3D printer kickstarter formlabs

Formlabs: From Kickstarter to Launch

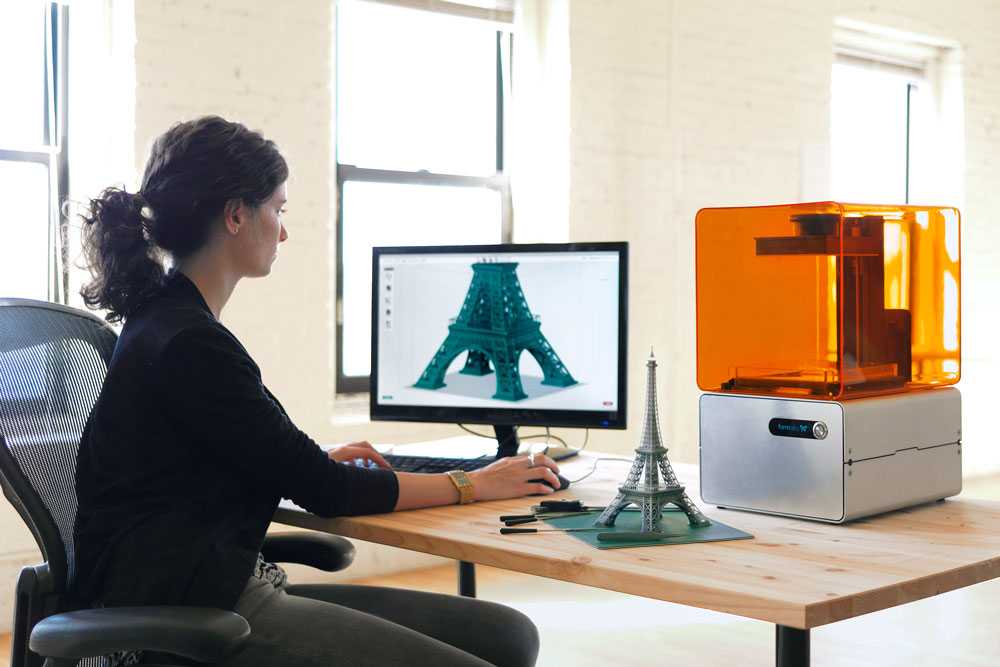

Innovation is just as likely to be found in the garage as in the boardroom. Individual inventors can bring new ideas to the table that big companies might have overlooked, or never even considered. Crowd-funding site Kickstarter is a godsend for inventors and small businesses to find startup capital to bring their ideas to life. Formlabs is a great example of a successful Kickstarter campaign leading to a rapidly growing business.

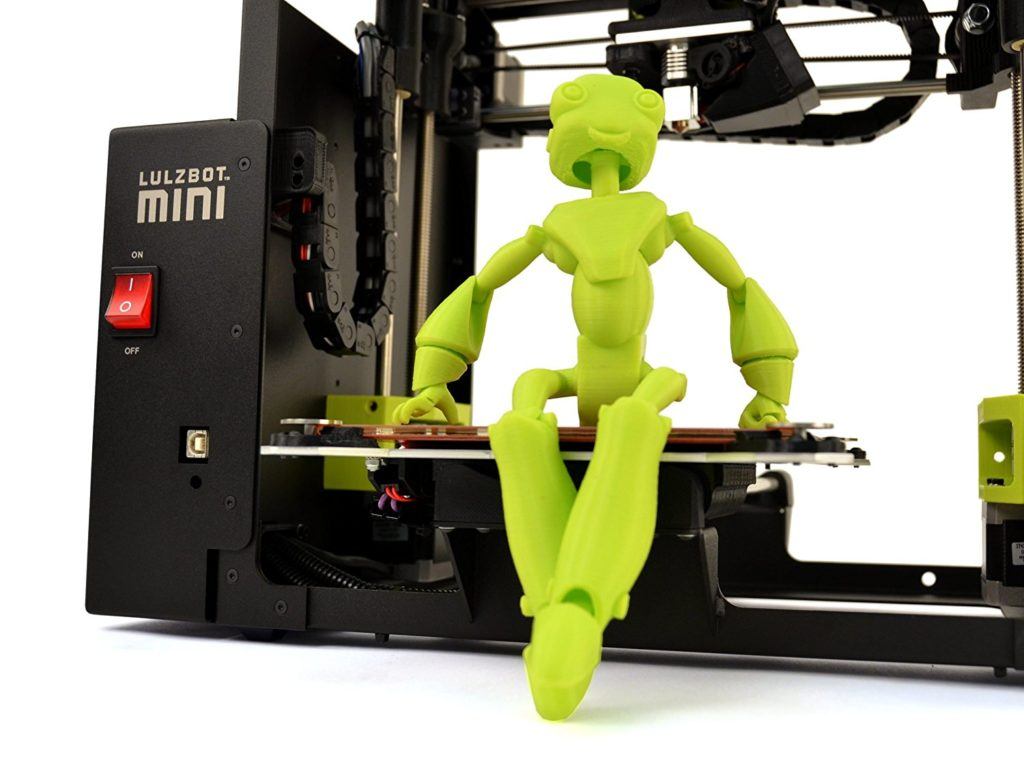

Rapid Ready initially covered Formlabs and its FORM 1 Kickstarter project all the way back here. Unlike many additive manufacturing (AM) systems found on Kickstarter, the FORM 1 offered something new; stereolithography printing in a desktop package. Tech junkies that follow Kickstarter developments were apparently as interested as we were, and Formlabs destroyed their $100,000 goal with a total of nearly $3 million pledged.

Now, a little over a year later, Formlabs has fulfilled its Kickstarter agreements, shipping out more than 1,000 3D printers to customers in over 30 countries. While fulfilling its promises might seem routine for most businesses, a number of Kickstarter ventures have run into trouble once manufacturing begins. That the FORM 1 has gone out, and in such numbers, is a testament to the organizational abilities of the crew at Formlabs, and speaks volumes about the company’s future potential.

“This is the end of a phase,” said Formlabs cofounder, Maxim Lobovsky. “We’re thankful for the incredible opportunity that our Kickstarter backers gave us, and with the amazing team we’ve built, we’re looking forward to continue to develop great tools.”

“The Kickstarter community is our rock,” added Natan Linder, another Formlabs cofounder. “They gave us our start, and we’re going to continue to support them. It’s great to be at this stage now, and we’ll be expanding our team to keep doing what they set us out to do. We’re building machines to change the world.”

