3D printers reprap

Build a reprap - RepRap

This page has been flagged as containing duplicate material that PartsSupplies also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that Darwin/Buyers Guide also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that What Tooling Do You Have also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page is out of date --Sebastien Bailard 04:34, 31 October 2010 (UTC)

This page is not only out of date, but contains in part simply nonsense - especially the "Software installation" section. For the lack of editors, this page should be removed. --Traumflug 21:18, 13 April 2011 (UTC)

Contents

- 1 Build a RepRap

- 2 Overview

- 2.

1 Object Creation Software

- 2.2 System control Software

- 2.3 Installing the Software (experimental)

- 2.4 Thermoplast extruder

- 2.5 Positioning system

- 2.6 Shopping list

- 2.

There are multiple ways to build a RepRap or RepStrap; the method selected for these instructions has been chosen to minimize skills and tools needed. If you wish to explore other options click Alternative Build Documentation.

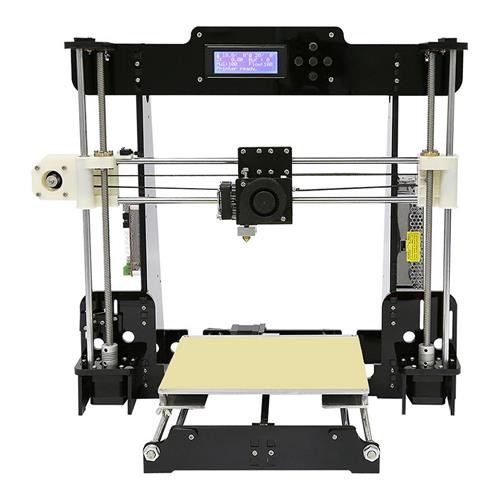

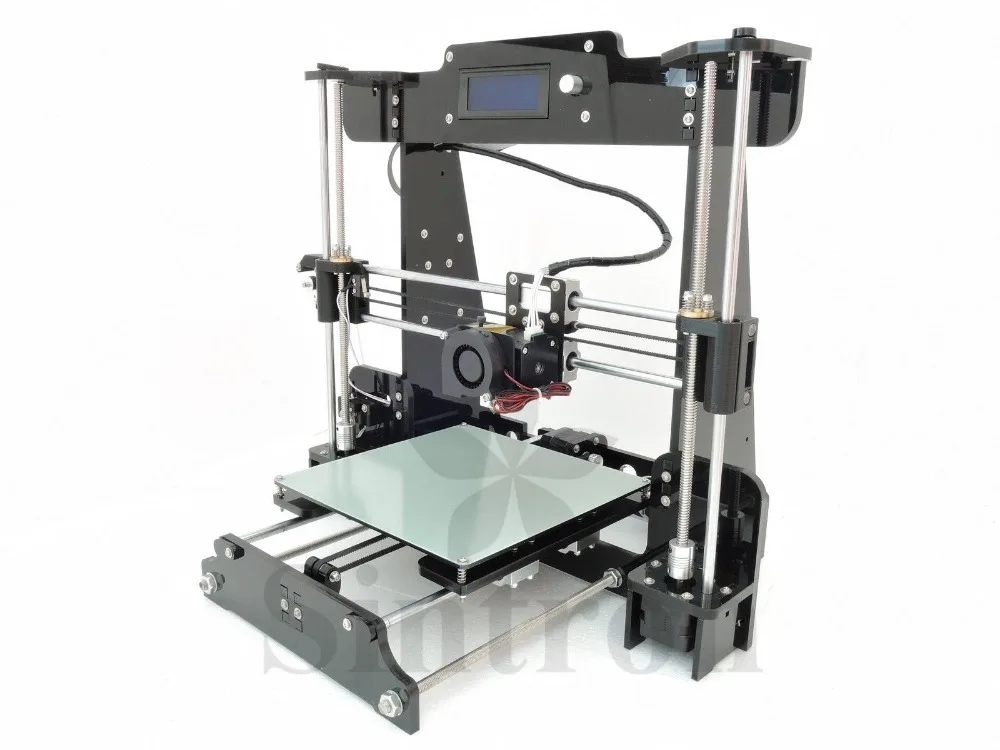

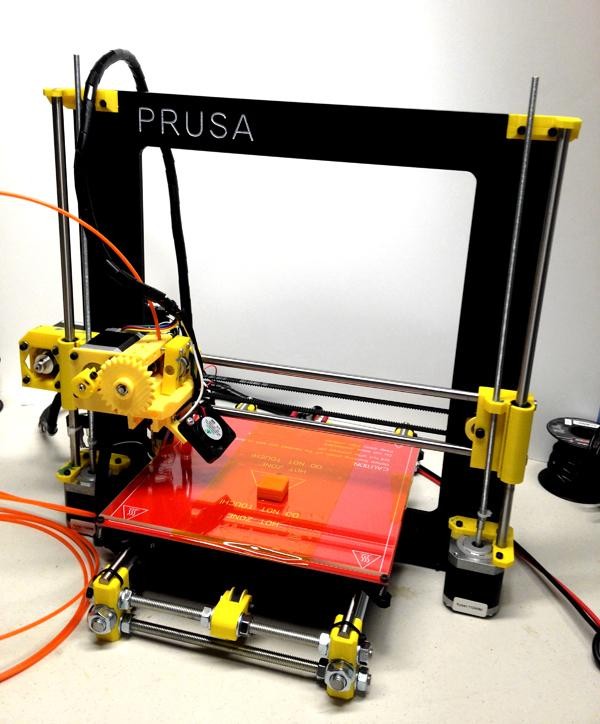

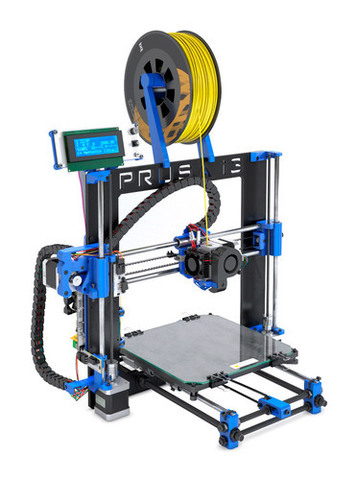

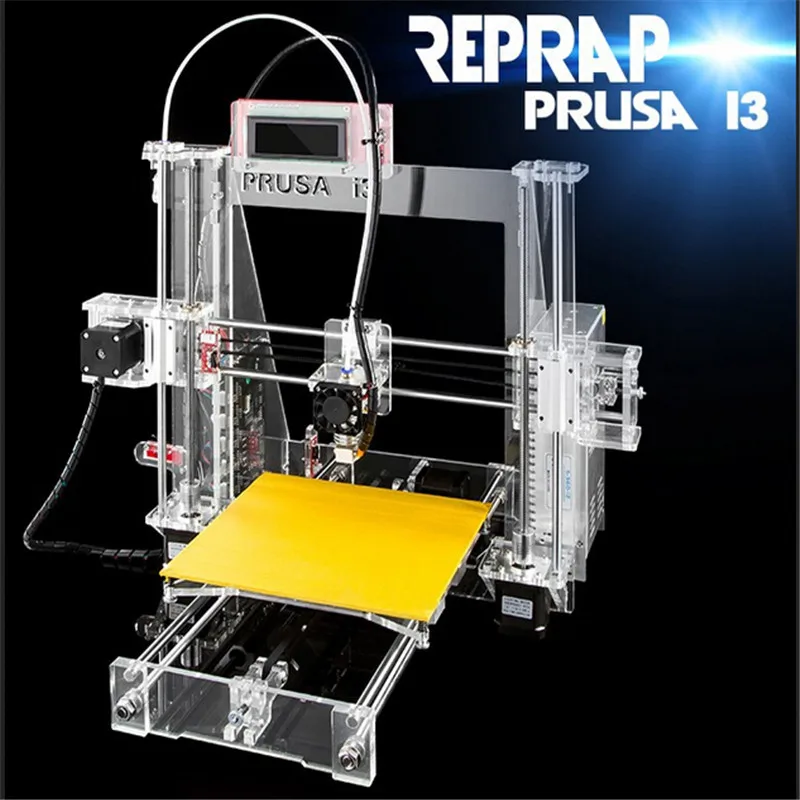

The Classic RepRap Design is "Darwin" pictured on the right. There are very full and accurate building instructions in Make Your Own RepRap.

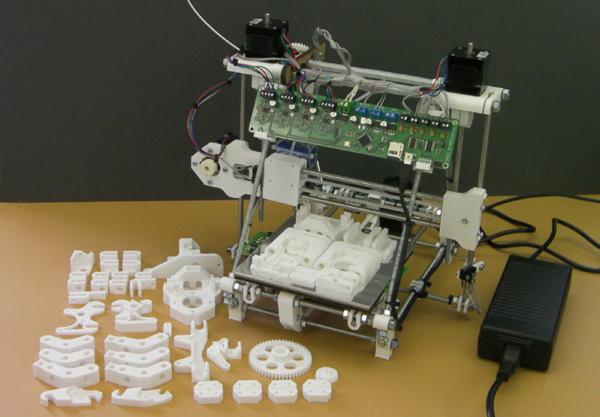

The RepRap was carefully designed to use only parts that can be made on a RepRap and other cheap parts that you can get anywhere. It was also designed to require few skills to assemble. The one snag is you have to find someone to supply you with the parts that must be made on a RepRap.

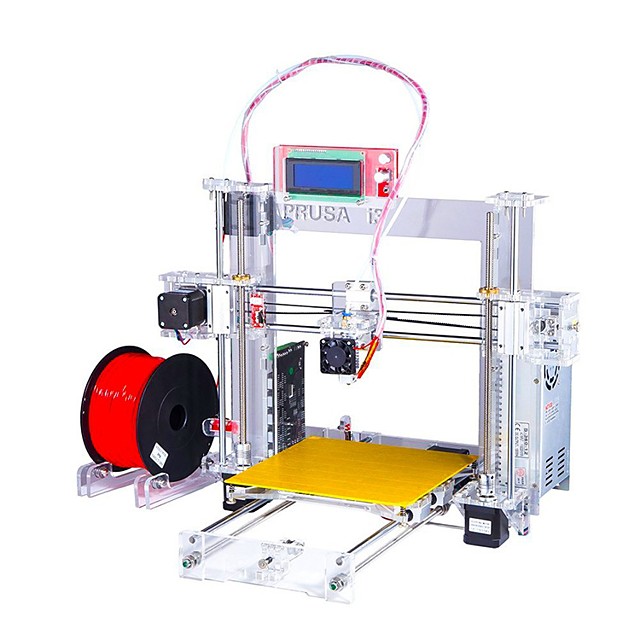

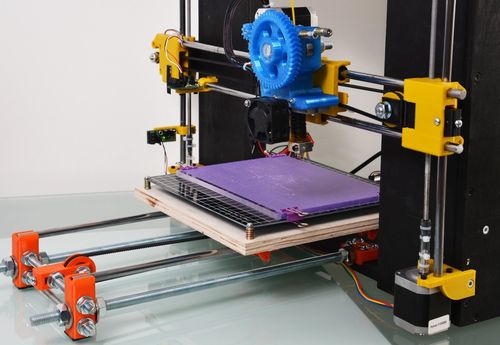

RepStrap Darwin Clones are RepRap designs which are fairly accurately copies of the Darwin design but the RepRapped parts are replaced by parts created some other way, Perhaps molded plastic or laser cut acrylic or plywood. Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

