3D printing outsourcing

Top 5 Reasons Fortune 500 Firms Outsource 3D Printing Projects

RECENT STORIES

5 Best Dual Extruder 3D Printers in 2022

November 11, 2022

9 min read

8 Best Resins for 3D Printers

November 11, 2022

10 min read

Fusion 360® vs. Onshape® - Software Comparison

November 11, 2022

10 min read

Not all manufacturers can build everything in-house. Even some of the largest Fortune 500 companies outsource 3D printing projects for both prototypes and production runs.

Why do they do this? Despite having a variety of resources at their disposal ‒ including sometimes their own 3D printing labs ‒ outsourcing for these firms can be a faster, less expensive and easier route.

Below are the top five reasons why.

Capacity

Even for large companies that have their own 3D printers, resource constraints can cause bottlenecks in production. If a firm’s 3D printers are tied up on other projects, teams can’t get parts built fast enough. As a solution, outsourcing this production allows them to harness additional capacity.

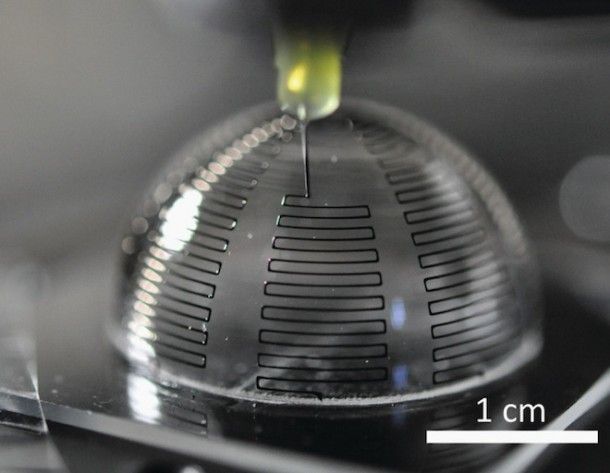

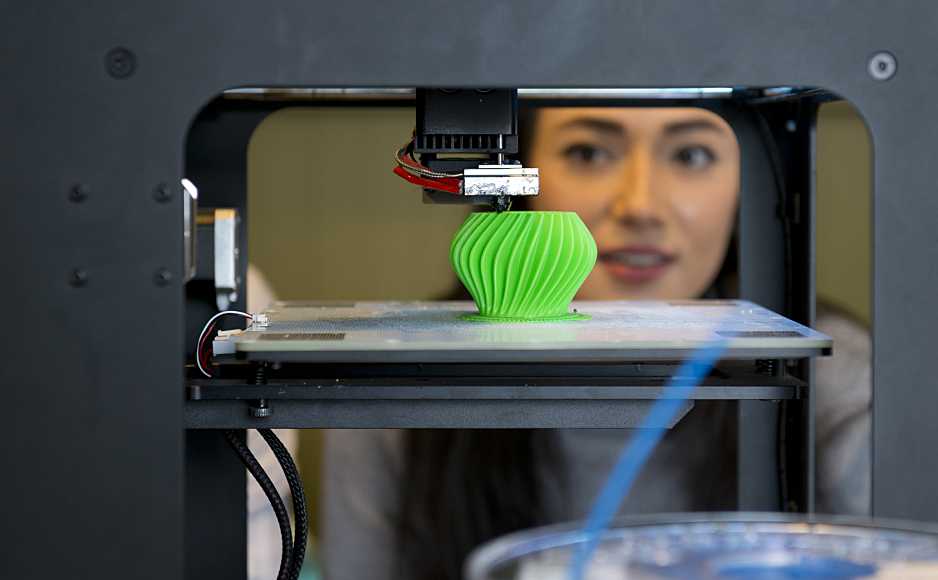

To help reduce lead times, we utilize multiple machines that run the same technology, as well as 3D printers with some of the largest build volumes on the market (like the FDM one at left). This combination allows us to maximize the number of parts we can print at once, and help eliminate production bottlenecks.

Technology

A Fortune 500 firm may outsource production, because they don’t have the right equipment. For example, they may own a SLA machine, but don’t have a metal 3D printer in-house.

Given the high upfront costs of professional 3D printers and the rapid pace of 3D printing innovation, many firms don’t want to pay for a new 3D technology, only to have it be outmoded by something better in a few years.