Kickstarter hasn’t been the only source of investment capital for Formlabs. Earlier this year, the company announced it had received additional investment funding worth $19 million. Among those interested in backing a desktop stereolithography machine were DFJ Growth, Pitango Venture Capital, Innovation Endeavors, and a number of returning angel investors. Along with continuing research and development, Formlabs is using the investment to move operations to an 11,000 sq.-ft. facility in Somerville, MA.

Among those interested in backing a desktop stereolithography machine were DFJ Growth, Pitango Venture Capital, Innovation Endeavors, and a number of returning angel investors. Along with continuing research and development, Formlabs is using the investment to move operations to an 11,000 sq.-ft. facility in Somerville, MA.

If all that success seems a little too easy, Formlabs has had its setbacks as well. Not long after the Kickstarter fund raiser proved a success, 3D Systems launched a lawsuit against the fledgling company, charging Formlabs with patent violations.

“3D Systems invented and pioneered the 3D printing technology of stereolithography and has many active patents covering various aspects of the stereolithography process,” said Andrew Johnson, general counsel for 3D Systems. “Although Formlabs has publicly stated that certain patents have expired, 3D Systems believes the Form 1 3D printer infringes at least one of our patents, and we intend to enforce our patent rights. ”

”

So far the case has gone nowhere, with Formlabs and 3D Systems embroiled in settlement talks. Even with that particular stumbling block in play, Formlabs can’t be called anything but an enormous success.

Below you’ll find the introductory video for the FORM 1.

Sources: GlobeNewswire, Formlabs

Are 3D Printer Kickstarters Changing Into Something New? « Fabbaloo

The future of crowdfunding may have just changed [Source: Creality]Crowdfunding ventures for 3D printers seem to have transformed significantly in the past few years.

The idea of crowdfunding was pioneered online for tech products by Indiegogo and Kickstarter, both of which still thrive in providing a platform for entrepreneurs to gain support for their emerging products. Or at least, that’s how the story is supposed to go.

Theoretically entrepreneurs would present their product concept and solicit funding to take the project to the next level. Crowdfunding backers would take a risk on the venture, just as typical angel investors might in the traditional manner. Backers would often receive a preliminary version of the product, usually at a bit of discount over the intended retail price.

Crowdfunding backers would take a risk on the venture, just as typical angel investors might in the traditional manner. Backers would often receive a preliminary version of the product, usually at a bit of discount over the intended retail price.

3D Print Kickstarters

In the Cambrian Explosion of desktop 3D printing that occurred right after the original 3D printing patents expired, some entrepreneurs leveraged crowdfunding to jumpstart their projects. Some were extraordinarily successful, such as Formlabs, which began with a simple Kickstarter project, and now is among the most powerful companies in the space.

However, they were the exception. Many, many 3D print crowdfunding ventures failed. While early ventures such as Formlabs were able to capitalize by being one of the few 3D print companies one could support, later entries faced massive competition from essentially undifferentiated offerings.

The competition was ruthless. Ventures not offering innovation were ignored. Ventures with inexperienced management inevitably failed when parts supplies ran out.

Ventures with inexperienced management inevitably failed when parts supplies ran out.

And yes, there were outright cases of fraud, where the world was promised, but only empty wallets resulted.

Perhaps the wildest case I’ve encountered was the Peachy Printer story, which involved poor management, fraud, police, a million dollars, undercover videos and much more. If you haven’t read about that incident, please do so.

In recent years the number of 3D printer crowdfunding ventures has slowed. For a while there were a few projects misguidedly intending on repeating the success of the early projects. But those days were long gone, and the bar for success had been raised far above what could be accomplished in a personal workshop. Some ventures even received ZERO funding.

Creality’s Kickstarter

There’s been a bit of a break since then, but recently I’ve seen some crowdfunding launches that seem a bit different. One in particular caught my eye: Creality’s recent launch of their new CR6-SE desktop 3D printer. This is a device that has received very good reviews since its launch.

This is a device that has received very good reviews since its launch.

The launch was incredibly successful: Creality obtained more than 10,000 backers and raised US$4.4M, one of the largest 3D print Kickstarter projects in history, even larger than Formlabs’ original project.

The difference is that Creality was no startup company. Creality has been around for six years, and can now produce 800,000 units per year. They have exported 3D printers from China to over 100 countries.

In 2020, they are a well-established player in 3D printing.

What are they doing in a Kickstarter?

It seems that for them it’s an excellent platform for launch products, regardless if they have completed development of the device. This is quite unlike “traditional” Kickstarter projects, where the outcome of the project is uncertain. Rather than backing a project you believe in and want to support, here you are simply selecting a product from a well-known provider using a different ordering platform.

I believe one key reason for this move was that Asian companies seem to have a hard time breaking into the Western market. I’m not sure why; it might be a language or cultural thing, or even a timezone effect. Some of the Asian companies are too small to afford to establish a regional office in the USA and/or Europe, for example, and thus their “reach” is limited.

But Kickstarter is one language everyone understands, and Creality has demonstrated this is indeed the case. Their product appeared on the platform alongside products from many regions, and often it doesn’t even matter where a product originated.

I suspect we’ll see more of this form of crowdfunding in the future, particularly from Asian manufacturers or others having trouble breaking through into the Western market. That’s a good thing, because more choice of machines means more competition and innovation in the long run.

