3D printer tattoos

Engineers 3-D print a “living tattoo” | MIT News

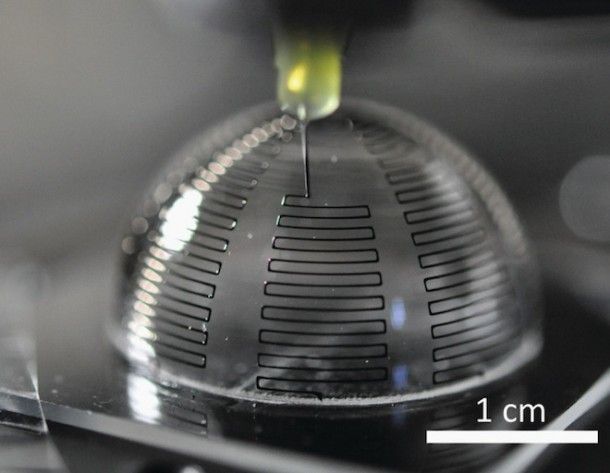

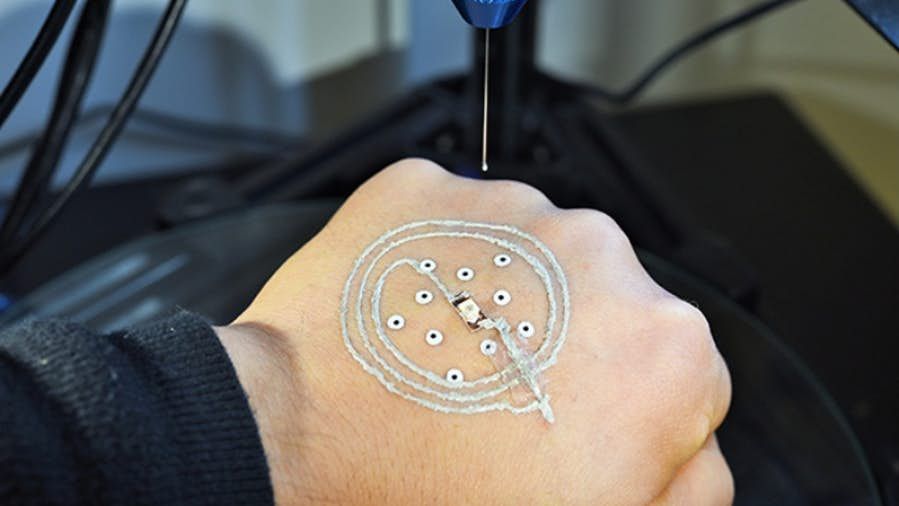

MIT engineers have devised a 3-D printing technique that uses a new kind of ink made from genetically programmed living cells.

The cells are engineered to light up in response to a variety of stimuli. When mixed with a slurry of hydrogel and nutrients, the cells can be printed, layer by layer, to form three-dimensional, interactive structures and devices.

The team has then demonstrated its technique by printing a “living tattoo” — a thin, transparent patch patterned with live bacteria cells in the shape of a tree. Each branch of the tree is lined with cells sensitive to a different chemical or molecular compound. When the patch is adhered to skin that has been exposed to the same compounds, corresponding regions of the tree light up in response.

The researchers, led by Xuanhe Zhao, the Noyce Career Development Professor in MIT’s Department of Mechanical Engineering, and Timothy Lu, associate professor of biological engineering and of electrical engineering and computer science, say that their technique can be used to fabricate “active” materials for wearable sensors and interactive displays. Such materials can be patterned with live cells engineered to sense environmental chemicals and pollutants as well as changes in pH and temperature.

What’s more, the team developed a model to predict the interactions between cells within a given 3-D-printed structure, under a variety of conditions. The team says researchers can use the model as a guide in designing responsive living materials.

Zhao, Lu, and their colleagues have published their results today in the journal Advanced Materials. The paper’s co-authors are graduate students Xinyue Liu, Hyunwoo Yuk, Shaoting Lin, German Alberto Parada, Tzu-Chieh Tang, Eléonore Tham, and postdoc Cesar de la Fuente-Nunez.

