3D printer pizza nasa

NASA Funds 3D Pizza Printer

NASA is funding the development of a prototype 3D food printer that can create meals, such as 3D-printed pizza, for astronauts on long-duration space missions. (Image credit: Afonso Lima | Stock.XCHNG)NASA has doled out a research grant to develop a prototype 3D printer for food, so astronauts may one day enjoy 3D-printed pizza on Mars.

Anjan Contractor, a senior mechanical engineer at Systems and Materials Research Corporation (SMRC), based in Austin, Texas, received a $125,000 grant from the space agency to build a prototype of his food synthesizer, as was first reported by Quartz.

NASA hopes the technology may one day be used to feed astronauts on longer space missions, such as the roughly 520 days required for a manned flight to Mars. Manned missions to destinations deeper in the solar system would require food that can last an even longer amount of time.

"Long distance space travel requires 15-plus years of shelf life," Contractor told Quartz. "The way we are working on it is, all the carbs, proteins and macro and micro nutrients are in powder form. We take moisture out, and in that form it will last maybe 30 years."

Dividing the various components of food in powder cartridges would theoretically enable users to mix them together, like the ingredients in normal recipes, to create a diverse array of nutritious meals.

To prove his idea works, Contractor printed chocolate. Now, he's aiming to build a more advanced prototype to print a pizza, according to Quartz.

The system will start by "printing" a sheet of dough, followed by a layer of tomato "sauce," which will consist of the powder mixed with water and oil. Instead of traditional toppings, the 3D-printed pizza will be finished off with a layer of protein, which can be derived from animals, milk or plants, Contractor told Quartz.

While NASA sees applications for 3D printers on future manned space missions, Contractor said his food synthesizer could also be an effective way of addressing the problem of food shortages from rapid population growth.

"I think, and many economists think, that current food systems can't supply 12 billion people sufficiently," Contractor told Quartz. "So we eventually have to change our perception of what we see as food."

Follow Denise Chow on Twitter @denisechow. Follow us @Spacedotcom, Facebook or Google+. Originally published on SPACE.com.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: [email protected].

Denise Chow is a former Space.com staff writer who then worked as assistant managing editor at Live Science before moving to NBC News as a science reporter, where she focuses on general science and climate change. She spent two years with Space.com, writing about rocket launches and covering NASA's final three space shuttle missions, before joining the Live Science team in 2013. A Canadian transplant, Denise has a bachelor's degree from the University of Toronto, and a master's degree in journalism from New York University. At NBC News, Denise covers general science and climate change.

At NBC News, Denise covers general science and climate change.