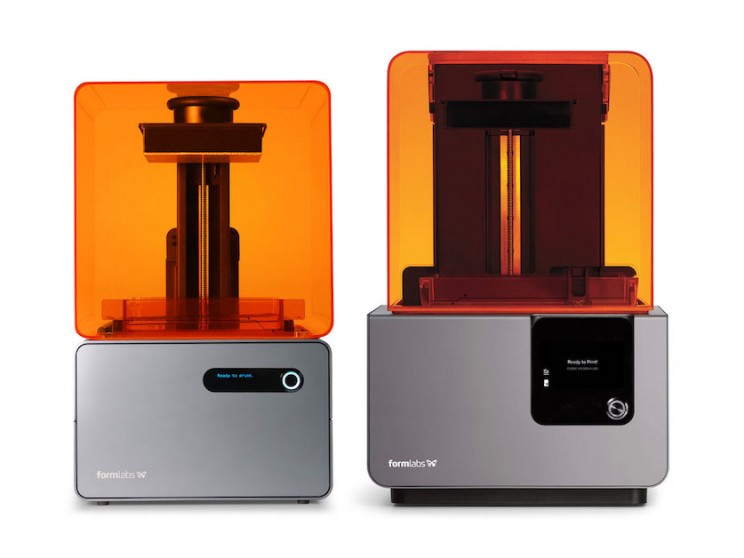

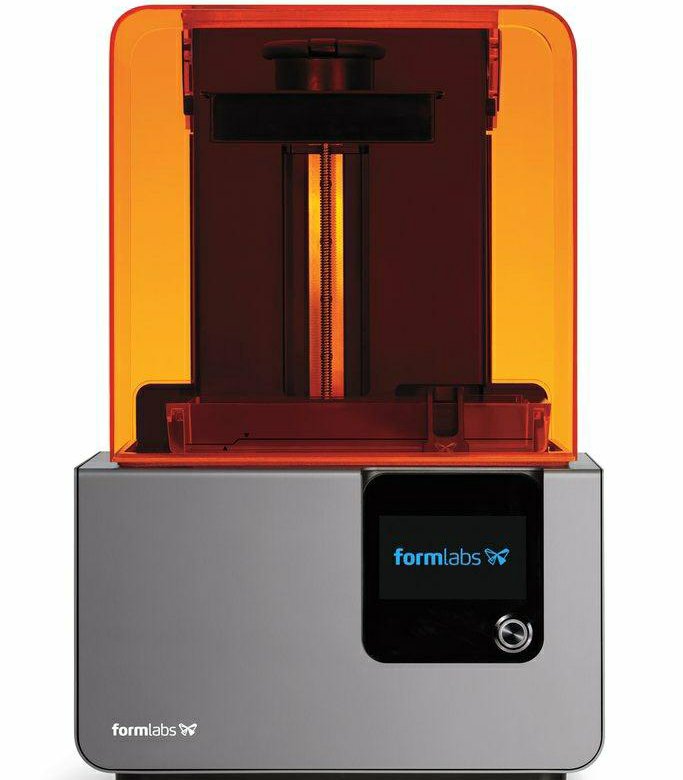

Review of Formlabs Form 3 photopolymer 3D printer. Formlabs 2 VS Formlabs 3

Hello, Friends! 3DTool is with you!

Formlabs is one of the world's leading manufacturing companies in the field of additive manufacturing. The Form 3D Printers became famous back in 2011, when a young team of developers started their journey in the laboratory of the Massachusetts Institute of Technology. However, a serious approach became visible already from the first attempts, since the technical task was to create the most automated device that does not require the user to have special skills in working with 3D printers and its settings. We must pay tribute to the team, they coped with the task « to excellent "and after a successful campaign at the" Kickstarter "the first 3D printer from the manufacturer FormLabs - Form 1 was presented to the public. Of course, the printer had certain childhood diseases and rough edges, but the precedent set in SLA technology certainly stirred up the market. In today's review, we got a representative of the third version of this equipment - Formlabs Form 3 . Let's take a closer look at what Form 3 is, where and how it can be used, and what are the advantages over analogues on the market SLA 3D printers.

The Form 3D Printers became famous back in 2011, when a young team of developers started their journey in the laboratory of the Massachusetts Institute of Technology. However, a serious approach became visible already from the first attempts, since the technical task was to create the most automated device that does not require the user to have special skills in working with 3D printers and its settings. We must pay tribute to the team, they coped with the task « to excellent "and after a successful campaign at the" Kickstarter "the first 3D printer from the manufacturer FormLabs - Form 1 was presented to the public. Of course, the printer had certain childhood diseases and rough edges, but the precedent set in SLA technology certainly stirred up the market. In today's review, we got a representative of the third version of this equipment - Formlabs Form 3 . Let's take a closer look at what Form 3 is, where and how it can be used, and what are the advantages over analogues on the market SLA 3D printers.

1. What is Formlabs Form 3?

Form 3 photopolymer 3D printer with a rich history of predecessors, a competent approach to development and one of the best, if not the best in its class. Thousands of previous Formlabs models have worked successfully in every industry imaginable and have performed well. Form 3 first of all, it is powerful and easy to use, highly automated SLA (LFS) 3D printer . By using proprietary FormLabs cartridges with different properties, the risk of printing errors is minimized. Everything is thought out for the user.

So, what is Form 3 ?

Form 3 is a professional-grade desktop stereolithographic 3D printer for adequate money. This is a great and thoughtful design, convenient and smart software. As well as a real ecosystem FormLabs includes: Form 3 3D printer, Pre-Form software, photopolymers of various properties and types, Form Wash and Form Cure post-processing systems, as well as a powerful user community. FormLabs Form 3 is an automated working solution for SLA (LDS) 3D printing of out of the box, requiring no special knowledge from the user. Follow the instructions on the screen and everything will work by itself. Working with various photopolymer 3D printers , our 3Dtool engineers said unanimously: this 3D printer - Iphone, among the variety of models SLA / DLP 3D printers . Those. everything is also convenient and thoughtful, reliable as in products from Apple .

FormLabs Form 3 is an automated working solution for SLA (LDS) 3D printing of out of the box, requiring no special knowledge from the user. Follow the instructions on the screen and everything will work by itself. Working with various photopolymer 3D printers , our 3Dtool engineers said unanimously: this 3D printer - Iphone, among the variety of models SLA / DLP 3D printers . Those. everything is also convenient and thoughtful, reliable as in products from Apple .

2. FormLabs photopolymer resin overview.

Thanks to a wide range of photopolymers with different properties, Form 3 is used everywhere, where high surface quality and ease of use are required.

Starting from engineering workshops, prototyping departments, continuing with hobbyists and collectors of miniatures and wargames, and ending with medicine - dentistry and surgery. Let's start in order: nine0017

- Hobbies and prototyping.

In the basic version, the printer comes with one polymer cartridge - Standard Gray . It allows you to achieve high quality printing, while not requiring excessive post-processing. It is enough to wash the product with isopropyl alcohol from the excess of uncured photopolymer.

Photopolymer resin "Standard" comes in several colors and is considered "basic", it is used, for example, in prototyping or prototyping of any parts that do not require special properties, but with a high-quality surface of the part. This is the basic type of photopolymers Formlabs .

If necessary, you can also use a transparent version of the material. If you need to print elements with a certain light transmission. For example, a display on the body of the device, or a transparent glazing of a car model. This material is also optimized for printing master models for subsequent casting in silicone.

For example, a display on the body of the device, or a transparent glazing of a car model. This material is also optimized for printing master models for subsequent casting in silicone.

The color of the resin also affects its properties.