At Xometry, we’re constantly evaluating the latest 3D printing technologies, and adding more processes and materials, so customers can build exactly what they need.

Cost

Owning a high-end 3D printer can be expensive. On top of the machine costs, firms also need raw materials, special infrastructure (e.g., lots of electric), and skilled labor to operate them. Despite advances in technology, much of professional 3D printing is still a manual process, which is why labor is critical.

Even if a firm has the right equipment in-house, it may actually be less expensive to outsource a project than to build it themselves. At Xometry, we order raw material in bulk and build multiple orders at once (similar to the SLS parts at left), generating economies of scale and driving down costs.

Expertise

Like other manufacturing technologies, the professional 3D printing learning curve can be steep. Given that the sector that is still relatively new, expertise is a key component to 3D printing operations.

Firms need the right knowledge and experience to not only operate the machine, but also to set up the parts in an ideal manner. Small changes in equipment, build orientation, mix of materials, and support material (if applicable) can all impact results.

Small changes in equipment, build orientation, mix of materials, and support material (if applicable) can all impact results.

Additionally, complementary processes to 3D printing, such as achieving the right finish through CNC machining, or adding custom features, also plays large role here.

Lead Times

Production lead times often go hand-in-hand with the earlier section on available capacity. If constrained by time, and it can be faster for firms to outsource 3D printing.

But another major advantage for outsourcing production is reducing the lead time that it takes to get a specific kind of of material.

For example, we stock dozens of PolyJet 3D printing materials — including Rigid Opaque, Rubber-Like, Simulated Polypro, and Translucent/Clear — in-house. This way, orders can be fulfilled and shipped out as quickly as possible.

Team Xometry

This article was written by various Xometry contributors. Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more.

3D printing – Outsource, or print in-house?

David Roberson5 July 2018

Applications

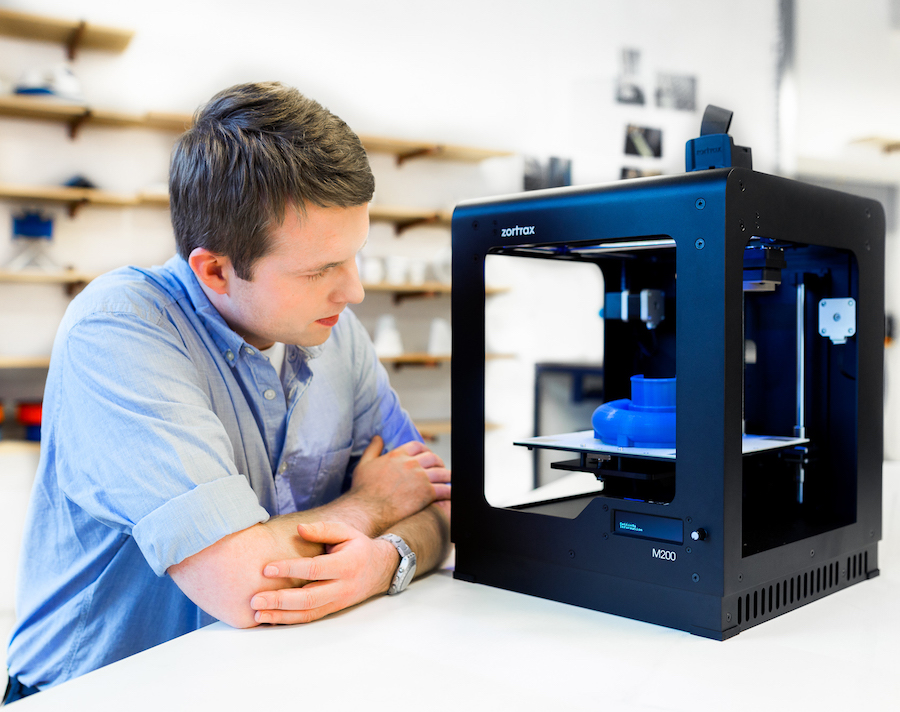

3D printing is becoming increasingly integral in the workplace. It helps companies validate designs, perform functional tests, and bring products to market more quickly. 3D printed prototypes are useful for communicating concepts with stakeholders, resulting in faster iterations and better quality products. Executives seldom need to be convinced of the benefits – yet many continue to outsource their 3D printing tasks; especially when it comes to final part production.