A hardy alternative

In recent years, scientists have explored a variety of responsive materials as the basis for 3D-printed inks. For instance, scientists have used inks made from temperature-sensitive polymers to print heat-responsive shape-shifting objects. Others have printed photoactivated structures from polymers that shrink and stretch in response to light.

Zhao’s team, working with bioengineers in Lu’s lab, realized that live cells might also serve as responsive materials for 3D-printed inks, particularly as they can be genetically engineered to respond to a variety of stimuli. The researchers are not the first to consider 3-D printing genetically engineered cells; others have attempted to do so using live mammalian cells, but with little success.

“It turns out those cells were dying during the printing process, because mammalian cells are basically lipid bilayer balloons,” Yuk says. “They are too weak, and they easily rupture.”

Instead, the team identified a hardier cell type in bacteria. Bacterial cells have tough cell walls that are able to survive relatively harsh conditions, such as the forces applied to ink as it is pushed through a printer’s nozzle. Furthermore, bacteria, unlike mammalian cells, are compatible with most hydrogels — gel-like materials that are made from a mix of mostly water and a bit of polymer. The group found that hydrogels can provide an aqueous environment that can support living bacteria.

The group found that hydrogels can provide an aqueous environment that can support living bacteria.

The researchers carried out a screening test to identify the type of hydrogel that would best host bacterial cells. After an extensive search, a hydrogel with pluronic acid was found to be the most compatible material. The hydrogel also exhibited an ideal consistency for 3-D printing.

“This hydrogel has ideal flow characteristics for printing through a nozzle,” Zhao says. “It’s like squeezing out toothpaste. You need [the ink] to flow out of a nozzle like toothpaste, and it can maintain its shape after it’s printed.”

From tattoos to living computers

Lu provided the team with bacterial cells engineered to light up in response to a variety of chemical stimuli. The researchers then came up with a recipe for their 3-D ink, using a combination of bacteria, hydrogel, and nutrients to sustain the cells and maintain their functionality.

“We found this new ink formula works very well and can print at a high resolution of about 30 micrometers per feature,” Zhao says. “That means each line we print contains only a few cells. We can also print relatively large-scale structures, measuring several centimeters.”

“That means each line we print contains only a few cells. We can also print relatively large-scale structures, measuring several centimeters.”

They printed the ink using a custom 3-D printer that they built using standard elements combined with fixtures they machined themselves. To demonstrate the technique, the team printed a pattern of hydrogel with cells in the shape of a tree on an elastomer layer. After printing, they solidified, or cured, the patch by exposing it to ultraviolet radiation. They then adhere the transparent elastomer layer with the living patterns on it, to skin.

To test the patch, the researchers smeared several chemical compounds onto the back of a test subject’s hand, then pressed the hydrogel patch over the exposed skin. Over several hours, branches of the patch’s tree lit up when bacteria sensed their corresponding chemical stimuli.

The researchers also engineered bacteria to communicate with each other; for instance they programmed some cells to light up only when they receive a certain signal from another cell. To test this type of communication in a 3-D structure, they printed a thin sheet of hydrogel filaments with “input,” or signal-producing bacteria and chemicals, overlaid with another layer of filaments of an “output,” or signal-receiving bacteria. They found the output filaments lit up only when they overlapped and received input signals from corresponding bacteria .

To test this type of communication in a 3-D structure, they printed a thin sheet of hydrogel filaments with “input,” or signal-producing bacteria and chemicals, overlaid with another layer of filaments of an “output,” or signal-receiving bacteria. They found the output filaments lit up only when they overlapped and received input signals from corresponding bacteria .

Yuk says in the future, researchers may use the team’s technique to print “living computers” — structures with multiple types of cells that communicate with each other, passing signals back and forth, much like transistors on a microchip.

“This is very future work, but we expect to be able to print living computational platforms that could be wearable,” Yuk says.

For more near-term applications, the researchers are aiming to fabricate customized sensors, in the form of flexible patches and stickers that could be engineered to detect a variety of chemical and molecular compounds. They also envision their technique may be used to manufacture drug capsules and surgical implants, containing cells engineered produce compounds such as glucose, to be released therapeutically over time.

