Spring 3d print

Spring best 3D printer files・Cults

RC Car Drift 1:10 Shock Absorber Spring Maker

€2

Teelicht

Free

Civic 7th gen rear shock spacer

Free

woman frame

€1

flower frame

€1

Chest Rig BB container for Airsoft

€1.43

Snowman

€2.50

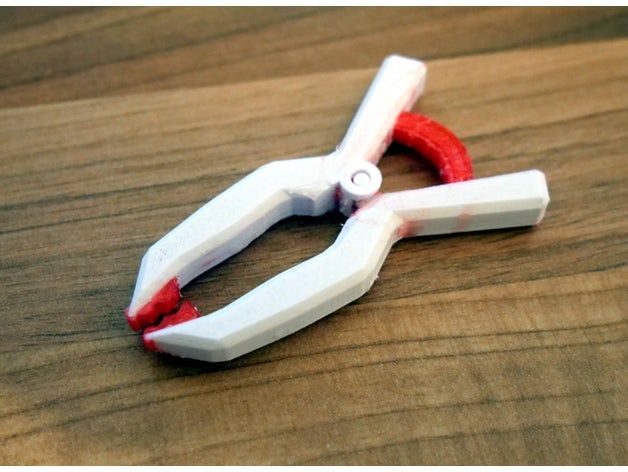

SAITEK Pedal spring cliper 3D print model

€3

Keychain Trumpet // Trompeta keychain

€0.75

Ultimaker Vibration Spring

Free

Spring Clip for Delta Printer Rods - 5 mm

Free

Spring Animation

€50

Airsoft spring grenade

€6. 25

Egil the Easter Bunny Gonk

€2.86

Mercedes Benz ML W163 Sun Roof Wind Deflector Spring Arms Clips

€4.90 -50% €2.45

Plastic Bags Holder

€3

Flower Flowers key chain key chain Pack

€0.55

Spring and Pin Set for Foam Dart Pistol

Free

Airsoft tokyo Marui Glock spring guide /pin

€0.52

Airsoft midcap spring joint

€0.52

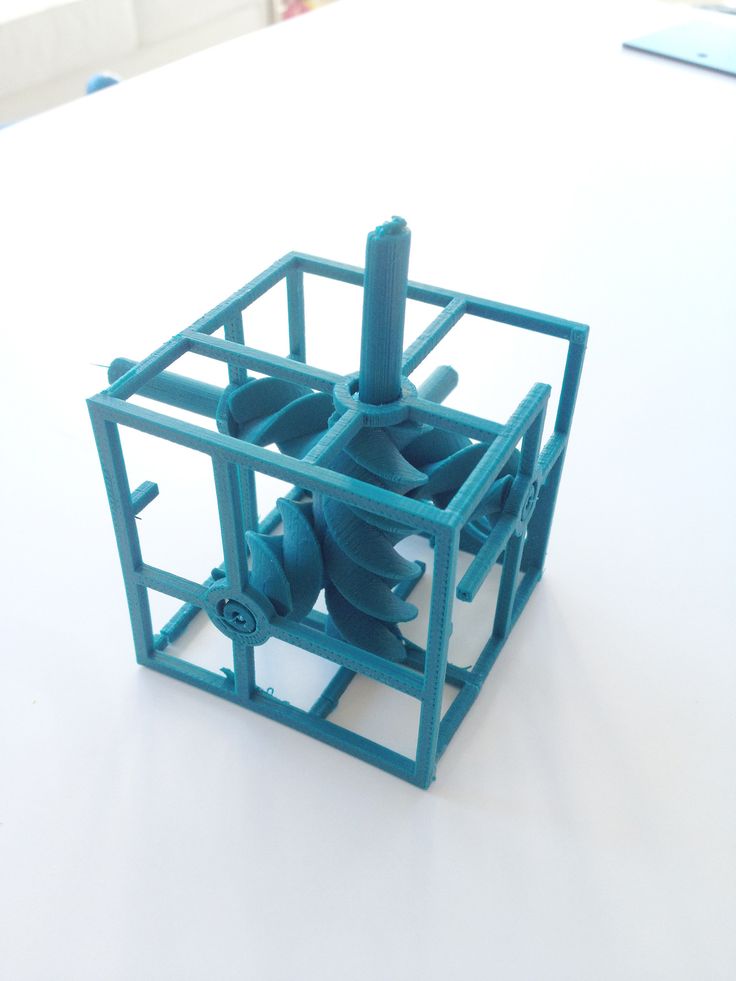

Constant-Force Mechanism for FDM

Free

Shock Absorber

€1. 70

70

Pflanzen Stecker Ostern 3er Set

€2

Spring

Free

trolley with shock absorbers

€10

Minecraft Tulips

Free

Polymer clay cutter, wide cactus 5 points.