Why companies outsource

Outsourcing means no investment in machinery or training. It also eliminates uncertainty about in-house manufacturing of functional prototypes or final parts. SMEs can’t afford expensive industrial additive manufacturing equipment – outsourcing gives them access to this, and to the right level of expertise, which improves their pipeline efficiency. Even engineering teams in large enterprises haven’t always got the budget to invest in expensive training and equipment.

An alternative solution

Models and prototypes are crucial at the design stage, and companies want quicker, more effective ways to develop their product concepts. Outsourcing lets them use 3D printing technology without a large initial investment; but the throughput times can still be significant, undercutting the short iterations usually associated with 3D printing.

Desktop 3D printers offer a great alternative, without requiring a significant financial investment. They deliver professional results and other benefits; lower costs, quicker lead times, more customer interactions and higher scalability. They’re also easy to operate, resulting in more capacity, more teams, and more departments making use of them. In short, they make 3D printing accessible to more professional users, regardless of industry.

What are your options?

This depends both on purpose and application. Businesses have three options when it comes to 3D printing: outsource the tasks, print in-house with industrial machines, or invest in cost-effective, accessible desktop 3D printers.

The following sections examine the pros and cons of each.

A collection of tools 3D printed in-house and outsourced

Outsourcing to third parties

Outsourcing is a good option if you’re looking for exceptional quality, low quantities, and high complexity. It’s the right choice if you need five parts or fewer per month, especially if the parts are large or require non-standard materials. It’s also useful for final parts that require unusual materials or applications.

However, be warned – this is the slowest, priciest option. Yes, you’ll have an expert performing the task without the associated risks of long-term commitment. But the hourly or project rate is often substantially higher than hiring an employee, and you’ll be waiting longer for them to complete the job.

Pros:

Several technologies available in-house, such as SLA, FFF, and SLS

More materials than an in-house system

Expert knowledge about materials (and their limitations)

No long-term commitment

No initial investment

Cons:

Cost per part is far higher than in-house printing

Slower process - weeks instead of days

More paperwork and more workflow steps.

You’ll need to contact suppliers, review quotes, put in a purchase request, pass over specifications, develop ideas, evaluate functionality, and more

You’ll need to contact suppliers, review quotes, put in a purchase request, pass over specifications, develop ideas, evaluate functionality, and moreSmall amendments are expensive

Multiple iterations take longer to create

Customer locked in with software, add-ons, or filaments

Structural underutilization

Inaccessibility. An operator is needed, engineers can’t use it directly, and maintenance means no availability