“We can use bacterial cells like workers in a 3-D factory,” Liu says. “They can be engineered to produce drugs within a 3-D scaffold, and applications should not be confined to epidermal devices. As long as the fabrication method and approach are viable, applications such as implants and ingestibles should be possible.”

This research was supported, in part, by the Office of Naval Research, National Science Foundation, National Institutes of Health, and MIT Institute for Soldier Nanotechnologies.

3D-printed electronic tattoos could charge up battlefield warfare

Innovation

Home Innovation

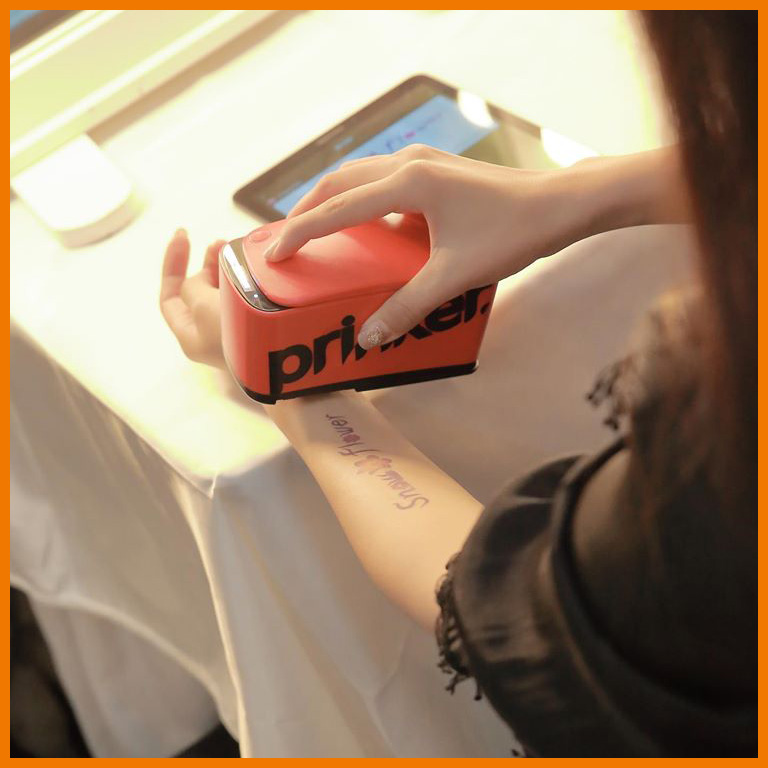

Low-cost 3D printers can be used to ink temporary sensors on the skin for a wide range of applications in the military and beyond.

Written by Charlie Osborne, Contributing Writer on

Researchers have developed a low-cost method to ink electronics on the skin, paving the way for military applications.

Featured

- Ugreen's GaN chargers are smaller, mightier, and cooler than yours

- Cloud computing is booming, but these are the challenges that lie ahead

- I cut my video streaming bill in half, and so can you

- Black Friday gaming deals: Laptops, consoles, and accessories on sale now

A team of scientists from the University of Minnesota has used a custom 3D printer to print electronics on human hands.

These electronic "tattoos" could be used for a number of purposes, including printing temporary sensors on soldiers to detect chemical or biological agents, or even acting as solar cells for charging critical electronic devices.

The new, low-cost technology has also been utilized to print biological cells on a mouse's skin wound, which may pave the way for direct skin graft printing out in the field.

"I'm fascinated by the idea of printing electronics or cells directly on the skin," said Michael McAlpine, the study's lead author and the University of Minnesota Benjamin Mayhugh Associate Professor of Mechanical Engineering. "It is such a simple idea and has unlimited potential for important applications in the future."

"It is such a simple idea and has unlimited potential for important applications in the future."

According to McAlpine, the printed markings could become a "Swiss Army Knife" for a variety of purposes made possible through one 3D printing tool.

The 3D printing technique is different from most as it allows for the body's small movements during the process. Temporary markers are placed on the skin and the surface is scanned, while the printer uses custom software to adjust to movements in real-time, which keeps circuit designs in place.