€1.30

Pot cutter for plants, polymer clay, ceramic... Pack 2 sizes

€2

Cutter polymer clay, ceramic... flower 5 petals

€1.50

Mechanical Counter

Free

Butterfly Tag

Free

PEI sheet holder (235 mm)

Free

Flex fox

€1.50

Wobble Toy UFO!

€0. 52

52

Wobble Toy Bikini Girl

€0.52

Wobble Clown Toy

€0.52

Evil Morty Bobble Head Display(remix)

Free

Lucky Money Bag 3D print model

€2.99

spring loaded mounting bracket for 3d scanner

Free

Airsoft and airgun suppressor 1/2x28

€1

AA 18650 Battery Tray

Free

Tokyo Marui HK45 Spring Guide

Free

everest 10 spring stiffeners

Free

CYMA / Marui springer / gas shotgun midcap

Free

Jumpy Ghosty

Free

High current 18650/21700 holders with integrated spring

Free

Rock Band Guitar Strummer spring fix

Free

Helix / spring

Free

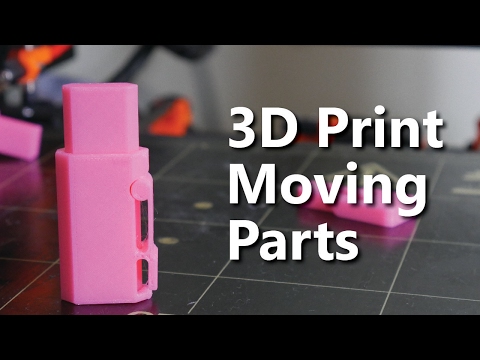

3D Printed Spring: Easy Tips To 3D Print Springs

ADVERTISEMENT

Table of Contents

Industrial springs are the most functional thing you will find across the world. Even if you give a glance at what exists in plenty, you will find many products functioning on the base of spring. You can get a ball pen, remote control, a clipboard, a chair, and even the computer keys. All of them make use of spring.

Even if you give a glance at what exists in plenty, you will find many products functioning on the base of spring. You can get a ball pen, remote control, a clipboard, a chair, and even the computer keys. All of them make use of spring.

They are the most utilitarian thing ever created by humans. So, it is natural to associate the most utilitarian thing with the current state-of-the-art technology 3D printing and know whether it’s possible to 3D print spring? If yes, what are the tips for a 3D printing spring?

That’s exactly what our article aims to take you through! And we will start with how to generally 3D print a spring – any type of spring; a compression spring, torsion spring, a spring that produces tension or squeezing effect.

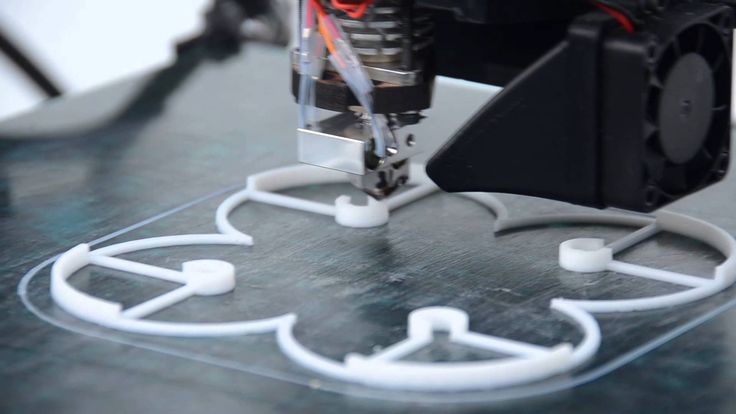

The process of 3D printing SpringOne of the benefits of 3D printing over all other traditional manufacturing processes is that this technology has a general way of creating things. So just like every other part, there are three basic steps of 3D printing spring.