Not scalable

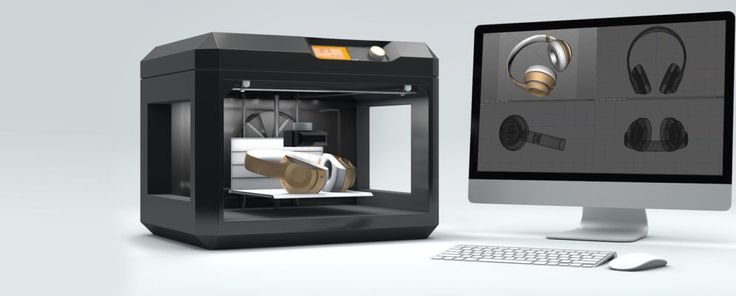

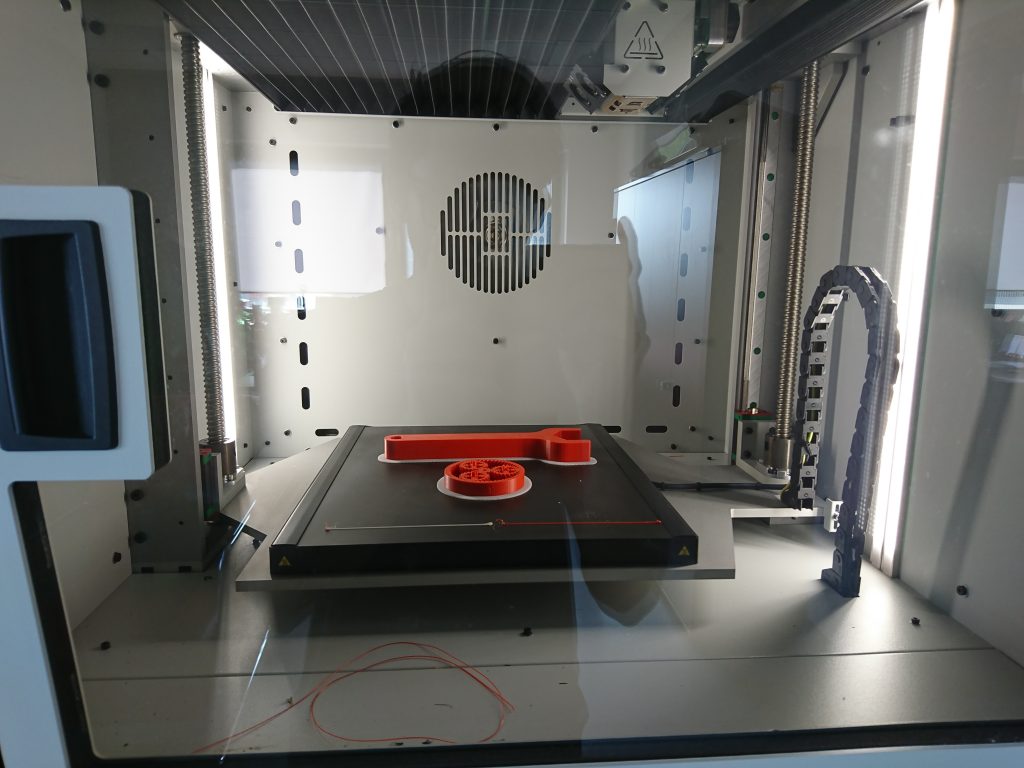

Parts inside the build chamber of a large industrial 3D printer

In-house industrial 3D printers

Industrial printers are ideal if you’re producing large batches of parts. You’ll need to use the printers frequently to justify the considerable investment and training involved.

Pros:

Wide range of high-performance materials available

When implemented, it’s quicker than using third-party service bureaus

Cost-effective option (when printing in large batches)

Cons:

Significant up-front investment.

Expect to pay between $250,000 and $1 million for a comprehensive manufacturing system

Expect to pay between $250,000 and $1 million for a comprehensive manufacturing systemLots of space required. True manufacturing systems require over 30m2 of floor space, industrial HVAC, finishing stations, cleaning stations, and more

Accounting for all costs, a single build would cost more than a desktop 3D printer (approximately $3,000, plus usage and labor)

Unsuitable for short batches – costs a lot more per printed product

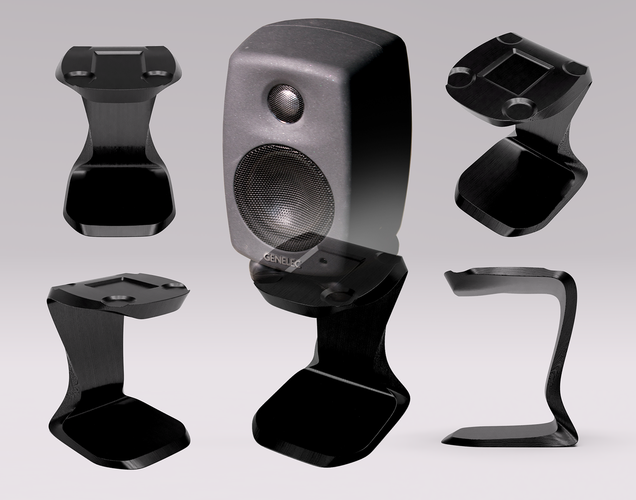

Desktop 3D printers provide a cost-effective and versatile solution

In-house desktop 3D printers

Desktop 3D printers are perfect for rapid prototyping. If you’re doing a lot of printing, a print farm of multiple desktop machines is far cheaper and easier-to-scale than industrial printing. Multiple printers and 3D print clusters also offer more flexibility and control (e.g. printing one part per machine).

Pros:

Most cost-effective option. An outsourced prototype can cost thousands of dollars (for complex models).