Other RepStraps, these are 3D printers capable of making RepRap (Darwin) parts but are not structurally similar to Darwin. These machines may vary a lot but may be separated into two kinds. Those like Darwin in which the extruder (print head) is moved in the x and y directions and the work is slowly lowered as the print progresses and others where the work is moved in the x and y directions under a stationary head which gradually moves upwards as the print progresses. Here are some references to various RepStrap Machines.

If this is your first RepRap that you are building, here is a basic guide of which build option you should choose:

- If you have a friend nearby that can print out the RepRap part on their RepRap or some other 3D printer. Choose the Classic Darwin

- If you don't have access to a 3d printer then you have 3 options.

- You can build a Classic Darwin, but this means you will have to use a commercial service to print out parts for you; it can easily cost over $1000 for just those parts depending on what deals you can get. This option is probably the most expensive option.

- You can build a RepStrap Darwin Clone. This means you can either buy a lasercut acrylic kit from Bits from Bytes or make some part yourself by machining them. This option is becoming the more common option especially because soon you will be able to buy a lasercut kit from Ponoko which has offices in the US. This is also usually cheaper than the first option.

- The third option is to build non-clone RepStrap that does not have the same frame as a Darwin, such as McWire which uses pipes for the frame. This option is usually the cheapest, but each RepStrap has it own weaknesses. The good thing is that when complete they can print out parts so that you can build a Classic Darwin. The electronics are compatible with Darwin so you only have to buy them once.

