Glass 3d printer filament

Glass 3D Printing Filaments: A Complete Guide

Glass 3D printing filaments are a handy way of adding strength to your models, and can be made safely and easily using many desktop 3D printers. Hobbyists and professionals alike will find their 3D printing endeavors vastly improved by using these filaments.

In this article, we will take you through two of the most popular glass 3D printing filaments, glass PLA and NylonG, their advantages and disadvantages, and some innovative ways in which glass is being implemented in the 3D printing industry.

- For a guide to every filament, also check out our complete 3D printer filament guide.

Part 1: Glass 3D Printing Filaments Printing Parameters

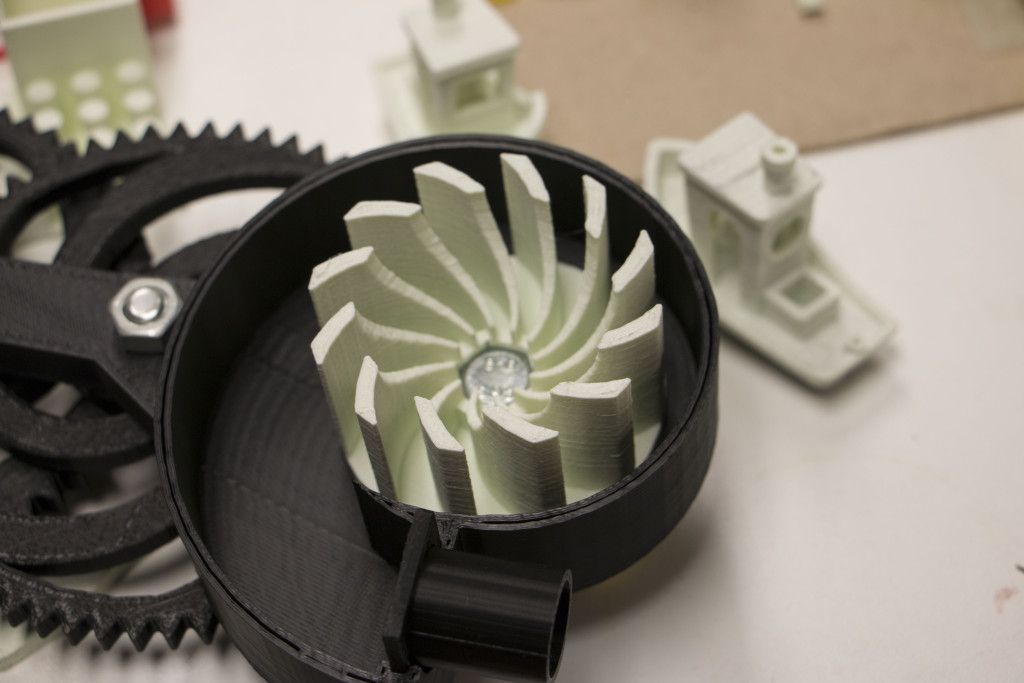

The main way in which glass is incorporated into these 3D printing filaments is through making composite filaments with tiny fragments of glass fibers within. These ‘composite’ filaments, encompassing not only glass infused filaments but also carbon fiber, are vastly stronger than their pure plastic counterparts.

The inclusion of other materials such as glass in these filaments improves strength and reduces susceptibility to bending and breaking. This means that the parts produced have far greater tensile strengths and are much more durable.

Glass filaments also have a number of benefits that make the 3D printing process much easier as well. They have a much lower potential for warping than other plastics, meaning less special attention is needed during the cooling process. They also do not produce the same odors or toxic gasses that other plastic filaments do.

There are two particular glass-infused filaments that are noteworthy as they have become increasingly prevalent in the last few years.

Glass-Infused PLA

- Printing Temperature: 180°C-220°C

- Bed Temperature: 40°C (Optional)

Polylactic Acid (PLA) is a favorite material among many beginners in 3D printing as it is much easier to print than many other plastics. Its 180°C extruder temperature is far lower than ABS or PP.

It is a stiff, brittle plastic used for prototypes, ornaments and cosmetic accessories, helped to no end by the wide array of colors that it comes in. PLA is also biodegradable, making it among the most environmentally friendly plastic filaments.

