Fablab 3d printing

3D Printing Service Montreal, Quebec, Canada – Fablab Inc.

3D Printing Service Montreal, Quebec, Canada – Fablab Inc.3D Printing

Consult the printing costs immediately and obtain your parts in just a few days by using our intuitive online platform.

- arrow_right Wide selection of technology and material options

- arrow_right Chose the color and surface finish for your parts

- arrow_right The prices are calculated and displayed in real time

- arrow_right Allow others to print your models via an email link

- arrow_right Request and save a quote for larger quantities

- arrow_right Save your 3D models in your catalogue for later

- arrow_right Easily review your previous orders and invoices

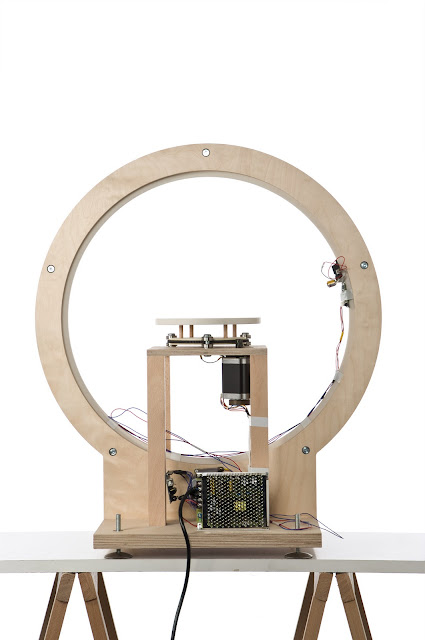

3D Scanning

The scanning process allows you to convert your real life items into detailed 3D models. You can then reproduce the object, or reverse engineer it's design.

- arrow_right Generate a highly detailed 3D model

- arrow_right Works with any object size

- arrow_right Accuracy up to 50 microns

- arrow_right Captures the actual textures of your object

- arrow_right Convert real objects to digital objects, and vice versa

Design

Let us help you with our expert advice and 3D modeling services. We can assist with every step of your project, ranging from the initial design ideas to your final prototypes.

We can assist with every step of your project, ranging from the initial design ideas to your final prototypes.

- arrow_right Develop your ideas and designs

- arrow_right Prepare professional renderings

- arrow_right Parametric 3D modeling

- arrow_right 3D surface modeling

- arrow_right Finite element analysis

- arrow_right Development of specifications

- arrow_right Small series production

Our service in three steps:

Use our online quoting tool to upload your 3D files

We print and prepare your parts accordingly to your demand

We ship the printed parts directly to you

Materials

Castable Wax resin is now available at Fablab Inc!

We have incorporated a new engineering resin into our material options which is used in the lost wax casting process.

This resin is a material containing 20% wax, allowing reliable and clean burning, without residue or ash. It perfectly reproduces intricate details and results in smooth surfaces characteristic of stereolithographic printing. The printed parts are strong enough to be handled without UV curing after printing, to undergo fittings and to be used directly for casting.

Read more

New product

Use polyjet technology to bring new opportunities to your business

Our new polyjet machine is now ready to produce your parts!

Able to go up to a resolution of 13 microns, this technology makes it possible to combine precision and speed. It can also print large parts thanks to its 260 x 260 x 200 mm (10.24 × 10.24 × 7.9 in) area.

Several materials are available to order!

New: The RUSH 24 delay option is now available for this technology.

Read more

Materials

Sacrificial tooling for composite part fabrication

Although basic shapes and cross-sections are easily manufactured using traditional techniques, complex parts with hollow interiors still present a real challenge to manufacture in the composite parts industry.

Using thermoplastics that can be dissolved after printing, it's possible to better control the dimensions and even simplify components with complex geometries.

There are many advantages to using this material and you can learn more about them here.

Read more

New service

Receive your parts as quickly as you need using our RUSH options

Using our 3 RUSH production options, your parts can be ready in 24, 48, or 72 hours.

These accelerated lead times will help you validate your 3D designs and build of your prototypes faster.

Connect to our online quoting services to place your order now.

Read more

Guide

The advantages of 3D printing in the medical sector

The medical field is a sector where there are many constraints that are always evolving and changing with the new technologies being developped. The resources used in surgery or to treat patients must be very precise and personalized. This means that the parts required are limited and therefore very expensive. 3D printing is a solution that is increasingly being considered and which brings a lot to the future of health and allows care adapted for each patient.

New applications of this technology are used creative ways, find out how these could one day help you!

Read more

Stay in touch

Our online platform is constantly evolving, as are our printing technologies and material options. You can keep informed of our news, services, and latest offers by subscribing to our mailing list.

You can keep informed of our news, services, and latest offers by subscribing to our mailing list.

We send a maximum of one email per month.