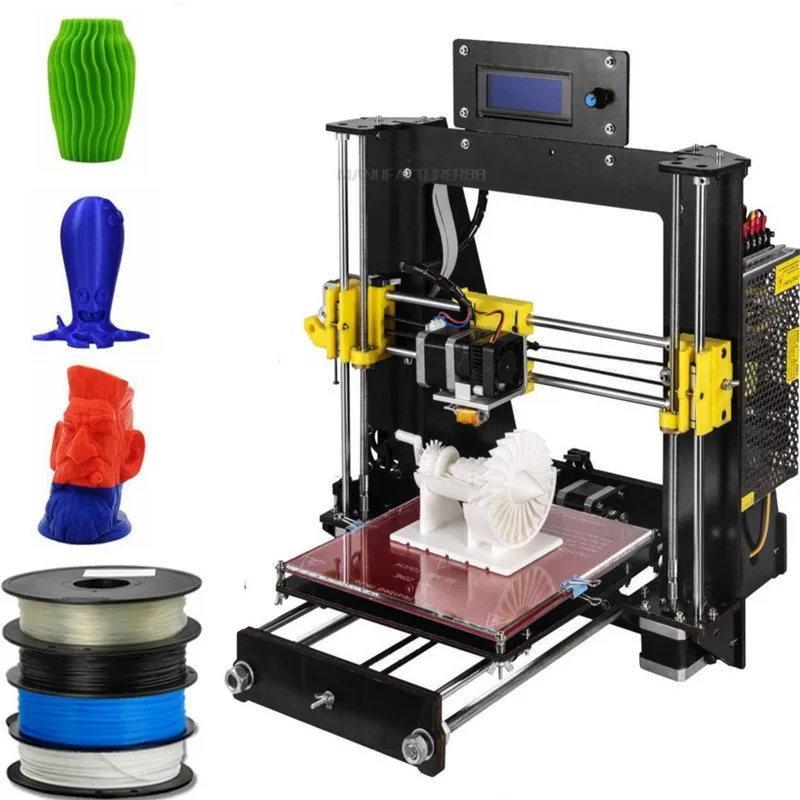

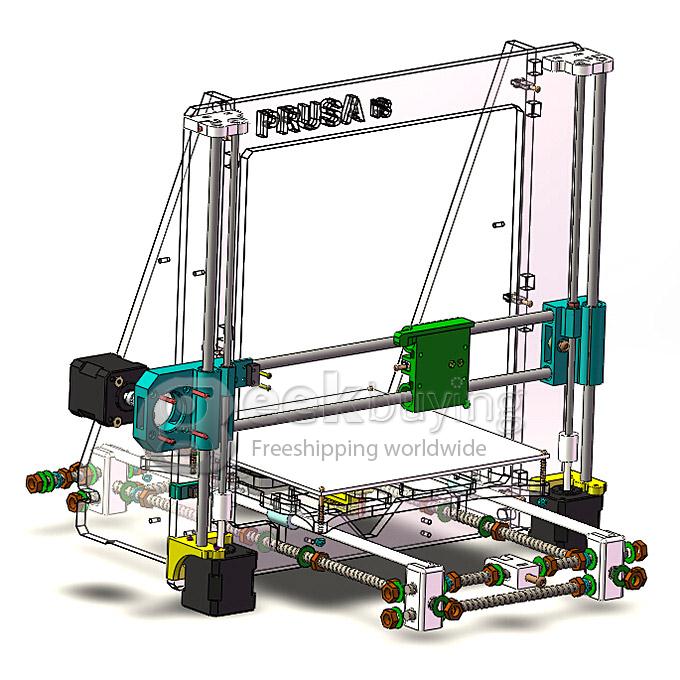

A RepRap or RepStrap (A RepRap can build itself, a RepStrap can build something that can build itself) can be divided into several key areas:

- Object creation Software

- System control Software

- Thermoplastic extruder

- Positioning system (the Cartesian Bot)

- The electronics to control the positioning system

Object Creation Software

Art of Illusion is currently the software most recommended for designing objects to be printed. It's not a CAD package but it is easy to use. The software allows you to create and manipulate 3D shapes. You can store these shapes in STL file format. STL files are object files that are used in Rapid Prototyping. These STL files can be printed off into real 3D objects using your 3D printer (RepRap).

The software is free (GNU GPL version 2) and it is available for Mac OS X, Windows and Linux. If you want to try it out without installing it's available bundled in the Linux distribution liveCD with the rest of the hosted software for the RepRap project.

System control Software

RepRap is controlled via USB or an RS232 interface. You may find a description or download from RepRap Host Software.

There is a RepRap variant which allows you to print an object from a file saved onto a SD card.

Installing the Software (experimental)

This set of instructions tells you how to set up all the software you need for a Reprap in one big blow under Linux Debian.

It involves 5 steps that anyone should be able to complete in a few hours of his/her spare time.

It's easy.

Really.

Warning: Proceed at your own risk. The instructions are not double checked yet.

Prerequisites

You'll need

- a PC (not too old)

- broadband internet access

- some time

Step 1: If you have Windows, go to [Here], get your copy of the Debian installer with one click and start it.

If you already have Linux: Install Debian Lenny some way or the other (you know how to do that ;-)) and continue with Step 3.

Step 2: Follow the instructions. I suggest installing on a 4GB USB stick - but you can also install it all on your hard disk. Be careful to select "testing" instead of stable - this installs Lenny instead of etch. Otherwise the standard settings should be ok in most cases. Don't say "yes" to things you might regret. After a while, a standard system should be installed. Don't forget to install the GRUB boot loader.

Step 3: Log in and say

sudo apt-get install firefox

on the command line.

Step 4: Start firefox and download this Media:Reprap_setup.sh script.

Step 5: Run the script from the shell with

sudo ./Reprap_setup.sh"

Now all the software specific to Reprap is retrieved and installed.

This includes the AVR-Tools, Subversion, Java3d, the Reprap-source tree etc. Installing all that will take some time.

Having successfully reached this point you should try to start the software in reprap-host with:

ant run

If you now see the main window of the host software, you're done.

Congrats! You have made it!

You still have to learn how to use it - but that is another story and another tutorial.

Thermoplast extruder

There are three different extruders all of which, in the end, perform the same function. There is the "official" extruder that can be made by another RepRap. Then there are the kits which are mass produced so it is easier to start printing your first parts. Both kits are designed to be interchangeable with the official extruder.

- RepRapable Thermoplast Extuder

Can be made by another RepRap or commercial rapid prototyper. These are not the only ways the parts can be made but are the easiest. Some builders have made them from machining aluminum or plastic. Others by making molds and casting from resin. This is only for the main pieces of the extruder. The drive screw and other mechanics must be bought or machined. - Kit from Bits from Bytes (laser cut acrylic)

There is an extruder kit currently available from Bits from Bytes who are based in the UK. The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

Bits from Bytes Extruder Assembly instructions

Bits from Bytes Extruder 3d Model - the model requires a recent copy of Adobe Acrobat.

There are videos of the construction process, in the 'Tutorials' section of the website.

Bits from Bytes Heater Barrel Assembly

Bits from Bytes Extruder Drive Assembly

- Kit from Ponoko (laser cut plywood)

A kit will soon be available via Ponoko which has offices in the US.

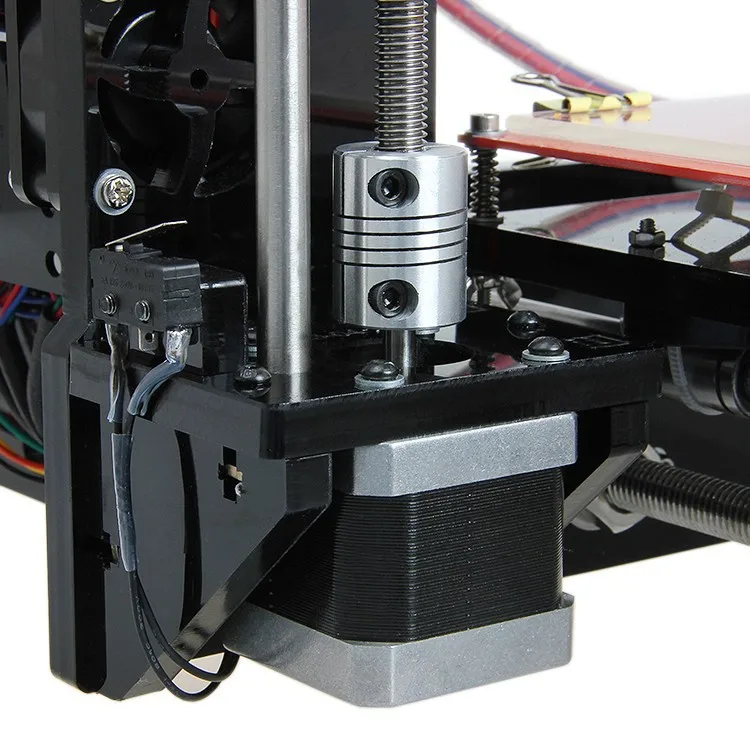

Positioning system

The positioning system is the greatest part of the size of a RepRap. It is what moves the extruder head from place to place. Kits are available from Bits from Bytes, either the FULL Mechanical Kit - Silver or Gold contain all the components necessary to build a positioning system and extruder. Assembly instructions are available on the bits from bytes website in the 'Assembly Instructions' area:

Bits from Bytes Assembly Instructions

Shopping list

The following list contains all the components necessary to build a RepStrap and enough plastic to print a RepRap. Some handtools are required for assembly, but the only power tool used is a soldering iron.

Some handtools are required for assembly, but the only power tool used is a soldering iron.

Extruder and Positioning System

Bits from Bytes - FULL Mechanical Kit - Silver or Gold

Ponoko - coming soon

(only one required)

Electronics

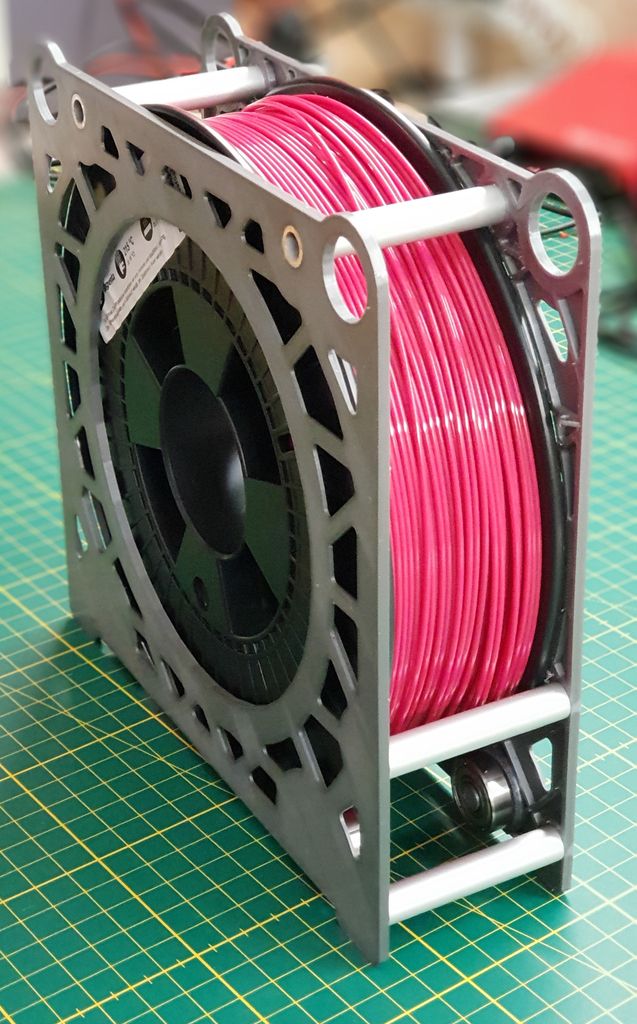

Plastic

The extruders all use 3mm diameter plastic filament/wire. ABS is the recommended plastic for its combination of strength, availability and dimensional stability. Suitable plastic is available from RRRF in 5lb reels. It is also available by request from plasticweldingrod.com.

Total

Shipping and tax vary by country of order but $1000 total is a reasonable approximation.

About - RepRap

From RepRap

Jump to: navigation, search

About | Development | Community | RepRap Machines | Resources | Policy

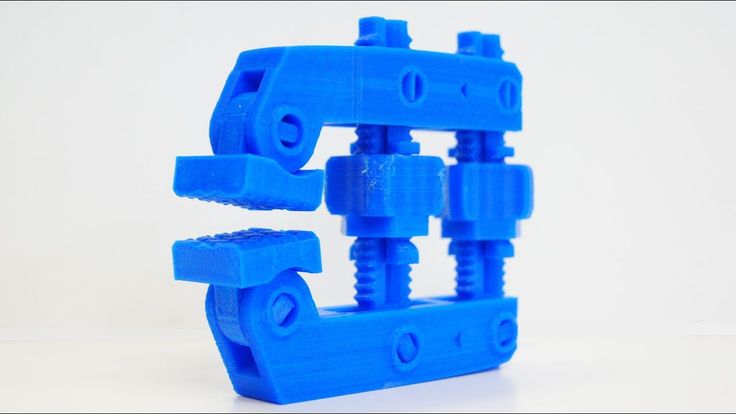

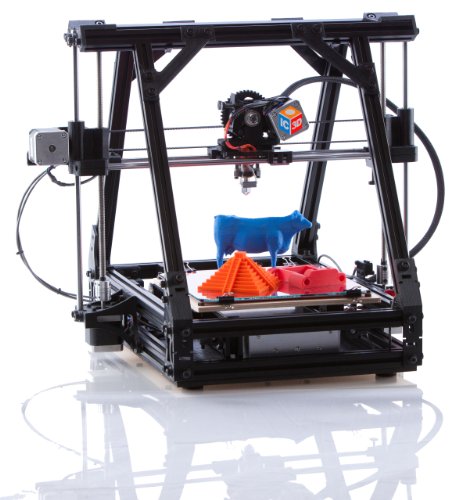

an exhibition of repraped parts

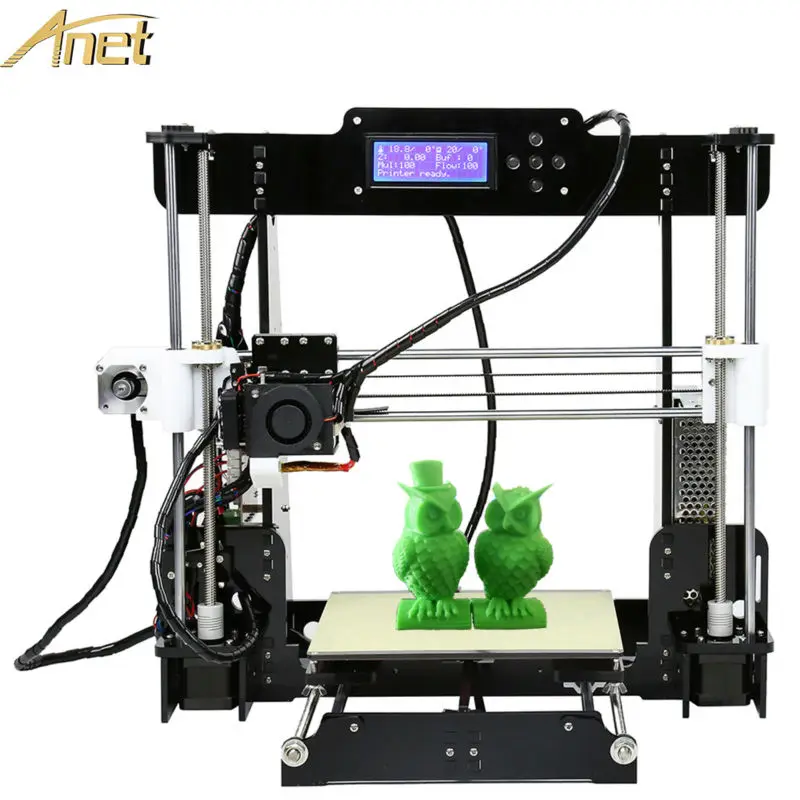

Look at your computer setup and imagine that you hooked up a 3D printer. Instead of printing on bits of paper this 3D printer makes real, robust, mechanical parts. To give you an idea of how robust, think Lego bricks and you're in the right area. You could make lots of useful stuff, but interestingly you could also make most of the parts to make another 3D printer. That would be a machine that could copy itself.