The addition of glass into PLA filaments helps to remove these shortcomings, and makes PLA a much more well-rounded and versatile material. Composite glass-infused PLA is 1.5x stronger and impact resistant, and also twice as flexible than standard PLA.

This means it is more durable than Acrylonitrile Styrene Acrylate (ASA), a popular plastic in outdoor applications, yet nearly as flexible as pure nylon, giving it an unforeseen range of improvements that broaden the material’s capabilities.

This makes PLA ideally suited for exterior fittings and outdoor tools, and can be printed much easier than other comparably strong materials.

NylonG

- Printing Temperature: 260°C-280°C

- Bed Temperature: 60°C-75°C

Similarly to PLA, the infusion of glass fibers into nylon has maintained what makes it unique and useful, but helped to correct some of its deficiencies.

Pure nylon is among the most flexible 3D printing filaments on the market, making it useful in producing products such as cable ties, fishing lines, and various forms of clothing where flexibility and durability are key. It is also extremely resistant to wearing down, meaning harder variations of nylon are used for things like skateboard wheels.

- If you are interested in printing flexible filaments, we also have a guide to 3D printing TPU filaments.

However, nylon 3D printing does have a number of flaws and potential pitfalls. It requires expert care as it is very prone to warping and disfiguring if cooled too fast. The filament itself is also very hygroscopic, so the filament must be kept in an airtight container or it will deteriorate, printing weaker parts with bubbly imperfections.

- We have another article on Nylon carbon fiber composites.

After production, it must also be properly dried to avoid serious printing defects and for this reason, nylon is extremely unsuitable for moist or humid environments.

NylonG removed many of these concerns. Without losing any flexibility, the glass gives the nylon filament extra structure and makes it much stronger. This increased density also gives the added benefit of making the filament less absorbent, and reduces the possibility of moisture damage.

Also, similar to the benefits of glass-infused PLA, NylonG warps less during printing, simplifying the printing process and making the material much more accessible to hobbyists and professionals alike.

Part 2: How Much Do Glass 3D Printing Filaments Cost?

Glass 3D printing filaments are naturally slightly more expensive than their pure polymer counterparts. Glass PLA filaments start around $68 per kilogram, with NylonG starting at a much pricier $100 per kilogram.

Where to buy Glass filaments

We recommend the following glass filament selections:

- Glass filament selection of both standard and professional composites on Matterhackers here

- NylonG selection on Matterhackers

Part 3: Best Practices for Glass Filled Filaments

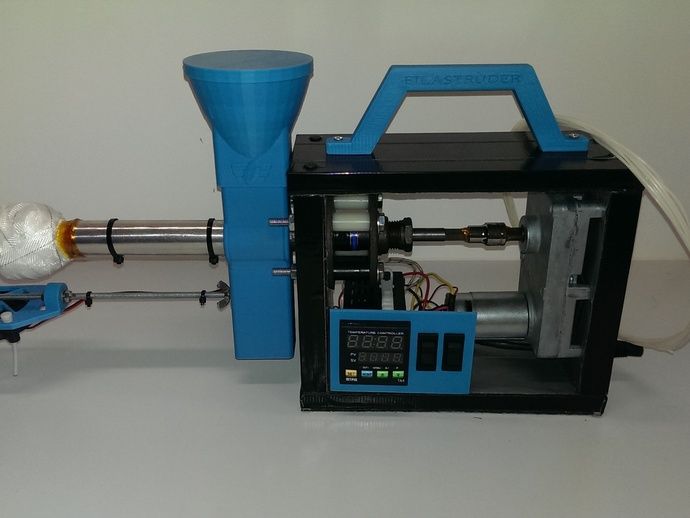

Use a Hardened Steel Nozzle

Glass 3D printing filaments are packed with tiny, almost microscopic fragments of glass. These are guaranteed to rub against your extruder nozzle as they are deposited, wearing away softer brass nozzles that ship with standard affordable 3D printers.

These are guaranteed to rub against your extruder nozzle as they are deposited, wearing away softer brass nozzles that ship with standard affordable 3D printers.

For this reason, upgrading to a steel nozzle rather than using a standard brass nozzle will save the time from constantly switching these worn down nozzles out. Hardened steel nozzles hold up better against the abrasive fibers within glass filament. This will greatly increase the longevity of your setup.

