly.

ASA took first place, followed by nylon, PC and ABS, respectively. PLA and PVA turned out to be the most environmentally friendly.

This is how the size distribution of emitted particles looks like when printing a sample for pollution leaders:

And this is how the graphs for PLA of various companies and PVA look like:

The difference in the graphs is obvious. Please note that PLA and PVA emit particles at the very beginning of printing, and then, after a while, the release of particles almost stops.

Here are the results of measurements made by the authors of another study [3]:

On this graph, manufacturers and the type of plastic are labeled at the bottom, and the intensity of the release of suspended particles is measured along the vertical axis. Again, ABS and PC are among the leaders in terms of pollution. Additionally, HIPS and nylon joined them in this study. The most environmentally friendly again turned out to be PLA.

As far as carbon or fiberglass reinforced plastics are concerned, they are practically unexplored. In one of the works [4], along with other plastics, I was able to find this:

Underlined in red is PETG with 8-12% fiberglass. As you can see, such plastic is the leader in the selection of large particles. Once again I will say that this is the only result that I could find, so I can’t draw serious conclusions here, but anyway I decided to add it to the publication.

Now let's move on to the isolation of volatile organic compounds. In short, when printing with almost any filament, dozens of different compounds are released. Here, for example, is a table from [4]:

Plastics are signed in the table above. The first column lists the names of the chemical compounds. If there is no number for some connection, it means that it was not fixed by the device during printing with a specific plastic. Analyzing the table, we see that ASA and ABS plastics again become leaders in the anti-rating (ULTRAT is ABS with the addition of 3% polycarbonate). PETG becomes the most environmentally friendly (GLASS Transparent is also PETG, but with the addition of fiberglass).

PETG becomes the most environmentally friendly (GLASS Transparent is also PETG, but with the addition of fiberglass).

Now let's turn to the results of research from another work [3], which examines a slightly different set of plastics:

This figure shows two histograms. The left histogram shows plastics with a maximum release of volatile organic compounds up to 40 micrograms per minute, and on the right - with an intensity of more than 40 micrograms per minute. The name of each column indicates the printer on which the material was printed.

Polycarbonate and TGlase (PETT plastic) are the most environmentally friendly. PLA looks a little worse. And nylon turned out to be the worst in terms of the number of emissions. It is interesting to note that for ABS plastics, the amount of emissions is highly dependent on the 3D printer on which they are printed, and can differ by as much as five times.

Pay attention to polycarbonate. If it is one of the most polluting in terms of the release of suspended particles, then it is the most environmentally friendly in terms of the release of volatile organic compounds.

2 At what point in time is the emission of suspended particles maximum?

Let's look at two graphs from [5]:

The left graph shows the particulate concentration inside the MakerBot 3D Printer, while the right graph shows the particulate concentration in the room where the 3D printer is located. Two peaks on the graphs mean two consecutively printed parts. Again, we see that a sharp increase in the number of suspended particles occurs at the very beginning of the printing of the part.

And here is another graph from another work [2]:

Shown here are three graphs showing the change in the concentration of suspended solids when printed with ABS plastic. According to the legend, the graphs differ in nozzle temperature. As in the previous work, it can also be seen here that after heating, at the moment of printing, an increase in the concentration of suspended particles occurs. From these graphs, another interesting point is visible.

3 Effect of print settings

These three graphs show that as the temperature of the nozzle increases, the concentration of suspended particles increases. However, the difference between the charts is significant. Other scientific works [4] confirm this:

This graph shows particulate matter concentration versus ABS nozzle temperature. It can be seen that at a nozzle temperature above 250 degrees there is a sharp increase in the number of ejected particles.

It is interesting to note the effect of printing speed on the concentration of suspended particles. Here is a graph from [2]:

These graphs show the dependence of the concentration of suspended particles when printing with ABS plastic at different print speeds. We compared printing at speeds of 30 mm/s (FR30 in the graph), 60 mm/s (FR60) and 90 mm/s (FR90). It is interesting to note that the maximum concentrations are observed at an average printing speed. In this case, the minimum concentration is observed for a speed of 90 mm/s.

4 Particulate matter and VOC control techniques

4.1 Studies have shown that reducing nozzle temperature reduces the amount of suspended particles released. Therefore, do not raise the nozzle temperature unnecessarily.

4.2 Increasing the print speed reduces the concentration of suspended particles. Another positive effect of increasing the printing speed is to reduce the printing time, which leads to a decrease in the time during which suspended particles are released.

4.3 Filtration. HEPA filters are effective for almost all sizes of particulate matter, but to be useful, you need a 3D printer with a closed chamber. In addition, HEPA filters do not capture volatile organic compounds at all, which, as it turns out, are emitted in abundance from some plastics. They need charcoal filters.

4.4 Ventilation or ventilation. I think this is the most efficient way for most conventional FDM 3D printers used at home and in workshops. Here are pictures from [5] showing the distribution of the concentration of suspended particles in a room with a 3D printer:

Here are pictures from [5] showing the distribution of the concentration of suspended particles in a room with a 3D printer:

In a well-ventilated room, the concentration of particles is an order of magnitude lower and at a distance of more than a meter from the printer, only slightly higher than the background level.

4.5 Optimize printer performance. In paragraphs 4.1 and 4.2, I have already touched on the printing modes, but the authors of the scientific work [2] went further and proposed an interesting way to reduce the amount of suspended particles released. Its essence lies in the fact that we first heat up the empty nozzle to operating temperature, then load the filament and immediately start printing. After printing is completed, remove the filament. Here are graphs from [2] showing the result of such manipulations:

Both graphs show the emission of suspended particles when printing ABS with a nozzle temperature of 240°C and a speed of 60 mm/s. The top graph is printing without loading/unloading the filament.