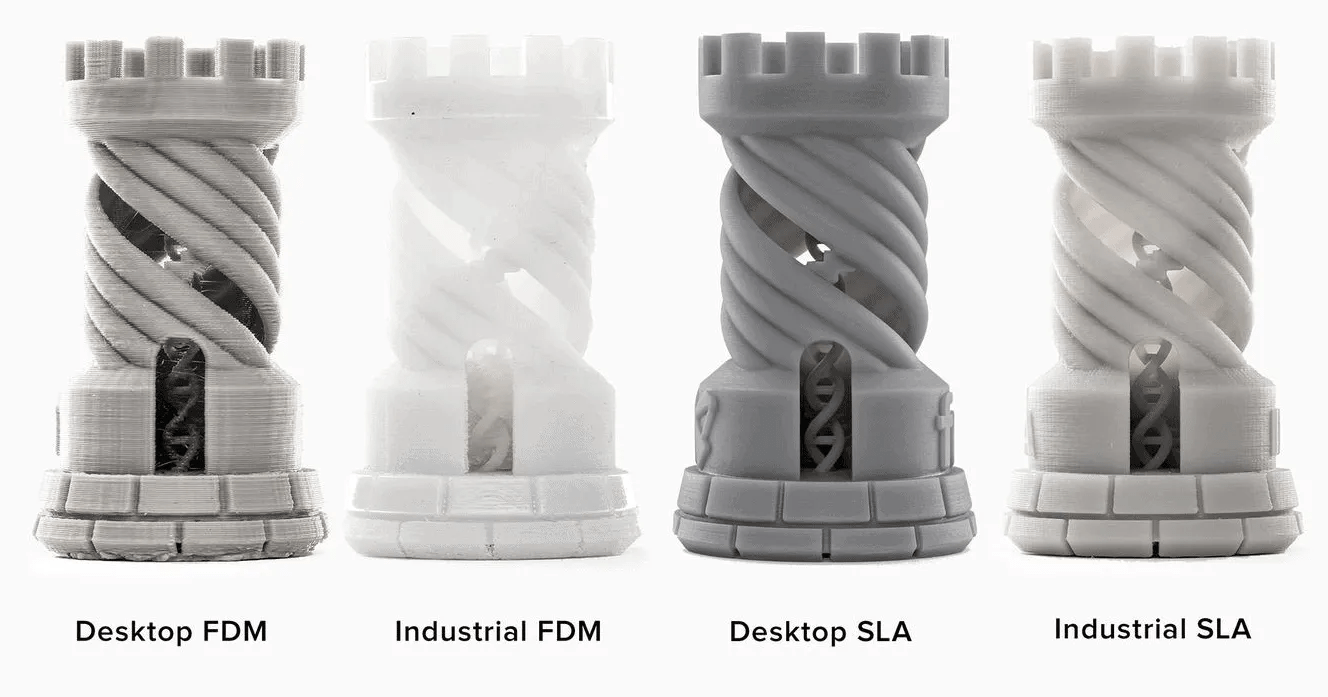

For example, Gray Standard resin is suitable for models with fine details, while White Standard resin is suitable for parts that require an extremely smooth surface. nine0017

Another material in this range is Draft Resin, which is specifically honed for really fast SLA 3D printing at 300 microns (or 0.3mm) if you need fast results in a limited amount of time.

This is followed by a line of engineering photopolymers.

- Functional samples.

Engineering materials are represented by a wide range of photopolymers with various useful mechanical and isotropic properties. First of all, these materials are used in functional prototypes, in complex products that require different physical properties from its elements and, if necessary, to make something that will be actually used and work, and not just demonstrate the concept itself. nine0017

nine0017

The first three materials are Resin Gray Pro Resin , Rigid Resin and Durable Resin . The first, as you might guess, is an improved version of the standard material and allows you to perform lightly loaded mechanisms with rubbing parts, has low shrinkage and good viscosity.

The second type of resin is Riged Resin , a high hardness reinforced composite, excellent for thin wall applications and various blades and fans.

The third type of resin - Durable Resin , resembles nylon in properties, it should be used in parts loaded with friction.

Three special materials follow - Elastic Resin , Flexible Resin and Hight Temp Resin . You can already guess from the name that the first two are Formlabs elastic resins with slightly different stiffnesses and appearance, but their main area of application is where the production of flexible products is required.

Elastic Resin is the softest 50A Shore engineering resin in the Formlabs range. It is great for prototyping models usually made from silicone. nine0005 Elastic Resin should be chosen for models that will need to bend, stretch, compress and withstand repeated cycles without breaking.

Flexible Resin is used primarily for low-deformation flexible models. With a hardness of 80A Shore and a soft touch matt black finish, this polymer is the choice for ergonomics in larger assemblies. It is ideal for cushioning and damping, wearable and consumer product prototypes, handles, grips and pads. nine0017

High Temp Resin - high temperature photopolymer resin from FormLabs, the main property of which is heat resistance up to 238 degrees Celsius. This photopolymer is also very durable and can be used in thermally stressed environments.

The most common of the engineering materials is Tough Resin, its balanced strength characteristics perfectly withstand variable loads. It is quite light but does not lose strength and can be used, for example, for a quadrocopter frame. nine0017

It is quite light but does not lose strength and can be used, for example, for a quadrocopter frame. nine0017

- Jewelry and stencils.

Formlabs offers two resin options for this application.

These are burnt out photopolymer resin and burnt out wax.

Castable Wax Resin is a 20% wax polymer that provides reliable casting with zero ash and clean burnout. It accurately renders complex elements and produces the smooth surface that stereolithographic 3D printing is known for. The printed models are durable, do not need additional illumination, and are ready for try-in and investment casting immediately after printing. nine0017

Castable Resin differs from the previous material in a new and original formula for investment casting. The burn-off curve for this resin is different from the standard wax burn-off curve. That allows you to use it when working with particularly thin elements of injection models and better optimize the process itself.

- Medicine. Surgery and dentistry.

nine0017

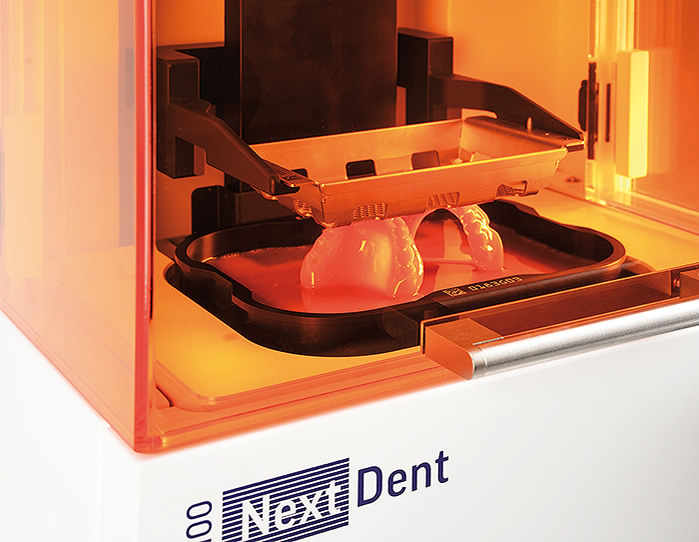

One of Formlabs' most sought-after product lines is dentistry. The company offers several types of biocompatible resins.

