3D printer food grade filament

The Essential Guide to Food Safe 3D Printing

3D printing offers unparalleled design freedom to produce custom parts and complex or organic shapes that would be costly or impossible to manufacture with traditional manufacturing methods.

These benefits can be compelling for a range of food-related applications. However, if 3D printed parts are intended for food contact items, you‘ll have to consider safety practices and regulations to avoid contact with toxic substances and prevent the buildup of harmful bacteria.

Food safe 3D printing is possible and the variety of materials approved as food safe is increasing, but there is a high degree of ambiguity around the workflows and finding the appropriate applicable regulations can be a challenge.

Read on for an introduction to food safety, food safety considerations for 3D printing, and a variety of methods to produce food safe products with common 3D printing processes, including stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS).

Please note

No Formlabs resins are food safe unless users take additional steps.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

To begin, it’s important to clarify a few key terms:

- Food grade means that the material is either safe for human consumption or permitted to come in contact with food.

- Food safe means that a food grade material meets the requirements determined by the intended use and will not create a food-safety hazard.

- Food contact surfaces include any surface that may come into direct contact with food. These surfaces must be made of nontoxic materials and designed to withstand the environment of their intended use, including exposure to cleaning compounds, sanitizing agents, and cleaning procedures.

Food grading and food safety concern a specific way to ingest parts, called migration. Particles as small as a few nanometers and up to several hundred nanometers may get transferred each time various materials encounter with each other, for example from components of the 3D printer to the 3D printed object, and from the object to the food.

Because migration levels are very low on occasional contact, food grading typically concerns items that are in prolonged contact with food such as containers, straws, utensils, plates, and food molds. Different testing institutions will adhere to different government-imposed risk tolerances and approved substances, which for the US is described by the FDA CFR 21 and for the EU in guidelines 10/2011.

Look for these labels indicating FDA and EU approval. Beware that a material being ‘compliant with’ doesn’t mean that it is explicitly approved by the institutions, so always check the technical datasheets for a certificate.

To be considered food safe according to the FDA Food Code, a material has to meet the following requirements:

- No migration of deleterious substances

- Does not impart colors, odors, or tastes

- Safe under normal use conditions

- Durable, corrosion-resistant, and nonabsorbent

- Sufficient in weight to withstand repeated washing

- Finished to have a smooth, easily cleanable surface without breaks and sharp internal angles

- Resistant to pitting, chipping, crazing, scratching, scoring, distortion, and decomposition

- Accessible to inspection

Any FDA or EU approved material includes not only the raw polymer but also the additives or masterbatch. These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

A 3D printed part can turn into a petri dish squirming with bacteria within weeks. Even though some materials will survive the dishwasher, so will dangerous bacteria such as E. coli and salmonella that live in the little nooks and crannies. Some toxic molds find favorable growth conditions on several types of plastic and are hard to remove. Neither cleaning with bleach nor microwaving your polymers is an option for eliminating germs.

While bacteria buildup might not be an issue for disposable items, if you’re planning to create a part for long-term use, using a food safe coating is highly recommended.

The best option to reduce the risk of particle migration and bacteria buildup is by dip coating the 3D printed parts with a food grade epoxy or polyurethane resin, such as Masterbond’s EP42HT-2FG or ArtResin or an FDA approved PTFE (known as Teflon®) to seal their surface.

However, note that coating also doesn’t guarantee food safety for prolonged use as not all of these coatings are dishwasher safe, and they may degrade over time, exposing the original, potentially non-safe surface.

Most 3D printing materials have a low heat deflection temperature (HDT), which means that the 3D printed parts might become brittle and crack, or deform and warp at elevated temperatures. If you’re planning to clean a 3D printed part in a dishwasher, make sure to double check that the material is dishwasher safe and if there are any specific recommendations for washing temperature.

As particles might migrate from components of a 3D printer to 3D printed parts, it is crucial that any components that might come in contact with the 3D printing material or the part are food grade and do not contain or leach harmful chemicals.

This includes taking precautions when using multiple materials, as some materials previously used in the 3D printer might have contained toxic particles and made contact with some components.

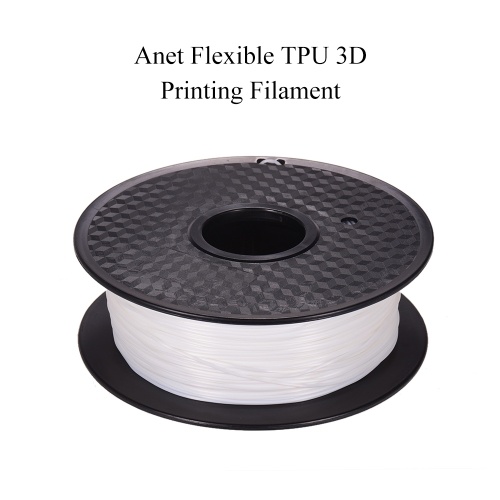

Many 3D printing materials are not food safe and might contain toxic chemicals. Only use materials to 3D print parts intended for food contact that are certified for food safety.