3D Printing – UVM FabLab

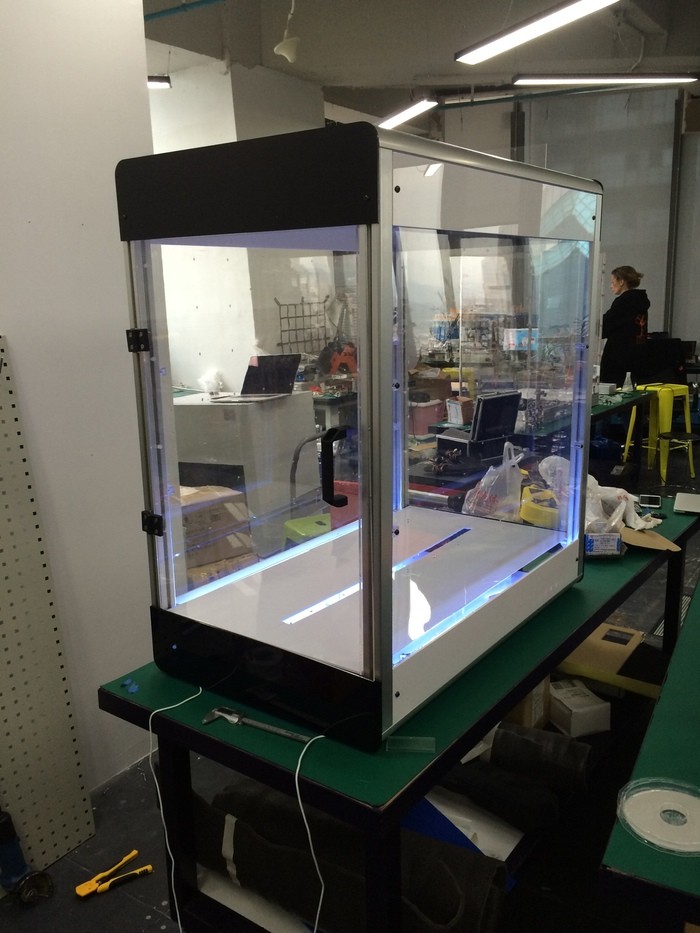

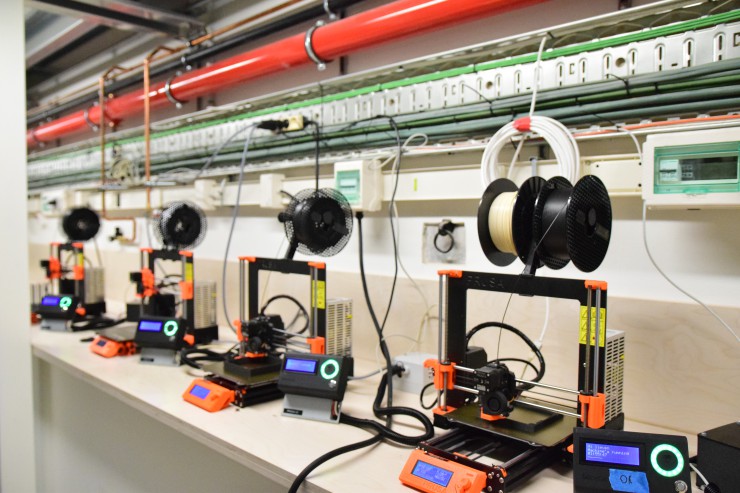

The UVM FabLab offers the use of its 3D printers to help students rapidly prototype small parts that would otherwise be difficult to manufacture or acquire. Keep in mind that FabLab resources can only be used for school-related projects and that, like any manufacturing process, 3D printing has physical and cost limitations that differ by machine.