Instead of printing on bits of paper this 3D printer makes real, robust, mechanical parts. To give you an idea of how robust, think Lego bricks and you're in the right area. You could make lots of useful stuff, but interestingly you could also make most of the parts to make another 3D printer. That would be a machine that could copy itself.

Contents

- 1 The Realization

- 2 Machine Self-Replication

- 3 Scholarship and History

- 4 Spread the Word

- 5 Glossary

- 6 Also See

- 7 Longer Video

The Realization

RepRap was invented by Adrian Bowyer and the idea first appeared online in February 2004.

The word RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer introduced in the video on the left - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology existed before RepRap, but the cheapest commercial machine then would have cost you about €30,000. And it wasn't even designed so that it could make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €350). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under an open source license (the GNU General Public License). So, if you have a RepRap machine, you can use it to make another and give that one to a friend...

This technology existed before RepRap, but the cheapest commercial machine then would have cost you about €30,000. And it wasn't even designed so that it could make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €350). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under an open source license (the GNU General Public License). So, if you have a RepRap machine, you can use it to make another and give that one to a friend...

The RepRap project became widely known after a large press coverage in March 2005.

Machine Self-Replication

Not counting nuts and bolts the latest RepRap can make 70% of its parts; the other parts are designed to be cheaply available everywhere. The primary goal of the RepRap project is to create and to give away a makes-useful-stuff machine that, among other things, allows its owner cheaply and easily to make another such machine for someone else.

The primary goal of the RepRap project is to create and to give away a makes-useful-stuff machine that, among other things, allows its owner cheaply and easily to make another such machine for someone else.

To increase that 70%, future versions of RepRap will be able to make their own electric circuitry - a technology we have already proved experimentally - though not their electronic chips. After that we'll look to doing transistors with it, and so on...

Adrian Bowyer (left) and Vik Olliver (right) with a parent RepRap machine, made on a conventional rapid prototyper, and the first complete working child RepRap machine, made by the RepRap on the left. The child machine made its first successful grandchild part at 14:00 hours UTC on 29 May 2008 at Bath University in the UK, a few minutes after it was assembled.

Scholarship and History

Academics and others seeking peer-reviewed journal articles on RepRap may care to start with this paper in Robotica. The citation and link are:

The citation and link are:

- Jones, R., Haufe, P., Sells, E., Iravani, P., Olliver, V., Palmer, C., and Bowyer, A.,: RepRap - The Replicating Rapid Prototyper, Robotica (2011) volume 29, pp. 177–191. Cambridge University Press.

For great insight to RepRap as a self replictor see:

- Bowyer, A., 2014. 3D printing and humanity's first imperfect replicator. 3D Printing and Additive Manufacturing, 1(1), pp.4-5. https://www.liebertpub.com/doi/abs/10.1089/3dp.2013.0003

If you are interested in the legal aspects of this technology, then you may care to read this paper:

- Bradshaw, S., Bowyer, A. and Haufe, P.: The Intellectual Property Implications Of Low-Cost 3D Printing, ScriptEd, April 2010 pp.5-31. Also available here.

If you are interested in how the RepRap can be used to assist in sustainable development see:

- J. M. Pearce, C.M. Blair, K.J. Laciak, R. Andrews, A. Nosrat, and I. Zelenika-Zovko, 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development, Journal of Sustainable Development', 3(4), 17-29, 2010.

'

'

If you are interested in the economics of RepRap see:

- B.T. Wittbrodt, A.G. Glover, J. Laureto, G.C. Anzalone, D. Oppliger, J.L. Irwin, J.M. Pearce (2013), Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers, Mechatronics, 23 (2013), pp. 713-726. http://dx.doi.org/10.1016/j.mechatronics.2013.06.002 open access (self built Mendel)

- Emily E. Petersen and Joshua Pearce. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5(1), 7; doi:10.3390/technologies5010007 open access (commercial Lulzbot RepRap)

- Emily E. Petersen, Romain W. Kidd, Joshua M. Pearce, Impact of DIY Home Manufacturing with 3-D Printing on the Toy and Game Market. Technologies 2017, 5(3), 45; doi: 10.3390/technologies5030045 open access

- Aubrey L. Woern and Joshua M. Pearce. Distributed Manufacturing of Flexible Products: Technical Feasibility and Economic Viability, Technologies 2017, 5(4), 71; doi:10.

3390/technologies5040071 open access

3390/technologies5040071 open access - André O. Laplume, Bent Petersen, Joshua M. Pearce, Global value chains from a 3D printing perspective, Journal of International Business Studies 47(5), 595–609 (2016). doi:10.1057/jibs.2015.47 open access

If you are interested in the environmental benefits of RepRap see:

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Life Cycle Analysis of Distributed 3-D Printing and Conventional Manufacturing of Polymer Products, ACS Sustainable Chemistry & Engineering, Engineering, 1 (12), (2013) pp. 1511–1519DOI: 10.1021/sc400093k Open access

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products. MRS Online Proceedings Library, 1492, mrsf12-1492-g01-02 open access

There is also a study on the spread of RepRap and its population:

- Erik de Bruijn: On the viability of the open source development model for the design of physical objects, November 8th 2010, University of Tilburg, The Netherlands.

For a reasonably up-to-date literature review of RepRap technology see:

- RepRap Lit Review

To get a copy of the entire RepRap Blog from its very start as a single PDF file download this (41MB; thanks to Gary Hodgson). The images in the early posts of the online blog are broken, but they are all in that file.

There are many reports, student RepRap projects and theses that are available as PDF files from this site. They are all linked from relevant pages but in addition we should, perhaps, index them as well. In the mean time you can get a complete list of all of them by following this link.

The very first RepRap - the RepRap Darwin made by Adrian Bowyer and Ed Sells at Bath University - is now in the collection of the London Science Museum.

Spread the Word

You can freely use the RepRap Logo (see the licence terms on the left) and QR code:

Glossary

- RepRap - n. any free rapid prototyping machine that can manufacture a significant fraction of its own parts; v.

t. (in lower case: to reprap) to make something in a RepRap machine.

t. (in lower case: to reprap) to make something in a RepRap machine. - RepStrap - n. any free rapid prototyping machine that doesn't make its own parts, but is intended to make parts for a RepRap.