As may be expected, the risk of migration is higher if the food is exposed to the 3D printed part for an extended time period. In general, try to limit food contact time and take further precautions for parts that will be in contact with food for longer periods of time.

Think about the reason why you’d like to use 3D printing for a food contact item. If it’s to create custom shapes and forms, in most cases, there are indirect ways to use 3D printing to create these custom parts, for example with molding. See an example in the next section.

SLA 3D printing uses a laser to cure liquid resin into hardened plastic in a process called photopolymerization, resulting in parts that have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies.

Is resin food safe? The answer is no. Substances may migrate from SLA parts which makes none of the resins and printed parts food safe by default. While some resins for dental and medical applications are certified biocompatible, that doesn’t mean that they’re food safe. These materials are certified for specific applications and should not be used for food contact products.

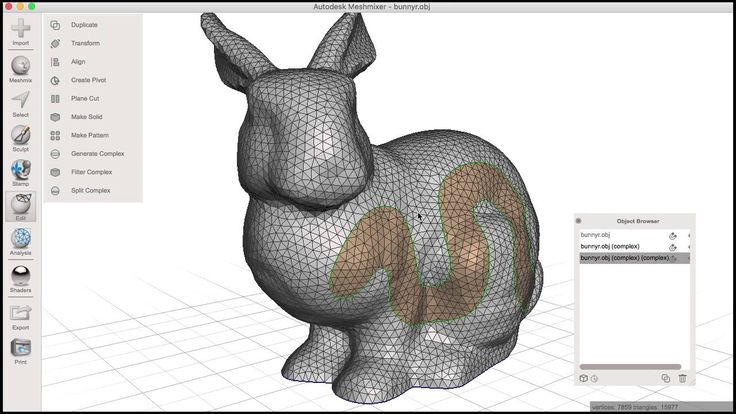

SLA parts have a smooth surface finish that makes it easier to use coatings to seal their surface and prevent the buildup of bacteria. The factors which affect the ultimate smoothness of a part include resin type, layer thickness, build orientation, mesh triangulation resolution of the 3D model, and the curing profile of the SLA resin. Printed parts require washing and post-curing according to the manufacturer's instructions before the coating is applied. However, note that coatings don’t guarantee food safety, as the coating may interact with the resin or degrade over time, exposing the original, potentially non-safe surface.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Creating custom molds is a common way to leverage the benefits of SLA 3D printing to produce highly detailed custom parts without having the 3D printing parts come into direct contact with food. While SLA 3D prints aren’t suitable for directly molding foods, SLA 3D printers are perfect tools to create mold negatives, which can be vacuum formed using food safe plastic.

The tools and techniques for creating 3D printed food molds are easy to master, and the results are often stunning.

3D printed molds for thermoforming and silicone enabled the creation of unique shapes and designs.

Learn more about creating molds for vacuum forming in our in-depth tutorial.

Electroplating is the process of coating parts with metal using an electric current. The process is most commonly used for decorative purposes or to prevent corrosion by creating a durable surface.

SLA parts are ideal for electroplating due to their smooth surface finish. However, as plastics are nonconductive surfaces, SLA 3D prints have to be rendered conductive by coating with graphite, conductive lacquer, electroless plate, or a vaporized coating.

Food safe metal coatings are available, but as the process involves various chemicals, making sure that the workflow is approved for food contact is the developer’s own liability.

SLA 3D printing offers the unique possibility to produce ceramic parts. After 3D printing, parts can be fired in a kiln to burn out the resin and form a true ceramic part that is strong and heat-resistant. With subsequent food safe glazing, the parts will become more hygienic and resistant to most chemicals.

A variety of food safe glazes are available on the market, but make sure to follow the manufacturer’s instructions in accordance with food safety guidelines.

3D printing in ceramics is ideal for fabricating complex geometries that wouldn’t be possible by hand.