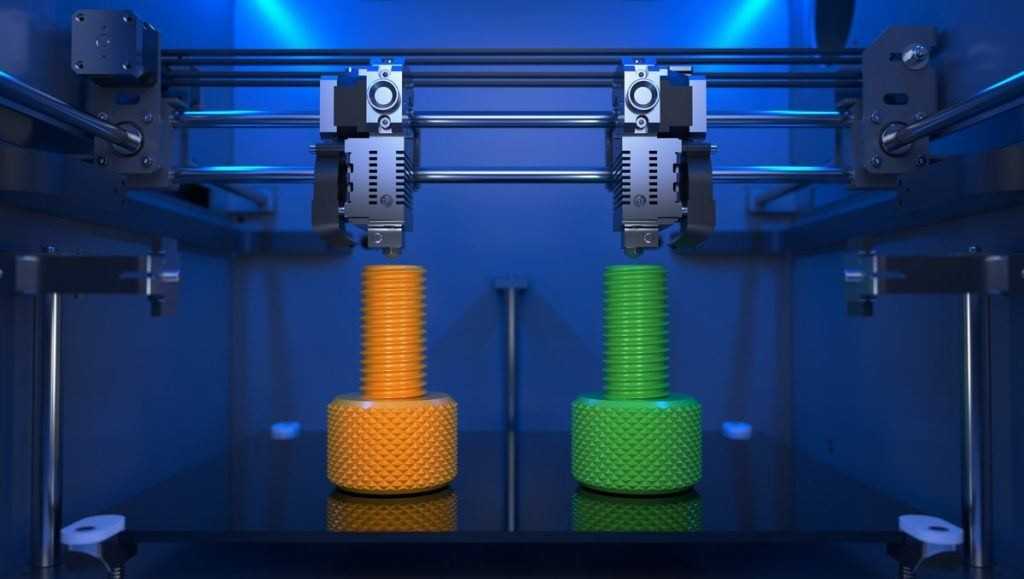

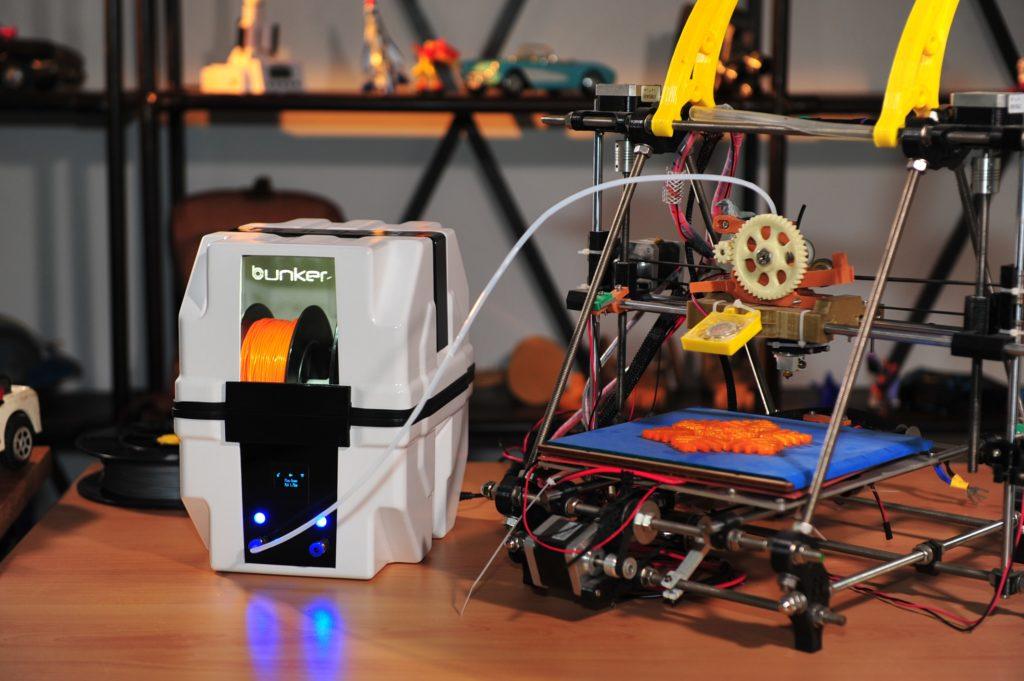

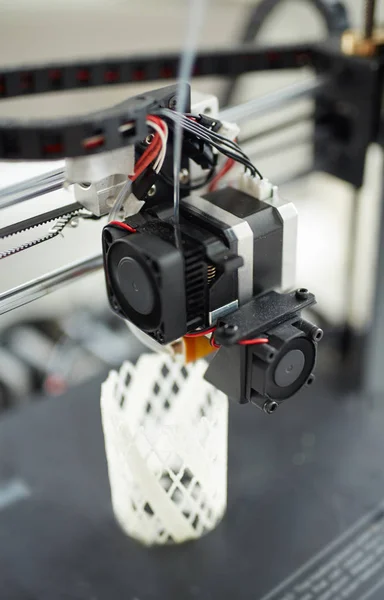

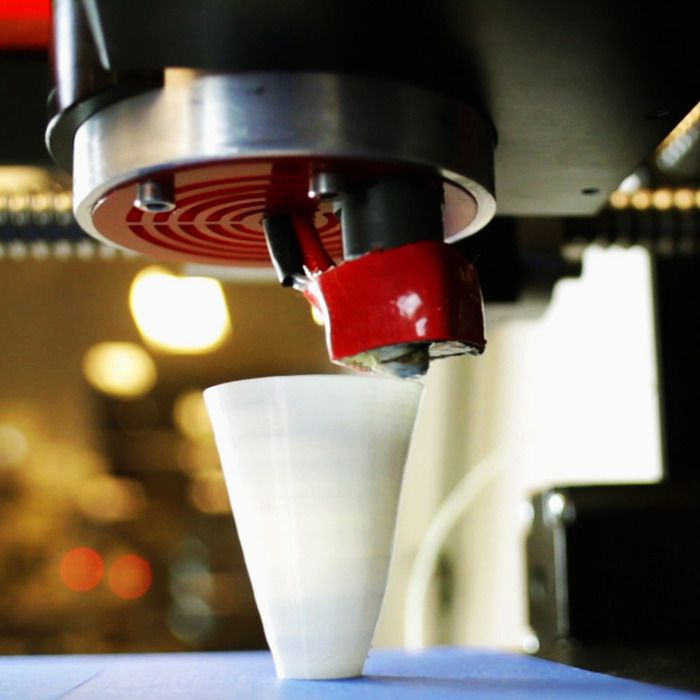

Extrusion-based 3D Printing:

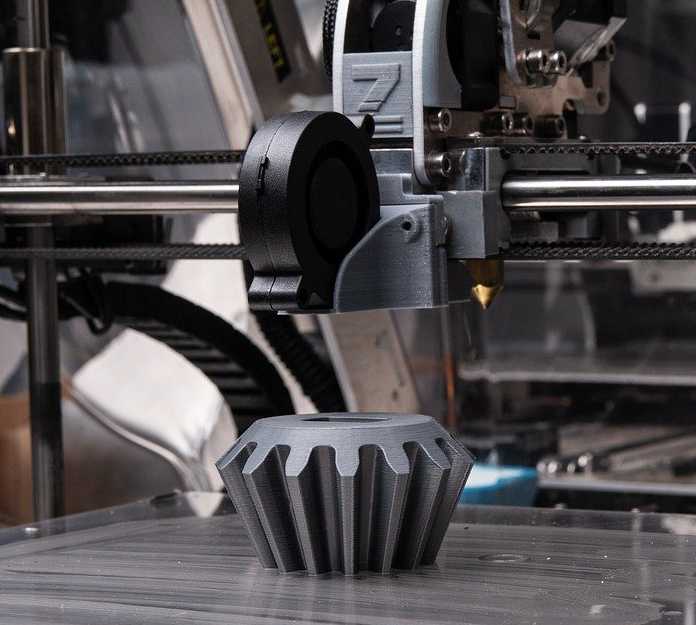

3D printing is a type of ‘additive’ manufacturing, which is the opposite of the traditional way of fabricating objects where material is removed to produce the desired product; like creating a clay sculpture. These machines heat thermoplastic filament (i.e. PLA and ABS) and extrude layer by layer to form the desired product. A 3D file is formatted within printing software to create a toolpath for the extruder that will create the shell of the product as well as an infill pattern within the shell to improve strength.