- reprapper - n. a person engaged in making or using RepRaps or RepStraps.

- reprapable - adj. capable of being made in a RepRap machine.

Also See

- Adrian Bowyer's One sheet Description of the RepRap Project

- Background

Longer Video

Here is a recent talk and Q&A by Adrian Bowyer about RepRap and self-replicating manufacturing machines.

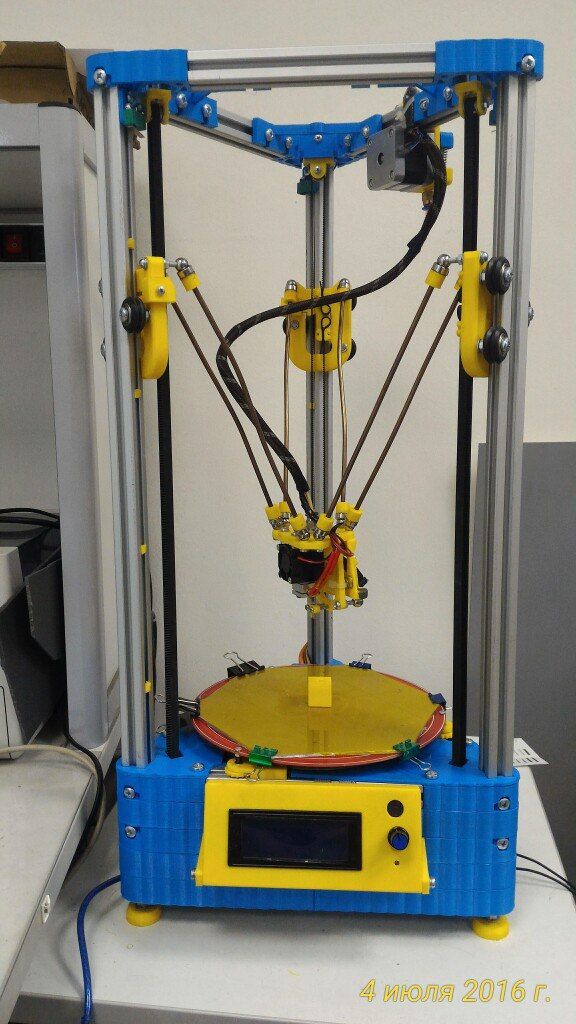

Repair of 3D printers in Krasnodar

Service center IT-Lab performs repairs of 3D printers in Krasnodar . We have quality original parts and components, modern equipment and experienced professionals. You pay for the result - only after the repair. In addition, we give a guarantee on all types of work!

In addition, we give a guarantee on all types of work!

Has your 3D printer stopped printing? Did it malfunction? Or does the 3D printer need to be professionally calibrated? Service center IT-LAB offers high-quality repair and maintenance services for 3D printers in Krasnodar. Our highly skilled craftsmen are guaranteed to bring your 3D technique back to life!

Maintenance and repair of 3D printers

A 3D printer is a rather complex device in technical terms, consisting of many moving parts that must be very precisely tuned and calibrated. Like other equipment, such devices sometimes require maintenance and repair.

If you have doubts about whether your 3D printer is working properly or the quality of printed parts has decreased - do not be discouraged! Most likely, the matter is in the downed slicer settings. Such problems can sometimes be solved with your own hands, guided by the manuals that usually come with the printer. If they did not help you (or if you are not confident in your abilities), then most likely you need to contact the service center for maintenance. Our experts will conduct a thorough diagnosis, determine the cause of the problem, perform repairs and accurately calibrate all components and systems!

If they did not help you (or if you are not confident in your abilities), then most likely you need to contact the service center for maintenance. Our experts will conduct a thorough diagnosis, determine the cause of the problem, perform repairs and accurately calibrate all components and systems!

Most common breakdowns and repair costs of 3D printers

| Diagnostics | Comprehensive 3D Printer Diagnostics | Free | Order Order |

| 3D printer does not work, does not turn on | Repair of power circuits | from 2000 rubles. | Order Order |

| Switch button repair | from 1000 rubles | ||

| Component or compute repair | from 3000 rubles | ||

| Firmware | from 1500 rubles | ||

| Plastic does not feed when printing | Extruder repair | from 1000 rubles | Order Order |

| Nozzle repair and calibration | from 1000 rubles | ||

| Clearing blockages in the extruder | from 1000 rubles | ||

| Computer "does not see" 3D printer | Interface repair | from 1000 rubles | Order Order |

| Driver installation | from 1000 rubles | ||

| Firmware | from 1500 rubles | ||

| 3D blank does not stick to the printing surface | Print bed repair | from 1000 rubles | Order Order |

| Nozzle to platform gap calibration | from 1000 rubles | ||

| Head calibration | from 1000 rubles | ||

| Platform re-adhesion | from 2000 rubles. | ||

| Not enough or too much plastic to print. Defects are visible on the workpiece | Maintenance, extruder gauge | from 1000 rubles | Order Order |

| Repair of moving mechanisms | from 500 rubles | ||

| Overheating of the material - the workpiece "flows". | OS driver installation (Windows) | from 350 rubles | Order Order |

| Extruder calibration | from 1000 rubles | ||

| Temperature sensor replacement | from 1000 rubles | ||

| Uneven or misaligned layers | Replacing belts | from 1500 rubles | Order Order |

| Replacing worn gears | from 1500 rubles | ||

| Nozzle to platform gap calibration | from 1000 rubles | ||

| Head calibration | from 1000 rubles |

Service center IT LAB repairs monoblocks of all firms and any faults. By entrusting the repair to us, you can be calm, because your property will return to you in full working order.

By entrusting the repair to us, you can be calm, because your property will return to you in full working order.

Our advantages

- We employ only qualified specialists with extensive experience;

- Our repair prices are below the average for Krasnodar;

- We use only high-quality and original spare parts;

- Warranty is always provided, despite the complexity of the repair;

- We have 4 service centers in Krasnodar, choose the closest one.

Still have questions?

Request a call, we'll tell you everything! 8(861)2907700

2-999-800 | 8961-509-11-33| 290-77-00

[email protected]

Viber

Fedor Luzana, 6

Mon-Fri 9:00 - 20:00, Sat 09:00 - 18:00

How to get there?

Partner network of collection points where you can hand over your equipment for repair.