Learn More About Ceramics

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

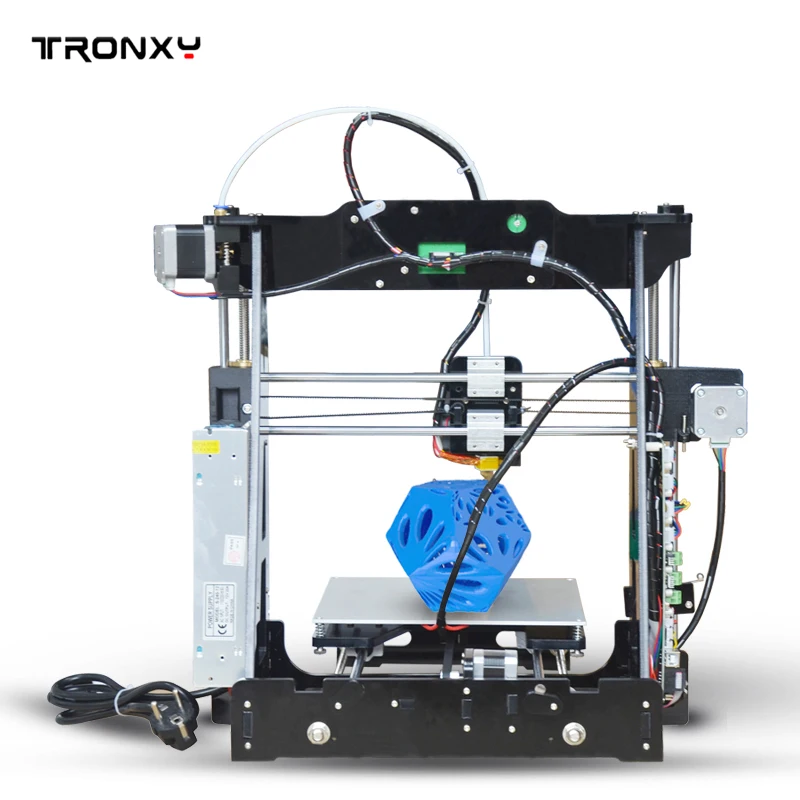

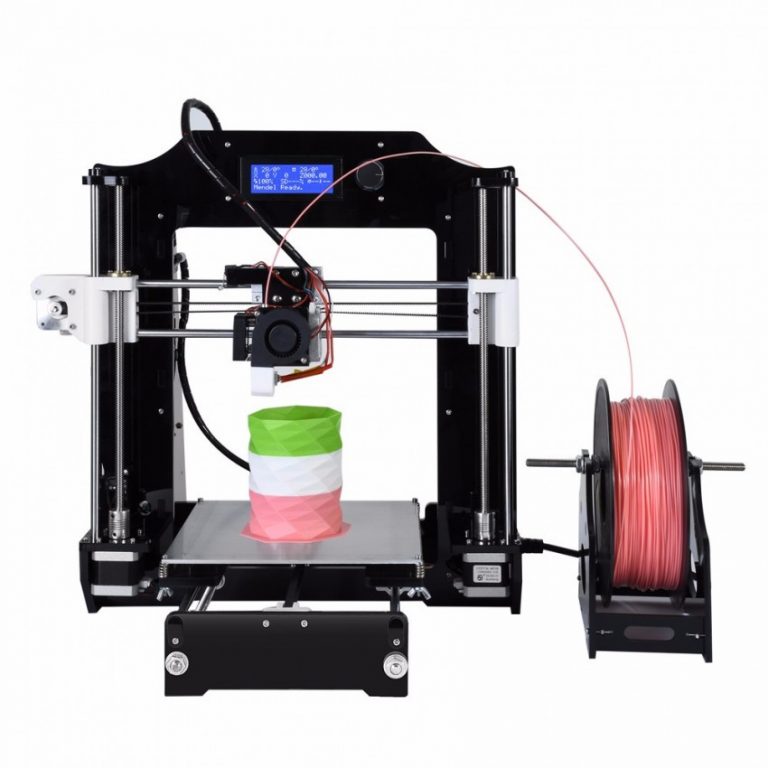

FDM is a 3D printing process that builds parts by melting and extruding thermoplastic filament, which a print nozzle deposits layer by layer in the build area.

The extruded material is circular in cross-section, which leaves very narrow crevices in between layers with a depth directly proportional to layer height. It is recommended in any case to print at the lowest feasible layer height for food safe parts.

Consequently, the main challenge with FDM parts is avoiding the buildup of bacteria. To be truly food safe in the long term, an FDM 3D print needs to have a smooth surface. Chemical smoothing with solvents like acetone, d-Limonene, or ethyl acetate removes many of the irregularities of the print resulting in a smooth, glossy appearance. However, applying a subsequent food safe coating is still highly recommended.

However, applying a subsequent food safe coating is still highly recommended.

Layers showing on FDM (left) and SLA (right) 3D prints.