Some extrusion-based 3D printers can print model filament with a chemically soluble or breakaway support material simultaneously, which improves the resolution of the finished product and allows the fabrication of complex geometries and hollow shapes.

Stereolithography 3D Printing:

An alternative to extrusion-based printing, stereolithography is a type of ‘additive’ manufacturing that involves photopolymerization of resin in a bath via a laser that cures the resin into hardened plastic layer by layer. This process forms solid products with isotropic properties. Our photopolymer resin materials include grey, clear, and white colors, as well as wax resin for casting parts.

This process forms solid products with isotropic properties. Our photopolymer resin materials include grey, clear, and white colors, as well as wax resin for casting parts.

Guidelines:

The following guidelines will help you determine whether your design is suitable to print in the FabLab:

- Your part must not be too small:

- If features are smaller than the printer’s resolution, they will not print reliably.

- Your part must not be too big:

- It should not use too much material or print time.

- It must fit within the dimensions of the printer.

- Your part must be structurally suitable for printing:

- The part must not be too delicate or have large unsupported sections.

- The part must not be too delicate or have large unsupported sections.

If your part is rejected for any of the reasons above, you are always welcome to modify the part and resubmit it for review. Our Fabbers are experienced and able to provide feedback on your designs throughout the design process.

Please keep in mind that 3D printed parts are not free! The FabLab sponsors each project for coursework, senior design, and some clubs and we only use approved materials for the safety of our Fabbers. For Engineering senior design budgets, prints are billed on a per-ticket basis, with the exception of the FormLab resin printer, in which case the SEED team should plan to purchase their own cartridge and tank. Beyond a single print, undergraduate students, graduate students, and faculty must pay the College of Engineering and Mathematical Sciences for the material used via a UVM chartstring.

Professional manufacturing options are available on and off campus. If you have a print job that is too large or time-consuming for the FabLab’s capabilities – for example, if you need a large number of parts made – this may be a better option. These facilities include the UVM Howe Library, Instrumentation and Modeling Facility (IMF) Labs, Shapeways, and the Generator Makerspace in downtown Burlington. If there is a well-founded reason this part must be 3D printed in the FabLab, such as extreme time constraints or lack of other options, please contact us at [email protected].

These facilities include the UVM Howe Library, Instrumentation and Modeling Facility (IMF) Labs, Shapeways, and the Generator Makerspace in downtown Burlington. If there is a well-founded reason this part must be 3D printed in the FabLab, such as extreme time constraints or lack of other options, please contact us at [email protected].

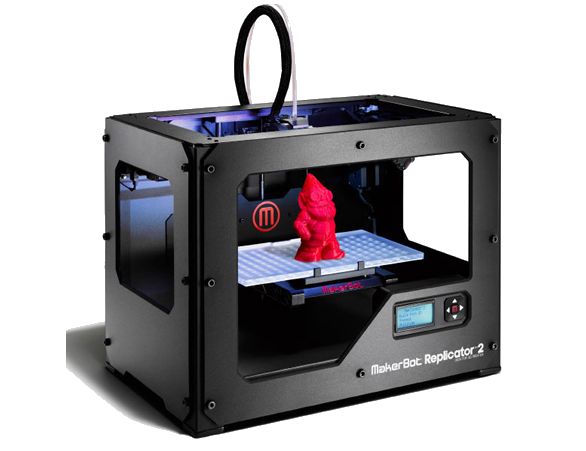

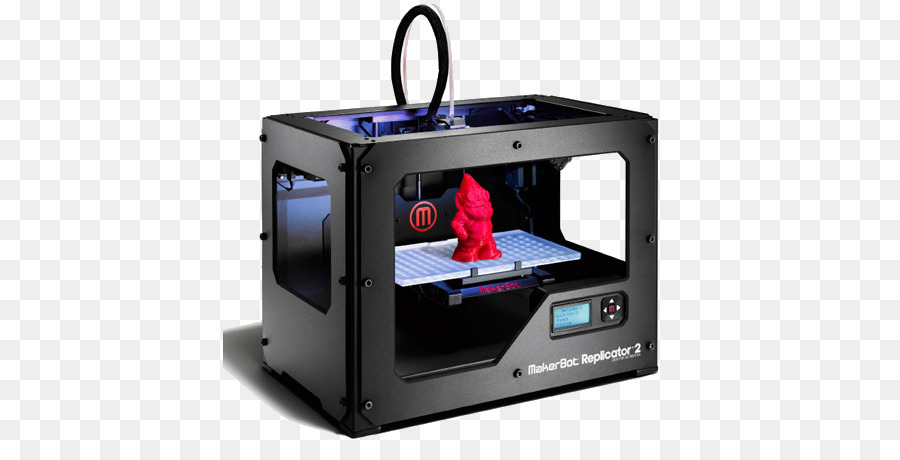

Extrusion-based 3D Printers:

Stratasys Dimension Elite (1) Stratasys UPrint SE Plus (1) Makerbot Replicator+ (2) Ultimaker S5 (2) Makerbot Sketch (2)Stereolithographic 3D Printers:

FormLabs Form 2 (1)Build volume dimensions:

- Stratasys Dimension Elite: Base 8″x8″; Height 12″

- Stratasys Uprint SE: Base 8″x8″; Height 6″

- Makerbot Replicator+: Base 11.