Start Heat Higher

It is best to start your heat high when 3D printing using glass-infused composites. While it is definitely possible to print at lower temperatures, especially with PLA, the glass fibers can do real damage if any clogs occur.

It’s best to avoid this by starting high and guaranteeing a good flow, and then lowering the temperature on later attempts until you find your optimum level.

Use a Raft

This is mainly for printing at lower temperatures, but using a raft is the best way to make certain of the best adhesion for your part. Starting off with a base of material and printing on top of that will give you enough of a foundation to make the best part possible.

Starting off with a base of material and printing on top of that will give you enough of a foundation to make the best part possible.

If you notice that separating the part from the raft after printing is difficult, you can adjust the raft-model spacing setting to reduce this.

Part 4: Advantages and Disadvantages of Glass 3D Printing Filaments

Advantages of glass 3D printing filaments

Stronger Parts

The rigid structure that the addition of glass provides makes these filaments much stronger than their pure alternatives and makes them competitive with some of the strongest plastics on the 3D printing market.

They have higher tensile strengths and higher levels of impact resistance, and, despite being biodegradable, are among the most durable plastic filaments money can buy.

Overall Easier to Print

There are a number of other aspects that make these filaments easier to print than other polymers, and even more than their pure alternatives. The addition of glass makes them less prone to warping and thereby reduces the amount of special care needed to print effectively.

The addition of glass makes them less prone to warping and thereby reduces the amount of special care needed to print effectively.

On top of this, they produce less odor and harmful fumes, require no special extruder, and PLA does not even need a heated bed.

Disadvantages of glass 3D printer filaments

More Expensive

In exchange for added strength and durability, your wallet is going to have to do some heavy lifting. Both glass-infused PLA and NylonG are more than double the price of their pure polymer counterparts.

For this reason, these filaments are not ones to try out unless you have money to burn. If you are a beginner, you may fall into the traps that anyone could with any filament. The pure forms of these plastics, especially PLA, are much cheaper and give you the room to experiment with if you are on a tighter budget.

However, for professionals and industrial prototypers, engineers, and for a variety of other industrial applications, these improved material characteristics more than justify the investment.

Part 5: Alternate Methods of Glass 3D Printing

Aside from using polymer filaments, researchers have been experimenting for years with ways to 3D print using pure glass. However, despite successes, there are huge limitations. Traditional glass manufacturing requires extraordinarily high temperatures, upwards of 1500°C.

When first experimenting with 3D printing glass, manufacturers tried two different techniques. Firstly, they attempted to use deposition printing with molten glass.

However, this had significant drawbacks with the need for prolonged heating at high temperatures, as well as similarly heat-resistant equipment that did not previously exist in the 3D printing industry.

Elsewhere, experiments were conducted involving using powdered ceramic which could be deposited at room temperature, and sintered with a high-powered laser, similar to Direct Metal Laser Sintering (DMLS). Yet this reduced the capacity for complex designs for small intricate parts.

A new and slightly more accessible technique has been developed by researchers at Swiss institute ETH Zurich. Their process is very similar to stereolithography, among the first 3D printing techniques, and uses resin, containing plastic and a mixture of molecules used in the traditional manufacturing of glass.

Once deposited, the resin is irradiated with ultraviolet light to harden. The finished product is then heated, first to 600°C to burn away the polymer, and then to 1000°C to form the remaining ceramic structures into glass.

While the heating process significantly shrinks the glass model, the remaining part is crystal clear and highly detailed. Naturally, this is solely an industrial-level process, but successful products are able to maintain an extraordinarily high level of complexity, with intricate edges and designs.

Like traditional glass products, they are still very brittle and will crack and shatter under moderate stress. Due to the shrinkage issues, it is also not possible to print large designs. However, with this small but significant first step, the glass 3D printing industry is well on its way to major development.

However, with this small but significant first step, the glass 3D printing industry is well on its way to major development.

While completely impractical for home printing, new techniques could give glass a new lease of life in the manufacturing industry, with applications in industries ranging from jewelry to aerospace to communications.

What we do see now though is glass 3D printing filaments are becoming a fixture of in-home 3D printing, and taking the first steps towards wider adoption of glass in the industry.