On average, printing in-house costs a tenth of the price

On average, printing in-house costs a tenth of the priceQuicker turnaround time. Outsourcing 3D printed parts takes about a week. An in-house 3D printer produces a prototype in a matter of hours, shaving weeks off the development cycle. Products can be brought to market in a fraction of the time

Greater flexibility – tweak designs at a far lower cost

No risk of designs being leaked – it’s all done in the safety of your business premises

Total design control – print fine details, smooth surfaces, and even moving parts in a single build

Less room required

Relatively inexpensive and scalable

Cons:

Most desktop 3D printers are technically limited to printing high-performance materials

More suited for smaller-size parts

Not as suitable for mass customization

Employee training is required (but less intense and complicated compared to industrial machines)

Questions to ask

Before committing to a 3D printing solution, ask yourself the following:

What do you need the parts for? Functional prototyping? Visual display? Casting into end products?

What materials will you be using?

How many parts will you need per week? How many parts can you fit into one build volume on a desktop, or on an industrial machine?

How familiar are your employees with additive manufacturing processes? Is additional training required?

What is the timeline for implementing 3D printing into your workflow?

What best suits your working environment?

In most cases, investing in several in-house desktop printers is the best option, then outsourcing final parts with specific requirements to a service bureau. It’s the cost-effective choice, not only for knowledge workers and design or engineering teams, but also for multinational companies. Industrial machines are often underutilized and not worth the investment, unless your business model involves mass customization or low-volume, high-profit activities. If you’re confident that you’ll need large batches of parts with high compliance (e.g. aerospace), then this may be a viable option for you.

It’s the cost-effective choice, not only for knowledge workers and design or engineering teams, but also for multinational companies. Industrial machines are often underutilized and not worth the investment, unless your business model involves mass customization or low-volume, high-profit activities. If you’re confident that you’ll need large batches of parts with high compliance (e.g. aerospace), then this may be a viable option for you.

Consider not only your current requirements as a company, but what you’re looking to achieve in the future. Cost and practicality should always be a priority, but so too should scalability and creative potential.

Explore more 3D printing knowledge

Outsourcing 3D printing of detailed HP PA 12

How 3D printing studios use MJF technology

Printing complex orders

If your equipment technology does not allow you to print products with high accuracy and repeatability, outsource 3D printing. This will allow you to retain customers and provide them with quality products on time.

Fast high-volume printing

The HP Jet Fusion 5210 can run around the clock. This equipment allows you to create products from high-quality plastic that are not inferior to cast ones. Due to the high resolution and precision of printing, the products do not require further processing: after removing the powder residue, they are ready for use.

Quick cost estimate

Thanks to the online calculator, 3D printing studios will find out the cost of printing in a few minutes - and they can announce it to the customer.

3D printing studios 20% off total order

Printing studios have a permanent 20% discount. To receive it, fill out the form and tell us about your business. When we process and approve the application, you will receive a discount on the first and all subsequent orders.

Benefits of 3D printing

01

High precision printing

Infomir equipment allows you to print products with a high resolution of 1200 × 1200 dots per square inch. Thanks to this printing accuracy, it is possible to produce objects with a smooth surface that does not require further processing.

Thanks to this printing accuracy, it is possible to produce objects with a smooth surface that does not require further processing.

02

One-piece complex structures

3D printing creates complex structures - swivel joints, chains and an object that is inside another like a nesting doll. They are not printed in parts, but all at once, which avoids gluing or soldering.

03

Printing from durable material

Infomir manufactures products from durable waterproof polyamide HP PA 12. This material retains its properties at high temperatures, is not affected by greases, oils, oil, gasoline, aliphatic hydrocarbons and alkalis.

04

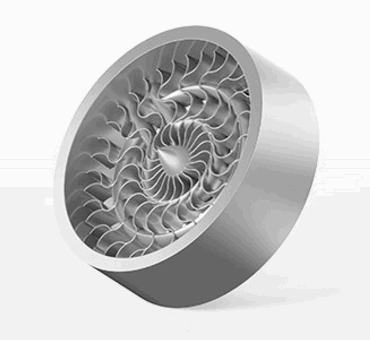

Printing objects with complex geometries

3D printing allows you to diversify the design - to produce objects with a smooth, corrugated, porous or perforated surface. Thanks to this, lightweight, durable hollow structures can be printed.