ADVERTISEMENT

Creating a 3D Model of Spring

The 3D model of any part or functional prototype can be made via an online 3D model creator. CAD software is typically used for this process and there are many options available online.

You can own CAD software, use its tools, shapes, and other functions and create the exact geometry of spring that you have in your mind using the preferred software. And, you are ready to go the step number two in the process of spring 3D printing.

Alternatively, and this is because of the development of 3D printing technology and the increase in its accessibility – you can download a 3D model file of a spring that closely represents the one in your mind.

And this is possible from the online 3D printing repositories such as Thingiverse, MyMiniFactory, GrabCAD, Cults3D, or any other.

There are paid as well as free versions of a 3D model of spring available on these websites that are generated by professional 3D model designers, which are not only safe but also reliable to 3D print. Typical examples of which are mentioned below.

Typical examples of which are mentioned below.

Options of Springs Available Online for Download

These models are available on GrabCAD

Tension Spring

Available on Rendering as well as SolidWorks software this is a typical 3D model of tension spring which finds its use in many mechanical devices and industries. The 3D model of this file can be downloaded for free.

ADVERTISEMENT

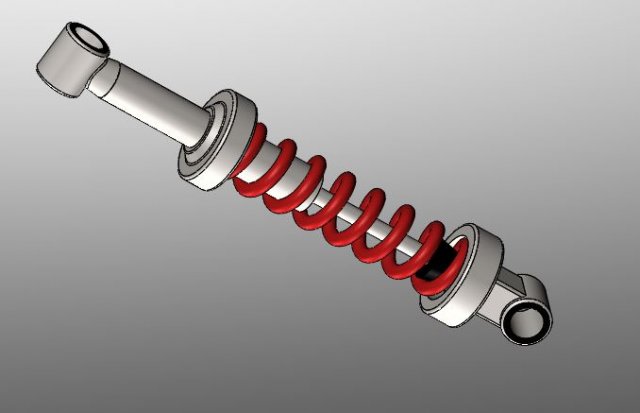

Shock Absorber

As the name itself suggests, the use of these types of springs is made in parts that are subjected to high loads.

The designer suggests such type of springs is typically used in a two-wheeler for saving the bike or scooter from the shocks its arrangement is subjected to while going above the bumps.

Shock Absorber is also available for a free download.

Leaf Spring

Generally, leaf springs are known to be used in a trailer or a caravan. This 3D model by the designer is available for software such as Solidworks and Rendering. At the time of writing the file has already been downloaded 25 times.

At the time of writing the file has already been downloaded 25 times.

Trailer Leaf Spring

Available for download on software such as Rendering, Step/IGES, and Solidworks this trailer leaf spring has the hub face to hub face length of 57.05 inches, the bolt pattern 5 on 4.5 inches, and a weight capacity of 1875 lbs.

At the time of writing, the 3D model file has already been downloaded 33 times.

So, such models are always available at your disposal that will let you be free from the efforts of making a 3D model.