6″x7.6″; Height 6.5″

6″x7.6″; Height 6.5″ - Ultimaker S5: Base 13″x9.5″; Height 11.8″

- FormLabs Form 2: Base 5.7″x5.7″; Height 6.8″

- Makerbot Sketches Base 5.9″x 5.9″; Height 5.9″

FabLab - 3D printing is getting more and more popular. Perhaps soon we will print entire cities - FEA.RU | CompMechLab

"The coming revolution on your desktop: from personal computer to personal production" - with this loud phrase begins his book "Fab" about the ongoing "industrial revolution 3.0" and about the cities of the future professor Massachusetts Institute of Technology , Director MIT Center for Bits and Atoms Neil Gershenfeld .

“The image of smart people changing the world, armed with little more than a simple Internet connection and their own ideas, fully reflects the future of manufacturing,” says Chris Anderson , who served as editor-in-chief for 12 years of the popular magazine Wired .

There is much less provocation in these statements than it might seem at first glance. It is rather an adequate and quite realistic look into the future. What will become of our cities in this future? Let's try to figure it out

One click

Many of the daily tasks faced by citizens will soon be instantly solved by robots.

We will save time on obtaining and providing services, we will expand the possibilities of production, in which the person will only be required to set tasks and start the process.

A key role in these changes is played by 3D printers - robots capable of printing volume and accurately reproducing real objects or creating something new, according to user-specified parameters (principles and varieties of 3D printing are described below in article Petra Novikova ).

3D printing predicts a revolutionary significance in most scientific fields and in all forms of urban life: they will change both material objects and the urban environment (the “hard” of our cities), as well as perception itself, the attitude to production, to human and “non-human” » labor ("software" of the city).

3D printers are used to print bones and organs, create cheap analogues of priceless objects, restore relics.

Printer-made toys and accessories appear, and food printing is also being discussed.

3D printing is able to revolutionize the construction industry, speeding up processes, expanding possibilities, increasing accuracy, quality, efficiency - sooner or later, one press of the “start” button can stand between the erected building and its plan.

We are not yet talking about the construction of full-fledged buildings, but developments are underway, prototypes are being created - in futuristic thinking, this can already be allowed.

Meanwhile, the city is on the verge of global change and without building in one click.

The city of consumers is turning into a city of producers.

Invented? Do It!

3D printers may soon be available for use by "ordinary" city dwellers, turning handmade from a fun and leisure activity into a full-fledged production at home.

The popular Do It Yourself (DIY) movement will be developed to a new level - something like Do With Your Robot - and will concern not only small actions subject to a person, but also large-scale changes.

Chris Anderson stepped down as editor-in-chief to pursue robotics and DIY initiatives, primarily 3D printing.

He is confident that these technologies mark a new cycle of human development - a time when each of us will be able to create at a new level.

Just as the ability to print on a personal printer once revolutionized the printing industry (when the need for printers plummeted and a large-scale industry began to compete with a small “print” button on a computer screen), so the new revolution in production pits the scale of the industry against the “create” command - one clique or word that transfers the task to the robot.

“3D printing is bigger and more powerful than the web. That's why I left my old job. "

"

The new phenomenon associated with personal production and 3D printing in particular is indeed often compared to the World Wide Web, calling it the “Internet of atoms”.

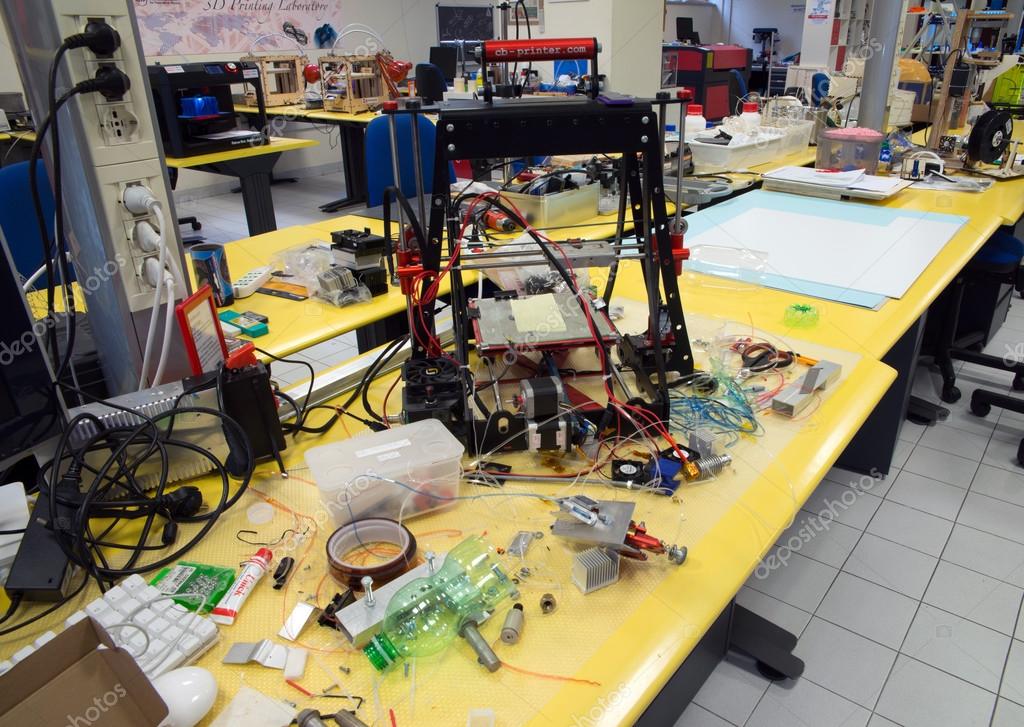

The official name of the phenomenon - FabLab - stands for Fabrication Laboratory - "production laboratory" - or Fabulous Laboratory - "magic laboratory".