05

Post-processing

Printed products have a uniform structure. Such items are easy to process - staining, sanding and puttying. They do not crumble, which allows, if necessary, to refine them: drill, saw or cut.

Such items are easy to process - staining, sanding and puttying. They do not crumble, which allows, if necessary, to refine them: drill, saw or cut.

06

Printing oversized items

The HP Jet Fusion 5210 print line can produce solid items measuring 380 x 284 x 380 mm. Larger items are printed in parts, then the components are glued together. The joints are ground, and are invisible in the finished product.

Project Portfolio

View more projects View more projects

Frequently Asked Questions

The printing cycle lasts 3-5 days. For this, only a 3D model of the future product is needed. To find out the exact terms of printing and delivery, please contact the Infomir manager:

+38 (099) 075 5995

create products with a layer thickness of 80 microns. This is comparable to the diameter of a human hair.

You will be able to pay for the order after you agree on its terms with the manager. Payment methods:

Payment methods:

- prepayment to the Privatbank card

- bank transfer.

Finished products are only sandblasted to remove resin residue. Optionally, we provide coloring services.

Two methods are available:

1. Dyeing is the classic dipping of parts into a dye tank.

2. Graphite blasting - Similar to sandblasting, but this method uses carbon and glass as the abrasive.

Painting and blasting is an inexpensive and effective way to get products with a quality finish. Available colors are graphite, black and grey. We'll be adding more cover options soon.

The HP Jet Fusion 5210 line uses Hewlett Packard's proprietary polyamide, HP PA 12 polyamide. The material retains its properties and shape over a wide temperature range from -50°C to 110°C. Polyamide HP PA 12 is more resistant to high temperatures than ABS plastic: the former melts at 150 °C, the latter at 105 °C.

HP PA 12 withstands physical stress and vibration: the material is used in automotive and aerospace applications. However, the strength of the product is also affected by the design features and the thickness of its walls. To develop the optimal product model, follow our recommendations for preparing models for printing.

However, the strength of the product is also affected by the design features and the thickness of its walls. To develop the optimal product model, follow our recommendations for preparing models for printing.

Finished products are sent to the customer by courier (in Odessa) or New mail (in Ukraine). To find out about the terms of delivery to your country, please contact the Infomir manager by phone or e-mail:

Tel.: +38 (099) 075 5995

Email: [email protected]

Limitation of the printer working space is 380 x 284 x 380 mm. If the model is larger, we will split and print it piece by piece, and then assemble it. This is how bumpers and torpedoes for cars, architectural models and sculptures are created. The online calculator does not divide large models into parts, so only project managers can estimate their cost. Send overall models to the manager:

Tel.: +38 (099) 075 5995

Telegram: https://t.me/infomir3dprinting

Email: 3dprint@infomir. com

com

How to order printing on a 3D printer

color

3. Pay for the order

4. We print the product

5. Send by delivery service

Order 3D printing Order 3D printing

10 reasons to contact the prototyping center

Analytics and business

Rapid prototyping

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

1. Supply chain management | 2. Large selection of materials | 3. Variety of colors and finishes | 4. Large format 3D printing | 5. Professional quality parts | 6. Cost reduction | 7. Save time | 8. Scalability | 9. Expert advice and assistance | 10. Services of professional designers

The 3D printing services business is growing faster than ever. This happens because more and more people are striving to realize their ideas by means of additive technologies. Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

Today, 3D printing services are based mainly on working with professional clients. Of course, orders are also carried out for individuals, but most of the market is the B2B segment.

Even if you have access to a 3D printer, sometimes it's better to hire an outside contractor. Let's say you need a part in a material or color you don't have, and you'd rather not buy the whole lot. It is much wiser to order the missing part, and not to purchase all the equipment and inventory that may not be needed in the future.

We will look at ten reasons why additive manufacturing using a service can be more profitable.

Do you have projects that you would like to realize using 3D printing, 3D scanning or 3D modeling? Order a service from our company!

Leave a request

1.

Supply chain management

Supply chain management Additive technologies have been improved over the years, and today they allow the production of both prototypes and final parts, especially when solving certain problems.