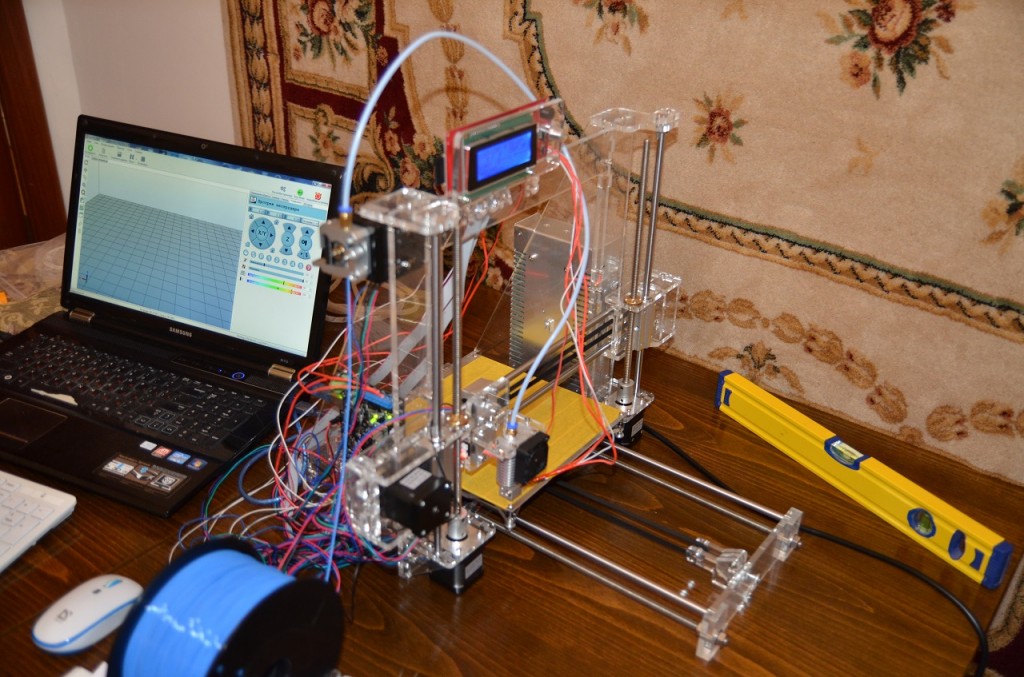

3D Printing Spring

After having a 3D model at your disposal, you have cleared the first checkpoint. The second step thereafter is slicing the 3D model.

Slicing is the process of converting the 3D model into a GCODE pattern that a 3D printer can be fed and after which it can start 3D printing actual spring.

And you can do this with slicers that are compatible with your 3D printer. If your printer is an open-source 3D printer, it will compatible with Simplify or Cura software.

And here is where you got to take care of the expert tips if you are 3D printing spring for the first time.

ADVERTISEMENT

Easy Tips for 3D Printing SpringBelow mentioned the lessons learned by experts who have tried to 3D print a spring for themselves.

Going With the Flow

This suggestion deals with the typical flow rate that you need to maintain to make sure you are not over or under extruding. The ideal extrusion flow rate is 1:1 for the amount of distance traveled.

Because, by not extruding enough material you will pull on the part, deform it and also sometimes get it too much thin or eventually break it.

On the other hand, if you are extruding too much material it will cause uncontrollable ripples, sags, or globs in case it collides with previous layers that you’ve 3D printed.

Moving Slowly and Evenly

Working with plastic is taking too much amount of time for cooling even if you are working with artificial fans. And this would also demand that you work extremely slowly with the print head in the midair so that the plastic hardens as you move forward.

And this would also demand that you work extremely slowly with the print head in the midair so that the plastic hardens as you move forward.

Many plastic materials are also known to ooze differently than others as their feed rates and temperature change. Printing the first few layers is quick but then eventually you need to move much more slowly.

ADVERTISEMENT

Bubbles are Known to Break Things

Ensure the filament that you are using should be dry and unlikely to bubble. Having stated so, the older filaments are known to have moisture trapped in the plastic that boils and comes out as it gets heated.

This would lead to uneven flow rates and weak sections. While solid part printing, small bubbles are a concern as they cause the part to fail. This is where you need to take care of the most while 3D printing springs.

Compensating for the Extruder’s Pull

Every filament is known to tugging slightly on the existing cooled strand, once it’s extruded. Near the filament’s bottom where the part is known to have enough support all of it has very little impact, but as the part grows taller the force simply displaces the strand even more.

Near the filament’s bottom where the part is known to have enough support all of it has very little impact, but as the part grows taller the force simply displaces the strand even more.

Note that fully modeling an extruder’s pull or push is very tricky in the case of under/over extrusion. So, prints that only stretch out into midair don’t need to compensate too much, but others like tall springs are known to produce accurate parts.

By following these tips, you can simply gain a result with which you’ll be satisfied. And since these are proven and tested by experts, they are completely reliable.

Also, you will reduce the chances of 3D printing spring failure and get a spring of decent quality that you can actually put into application.

ADVERTISEMENT

Post Processing

After having sliced the files, and 3D printing spring using above mentioned tips, you will have to let the printed spring cool down.

Once the spring has cooled down, you can decide whether or not to post-process it! Springs too, like other 3D printed parts can undergo a simple process of post-processing starting from sanding, to finishing.