What is FabLab?

This is a workshop equipped with various tools for "digital production", in which human participation is limited to setting tasks through computer programs.

The concept of FabLab began with a course by professor Neil Gershenfeld at MIT called "How to do almost everything."

Prof. Gershenfeld really taught students how to make anything their heart desires with the help of advanced technology.

Like all great ideas, FabLab's idea wasn't overly ambitious or overly intricate.

Just an awareness of the feasibility of ideas and a few tools to back up this awareness with real facts - and people really master the creation of "almost everything" from "virtually nothing".

Again, like all brilliant ideas, FabLab exceeded the creator's expectations and promises to shock him and us all in the future.

The course for students has developed into an international network of laboratories, which will be consolidated and at some point may become available to any city dweller.

“The digital revolution has happened, we no longer need to say it, what will happen next is a production revolution,” says Gershenfeld .

Let's add free time to the possibilities of FabLab, which is increasingly falling on the heads of citizens.

Let's multiply all this by the natural desire to create, participate and share, which is actively manifested as soon as an opportunity presents itself. And he, the case, is here: in a growing assortment and on a scale that transfers it from the category of accidental to regular and ordinary. This is the Internet as it is, and the "Internet of atoms" - FabLab.

This is the Internet as it is, and the "Internet of atoms" - FabLab.

NYU Professor Clay Shirky in his book Turn on your brains. Leisure Time in the Age of the Internet" says: "Clean consumption has never been a sacred tradition; it was just a collection of cases that were brought together and stopped happening when people started using new tools…”

Technology evolves, providing us with opportunities, tools, and incentives to create something new on our own.

What's more, they provide venues for networking, sharing ideas, crowdsourcing - collective production - and sharing the fruits of our labor.

“One of the hallmarks of our wonderful era is that we can treat free time as a common social asset that can be used to carry out large, socially significant projects,” says Clay Shirky .

Large, socially significant projects? As a result of all the arithmetic operations with technology, free time and a "culture of participation", we get something unimaginable in scale - maybe even a full-fledged city.

City by citizens' hands – why not?

Imagine being able to print earrings to match a dress, reproduce a broken vase, imagine creating a chair, a closet, building a dog house, and then a full-fledged building in an extremely quick and easy way.

To what extent will new technologies change our attitude to human labor, to historical heritage, to construction and architecture, to the city as a whole?

Of course, fear and skepticism cannot be avoided. How will everyone get the opportunity to produce something - not to do it anyhow, but to produce - what kind of arbitrariness will this be?

It is worth remembering Gutenberg's achievement and reasoning about the risks of the printing press, and then the development of social networks, in connection with which only the lazy did not promise the degradation of communication, the destruction of the language, and if not the end of the world, then what something that is clearly close.

New opportunities are generally viewed with apprehension. They infiltrate our lives in one way or another, but they have to go through a huge series of stereotypes until we allow them to reach their full potential and begin to take them seriously (both from a research and consumer point of view). ).

Of course, most of the fears, if they are not exaggerated and seasoned with "clinical nihilism", have a reason and a right to exist. New opportunities raise the question of the relationship between quantity and quality, they scare the risk of chaos, the spread of "consumer goods", the destruction of basic truths and true values.

“An abundance of books is a great evil. There are no limits to this feverish desire to write; everyone needs to be an author; some want to be it out of vanity, to gain honor and exalt their name; others are in the name of money.” (M. Luther)

3D printing and other possibilities created by robots can be welcomed with similar greetings. Fast and accurate? And how accurate? And what about tasks and content, what about quality?

Fast and accurate? And how accurate? And what about tasks and content, what about quality?

A couple of weeks ago the Financial Times published an article about the contribution of social networking to language development. Not in degradation, but in progressive development. With examples: both practical and theoretical.

In a natural way, no matter how much we resist, technologies make changes in our lives that activate us, create provocations that enliven our thinking - and positive effects cannot be avoided.

Experimentation inevitably leads to the appearance of base “masterpieces”, but also allows you to create something really valuable, unique and admirable (and you can gradually increase the “sample” of your amateur work by training and learning new technologies).

Modern cities (including Moscow) have every chance of becoming "everyday masterpieces" of their inhabitants.

The magazine Popular Mechanics cites, for example, the inspiring experience of FabLab in developing countries: living conditions by solving the problems they face on a daily basis. In Ghana, some of FabLab's first projects were Tesla's electric generator and refrigeration system for trucks transporting groceries. In the Indian village of Pabal, FabLab created milk quality sensors that made it possible to control its freshness and microbiological and chemical purity.”

In Ghana, some of FabLab's first projects were Tesla's electric generator and refrigeration system for trucks transporting groceries. In the Indian village of Pabal, FabLab created milk quality sensors that made it possible to control its freshness and microbiological and chemical purity.”

The Fab Central website MTI provides a constantly expanding list of workshops around the world, but here is a generalizing map (68 FabLabs already in mid-2011): fablabs.

The first certified laboratory was a joint project MTI , MISiS and the Government of Moscow, launched about a year ago (April 2012).