NASA astronauts may soon be able to 3D-print pizzas in space

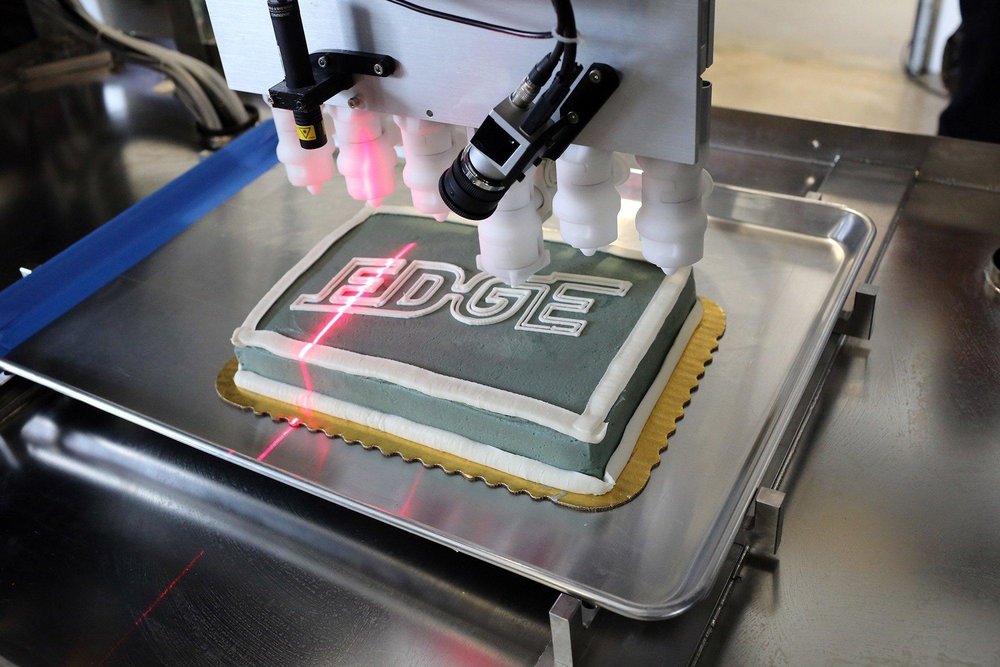

(Image: BeeHex)NASA astronauts may soon be able to 3D-print pizzas in space, thanks to technology built by Columbus and Silicon Valley-based startup BeeHex.

BeeHex's flagship Chef 3D robot -- which can print 12-inch pizzas in less than five minutes -- could mean that space travellers will have a more terrestrial alternative to freeze-dried, prepackaged meals that are designed for nutrition and ease of consumption in microgravity.

Featured

- Apple's M2 MacBook Air: ZDNET Product of the Year

- ZDNET editors loved these tech products and gadgets in 2022

- The drone wranglers: How the most authentic Old West town in the US is delivering the future of flight

- Change this one iPhone setting now to stop thieves in their tracks

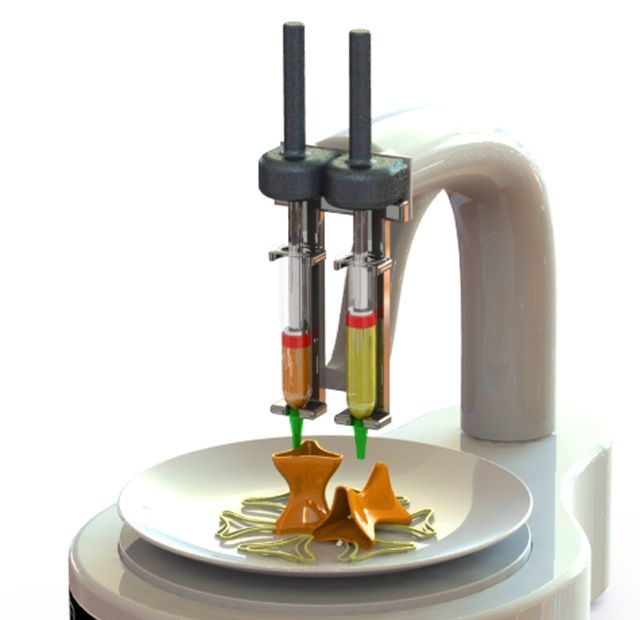

In addition to producing a range of toppings from fresh ingredients, Chef 3D can fabricate gluten-free and custom-shaped pizzas, according to BeeHex. Like other 3D printers, Chef 3D connects to a computer that tells it which dough, sauce, and cheese to use.

Like other 3D printers, Chef 3D connects to a computer that tells it which dough, sauce, and cheese to use.

The cartridges are filled with all the necessary ingredients, and the robot's nozzle starts layering liquefied dough, followed by sauce, toppings, and melted cheese.

The reason pizza was chosen as one of the first foods to be 3D-printed is because it involves layering ingredients, which suits the capabilities of the technology, BeeHex said. Unlike traditional additive manufacturing technologies, Chef 3D relies on pneumatic systems to move ingredients around.

While BeeHex was born out of a NASA project -- NASA provided a $125,000 grant to Systems and Materials Research Consultancy to research how 3D printing could be used to make food -- the startup is focusing on broader commercial applications in places like theme parks, festivals, shopping malls, and sports arenas.

It recently closed a $1 million seed funding round led by food automation specialist and Donatos Pizza founder Jim Grote to support commercial development and deployment.

BeeHex's pre-production prototypes have been exhibited at various conferences, with a soft launch slated for later in the year. The startup will be working with pilot customers in the food business to test the efficacy of the technology.

The startup's co-founders, Anjan Contractor, Chintan Kanuga, Jordan French, and Ben Feltner, as well as investors, are looking to provide printing solutions to high-volume pizza restaurants like Domino's and Pizza Hut.

BeeHex hopes that in the near future, 3D-printed meals will be ordered via an app, with customers also having the ability to customise meals according to their preferences.