See also: Sensors under the skin monitor your alcohol intake

An ink made from silver flakes which can cure at room temperature is used, which makes the direct printer-to-skin process safe and keeps hands from burning. The majority of today's 3D printers require extreme heat to cure which would ruin human skin if it was used as a surface.

The temporary "tattoo" can be removed by washing it away in water or simply peeling it off.

"We are excited about the potential of this new 3D-printing technology using a portable, lightweight printer costing less than $400," said McAlpine. "We imagine that a soldier could pull this printer out of a backpack and print a chemical sensor or other electronics they need, directly on the skin."

The study has been published in the academic journal Advanced Materials.

The research was supported by grants from the National Institutes of Health and Regenerative Medicine Minnesota.

Previous and related coverage

- Medical device 'birth certificates' could solve healthcare security woes

- New 3D-printing method gives soft robots sense of touch

- Artificial intelligence will be worth $1.2 trillion to the enterprise in 2018

Related

3D printer - tattoo machine! A new page in the history of 3D technologies.

An original 3D printer-tattoo machine has been created

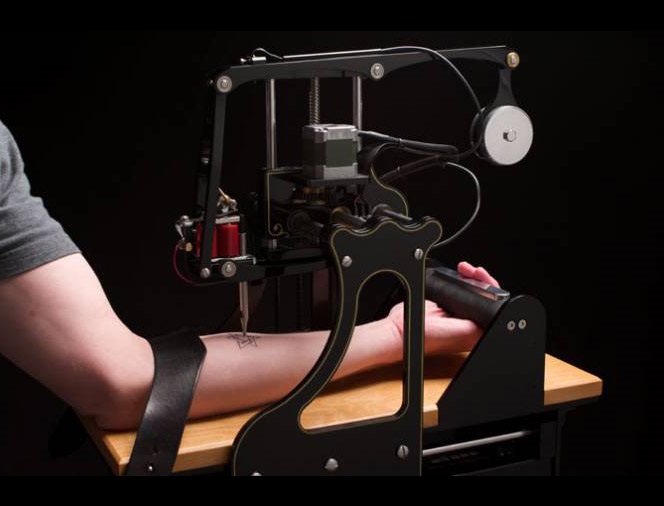

The relative novelty of 3D printing technology leads to its many unique applications in various fields. Obviously, too little time has passed for a complete transformation of the methodology, since society has not had time to fully master the existing methods of additive manufacturing. However, the bright minds of mankind are constantly working on the development and improvement of 3D printing technology. And sometimes this leads to very unexpected results. In each case, the technique itself is directly involved, or rather, special equipment for it. But what happens if we discard all unnecessary and leave only the principle of operation of a 3D printer? We have a great example: a 3D printer - a tattoo machine.

Obviously, too little time has passed for a complete transformation of the methodology, since society has not had time to fully master the existing methods of additive manufacturing. However, the bright minds of mankind are constantly working on the development and improvement of 3D printing technology. And sometimes this leads to very unexpected results. In each case, the technique itself is directly involved, or rather, special equipment for it. But what happens if we discard all unnecessary and leave only the principle of operation of a 3D printer? We have a great example: a 3D printer - a tattoo machine.

Back in 2014, a group of enthusiasts from France set an extravagant goal: to combine a 3D printer with a tattoo machine and actively began to implement their idea. Thus was born an unusual invention that fully performs its functions with some limitations. In 2015, the developers presented their creation to the world, which by that time was able to draw a picture on a human hand well fixed in the case. From such a blank, a 3D printer developed - a tattoo machine.

From such a blank, a 3D printer developed - a tattoo machine.

Of course, the French did not stop there and boldly continued experiments on an amazing device. One of the main intentions of the developers was to adapt the mechanism for applying a tattoo to any part of the body, and now, after some time, they found an original way to solve this problem.

3D printer - tattoo machine: features of

But before we get to it, we will tell you a little about the process of creating the first sample. To make a 3D tattoo machine, the developers removed the extruder from the MakerBot 3D printer and replaced it with a tattoo needle. The next step was to equip the device with special sensors that scan the surface of the user's skin, on the basis of which the device adapts to the size and structure of the skin of the limb, which significantly increases the accuracy of drawing the pattern.