Today, discussions are already underway on the development of a dense network of FabLabs in Moscow: “Already, 10 universities in Moscow have been supported, where by the end of the year there will be their own laboratories, in many respects similar to the FabLab project, each of which will have its own specifics dictated by the specifics of the university. Only in the Moscow region there are more than 800 thousand students and 900 thousand schoolchildren, many of whom would like to have the opportunity to study on the basis of FabLab, so the main goal for the next year is to equip the centers so that in each district of Moscow there is a school or university with its own laboratory ". (deputy head of the department of education of the city of Moscow V.Sh. Kaganov ).

Only in the Moscow region there are more than 800 thousand students and 900 thousand schoolchildren, many of whom would like to have the opportunity to study on the basis of FabLab, so the main goal for the next year is to equip the centers so that in each district of Moscow there is a school or university with its own laboratory ". (deputy head of the department of education of the city of Moscow V.Sh. Kaganov ).

“Now we exist in the DiTo (Data in, Trash out) format - cities consume, but only produce garbage. The idea of creating a Fab-City is the idea of changing the format of life in DiDo (Data in, Data out). We are working on organizing FabLabs in all parts of Barcelona, bringing them together into a large network. This will allow people to come and use resources for the purpose of learning or producing some simple things "for life", which will subsequently help to abandon the "centralized production". For example, take Ikea furniture. We use it in the form in which we buy it, and then, when we get tired of it, it ends up in the trash. FabLab has enough resources for anyone to come in and be able to remake their old furniture, modify it or make something completely different out of it.” ( Tomás Diaz, FabLab Barcelona, IaaC )

FabLab has enough resources for anyone to come in and be able to remake their old furniture, modify it or make something completely different out of it.” ( Tomás Diaz, FabLab Barcelona, IaaC )

The city itself will be perceived differently: not an alien space created by armies of builders, but a material subject to change, a platform for creativity. Architecture, construction and other highly professional areas will, of course, remain the prerogative of specialists. However, we will be able to touch on each of these areas, each of them will become more understandable, accessible, and interesting. The "robotization" of cities will allow us to save time and effort and direct all energy in a pleasant and necessary direction, pay attention to the world around us and participate in the ongoing changes.

The growing activity of urbanists to awaken, educate, activate citizens (experiments with participatory planning, support for grassroots initiatives, civic start-ups and urban activism) will meet with technologies that convert urban residents in the same direction.

How does 3D printing work?

Peter Novikov graduate Institute for Advanced Architecture of Catalonia (IaaC)

In the past year, the technology of 3D printing, until recently unknown, has been talked about by a lot of people in almost all professional fields. Doctors are implanting 3D-printed bones, engineers are printing unique Formula 1 car parts , and US President Barack Obama said that "3D printing has the potential to revolutionize the way we do almost everything."

It is already obvious that in the near future the new technology will penetrate almost all spheres of life and if not revolutionize, then it will greatly affect production and the economy. But before we start discussing exactly how 3D printing will change our lives and affect the economy of countries and cities, it is worth first explaining how this technology was invented and what are the main types of 3D printing.

As is often the case with inventions, several versions of 3D printing were created by different people almost simultaneously - in the late 1980s. But still, Charles "Chuck" Hull (Carles W. Hull) is considered the inventor of 3D printing, since it was his method of Laser Stereolithography (Stereolithography) that was first patented in March 1986.

The 3D printer didn't come about in a funny incident similar to the one that invented the inkjet printer (its creator had an epiphany when he saw coffee spill from a coffee pot). On the contrary, invention Hull 3D printer was quite natural. In the early 80's he worked for a small California company called Ultra Violet Products . Hull developed UV curable polymer coatings. After work, he stayed to experiment with layering to achieve the thickness of the coating. This is how Hull came up with the idea of layering polymer layers with different outlines on top of each other to create three-dimensional objects. The outlines of the layers were created by moving a laser beam focused on the surface of a liquid polymer along a given contour. In places where the beam passed, there were lines of hardened material. It looks something like this:

The outlines of the layers were created by moving a laser beam focused on the surface of a liquid polymer along a given contour. In places where the beam passed, there were lines of hardened material. It looks something like this:

3D Systems is one of several industry giants, along with Objet and Stratasys . The main advantage of stereolithography is resolution: the accuracy is so great (0.016 millimeters) that with this method an American student managed to print a real vinyl record.

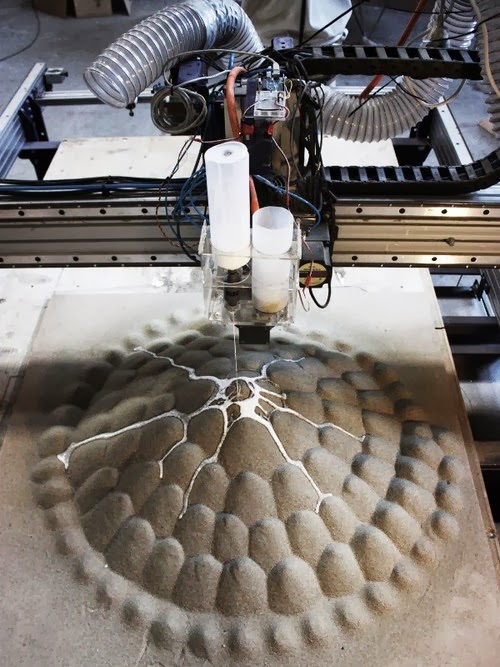

Selective laser sintering

Almost simultaneously with Charles Hull , in the mid-80s, Dr. University of Texas at Austin Carl Deckard , together with Dr. Deckard and Beeman called their technology Selective Laser Sintering.