While consumers are yet to fully digest the idea of 3D-printed food, there is interest among food companies to adopt the technology. In July last year, for example, London saw the arrival of a restaurant celebrating 3D printed food, furniture, and cutlery.

For three days and three special meals, pop-up restaurant Food Ink took up temporary residence in a Shoreditch side street to showcase the versatility of 3D printing.

The global market for 3D printed food is anticipated to be driven by a need for mass customisation, as 3D printing saves time, labour, and waste.

NASA Funds 3D Food Printer ?

- Food

- Technologies

- Cosmos

- CANCEL

NASA's ANJAN Contractor engineer (Anjan Contractor) print" food, reports Quartz. nine0019

The printer will prepare food from ingredients stored in powder form in replaceable cartridges. By mixing the components in different proportions and adding water or oil, you can get different dishes. The shelf life of a refilled cartridge is up to thirty years.

The shelf life of a refilled cartridge is up to thirty years.

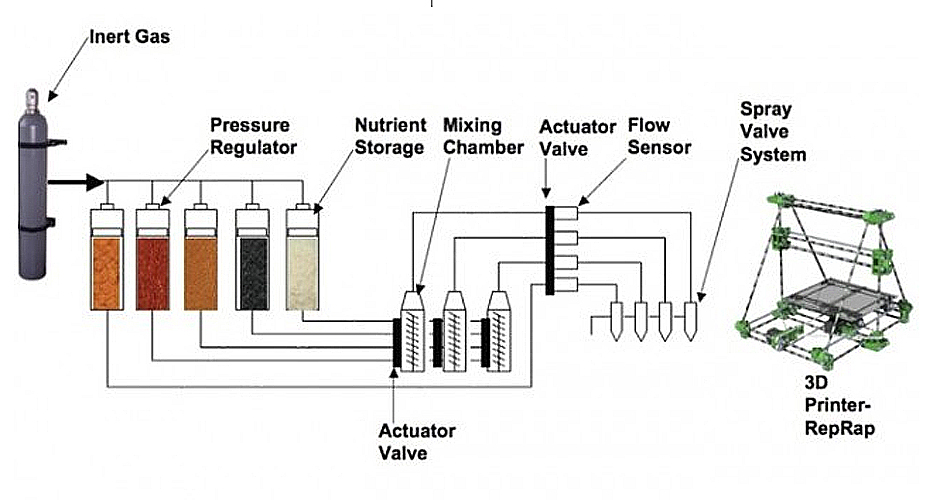

The company's grant application states its intention to use "advanced inkjet printing technologies" to create a "complete power system for long-range missions beyond Earth orbit." The device will mix nutrients such as starch, protein and fats, form a three-dimensional structure of the product and add flavors to the dishes. According to NASA experts, the use of the printer will help in solving the nutritional problems of astronauts during multi-month space flights, for example, to Mars. nine0019

“Ingredients stored as powders will be contained in dry, sterile containers and fed directly to the printer. In the print head, these elements will be combined with water or oil in predetermined ratios to minimize waste and product spoilage,” the application says. The ability to quickly prepare different dishes will make it possible to diversify the menu of astronauts, taking into account their diet, preferences and dietary restrictions due to illness.

The first product that NASA's funded printer can "print" is pizza. This dish was chosen for its simplicity of structure and ingredients, making it easy to create in layers. nine0019

The printer will use open source software. This will allow enthusiasts to improve the device, as well as to exchange recipes for "printed" dishes.

Cornell University 3D printer prints all sorts of food:

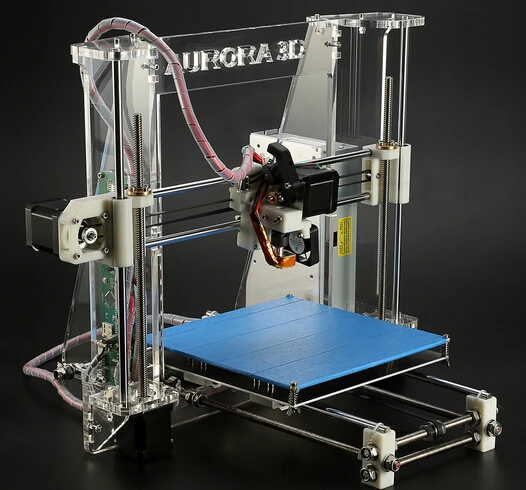

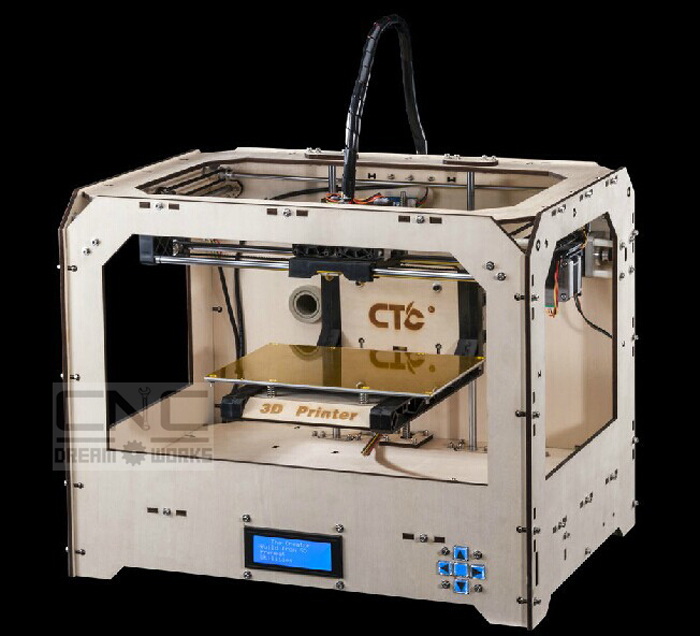

Anjan Contractor of Texas-based Systems and Materials Research Corporation received a NASA grant to build a prototype "3D food printer" for printing chocolate. The hardware of the device is based on the RepRap 3D printer, the schemes of which are distributed under the "free" GNU license. nine0019

Other researchers have suggested using 3D printing technology for cooking. So, the developers of the Fab@Home 3D printer believe that hydrogels with flavoring additives can be used as “consumables” for “printing” food.

Sources:

http://lenta.ru/news/2013/05/21/nasa/

http://www. gazeta.ru/science/2013/05/22_a_5332517.shtml 3d printing, nasa, food, perspective, technology

gazeta.ru/science/2013/05/22_a_5332517.shtml 3d printing, nasa, food, perspective, technology

Subscribe

-

Thought decoding machine. Cause for concern?

"Jack Gallant can read minds. At least he can understand what you see if you are inside his machine and watch the movie he…

-

10 predictions for the next decade from Silicon Valley futurologists in most countries of the world has long been a discipline that has found practical application. To the consultations of futurologists actively ...

-

An adorable game that will teach you how to master eye contact avoidance

Today we take it for granted. Entering an elevator in which there is already someone, a modern person almost reflexively takes out a smartphone and sticks ...

Photo

deciphering thoughts. Cause for concern?

"Jack Gallant can read minds. At least he can understand what you're seeing if you're inside his machine and watching a movie he. ..

..

10 predictions for the next decade from Silicon Valley futurologists

"Futurology in most countries of the world has long been a discipline that has found practical application. To the advice of futurologists actively ...

Today we take it for granted that when entering an elevator with someone already in it, a modern person almost reflexively takes out a smartphone and gets stuck…

NASA will fund a 3D food printer!

Archive

Subscribe to the author

Subscribe

Don't want

"I, like many economists, believe that it is not possible to feed 12 billion people today," says Anjan Contractor, senior mechanical engineer at Systems and Materials Research Corporation (SMRC) in Austin, Texas. "Thus, we must change our perception of what we see and used to call food." The contractor's company, Systems & Materials Research Corporation (SMRC), recently received $125,000 NASA grant - NASA Small Business Innovation Research (SBIR) program - to further develop a full-featured 3D printer to print nutritious food products for astronauts on long-duration space missions. Over the years, SMRC has been involved in a wide range of projects to develop innovative photo and 3D printing technologies, food 3D printing is one of their cutting-edge developments. The company recently demonstrated its achievements in this industry on a laboratory scale. Anjan, a licensed professional engineer and Six-Sigma Green Belt with 13 years of experience in research, prototyping and design, sees the future of 3D printers and people creating culinary delights from common powdered ingredients in every kitchen. Soon, he believes, everyone will be eating "foods with individualized nutritional composition, and the process of preparing them will require only the use of a printer with the right cartridge of powder and oil, which will be available at the nearest grocery store." If the cartridge runs out, it will need to be returned to the store. Since the cartridges will only contain powder, any ingredients containing the correct organic molecules can be included in its composition.