In general, the development and manufacture of a particular part can be expensive due to high tooling costs. 3D printing is an extremely flexible technology. Manufacture of many different products and refinement of their designs is no longer a complex problem, which makes additive manufacturing a reliable solution to problems with the active use of redesign.

Outsourcing 3D printing jobs saves costs and lead times © Leo Gregurić via All3DP

Today, many research groups and companies rely on 3D printing services as a supply chain. It is extremely useful for them to be able to easily create and deliver custom parts.

2. Large selection of materials

One of the strong selling points for 3D services is the variety of consumables (and technologies) on offer. Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies.

Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies.

Prototyping centers offer, as a rule, the three most popular additive technologies: FDM, SLA and SLS. Accordingly, polymer filaments or granules, photopolymer resin and plastic powders are used as consumables.

A wide range of options gives the customer the opportunity to obtain the material that is required for a particular project, based on mechanical and chemical properties and aesthetic requirements.

The variety of materials is practical not only for professional needs. The Professional 3D Services Center will also offer simple materials that may not be available to a private person. Buying a certain material and printing a product from it on your own can be more expensive than simply ordering the manufacture of a single part from this material.

iQB Technologies experts recommend an article: 9 products that are more profitable to make on a photopolymer 3D printer

3.

Variety of colors and finishes

Variety of colors and finishes With such a wide range of materials available, 3D printing service customers are not limited in their choice of colors and finishes. Creating the perfect combination for a specific task has never been easier.

Colors

FDM filaments (PLA, ABS, PETG, and others) are typically offered in a wide range of colors. The plastic granules from which the thread is made are easily dyed.

More advanced combinations of plastics in the form of filaments, such as polymer composites or nylon, are difficult to dye and their color range is not as rich.

With regard to SLA technology, various colors are available for photopolymers. True, there are not as many of them as for PLA. Methods like SLS use industrial grade nylon powder, which comes in white, black, or some color in between. This is also due to the difficulty of coloring.

Technology available for full-color 3D printing © Hubs

There are full-color 3D printers that are ideal for creating visually appealing prototypes and teaching models, such as anatomy and geography. Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Finish

The surfaces of products created on a 3D printer can be subjected to various post-processing methods. Details are processed until the layers are completely indistinguishable and, as a result, look as if they were not printed at all.

But this is only the beginning. Finishing can include sanding, polishing, electroplating and painting, and many other finishes. Not every 3D printing material is suitable for all post-processing methods, and the service provider should explain this point to you when ordering.

In addition to the huge selection of options, one of the biggest benefits of ordering a finishing service is quality and convenience. Post-processing can take a lot of time, and entrusting the work to professionals, you will be sure of a high-quality and reliable result.

4. Large Format 3D Printing

Sometimes you may need a large printer © WASP Team via Youtube

An additive manufacturing services company typically operates multiple 3D printers to meet high demand (and meet deadlines) and various other requests. This provides a number of advantages, among them - the flexibility of product sizes.

Sometimes splitting a large part into multiple sub-elements is not the best solution, so an additive setup with a large build platform is needed. An individual or company often does not have access to large 3D printers, while many 3D service providers do.

5. Professional quality parts

3D printers are becoming more reliable, and even the most affordable technology is showing impressive accuracy. However, many products (say, jewelry) require more precise workmanship or tighter tolerances to ensure perfect compatibility (for example, functional units). The professional results offered by the 3D printing service guarantee consistently high-quality workmanship in terms of precision and finish.

Professional machines are more reliable in terms of repeatability. This is an important factor to consider when printing a large number of parts that require constant and tight tolerances.

But not only machines determine the final result. The people who work with 3D printers make a significant contribution to the production of professional quality parts. They have the knowledge and experience to advise you on how to best prepare your model, select the most suitable material, and finally create the final part.