The top graph is printing without loading/unloading the filament.

5 Conclusions

As a conclusion, firstly, I would like to note that such plastics as ASA, ABS and nylon are leaders in terms of the amount of emitted particles and volatile organic compounds. The average highlights are polycarbonate and HIPS. The most environmentally friendly and in terms of suspended particles and volatile organic compounds are PLA and PETG.

Second, print in well-ventilated rooms or ventilate the room when printing. Try not to increase the temperature of the nozzle unnecessarily.

You may have noticed that I didn't say a word about how harmful it all is. The fact is that the assessment of the harmfulness of all this required quite a lot of time. I haven't been able to get definitive answers yet. Now I’ll just say that it’s rather harmful, especially with regular contact. Therefore, in this article, I deliberately did not touch on the topic of harmfulness. I hope that I will be able to deal with this issue to the end and then I will publish all the results.

I hope that I will be able to deal with this issue to the end and then I will publish all the results.

Video version of the article:

That's all for now.

Sources:

1. Chýlek, R., Kudela, L., Pospíšil, J., Šnajdárek, L. (2019). Fine particle emission during fused deposition modeling and thermogravimetric analysis for various filaments. Journal of Cleaner Production, 117790. doi:10.1016/j.jclepro.2019.117790

2. Deng, Y., Cao, S.-J., Chen, A., Guo, Y. (2016). The impact of manufacturing parameters on submicron particle emissions from a desktop 3D printer in the perspective of emission reduction. Building and Environment, 104, 311–319. doi:10.1016/j.buildenv.2016.05.02

3. Azimi, P., Zhao, D., Pouzet, C., Crain, N. E., Stephens, B. (2016). Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environmental Science & Technology, 50(3), 1260–1268. doi:10.1021/acs.est.5b04983

Environmental Science & Technology, 50(3), 1260–1268. doi:10.1021/acs.est.5b04983

4. Gu, J., Wensing, M., Uhde, E., Salthammer, T. (2019). Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environment International, 123, 476–485. doi:10.1016/j.envint.2018.12.014

5. Zontek, T. L., Ogle, B. R., Jankovic, J. T., Hollenbeck, S. M. (2017). An exposure assessment of desktop 3D printing. Journal of Chemical Health and Safety, 24(2), 15–25. doi:10.1016/j.jchas.2016.05.008

Print in an hour. Top 10 3D printer models for summer 2022

Modern man is constantly busy with something. Sometimes there is no time to wait several days for a job to print completely. And if something goes wrong, printing will have to be restarted.

Sometimes we want to print something just for fun, something that won't take more than an hour. So, here are 10 simple and fun 3D printables that will be ready in less than 60 minutes (maybe some extra infill and support settings will be needed for some models). Timing accuracy has been tested in the popular Cura slicer. But be aware that some 3D printers are faster.

Timing accuracy has been tested in the popular Cura slicer. But be aware that some 3D printers are faster.

4 SIMPLE STEPS TO 3D PRINT THE MODELS FROM ARTICLE

- Browse 's list of funny models for inspiration and ideas. Take your time. We will be here when you return.

- Download the STL file of your chosen model. Click on the link to go to the site where the files are located. You can download it absolutely for free. Please note that some sites may require registration to download.

- Slice STL file to prepare it for 3D printing. Whether you use an open source program like Cura or a paid solution like Simplify3D, slicing is a very important step for the quality of your model. Open the STL file and change settings such as padding, layer height and support.

- Convert STL file to GCode after you finish slicing. Save the GCode and upload it to your 3D printer using a USB cable, SD card, or network connection. Now start printing!

Now start printing!

TOP 10 MODELS

We all know what the washing machine does to clothes... No wonder the shape of those little collars disappears after washing.

With the help of a 3D printer, this issue is solved in a matter of minutes. Eight of these small plastic bones can be printed in half an hour, and your shirt collars will look decent and neat again.

Where to download : https://www.printables.com/de/model/210033-collar-stays

2. Fox wall decoration

Looking for an impressive last minute gift or something decorative to brighten up a boring bare wall? Here is a cool fox head design that you can print out in less than an hour. The model can be scaled to any size.

Where to download: https://www.thingiverse.com/thing:5392978

3. Studio Stand

If you want to take professional photos of your models, print out two parts, place a sheet of paper between them, provide lighting and photograph.

Where to download: https://www.thingiverse.com/thing:5212231

4. Spaghetti dispenser

In less than 60 minutes, you can print out a useful tool for measuring the ideal amount of dry spaghetti yourself. It guarantees consistently evenly measured portions of the popular pasta.

The tool has 4 measurements for the desired number of eaters from 1 to 4.

Where to download: https://www.printables.com/model/89329-spaghetti-pasta-gauge

5. Cable strap

Do you like it when cables are neatly tucked away?

Where to download : https://www.thingiverse.com/thing:5242299

6. Tape cutter

Easy to print small item. 40 minutes of printing and any tape will be easy to cut.

Where to download : https://www.printables.com/model/89506-tape-cutter

7.

Sunglass clip

Sunglass clip

A simple yet effective hack to hide your sunglasses. This 3D printed clip attaches to the sun visor. Fast, simple and smart. We like!

Where to download: https://www.thingiverse.com/thing:2545456

8. Multitool for keys

This compact key accessory features a bottle opener, phone holder, shopping cart token holder and LED light to find it at night. There is even an indentation to stick your name or phone number on.

Two parts will be printed in an hour. You don't need supports, glue or soldering. The LED requires a 2025 3V battery.

Where to download : https://www.printables.com/model/88414-multitool-the-only-3d-printed-keyring-youll-ever-n

9. Additional hanger hook

If you want to save space in your closet, you can print out these handy hanger holders. Available in three different hole sizes, all printed in less than an hour.