For example, Dental Model is a high-precision printing material for creating models of dentures and the production of transparent aligners. The main advantage of the material is a low degree of shrinkage, which allows printing products with clear edges and contacts within ± 35 µm. It is ideal for printing crown and bridge models, clear aligner models, orthodontic models, diagnostic models, dental implant models.

Another biocompatible resin used in dentistry is Dental SG. This material has high heat resistance and allows disinfection of items made from it in autoclaves. Due to its characteristics, it is used to 3D print precise surgical templates, allowing dentists to accurately position implants. nine0017

nine0017

guides and templates for drilling teeth and jaws.

Another material for dentistry is Dental LT Clear Resin. Long lasting clear biocompatible photopolymer for printing tires and nightcaps.

Also, when creating prostheses and other dental products by pressing, they use the already familiar Castable Wax Resin , which is used in the manufacture of cast caps and intraosseous parts of implants, cast crowns and crowns made by pressing and cast partial removable frames of dentures. nine0017

3. Formlabs Form3 Features, Package Contents and Appearance.

Let's start with the specs first:

-

3D printing technology : Low Force Stereolithography (LFS)

-

Material 3 Print D: Photopolymer resins

nine0068 -

Resolution XY: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250 mW laser

-

Power Requirements: 100-240VAC current, 2.

5 A, 50/60 Hz, 220 W

5 A, 50/60 Hz, 220 W - nine0004 Print volume (W x D x H): 14.5 x 14.5 x 18.5 cm

-

Layer thickness: 25 – 300 µm

-

Polymer Delivery System: Automatic

-

Layer thickness: 25 – 300 µm

-

Resin Cartridges: 1 nine0017

-

Support structures: Auto-generated

-

Working temperature: Automatic heating up to 35 °C

-

Network interfaces: Wi-Fi (2.4, 5 GHz), Ethernet (1000 Mbit), USB 2.0

-

Printer control: 5.5" interactive touch screen 1280 × 720 resolution nine0017

-

Notifications: Touch screen alerts, SMS/email via Dashboard, Dual status LEDs, Speaker for audible alerts

-

Software: PreForm Slicer

For comparison, Form 2 had a smaller working area - only 175 mm in height, and also had a less advanced material mixing system. The Form 3 also uses a completely new laser optical system to illuminate the photopolymer. nine0017

The Form 3 also uses a completely new laser optical system to illuminate the photopolymer. nine0017

The package, however, has not changed much. A standard set of various cuvettes for product processing, a huge bag of disposable gloves and the necessary tools.

And if you do not see the printer with your own eyes, you might think that it has not changed at all.

No matter how!

Form 3 differs markedly from its predecessors, which it replaced. First of all, the dimensions are striking. It is clearly larger than the old model, primarily due to the improved mixing and lighting system, but more on that later. nine0017

The control display has moved to the middle of the front panel. Removed all unnecessary buttons, now the printer is controlled exclusively from the touch panel.

Added a convenient opening handle on the protective cap and a very stylish Formlabs logo in the lower left corner.

The sides of the printer are empty, on the back wall there are well-known connectors: nine0017

Ethernet, USB, power connector and service information with printer serial number.

When you open the lid, you can see a solid ball screw, a convenient print platform bracket with branded fasteners, a modified cuvette and a mixing system that now works on two levels.

,

nine0017

4. Form 3 Key Features

What has changed in the new device in terms of the technical part?

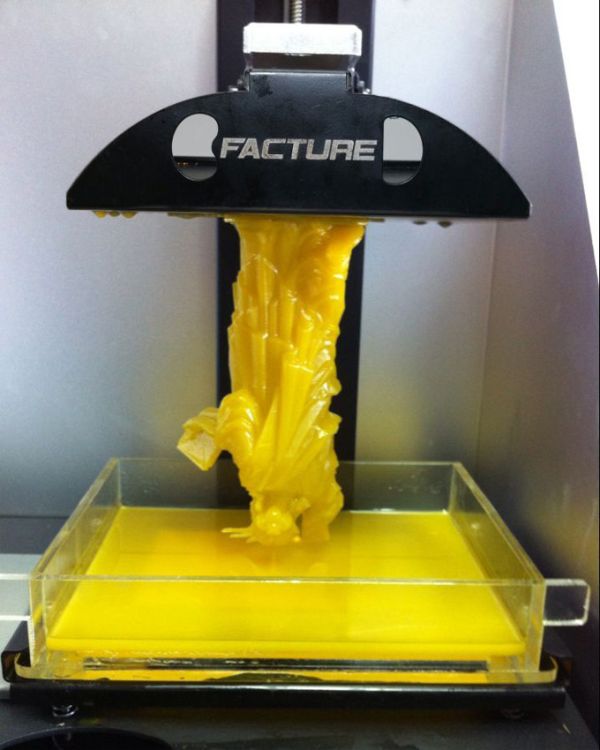

First of all, the approach to working with the material has changed. Although Form 3 is called an SLA 3D printer, in fact, the new technology is called LFS (Low Force Stereolithography)

Which uses a flexible cuvette and additional linear illumination, like on scanners, to achieve the ideal print quality and reliability. nine0017

nine0017

The laser illumination system of the device has also undergone a major change:

The use of a new more powerful laser with a high beam density, a special spatial filter and parabolic lenses made it possible to achieve, together with improved layer registration and additional surface illumination, really impressive results. nine0017

With the same layer thickness and standard parameters, the Form 3 noticeably outperforms the previous From2 model in terms of surface smoothness and line accuracy.

Also, the device has acquired several new sensors that control the 3D printing process and the flow of material into the cuvette, which greatly increased fault tolerance. However, the printer still needs to be leveled using a special menu on the display during the first start. The process itself is necessary to make sure that the liquid level in the cuvette is not skewed and there will be no overflows when printing on the model. In other words, in this way the system double-checks that the printer itself is perfectly level on your table, without skew. nine0017

In other words, in this way the system double-checks that the printer itself is perfectly level on your table, without skew. nine0017

5. Interface and software.

The functionality of the interface has not undergone major changes.