As it turned out, a very similar method was patented in 1979 by R. F. Housholder , who is not considered the founder of 3D printing only because his invention was not applied anywhere and published, in other words, was forgotten.

Laser sintering is very similar in principle to Stereolithography, only instead of a liquid polymer, the laser is directed at a surface with an evenly distributed layer of plastic powder, and as it goes it turns the powder into solid plastic.

An important advantage of this method is that the powder can be not only plastic, but, for example, metal.

Fused Deposition Modeling

In 1992 Scott Crump , the founder of Stratasys Deposition Modeling , completed the development of a new kind of 3D Printing Deposition Modeling and called it Fused Deposition Modeling. Unlike previous examples, this method creates three-dimensional shapes not with a laser, but by squeezing out a jet of heated liquid plastic.

Fused deposition modeling is now one of the most common 3D printing methods due to the patent Kramp expired in 2009 and it became much cheaper to manufacture and sell 3D printers based on it.

This article has listed the most famous 3D printing methods.

In fact, there are many more, and new inventions in this area appear literally every day.

Printing accuracy and speed are increasing, more materials are available, from wood to chocolate, and a development has recently been introduced that allows organs to be printed from stem cells.

So now we can start thinking about how this technology will change the future.

For example, this is how the creators of the exhibition see it Production laboratory at DHUB in Barcelona:

Create.ru | CMIT FabLAB "Station" | Center for Youth Innovative Creativity, Krasnodar | 3D printing

New version of the site

GO

CMIT is a station for young technicians in a modern format children, youth, young entrepreneurs.

Everything you need to realize your projects in one place.

DETAILS

Our goal is to unlock the potential of you or your child!

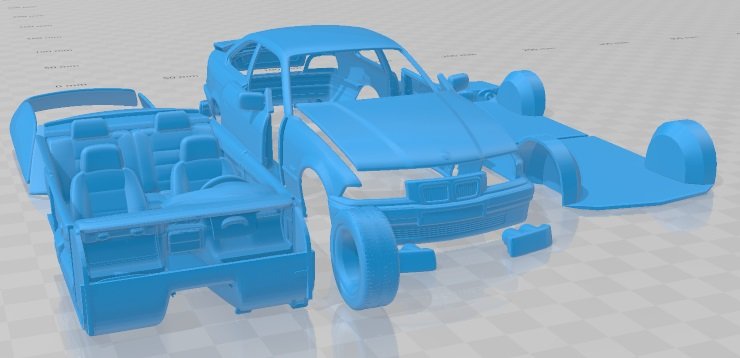

3D technology is a multifaceted field, it includes many specializations for which skills are important: create a three-dimensional model, apply a texture, create a model skeleton (for rigging) and animate it, reproduce the model partially or entirely using a 3D printer, 3D -scanner, laser or milling machines.

We have the right tools and knowledge, we are waiting for you!

DETAILS

What is CMIT?

The new generation of young people who want to do something really important and breakthrough for their city, their region, their country needs resource centers. In them, you can get the necessary knowledge on handling high-tech modern equipment and, armed with this knowledge, lend a shoulder to a country that is entering the era of automation, respect for the planet's resources and the era of space exploration.

Do you know that we are living through the 4th industrial revolution?

CMIT is an excellent platform for creating qualified personnel of new specialties - CNC machine operators, 3D printer operators, 3D modelers of augmented and virtual reality worlds, developers of simulators, simulators.

Look at the atlas of new professions, make sure that the old classic "working" specialties are rapidly becoming obsolete and disappear into oblivion!

More about CMIT...

Station Core - 3D printers. Our fleet includes 11 machines

CNC units: milling and laser machines

Own mini-printing house

Equipment for 3D modeling, 3D scanning and working with VR

3D printers

- printer industry)

- Duplicator-4X (Chinese workhorses)

- Z-morph VX 2.0 (not just 3D printers, but an MFP with a laser, cutter and paste machine)

- HTC Vive (Virtual Presence Systems)

- Leap Motion (Hand Recognition System)

- Shining 3D EinScan-PRO (3D Scanner)

- DJI Phantom 3 (3D Scan and Video/Photo Drones) High-performance workstations for creating all kinds of 3D content (printable models, virtual environments, computer games)

Nitrogen station mock-up

NPS mock-up for investors' business game

Cows for a layout of cowsheds

Mettant of the Polubud Unicorn gun

Rotonda layout

Master Model Model Swallow Nest to remove silicone forms and casting from gypsum

Master Model for subsequent casting

Souvenir for Peri

Valentine Valentine's Day

Small copy from photo

Creation of preoperative templates based on CT examinations

Anatomical model of the jaw joint for UIRS

Anatomical model of the jaw for UIRS

Anatomical model of the brain for UIRS

Anatomical model of the human lung for UIRS

Anatomical model of the human respiratory system for UIRS

Prototype of a prosthetic hand

9002 Heart preoperative template in UIRSModel of the aorta for participation in UIRS

Model of the kidney for participation in UIRS

Model of the head with muscles for UIRS

Uterus layout for WIRS

Prototype bottle for Kuban Molochik

Prototype Bath Dessert

Prototype of the Holder for GOPRO and shooting at 360

Prototype of the Hawaiian guitar -Lids Prototy of chesss

9000machine parts

Small batch production of machine parts

Small batch production of machine parts

Transport

According to 2GIS to CMIT 25 minutes from the shopping center "Gallery" by buses 3, 11 and 96, trolleybuses 21, 31, fixed-route taxi 35, trams 2, 5, 8, 15 (to the stop "Catherine Hall").