In the course of work, the creators had to face a number of difficulties, since a 3D printer in the traditional sense is not adapted to perform its functions on such an atypical surface. The need to follow the curves of the human body led the French to delve into robotics, which led them to another interesting idea.

The need to follow the curves of the human body led the French to delve into robotics, which led them to another interesting idea.

With the help of an industrial robot and 3D scanning technology, they could get the information needed to program a mechanical arm to tattoo a human body. Since the task turned out to be entirely feasible, the developers immediately took up its implementation, in which they were greatly facilitated by the conclusion of cooperation with the notorious company Autodesk.

Highlights of the 3D Printer - Tattoo Machine

As David Thomasson, an engineer at the latter's research lab, points out, “Our research is really focused on a closer interaction between man and machine, which will most certainly be achieved in the near future. With this project, we are moving almost to the limit. In fact, all developed devices imply complete separation from humans. It's completely new territory."

Finally, after much experimentation and countless 3D scan data, the device was completed. The 3D printer-tattoo machine has been successfully tested and is fully ready for its intended use. It looks like this is really a completely new page in the history of 3D technology.

The 3D printer-tattoo machine has been successfully tested and is fully ready for its intended use. It looks like this is really a completely new page in the history of 3D technology.

https://vimeo.com/175491863

Back to main page

| 3DNews Technologies and IT market. News at the forefront of science Always dreamed of getting a tattoo? Now... The most interesting in the reviews 04/06/2014 [10:39], Dmitry Prikhodko For everyone who has long been looking towards self-expression in the form of drawings on his body, but can not choose a professional tattoo artist, there is an opportunity to turn to an inanimate tattoo artist. The function of applying an image using subcutaneous ink injection can be taken over by a conventional 3D printer. According to the creators, an automatic device in the future will be able to perfectly cope with complex tasks and perform a whole range of different actions. The very idea of a 3D printer, capable of taking on the functions of a tattoo machine and partially replacing the master himself, spontaneously arose among the creators of the device during one of the seminars on electronics. This event attracted the attention of a huge number of talented and extraordinary young people and inspired a group of French students to work on an unusual tattoo machine. To do this, they took one of the MakerBot 3D printing devices as a basis. The concept of the printer was slightly corrected, after which the device became capable of creating not only toys and plastic parts of various shapes, but also applying simple outlines to the skin using paint. As for the constructive part of the device, it has not undergone significant changes in comparison with the original model. A special needle was installed in the Makerbot printer, with which tattoos are applied in salons. In turn, the developers had to seriously work on refining the “printing” technology, because human skin is a very sensitive and not very durable surface. The application of excessive pressure would cause discomfort and pain. sharepowered.com Initially, the test sample was tested on artificial leather. After a successful launch, it was necessary to find people willing to acquire a simple geometric tattoo figure already among people. Among the most important link in the transformation of the printer into a tattoo machine was the question of the sterility of the operation and compliance with all related sanitary standards. Only after making sure of complete safety and compliance with the established rules, the developers began real tests. sharepowered.com It's worth noting that this tattooing process has some inconvenience. First of all, the hand to be tattooed must be very tightly fixed, which is not always necessary when working with a living master. In addition, the conceptual tattoo device was made by modifying a conventional printer, which was intended for completely different purposes. Because of this, the dimensions of the camera of the device strictly limit the place of work, so it is not yet possible to apply a pattern on the back or even the shoulder. sharepowered.com sharepowered.com In the future, a 3D printer like this could be a successful replacement for simple procedures. Proponents of 3D printing technology argue that within the capabilities of the device lies the full application of a complex tattoo, which can sometimes be compared with a real work of art. In addition, the 3D printer is not subject to fatigue and can precisely coordinate the accuracy of each of its steps down to the millimeter. |

True, today a 3D tattoo printer is capable of only the simplest manipulations, and among the first drawing it created so far is a banal circle. Therefore, it’s still not worth counting on seeing Botticelli’s paintings in the form of new tattoos tomorrow.

True, today a 3D tattoo printer is capable of only the simplest manipulations, and among the first drawing it created so far is a banal circle. Therefore, it’s still not worth counting on seeing Botticelli’s paintings in the form of new tattoos tomorrow.