A single number for all collection points:

8-903-450-40-30

Tselinogradskaya 2nd, 44k2

Mon-Fri 8:30 - 19:00 Sat 9:00 - 18:00

-903-450-40-80

How to get there?

how the Top 3D Shop service works in Moscow and St. Petersburg / Sudo Null IT News0001

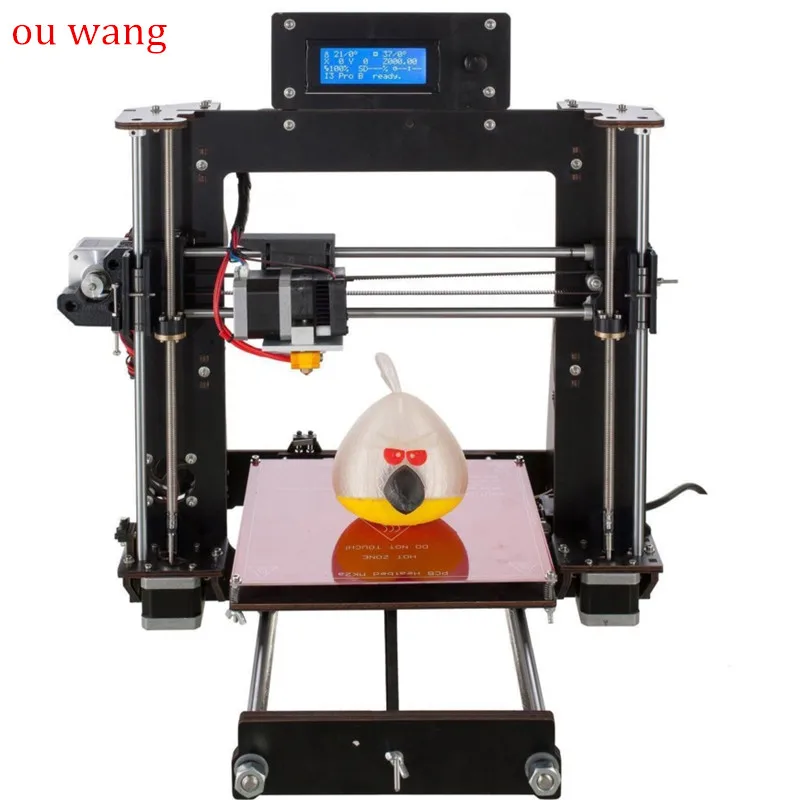

3D printing and CNC manufacturing have become an integral part of life, they are used by everyone: do-it-yourselfers in home workshops, small businesses creating things to order, development engineers to create prototypes and parts for new devices, and many others . The number of daily 3D printers and machine tools is constantly growing. The same can be said about robotics, equipment for 3D scanning and vacuum casting.

Like any technically complex equipment, all these devices need maintenance, repair and upgrade. In this article, we talk about how the service department of Top 3D Shop, the largest 3D printing and engineering company in Russia, works.

How it works

To carry out maintenance, the client addresses his problem to technical support, by mail [email protected] or by phone 8 (499) 322-23-19. During the communication, information about the printer, description, photo and video of the malfunction is requested - to provide an initial consultation on its elimination. Often it is possible to eliminate the malfunction during the consultation. This is convenient - the client does not need to take his equipment anywhere.

If the equipment still needs qualified repair, it is possible to order the necessary spare part from a remote warehouse in advance, find out the approximate terms of diagnostics and repair.

Upon receipt of the equipment by the service center, an acceptance certificate is issued, which will need to be presented upon receipt.

Diagnosis is carried out within three days after receipt, in some cases a little longer. After the diagnosis, if the repair is under warranty, it starts immediately.

If the warranty is over, or the equipment was not purchased from us, which also often happens, the cost (according to price list ) and repair time are agreed with the client. If the client is satisfied with everything, the service engineer starts the repair. After the repair is completed, a test print is carried out and an act is issued on the repair work performed.

What does the service do besides repair

In addition to repairs, the Top 3D Shop service also deals with equipment diagnostics, modification of printers and CNC machines, as well as pre-sale preparation and installation of equipment. This also applies to robotics, 3D scanners and ancillary equipment such as moulders, ultrasonic cleaners, high temperature furnaces and vibrating tables, injection molding ovens and injection molding machines.

Commissioning (commissioning)

The Top 3D Shop service department performs commissioning of 3D printers, CNC machines - laser and milling, as well as other equipment supplied by the company.

Our engineers travel to the customer's site to install the purchased equipment, test its operation and train the customer on how to use it.

This service is available to both individuals and organizations.

As an example, we recently completed the selection of equipment, pre-sales preparation, installation and training of the client's personnel at a plant producing electronics for river and sea vessels.

You can read more about this here .

What is the most common failure

The most common problems are related to the print head: plastic stuck in the thermal barrier, nozzle clogging, plastic fusing on the print head, insufficient gear pressure, loose gear on the motor shaft, temperature sensor failures, etc.

Then there are problems with belts, table calibration, motion end sensors and electronics.

When it comes to photopolymer printers, the most common problems are calibration and resin spillage.

What problems can arise during repairs and how they are solved

During the repair, problems with nodes that the client did not indicate during the registration of the printer for repair may be revealed. For example, they can bring a printer with a completely disassembled print head, or any other failed unit, and after its restoration, a malfunction with something else will be revealed.

The customer is warned before carrying out repairs that this situation is possible.

Do I need to improve my equipment

Brand new printers and machines usually require no modifications and work great out of the box or with a little initial setup. People who purchase such equipment want to get results quickly, without wasting time studying the technical part.