Related articles:

- Ender 3 glass bed – best upgrades

- 3D printed glasses – a feature story

GLASS - Semi-Transparent 3D Prinitng Filament

Z-GLASS

With Z-GLASS semi-transparent filament you can 3D print light-transmitting final parts and precise prototypes. The material lets you replace brittle glass with resilient thermoplastic. Z-GLASS is durable and resistant to scratching. Moreover, the material withstands exposure to salts, acids, bases, and solvents. That’s why it’s ideal for industrial prototyping in automotive industry and design.

That’s why it’s ideal for industrial prototyping in automotive industry and design.

Available Colors

| Dedicated for | Container | Weight | Diameter | Extrusion |

|---|---|---|---|---|

| Zortrax M200 | spool | 800 g ±5% | 1.75 mm | Single |

| Zortrax M200 Plus | ||||

| Zortrax Inventure | Single / Dual with Z-SUPPORT Premium | |||

| Zortrax M300 | 2000 g ±5% | Single | ||

| Zortrax M300 Plus | ||||

| Zortrax M300 Dual | Single / Dual with Z-SUPPORT Premium |

| Key Properties | Metric | Imperial | Test Method |

|---|---|---|---|

| Tensile Strength | 39.57 MPa | 5740 psi | ISO 527:1998 |

| Elongation at max Tensile Stress | 5. 94% 94% |

5.94% | ISO 527:1998 |

| Glass Transition Temperature | 78.06° C | 173° F | ISO 11357-3:2014 |

WORKSHOP LAMP. Transparent parts of the lamp 3D printed with two colors of Z-GLASS. The material is a perfect replacement for brittle glass.

Applications

- light-transmitting concept models

- transparent parts

- automotive industry

- models imitating glass

- decorative accessories

- parts tested outside

- parts required to be resistant to salts, acids, alkalis, and solvents

Light-transmitting

Objects 3D printed with Z-GLASS are semi-transparent. That’s why they can imitate glass. You can apply various coating substances to enhance the effect and make them even glossier.

That’s why they can imitate glass. You can apply various coating substances to enhance the effect and make them even glossier.

End-use products

Z-GLASS is perfect for end-use products, like a camera light diffuser, 3D printed at the fraction of the market price. Translucency of the models can be adjusted by changing settings in Z-SUITE.

Scratch-free

Z-GLASS material is scratch-resistant, making the 3D printed models usable over a long period of time. Combined with chemical resistance, the filament is ideal for prototyping and industrial tooling.

Oops.. there seems to be no such page

Apparently, you've landed on a page that either doesn't exist or was deleted long ago. Start your search first!

Request a call back

Telephone

By clicking on the button, you agree to the privacy policy of

Item added to cart

Go to cart

Product added to comparison

Compare products

Cannot compare more than 4 products

Invoice or quotation request

Organization name:

Your e-mail

Your phone

Name of contact person:

Legal address:

Comment:

By clicking on the button, you agree to the privacy policy of

Goods on the way, find out when delivery

Your name:

Your e-mail

Your phone

By clicking on the button, you agree to the privacy policy of

Contact us

How to call

By phone +7(495)155-45-19. Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch: nine0003

Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch: nine0003

- Write to Telegam @techno3dru

- Write to Whatsapp +74951554519

- Write Email [email protected]

Is the product in stock

On the product page, under the product name, there are 3 statuses:

- In Stock - We have this item in stock. Make a purchase with the Buy button.

- Pre-order - goods on the way, delivery soon. Find out about delivery times by clicking on 'Delivery times' or make a purchase using the Buy button.

nine0057

nine0057 - On order - The goods are delivered according to your order on a partial prepayment. Place an order using the Order button.

How to get an invoice for payment for legal entities

Add items to the cart, proceed to checkout. Payment method: Organization → Specify details → Get an invoice for payment

How to get a quotation

On the product page, click on the link Request a quote

How much is delivery

On the product page, block Delivery. With an accurate calculation of the cost and timing to your city. On the Delivery and payment page for more details about all delivery methods.

If you did not find your question among the questions, please contact us via Whatsapp

or Telegam

One-Click Order

Contact Name:

Contact Phone:

Email:

How to clean the 3D printer tray?・Cults

The plate is one of the most important parts of a 3D printer. For optimal printer performance, it must be properly cleaned after each print session. Traces of the thread are deposited on it over time. While cleaning a 3D printer plate is not a difficult task, it can quickly become one if you don't have an effective method or the right cleaner. How to clean this important part of the 3D printer? We invite you to identify the most effective methods.