You use regular sandpaper of normal grit to sand it. Of course, post-processing is not compulsory, it will depend on the application that you wish to use the spring for. After sanding, you can also color the springs and finally polish and finish it to get a certain kind of matte, or suede finish.

But be careful while doing the post-processing as springs are very delicate parts and messing with them is very simple. You can very easily end up ruining them while actually trying to better them.

So, always gain a bit of confidence with any of the process of post-processing that you are working on your 3D printed spring with, and only then try to apply it full-fledged.

The Conclusion

Although this all reads very easy, it’s always “easier said than done.” As mentioned above, springs are those mechanical parts that find their application almost everywhere. And 3D printing springs is a region wherein there are still not many options.

Things are still getting experimented and there is little success. But we hope, in the coming time there will be more options. And once that crack has will made, it will be a lot easier to 3D print springs.

But we hope, in the coming time there will be more options. And once that crack has will made, it will be a lot easier to 3D print springs.

At the moment prototyping of springs is where 3D printing is extremely useful, because of the accuracy it can provide. So, follow these easy tips to achieve excellent results with 3D printing springs.

Free STL file Spring・3D printing template for download・Cults

Lev

Free

David

Free

Lev

Free

Winter

Free

Angel

Free

Skull Monkey

Free

Kiss

Free

Reclining Nude

Free

Best Files for 3D Printers in the Art Category

flower Chinese bottle

Free

Mini Putt Champion Cup

Free

Face on hand

1. 99 €

99 €

Donkey Kong Barrel XL multi-component

Free

SPIDER ARMOR UPGRADE PACKAGE

5.06 €

Steampunk letter V

2.50 €

Willis Rising Simpsons fan art

7,50 €

biting chest

0.62 €

Art category bestsellers

GHOST ZU - GHOST WITH FEET

2.71 €

Astronaut on flexi printer

2.78 €

Flexi Print-in-Place Dinosaur Brachiosaurus

2.78 €

Item

7€ -25% 5. 25 €

25 €

Cute T-Rex dinosaur with flexi print

2,78 €

nine0003 Cute frog with flexi print1.83 €

Archaeopteryx nibbler

3 €

Stitch Love (easy printing without support)

1,50 €

Flexi PRINT-IN-PLACE Hand

1,83 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2,78 €

nine0003 Flexi print-in-place Phoenix3,72 €

Triceratops on flexi printer

2,78 €

Cute little fox with flexi print

2,35 €

Articulated toy "Python Snake", imprint body, snap head, cute flexi

3,72 €

Pink Dragon Valentine's Day Articulating Animal Flexi Wiggle Printing In Place Fantasy

3. 82 €

82 €

Elf on shelf in carbonite

€8.47 -fifty% 4.23 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us at maintaining the activities of and creating future developments of is very simple. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here. nine0006

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Best customer experience

Greetings, friends! Bestfilament is in touch. We are sure that each of you has heard the expression: “Something is fashionable, something is out of fashion, and something is forever.” Tik Tok, Slava Marlow and oversized fashion are the main trends of 2021, but the Lord of the Rings trilogy, Queen songs and the Chevrolet Camaro 19 sports car76 years will never go out of fashion. I would like to believe that BestObzor will also remain out of fashion and time and continue to delight us with talented and interesting projects, and you with high-quality domestic plastic.

We are sure that each of you has heard the expression: “Something is fashionable, something is out of fashion, and something is forever.” Tik Tok, Slava Marlow and oversized fashion are the main trends of 2021, but the Lord of the Rings trilogy, Queen songs and the Chevrolet Camaro 19 sports car76 years will never go out of fashion. I would like to believe that BestObzor will also remain out of fashion and time and continue to delight us with talented and interesting projects, and you with high-quality domestic plastic.

Well, let's start our tour of the fascinating world of 3D printing. The first stop will be Yaroslav Andreev's work .

And if in William Shakespeare's play poor Yorick did not give an answer to Hamlet's question "To be or not to be", then we will somewhat paraphrase the well-known monologue:

To start 3d printing or not to start, that is the question. It is worthy of

to humble yourself under the blows of fate,

IL must be resisted

and in a death battle with a clogged nozzle, a displacement of layers,

and from a table with an unlimited model worthy of the winner?

To start 3d printing or not to start, that is the question? - To begin!