Food grade filaments do not contain any composite particles so will not wear down the nozzle into the print. Nevertheless, avoid brass nozzles that contain lead and use a dedicated stainless steel nozzle instead for all food contact items.

Always check the compatibility of your 3D printer’s components with the filament. For example, PEI is a material that is FDA compliant and offers great mechanical benefits but needs to be processed at over 300 °C, which requires a specific printer solution.

The most common questions around FDM food safety concern two popular materials. Is PLA food safe? Is ABS food safe? The answer is, it depends.

Food safe 3D printing filaments include PLA, PP, co-polyester, PET, PET-G, HIPS, and nylon-6, as well as some brands of ABS, ASA, and PEI. Having to run parts through the dishwasher rules out PET, nylon, and PLA because these plastics soften and distort around 60–70 °C. For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

While not reflected in the regulations, some studies suspect that polystyrene may leach styrenes, co-polyesters might cause health concerns and that food grade FDM filaments might lose their safe status due to oxidation and thermal degradation from the printing process.

| Filament | Brand | FDA | EU | Smoothable | Dishwasher safe | Hot liquids |

|---|---|---|---|---|---|---|

| ABS | Adwire PRO | Approved | NA | Yes, acetone | Yes | Yes |

| Innofil3D | Approved except red, orange, and pink | Approved except red, orange, and pink | Yes, acetone | Yes | Yes | |

| ASA | Innofil3D | NA | Compliant | Yes | No | |

| Bendlay | Orbi-Tech | NA | Compliant | Yes, brake cleaner | No | No |

| Biocompound | Extrudr GreenTEC | NA | Compliant | |||

| Co-Polyester | Colorfabb XT | Approved | Compliant | No | Yes | Yes |

| HIPS | Easyfil | Compliant | Compliant | Yes, d-limonene | Yes | No |

| Fillamentum | NA | Compliant | Yes, d-limonene | Yes | No | |

| InnoFil3D | Approved | Approved | Yes, d-limonene | Yes | No | |

| Nylon | Taulman Nylon 680 | Compliant | NA | No | No | |

| PEI | ULTEM® 1000 | Compliant | NA | Yes | Yes | |

| PET | InnoPet EPR | Approved except red and orange | Approved except red and orange | Yes, ethyl acetate | No | No |

| Refil | Approved | NA | Yes, ethyl acetate | No | No | |

| Taulman T-Glase | Approved | NA | Yes, ethyl acetate | No | No | |

| Verbatim | Compliant | NA | Yes, ethyl acetate | No | No | |

| PET-G | Extrudr MF | NA | Approved | Yes, ethyl acetate | No | No |

| HDGlass | Approved | Approved | Yes, ethyl acetate | No | No | |

| PLA | Filaments. ca TrueFS ca TrueFS | Approved | NA | No | No | No |

| Fillamentum | NA | Compliant | No | No | No | |

| Innofil3D | Approved except red, orange, pink, apricot skin, grey, and magenta | Approved except red, orange, pink, apricot skin, grey, and magenta | No | No | No | |

| Copper3D PLActive Antibacterial | Approved | Compliant | No | No | No | |

| Makergeeks | Approved | NA | No | No | No | |

| Purement Antibacterial | Approved | Approved | No | No | No | |

| PLA-HT | Makergeeks Raptor | Approved | NA | No | Yes | Yes |

| Makergeeks Raptor | Approved | NA | No | Yes | Yes | |

| PP | Centaur | Compliant | Compliant | No | Yes | Yes |

| InnoFil3D | Approved | Approved | No | Yes | Yes | |

| Nunus | Compliant | Compliant | No | Yes | Yes | |

| Verbatim | Compliant | NA | No | Yes | Yes | |

| SBS | Filamentarno | NA | Approved only in Russia | Yes, d-limonene | Yes | Yes |

Selective Laser Sintering is a 3D printing process that use a high-powered laser to fuse small particles of polymer powder. The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

While some SLS powders are graded food safe, the particles on the surface of printed parts might not fuse completely, resulting in parts that are inherently porous and do not deal well with moisture and mold growth. Even though the nylon 12 powder can be steam cleaned in an autoclave, it is best to coat SLS parts with food safe coatings to seal their surface.

A common post-processing step for SLS parts is dying. But note that after an SLS part has been dyed, the dye may leach into the printed part which renders the item not food safe.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Food safety with 3D printing is not a simple matter that will boil down to a clear yes or no answer. Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

For further information on food safety and 3D printing, we recommend reading the following:

- FDA Regulations CFR 21

- EU Guidelines 10/2011

- Risk Assessment of 3D Printers and 3D Printed Products

- The Tricky Business of Choosing Plastic for Food Contact Applications

Food Safe 3D Printer Filaments - Complete Guide

There are plenty of awesome 3D printing projects out there, and some even help you around the house. 3D printing lets us make almost anything from toys and Lego figures to holiday decorations.