On the left side of the screen, we can switch between different settings - Main Screen, Print Queue, Printer Status and an impressive settings menu.

nine0017

In the last menu of the list, all the necessary settings are available to us. From network connection, to firmware updates and manuals for self-replacement of the LPU (additional illumination module) Yes, it is understood that the user can do it himself.

nine0017

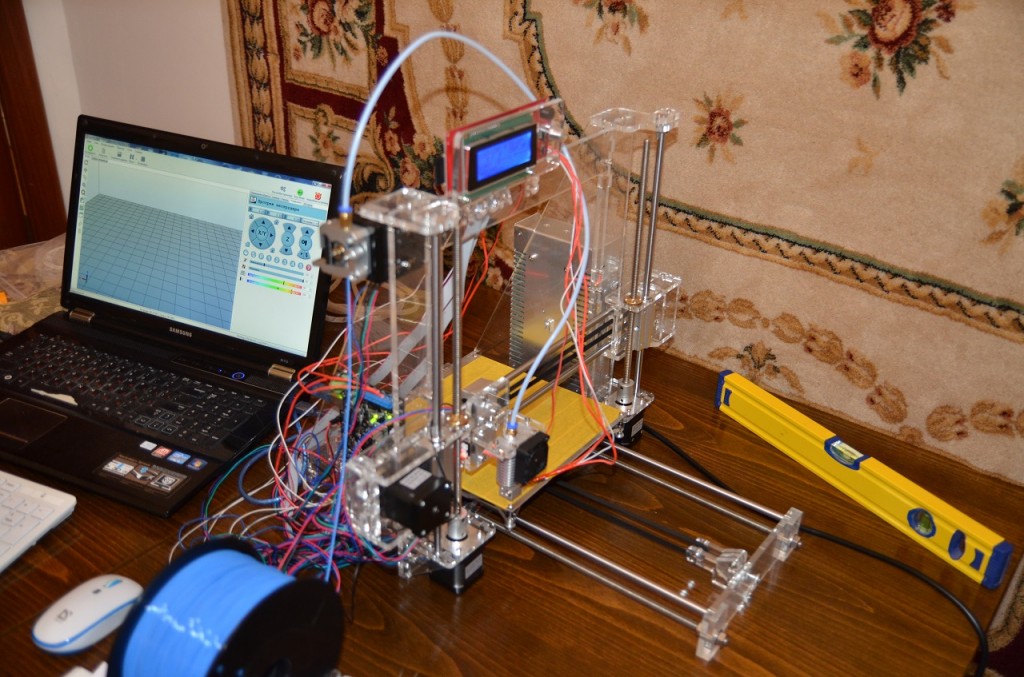

The software is a Pre-From slicer, let's connect our printer and move on to the 3D printing process. After installing the program from the manufacturer's website.

After installing the program from the manufacturer's website.

As you can see, the cartridge is already installed in the Formlabs Form 3 printer, and the printer itself is connected to the computer via a USB cable. PreForm has already automatically detected which photopolymer is installed. This is the very convenience of automating the process. You only need to load the cartridge and select the settings. nine0017

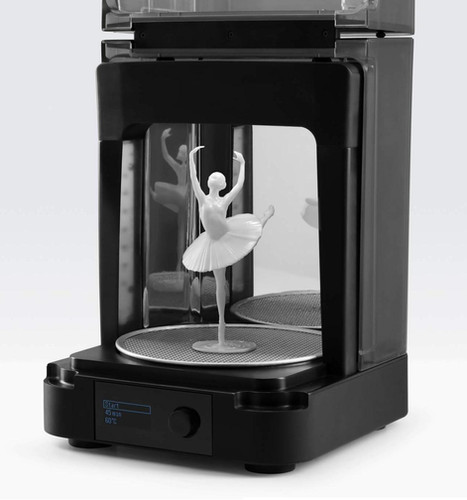

Let's load the model. We will print parts of a miniature soldier from a desktop wargame. At the same time, let's see how the printer copes with fine detail.

So let's choose a model.

Now you need to select all the parts, perform automatic repair, and then place the parts on the table. By the way, the program also does this automatically by pressing the corresponding key. nine0017

Supports are also generated automatically, but you still have full-fledged functionality for your own customization. Everything can be configured. From the thickness of the layer, to the size of the point of contact of the supporting column with the surface of the product.

Everything can be configured. From the thickness of the layer, to the size of the point of contact of the supporting column with the surface of the product.

We prepare all our files and send them for printing.

6. 3D printing process.

nine0017

After sending the model to print, PreForm will alert us to check the process on the printer screen.

Here we only need to press the print button and wait for the process to finish. Which, by the way, will take an hour and 20 minutes. Which is pretty good for a product with a 50 micron layer thickness.

Well, the result was not long in coming! The quality turned out great. Even at 50 microns, although the printer can print at 25 microns of quality, all the detail is captured perfectly. nine0017

And here is our soldier in comparison with the factory prototype. Not a big difference.

We will print a few more products to make sure the quality of the printer.

7. Result.

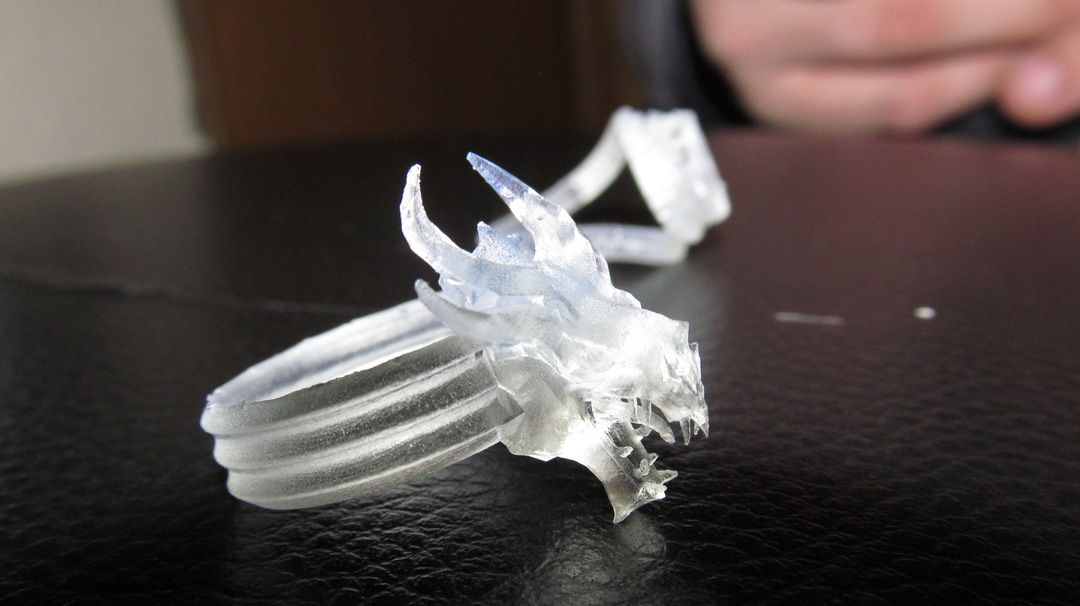

Well, the printed products speak for themselves. The ring is printed with thin walls and a 50 µm layer.

nine0017

The denture is 25 microns, its surface is just perfect.