For optimal printer performance, it must be properly cleaned after each print session. Traces of the thread are deposited on it over time. While cleaning a 3D printer plate is not a difficult task, it can quickly become one if you don't have an effective method or the right cleaner. How to clean this important part of the 3D printer? We invite you to identify the most effective methods.

Do you have a 3D printer? So how do I properly maintain my 3D printer is probably a question you often ask yourself, the first element of which lies, in fact, in the quality of the material you are using. As far as the print plate is concerned, when using the right cleaning tools, the various parts of your 3D printer will have good adhesion .

To clean the plate of your 3D printer, you will need the following tools: sandpaper, scraper, sponge, paper, cotton or microfiber towels and cleaners such as acetone or propanone, isopropyl alcohol (IPA) with a minimum concentration of 70%, soap for utensils. .. Ideal for effective cleaning of your 3D printer .

.. Ideal for effective cleaning of your 3D printer .

Cleaning your 3D printer's plate depends mainly on the plate material, as well as the product used for printing. Most often, the printing plate is made of glass, polyesterimide (EPI) or is covered with adhesive tape . The printing plate of the printer can also be made of plastic, garolite, ceramics, granite, aluminum, but this is much less common. When cleaning the 3D printer plate, you must also consider the use of surface treatments that promote adhesion of parts to the plate.

Cleaning the glass 3D printing plate

Glass is a common material used for 3D printing. It has a much longer lifespan than PEI. In addition, glass printing plate facilitates the use of adhesive and varnish in the 3D printing process. This is because its surface does not react with any material. It is also relatively easy to clean. The 3D printer's glass printing plate is commonly used with adhesives such as glue stick and hair sprays. They increase the adhesion of the surface for the first print layer, which is necessary to ensure the stability of the rest of the model.

They increase the adhesion of the surface for the first print layer, which is necessary to ensure the stability of the rest of the model.

The glass plate can be heated to remove material residue. Heat makes it easier to scrape off these materials. However, care must be taken when scraping, as the glass is easily scratched by sharp objects. Best use aligned objects such as a metal spatula or a plastic ruler. If you choose to use metal, we recommend applying only as much pressure as is necessary to avoid scratching the glass plate. A metal scraper or spatula is also very useful for cleaning the print tray if you are using ABS, PLA, or nylon filament.

Alternatively, you can use the scraper blade to clean the glass plate of your 3D printer. This tool is very sharp. To do this, press down with one hand while holding the edge of the print tray with the other. This will let you effectively remove the material residue from the 3D printer print tray. Then make sure you clean the part of the plate that is in contact with your hands. It very often leaves residues of oil and dirt.

Then make sure you clean the part of the plate that is in contact with your hands. It very often leaves residues of oil and dirt.

PEI plate cleaning

PEI sheets are also used as plates for 3D printers. Their resistance to wear under extreme temperatures and radiation levels is well rated. Regular maintenance of the PEI printing plate allows the to maintain its quality . Over time, the adhesion of PEI sheets weakens under the influence of temperature, printing radiation or inks. Traces of dirt, oil, glue, etc. eventually settle on the surface of your 3D printer's PEI plate. However, physical cleaning procedures such as scraping and scraping are not the most effective and may even damage the print plate.

The best solution for cleaning the EPI print tray is to use a cleaner such as unflavored IPA with a concentration of 70%. In the case of a plate surface that is more exposed to dirt and oil, purer IPA can be used. However, before you start cleaning, wait for your 3D printer's PEI plate to cool down. For your protection, make sure you use this cleaner in a well ventilated area.

For your protection, make sure you use this cleaner in a well ventilated area.

You can also use acetone to remove ink and plastic residue stuck to your 3D printer's PEI plate. This cleaner should not be poured directly onto the plate. Despite the fact that PEI does not dissolve in acetone Acetone can damage PEI if you pour too much of it on the plate. To do this, it is recommended to pour acetone on the fabric, and then wipe the print tray in a circular motion.

Tape plate cleaning

Adhesive tape is an inexpensive and easy to replace product. Therefore, it is widely used by people who are just starting to master 3D printing. Ribbon is mainly used with non-heated printing plates due to its thermal sensitivity.