Still, it's great that Yaroslav Andreev was not tormented by doubts for a long time, but took it and printed it! nine0006

Brrr, did you also feel that the realm of poor Yorick is cool enough? Therefore, let's continue our journey, and in order not to freeze, we will use the Stevenson Screen.

Stevenson screen - home "weather station", or more precisely, a shelter or attachment to meteorological instruments from precipitation and direct heat radiation from external sources. It is part of a standard weather station and contains instruments that may include thermometers (normal, max/min), hygrometer, psychrometer, dewcell, barometer, and thermograph. But since the external sensor is not particularly waterproof, colleagues from DDD. 3D Printing, 3D Printer, Miass printed a special white ABS protective case from Bestfilament. And if you also think that weather forecasters are wrong only once, but every day, then be sure to print your own home weather station.

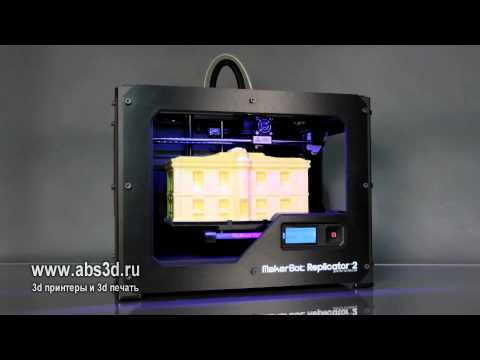

Continuing our acquaintance with the best works, we want to dwell on the project of friends of 3D printers from "3D Printing & Modeling Yekaterinburg" . The model of the house, stunning in its realism, evokes thoughts of a calm and measured life somewhere at the foot of the Alps. According to Yekaterinburg residents, the 3d model was built strictly according to the drawings, and special attention was paid to size matching. The main highlight of this layout is the ability to open and see how everything works from the inside. nine0006

According to Yekaterinburg residents, the 3d model was built strictly according to the drawings, and special attention was paid to size matching. The main highlight of this layout is the ability to open and see how everything works from the inside. nine0006

I would like to say that 3D printing is becoming more and more popular in the layout and modeling of various architectural projects. Unlike the traditional method of creation, which can take more than one month, 3D printing allows you to create and present architectural models at the very early stage of project approval, quickly make changes to the layout, make several copies of an object for simultaneous demonstration to several people, effectively present the project, showing it in different environments and at different scales, as well as saving time and money on the development of models, significantly reducing the time of the project. nine0185

And our Express on the route “Spring 2021: top 10 best works” is picking up speed. As we have already said, fashion is a capricious girl, and her mood changes more often than the weather in March. But the fashion for caring for one's own health continues to gain momentum, which, by the way, is very pleasing. But even more exciting for us is the fact that 3D printing has found its way into the creation of personal protective equipment and medicine in general.

As we have already said, fashion is a capricious girl, and her mood changes more often than the weather in March. But the fashion for caring for one's own health continues to gain momentum, which, by the way, is very pleasing. But even more exciting for us is the fact that 3D printing has found its way into the creation of personal protective equipment and medicine in general.

For example, at "Mnogo3D" projects were implemented to print filters with cotton pads for a 3M mask, as well as filters for masks of the 6500 series. take advantage of the proven time and experience of the filament. Without false modesty, we note that we are proud that colleagues from "Mnogo3D" chose black PETG from Bestfilament!

Probably the next part of our route can be called “Earth 3021”, because this Best reviewer is printing fantastic and futuristic 3D models! Let me introduce Ivan Volobuev . Ivan has his own creative 3D printing studio in Tomsk, where, together with his colleagues who are equally passionate about additive technologies, he creates and creates game attributes, clothing items and other iconic elements of game and movie universes.

It should be noted that Ivan is one of the very first clients of our company. Ivan began to use plastic from Bestfilament in his work back in 2013, when we were just starting our activities.

Our journey continues, and some of you are probably already thinking about a smoke break. As we have already said, Bestfilament is for a healthy lifestyle, so we do not smoke and do not advise you. But get past work from Ivan Erofeev just couldn't! Decorative blow for a hookah in the form of a dragon conquered us at first sight!