The well-known couple baby Yoda and his friend the Mandalorian, 100 microns, so as not to spend a lot of time printing.

The result is excellent.

8. Summary.

Well, in summary, let's go over the main advantages of the model once again and determine where this 3D printer can be used with the greatest success. nine0017

With improved print control systems and multiple sensors, the Form 3 delivers the most consistent print experience, a huge improvement over the company's previous models.

The new polymer illumination system using additional illumination and a flexible cuvette makes it possible to achieve the best quality and the absence of sags and overflows on the surface of the model, and also has a positive effect when printing at high quality - 50 microns or less. nine0017

nine0017

The expanded list of photopolymer resins expands the already extensive list of applications and deepens existing examples.

At the same time, it remains affordable both in price ( compared to industrial analogues ), and in terms of ease of learning the printing process and using the printer.

The Form 3 will make a great workbench on the table of the dental technician and dentist, as well as in the jewelry shop, or even the jewelry factory, thanks to the ability to print with high-performance burnout resins with a minimum ash content. At the same time, the use of engineering materials implies the printing of functional prototypes with various functions, which will be indispensable when working in an engineering bureau, design studio, or in a prototyping department in a large-scale production. nine0017

And thanks to its ease of use and a wide range of additional accessories, Form 3 will perfectly prove itself as a teaching tool in educational centers, CMITs and departments of prototyping and additive technologies of universities.

And that's all we have! We hope the review was useful to you.

You can purchase a Formlabs Form 3 3D printer from our company by contacting us: nine0017

• By email: [email protected]

• By phone: 8 (800) 775-86-69

• Or on our website: https://3dtool.ru

Also, don't forget to subscribe to our YouTube channel :

Subscribe to our groups in social networks:

In contact with

nine0017

setup instructions, print quality and detailed description

Formlabs Form 3: The Ultimate 3D Printer That Truly 1-Click Prints

The Formlabs Form 3 is the successor to the acclaimed Form 2 and is now at the top of our list of resin 3D printers. Formlabs Form 3 defies stereotypes with groundbreaking SLA printing technologies and custom materials. nine0017

Formlabs Form 3 defies stereotypes with groundbreaking SLA printing technologies and custom materials. nine0017

Form 3 was announced in the spring of 2019, and deliveries to the first customers began in the summer.

Pros

- Extreme productivity.

- All aspects of it are worked out extremely cleverly and logically.

- The printer works on the principle of "click and forget", printing on it can be done in one click.

Cons

- Problems with dust inside the laser unit quickly start.

- Polymer consumption in cartridges is not the most economical. nine0068

- Shutdown button missing.

The printer has many sensors and processors. It also comes with software that takes the concept of 3D printing to a whole new level. The Formlabs Form 3 is the easiest to use and most reliable 3D printer we've ever used.

If you're interested in high-detail, low-volume, and even rapid prototyping, the Form 3 is for you.

History

Formlabs is based in Massachusetts and started with crowdfunding on Kickstarter. Since then, it has established a reputation as the most reputable manufacturer of desktop 3D printers capable of printing high quality products at sky-high prices.

From the very beginning, Formlabs set out to democratize SLA technology by creating an easy-to-use system that can be placed on the desktop. The first device of the brand Form 1 fully met these requirements, so the Kickstarter campaign was successful immediately after the launch. The young company took the right approach in responding to the obvious demand for low cost desktop SLA printing. Pretty quickly, Formlabs expanded into Europe and Asia and achieved unicorn status. nine0017

With the Form 2, released in 2015, the manufacturer showcased a number of innovations. The need for manual handling of polymers has been eliminated, replaced by a much cleaner automatic cartridge system. The printer has become more convenient to use and better adapted to the professional environment.

For 5 years, the Form 2 has remained the undisputed leader in its segment, and almost no one could challenge it. However, the manufacturer saw fit to delicately retire it and replace it with the hot new Form 3. 9The 0017

Form 3 was a truly radical innovation as it brought unprecedented levels of detail quality, speed and repeatability to SLA printing, and reduced the need for post-processing finished products. It uses the basic concept of SLA laser printing in a completely different way than all previous devices.

Specifications

Formlabs has developed a brand new printing system for the Form 3. It is distinguished by its Light Processing Unit (LPU) and how it is implemented in the device. nine0017

Traditional SLA resin models use a stationary laser whose beam is guided by a pair of galvanometers with moving mirrors. The Form 3 uses Low Power Stereolithography (LFS), in which the laser beam passes through a single galvanometer (print guiding y-axis), a mirror, and a parabolic mirror. Throughout this process, the laser module moves back and forth along the X axis of the print.

Throughout this process, the laser module moves back and forth along the X axis of the print.

This video shows the LPU in action. nine0017

The beam path is so wide that it guarantees that it hits the polymer perpendicular to any point on the printing plate. This provides stability to the printing process from start to finish, as well as scalability (which will be clearly seen in action on the Form 3L, which will be released later that year and will feature a dual LPU).

The LPU moves along the stepper motor driven lead screw while dampening vibration. Allegedly, these new moving elements may cause noise during the printing process, but we did not notice this. nine0017

Outstanding Automation

The machine is equipped with a variety of print control sensors that control all aspects of printing at the micro level. The Form 3 has a large color touch screen and also connects to a computer. Thus, you are constantly aware of how the material from the cartridge is being used, what is happening with the resin reservoir, how many millimeters of resin are going into this particular print, what will be the final print time, resolution and number of layers. You will also have access to the full print history, which will be displayed in Gantt chart format. The print history also contains information about the user who started the printing process, and about the specific printer (apparently, this is designed so that several devices can connect to the Formlabs network at once). nine0017

Thus, you are constantly aware of how the material from the cartridge is being used, what is happening with the resin reservoir, how many millimeters of resin are going into this particular print, what will be the final print time, resolution and number of layers. You will also have access to the full print history, which will be displayed in Gantt chart format. The print history also contains information about the user who started the printing process, and about the specific printer (apparently, this is designed so that several devices can connect to the Formlabs network at once). nine0017

Formlabs Form 3 3D Printer

- Laser spot diameter 85 µm

- Laser wavelength 405 nm

- Laser 1x250 mW

- Seal LFS

- Working chamber area 145x145x185 mm

- Materials used Photopolymer

- Layer thickness from 25 µm

- Display Touch 5.