Over the years, SMRC has been involved in a wide range of projects to develop innovative photo and 3D printing technologies, food 3D printing is one of their cutting-edge developments. The company recently demonstrated its achievements in this industry on a laboratory scale. Anjan, a licensed professional engineer and Six-Sigma Green Belt with 13 years of experience in research, prototyping and design, sees the future of 3D printers and people creating culinary delights from common powdered ingredients in every kitchen. Soon, he believes, everyone will be eating "foods with individualized nutritional composition, and the process of preparing them will require only the use of a printer with the right cartridge of powder and oil, which will be available at the nearest grocery store." If the cartridge runs out, it will need to be returned to the store. Since the cartridges will only contain powder, any ingredients containing the correct organic molecules can be included in its composition. This system will bring an end to food waste, as the powder in Anjan's device will have the ability to retain its beneficial properties for 30 years. nine0047 NASA Grant was awarded to a Contractor to develop a food printing system for astronauts on long-duration space missions such as Mars. "Long-distance space missions require products with a shelf life of more than 15 years," says Anjan. "Our job is to create carbohydrates, proteins, micro and macro elements in the form of a powder. We extract moisture from products, after which their shelf life reaches 30 years." And yet, which dish is best for 3D printing? - Pizza! "Because each layer of the product can be printed separately, therefore the print head can work with one ingredient at a time." Work on the pizza printer is scheduled to begin within the next two weeks. The basis of the pizza printer was a device for printing chocolate, the project of which from the developer RepRap Mendel is in the public domain.

This system will bring an end to food waste, as the powder in Anjan's device will have the ability to retain its beneficial properties for 30 years. nine0047 NASA Grant was awarded to a Contractor to develop a food printing system for astronauts on long-duration space missions such as Mars. "Long-distance space missions require products with a shelf life of more than 15 years," says Anjan. "Our job is to create carbohydrates, proteins, micro and macro elements in the form of a powder. We extract moisture from products, after which their shelf life reaches 30 years." And yet, which dish is best for 3D printing? - Pizza! "Because each layer of the product can be printed separately, therefore the print head can work with one ingredient at a time." Work on the pizza printer is scheduled to begin within the next two weeks. The basis of the pizza printer was a device for printing chocolate, the project of which from the developer RepRap Mendel is in the public domain. The main principle of its work is the printing of dough, which at the same time is baked on a heated plate at the bottom of the printer. Then a "tomato layer" is printed, "which is also initially in the cartridge as a powder and then mixed with water and oil," says Anjan. Finally, the last “protein layer” is applied, the basis of which can be proteins of both animal and dairy or vegetable origin. The contractor also plans to make the design of his device public so that anyone can borrow his recipes, or find their own creative use for the device. The ultimate goal of the project is to turn the system for printing products into a device that anyone can license and use as the basis of a new business. Undoubtedly 3D printed food is a very interesting idea. If the project is successful, then such 3D printers will not only provide food for astronauts during long missions, but will also become an indispensable item in the kitchen. Developing, technology can take root both in space and on earth, where people will need food.

The main principle of its work is the printing of dough, which at the same time is baked on a heated plate at the bottom of the printer. Then a "tomato layer" is printed, "which is also initially in the cartridge as a powder and then mixed with water and oil," says Anjan. Finally, the last “protein layer” is applied, the basis of which can be proteins of both animal and dairy or vegetable origin. The contractor also plans to make the design of his device public so that anyone can borrow his recipes, or find their own creative use for the device. The ultimate goal of the project is to turn the system for printing products into a device that anyone can license and use as the basis of a new business. Undoubtedly 3D printed food is a very interesting idea. If the project is successful, then such 3D printers will not only provide food for astronauts during long missions, but will also become an indispensable item in the kitchen. Developing, technology can take root both in space and on earth, where people will need food.