Despite the fact that this model is on the thingiverse website, Ivan still slightly modified it. By trial and error, it was decided to make a "chimney" gasket along the tail in the back and already further into the dragon's mouth. Also in this model, the scale is slightly increased, the diameter of the air channel is up to 10mm and the valve is improved.

The next stop on our journey will be the 3D printing and cosplay station. After all, with the help of a 3D printer, it is possible to implement a project of any degree of accuracy and detail and get the maximum match to the character. nine0006

nine0006

In "ElinoomLabs / 3D printing in Kursk" the Predator backpack was printed. The guys spent about 60 hours printing, as the model was cut into pieces for convenience and ease of printing. After gluing, the surface of the backpack will be processed, smoothed and painted. Also, this backpack will be equipped with an automatic gun.

Remarkably, the Predator costume for the film and the work of Stan Winston's studio cost $1.5 million. Initially, they wanted to save money on the costume, and the Predator looked like a giraffe crossed with an arthropod. And thanks to a 3D printer and plastic for printing, the cost of creating the necessary elements for a costume fit into a more modest amount! nine0006

Continuing the theme of large-scale projects, I would like to show the work by Denis Voronov . With the help of additive technologies, the symbol of Krasnoyarsk was printed - the Chapel of the Holy Great Martyr Paraskeva Pyatnitsa. There are many rumors and legends around the history of the name of the chapel, as one of them says, the chapel was named after a Cossack girl who picked berries on the slope of Karaulnaya Mountain and, seeing nomadic tribes approaching the city, raised a fuss, for which she died a martyr's death. This girl's name was Paraskeva. nine0006

This girl's name was Paraskeva. nine0006

Whatever it was, the chapel to this day is the decoration of the city. And now you can admire the chapel on a smaller scale. Although it is rather difficult to call the resulting 3D model small, because its height is about 1 meter.

Our express train is slowly moving along the Spring 2021 tour, but the degree of intrigue is growing at a rapid pace! The question of who became the author of the best work remains open.

Let me introduce a talented 3D printer Evgeny Kozhevnikova, whose work our jury liked so much. Eugene printed a backlit case for a PC. The project was carried out in several stages: design, 3D printing, assembly and gluing of all parts into a single whole. As the author of the model himself admits, the work required a lot of effort and patience, something had to be finalized in the printing process, some ideas had to be abandoned or rethought. As a result, an original author's case came out, which will definitely become a highlight of the interior. As a reward for the work done, Eugene receives a Bestfilament plastic spool and a 30% discount, which will be valid for a month. nine0006

As a reward for the work done, Eugene receives a Bestfilament plastic spool and a 30% discount, which will be valid for a month. nine0006

Unusual, stylized as a favorite fandom PC case will be a great gift for a gamer or fan of fictional universes. And the best part is that such a surprise does not require a lot of effort and financial investments. It is enough to have a 3D printer, filament and a little imagination!

The next work, which was noted by the jury members, was the Akali helmet from KDA, performed by colleagues from BRIlKO Orenburg 3d Printing Studio. The helmet is still in development. At the moment, a visor has been made, the illumination of the pattern on it is being worked out, as well as the suspension system (a system of belts and inserts fixing the helmet on the head). nine0006

While studying the work, we became interested: who is Akali and what is KDA? The all-knowing GOOGLE has told us that Akali is a ninja assassin who holds the position of a rapper in a virtual K-pop girl group consisting of four League of Legends characters.

It is noteworthy that on November 6, 2020, the band's debut mini-album "All Out" was released on Spotify, YouTube and Apple Music platforms. In addition to the title track "More" and the single "The Baddest" published back in the summer, the album includes three more songs: "Villian", "Drum Go Dum" and "I'll Show You". nine0006

Colleagues, thank you for giving us a great opportunity to broaden our horizons and present you with a Bestfilament plastic spool and a 30% discount that will be valid for a month.

You can see the work in here.

Another author whose skill was noted by the jury was Evgeny Kiskin and his work Bat.-Châtillon 25 t. Being a fan of playing World of Tanks, Eugene decided to become the owner of not only a virtual, but also a real tank. Naturally, we are talking about a collectible mini-version. Therefore, armed with a filament, Eugene started printing! nine0006

You can see the result yourself. And we, in turn, want to reward the 3D printer tanker with a spool of plastic from Bestfilament and a 30% discount that will be valid for a month.