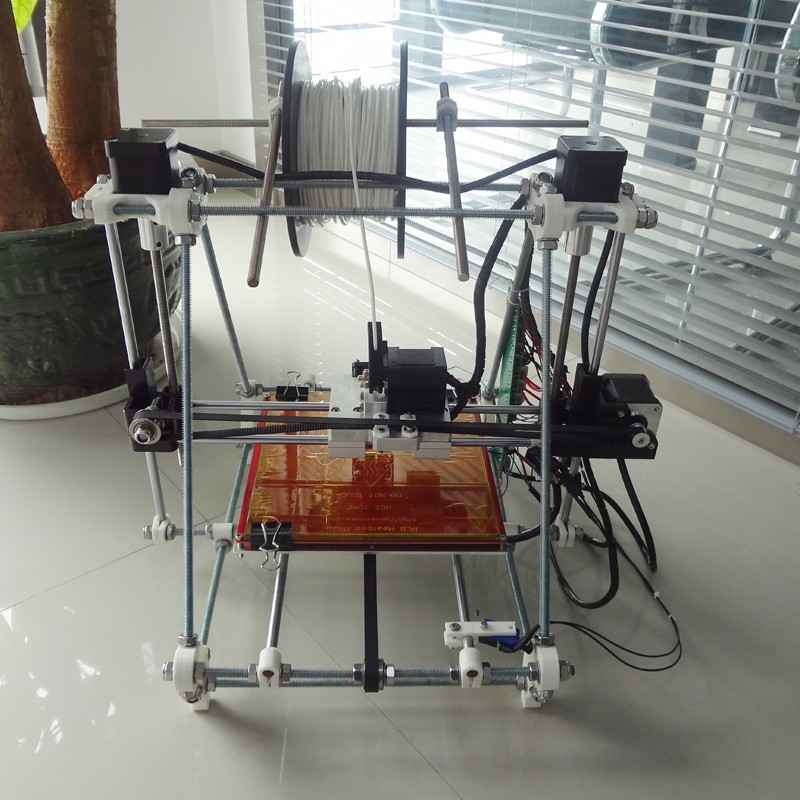

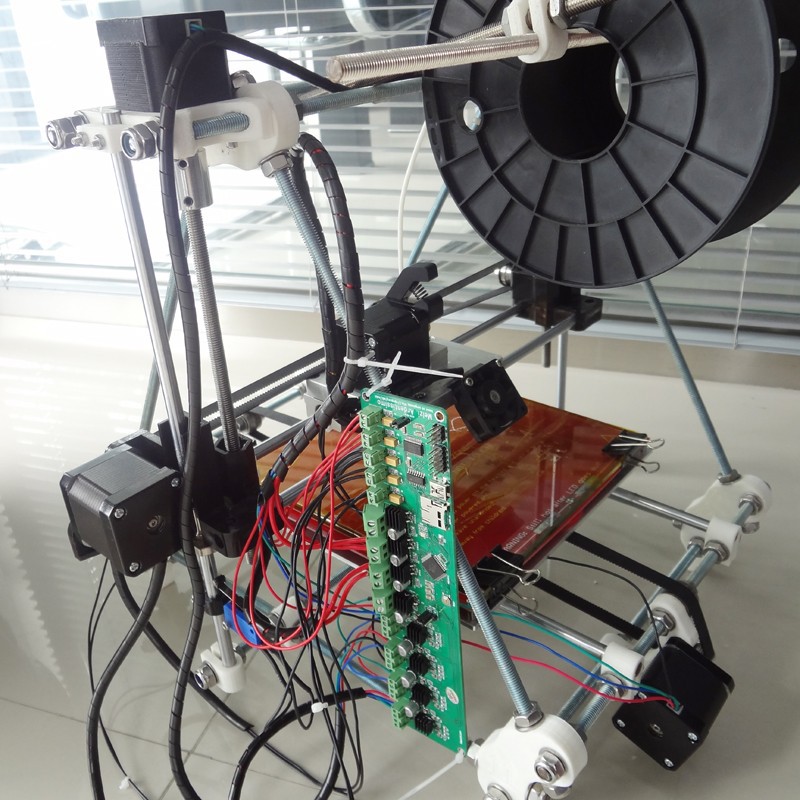

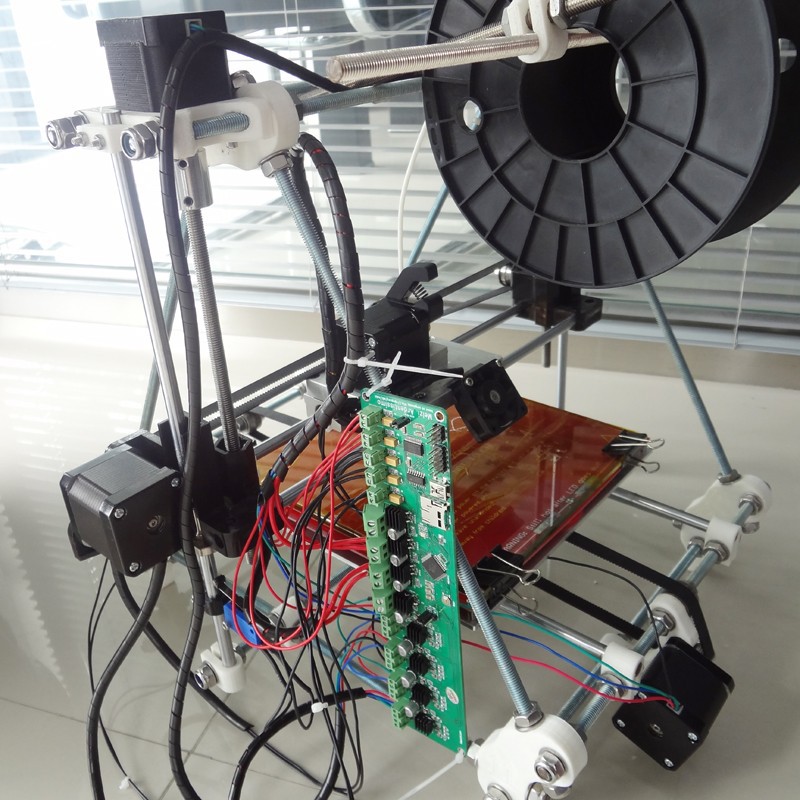

RepRap and DIY kits are usually modified, the quality of components in which often leaves much to be desired, and assembly by an inexperienced user can lead to malfunctions.

Modification allows you to replace or add some components to improve the operation of the device. For 3D printers, for example, add a heated table, airflow to the model, a closed chamber, replace sensors, guides, strengthen the frame, etc., for machine tools, replace the spindle or laser tube with more powerful ones, add a more powerful cooler or compressor, install optional nodes.

Sometimes the manufacturer himself releases additional modification kits. Such kits allow you to optimize the equipment for specific tasks.

The simplest and most complex repair cases in our practice

The simplest thing that happens is fitting and switching loose or incorrectly connected contacts, replacing components and calibrating the printer.

Sometimes, after fixing these kinds of problems, more complicated problems appear.

Difficult ones include working with printers of unknown origin.

Non-standard design solutions, lack of documentation and the use of unknown spare parts turn the maintenance of such a printer into an interesting, but long and laborious quest. Often, it is necessary to refine the design, functionality and firmware of the printer so that all nodes work correctly.

Often, it is necessary to refine the design, functionality and firmware of the printer so that all nodes work correctly.

Interesting and informative cases

Any complex repair is interesting in terms of experience. Repairing printers of unknown origin and making improvements to the design of printers are just in this series.

How Top 3D Shop maintains the quality of service

Any equipment, upon completion of work on it in our service, undergoes calibration and test printing. During work, all actions are recorded, which are then entered into the act of work performed. A photo report is being made - before and after the repair work. All works and terms are negotiated; if something changes, the new information must be agreed with the client.

How we improve our skills

The company successfully operates a system of initial training of employees and advanced training. We create training programs for all positions, including engineering, in the company's arsenal of dozens of existing courses, from theoretical to practical.

We create training programs for all positions, including engineering, in the company's arsenal of dozens of existing courses, from theoretical to practical.

We make sure that our engineers are ready for any problems that customers may have.

Service employees carefully study new equipment, both independently and in cooperation with suppliers, including at the manufacturer's enterprises, where they have the opportunity to communicate with the people who created this equipment.

Study trips, including abroad, allow not only to study the equipment according to the manufacturer's program, but also to personally get acquainted with the developed culture of production.

In the last year alone, our engineers have traveled several times to study in Germany and Poland, Italy, China and the USA.

During these trips we obtained the necessary knowledge about the equipment and certification from HP, Omni 3D, Apium and Sinterit, Shining 3D, DWS, and other manufacturers.

As part of the training, engineers got to know the products of these companies in detail and considered possible problems and ways to solve them.

Another advantage of such international communication is the opportunity to share experiences and compare approaches. Not every engineer can boast that he has worked side by side with specialists from other countries. This communication is useful not only for engineers - the manufacturer himself can get useful feedback on his product and, possibly, improve something in its design.

Advice to owners of 3D printers and CNC machines from our engineers

Like any complex technical device, 3D printers and CNC machines require careful handling and timely maintenance. It is necessary to monitor the cleanliness of the surface of the working platform, print head and moving parts, lubricate and clean in a timely manner. Comply with the operating and safety regulations.

Beginning users must read the manual that is attached to the equipment in paper or electronic form or is taken from the manufacturer's website.