5" 1280 × 720

5" 1280 × 720 - Interfaces WiFi;Ethernet and USB

Go to product

The LPU automatically presses the flexible film of the resin reservoir into contact with the print plate as it slides back and forth along the X axis. It also automatically fills the resin reservoir from closed resin cartridges and mixes them prior to printing.

The print space is 145 x 145 x 185 mm, which is the same size as the Form 2 (albeit with a slightly shorter Z-axis). This gives the Form 3 the added bonus of being compatible with the Form 2's platen.

Impressive performance

This printer has been designed to have as little user control as possible. The reviewer, of course, faced a paradox: how to evaluate a device that does almost everything by itself? But for an engineer or for enterprises, this alignment is the most favorable.

With the Form Wash and Form Cure stations, you can single-handedly manage the entire printing process, from preparation to post-processing of printed products. But you may not want to do this, because polymers are not the most pleasant material, and it is better not to risk spilling even a drop. However, it must be recognized that from the moment the printing plate is opened to the stage of work with the washing and curing stations, the printer really requires only minimal control from the user. nine0017

But you may not want to do this, because polymers are not the most pleasant material, and it is better not to risk spilling even a drop. However, it must be recognized that from the moment the printing plate is opened to the stage of work with the washing and curing stations, the printer really requires only minimal control from the user. nine0017

But there is a nuance

However, even Form 3 is not perfect. During the printing process, we had a little chat with Formlabs support about minor dents on the surface of the prints. We faced this problem twice.

The consultants told us that in the first case the core of the problem was the polymer tank. To fix it, it was necessary to insert a new reservoir. In the second case, large dust particles settled on the inside of the LPU window.

The dust problem is more difficult to fix. When the printer is not in use, the LPU is hidden from view and located near the base of the device. The only time we saw an LPU in a position where dust could settle on it was when we tried to mimic an LPU replacement. We made this simulation just in order to remove dust from the LPU.

We made this simulation just in order to remove dust from the LPU.

Another problem (or rather missed opportunity) is that the printer firmware can only be updated via a USB connection to a computer. Although there is a Wi-Fi connection between the printer and the computer, the firmware cannot be updated in this way. nine0017

The $3,499 device could also include a kill button.

Setup

To set up the machine, you need to enter a Wi-Fi password and create a user account. Each device is assigned a funny identifier - ours, for example, is called ImaginaryBunny - "Imaginary Bunny". This ID is used to associate the printer with the PreForm software.

You will then need to align the printer and connect it to the network. You can also connect using the Ethernet cable that comes with the kit. On the web, you must create a Formlabs account to access the web dashboard. There you can view printer status, job history, active cartridges, and resin reservoirs. nine0017

Resin cartridges are inserted into the back of the printer - you have to lift the cover to get to it. When the resin tank enters the print chamber, it makes a distinct thud. After both steps, the printer sends notifications confirming that the correct resin has been selected for the job.

When the resin tank enters the print chamber, it makes a distinct thud. After both steps, the printer sends notifications confirming that the correct resin has been selected for the job.

The platen is locked in place with a Formlabs-specific single-lever latch. After that, you should start setting up and preparing for printing through PreForm. nine0017

PreForm

The program interface is made in a combination of white, orange and blue colors. PreForm is ideal for 1-click printing.

The model can be loaded into the program, either dragged into the workspace or accessed through the file explorer. The program will position and orient the workpiece, add support structures, and then ask you through a dialog box to confirm the start of printing.

PreForm is pretty conservative with settings, offering more supports than needed and avoiding printing on the plate (sometimes saving time and material). nine0017

The PreForm consists of two areas: a workspace and a job information field. Size, Orientation, Support, and Layout options can be automated for easy 1-click printing.

Size, Orientation, Support, and Layout options can be automated for easy 1-click printing.

The inability to make large models hollow through PreForm catches the eye. This option is important to save material when using samples that will not perform any mechanical function. FormLabs recommend using Autodesk's Meshmixer, a third party software for this purpose. nine0017

Control Panel

You can manage printing not only through PreForm, but also through the control panel. This panel gives an overview of all devices available to the user, all print jobs, all aspects of printing and materials used.

FormLabs keep the user up to date on material consumption. Cartridges run out of resin quickly and reservoirs have a limited lifespan. You can order new consumables directly through the control panel. nine0017

If you use the default profiles, you only need to do one thing: choose the pre-approved layer thickness for that resin.

Standard resolution ranges from 25 to 100 microns, but may be outside this range depending on the material.

Print quality ranges from "decent" to "excellent". The quality of the finish depends on the material used. Standard V4 profile gray resin produces prints with a flawless finish. nine0017

Most surface defects are obtained by using a standard polymer which can be transparent. These flaws can be eliminated by wet grinding.

Materials

Form 3 offers little to no room for material experimentation. If you pour resin directly into the reservoir, bypassing the cartridge, you will not be able to control the laser and LPU through PreForm. To take full advantage of the device, you need to purchase only Formlabs supplies for it. nine0017

Post-processing

The Form 3 includes the basic Finish Kit post-processing tool. It features dual trays, a lid that can be operated with one hand, and a basket for storing prints and moving them between trays. The printing plate will then be separately and securely fixed on a stable stand.

Squeezable bottle with long spout included for cleaning hard to reach areas.

Form Wash and Form Cure instruments available separately. nine0017

Unlike the Finish Kit, Form Wash and Form Cure provide for automated post-processing of printed products instead of manual. The Form Wash washes the samples and the Form Cure sinters them with UV light.

Is it worth it?

Form 3 will obviously be recommended for small or medium businesses that need a "workhorse" capable of meticulous attention to detail. It is extremely easy to handle and ensures consistent production of highly detailed prints. Also, thanks to new polymers, he is able to produce large-scale rough models. nine0017

Some people think Formlabs supplies are too expensive. However, they provide outstanding reliability, which is essential in an industry where time is money.

Honestly, if we could spend the rest of our 3D printing career with a Form 3 printer and Draft resin, we'd be in seventh heaven. This printer is set up in just a few seconds, and in a few seconds you can start 1-click printing or set up a partially automated print job.