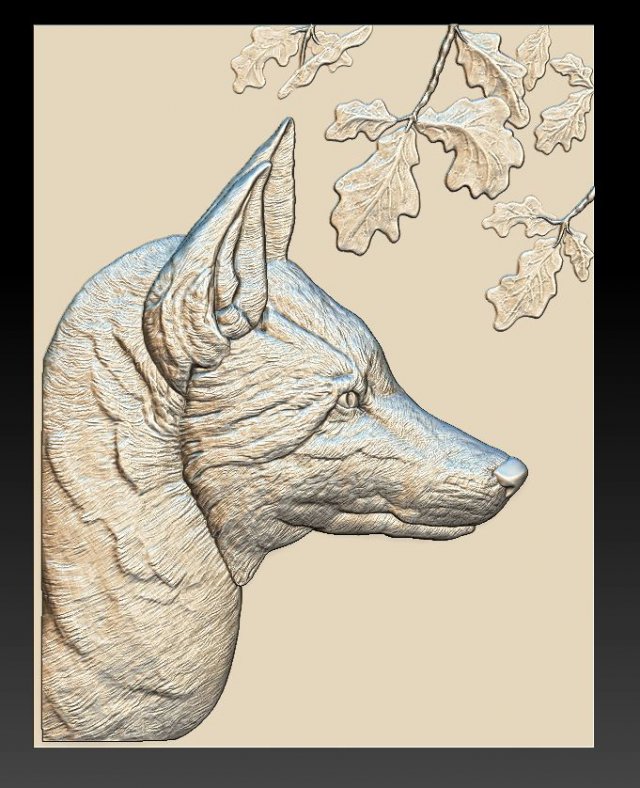

A high-quality prototype created on an industrial SLA printer at the TWIZE Prototyping Center © TWIZE

6. Cost reduction

If you need to make something on a 3D printer, there are two options: either buy equipment and print the parts yourself, or order printing and receive finished products. Using a 3D printing service can save you money.

When a business is considering launching its own additive manufacturing, outsourcing through a service provider first makes sense. This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment.

This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment.

There are other scenarios as well. Some businesses can save money in the prototyping phase by having them 3D printed before putting the final version into production through another process such as injection molding.

However, outsourcing a project can save a lot of money until a “tipping point” is reached, at which point the cost of acquiring the equipment becomes a worthy investment.

Considering starting a 3D services business?

We share our experience in the article 3D printing as a business: the most profitable concepts of the RP Center

We will consult and select ready-made solutions. Contact us!

7.

Save time

Save time When ordering 3D printing from a service provider, you don't have to worry about printer setup and maintenance. In fact, you make a payment and get the parts you need. Everything is done on a turnkey basis, and you don't have to think about all the additional costs associated with setting up, maintaining and operating the equipment.

3D printing of some parts may require time that you do not have © Leo Gregurić via All3DP

And even if you have printers, they may not be enough to print a large number of products in a short time. Since prototyping centers usually have a large stock of equipment, large batches can be produced very quickly.

Of course, the order may take a long time, so choose the service wisely. But the turnaround time for an order (printing from standard media with standard post-processing) may well be shorter than the total time it takes to set up, maintain, and operate the related equipment. For many, this alone is enough to apply for a service to a contractor.

In addition, the production of an object on a 3D printer takes hours or days - this requires control, which not everyone can do.

8. Scalability

Since the advent of 3D printing, it has been described in the mainstream media as a slow process. What is usually meant is that additive manufacturing cannot compete with traditional methods such as injection molding when it comes to high volume production.

There is some truth in this, but it is important to understand that 3D printing is a very effective process in certain circumstances. When you need to produce large batches of the same parts, this is not the best option, but 3D printers are more than capable of producing in small and medium volumes.

This is especially beneficial when we are dealing with individual designs or iterations, that is, when classical methods involve much more time and money.

For this reason, 3D printing services in particular can provide scalable manufacturing solutions that meet the needs of even medium volume production. Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

3D service providers can deliver scalable solutions © BMW Group

9. Expert advice and assistance

As already mentioned, 3D printing services are available to a large number of different customers. These can be both individuals who want to print a cartoon character figurine on a 3D printer, and world-famous corporations seeking to optimize their workflows. In any case, consultation is an important factor that can help close the deal.

The additive manufacturing experts at the 3D Services Center can help customers determine the right course of action before launching a project. Working with the client on the specific needs of his project, he is explained the available options.

Identifying the exact applications for 3D printing as well as discussing technical issues and specifics (such as what material is best for the purpose) are all part of the consulting service.