But some of the coolest and most useful things you can make are 3D printed food preparers.

While you can’t quite 3D print your own microwave just yet, it’s easy to use your 3D printer to make kitchen helpers like coffee filters and cookie cutters.

However, not all materials are made equal, and not all 3D printer filaments are safe to use in the kitchen.

From making your own cutlery to designing your own kitchen tools, 3D printed food utensils and cookware are a great way to spice up your home without breaking the bank.

However, using dangerous plastics or unsuitable materials for 3D printing cooking utensils is hazardous to your health. Because of this, it’s very important to know what the food-safe 3D printing materials are before you start making your own personalized forks and spoons.

Identifying and maintaining the food safety of anything that gets used in your kitchen is a number one priority in staying as healthy as possible. Not all culinary hazards are immediately obvious and visible, so be sure to keep these things in mind before 3D printing some crockery.

Which Filaments Are Food-Grade?

FDM printers seem like they can do just about everything, and here at 3DSourced, we’ve spoken about using food-safe 3D printer filaments to make some of the coolest 3D printer projects. But before you go from printer to plate, you should familiarize yourself with which filaments you should and shouldn’t use and why.

But before you go from printer to plate, you should familiarize yourself with which filaments you should and shouldn’t use and why.

PLA – Food Safe

PLA is generally considered to be a food-safe 3D printer filament, which is excellent news given that it’s the standard filament choice for many FDM 3D printers.

Despite not being as heat resistant as many other filaments, it’s non-toxic and safe to use for 3D printing your own kitchen utensils. However, it’s still recommended that you limit its exposure to food.

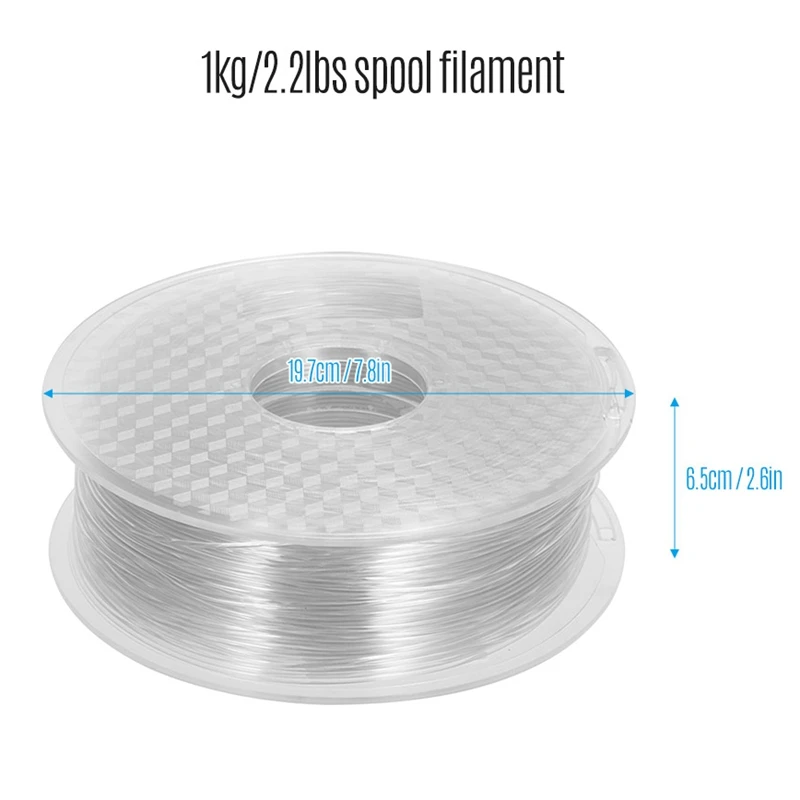

Specialized food-grade PLA is also manufactured, such as this one.

Read more: the best food 3D printers

ABS – Not Food Safe

ABS has better heat resistance than PLA, making it less likely to degrade with constant use and washing. This seems ideal on the surface, as its durability means it’s less likely to form notches and grooves to house bacteria, but don’t be fooled.

ABS is quite toxic when ingested, especially when heated up. Even using ABS for minimum contact tools can be hazardous to your health. All-in-all, ABS is not considered to be a food safe 3D printer filament, and should be kept out of the kitchen by all means.

Even using ABS for minimum contact tools can be hazardous to your health. All-in-all, ABS is not considered to be a food safe 3D printer filament, and should be kept out of the kitchen by all means.

PETG – Food Safe

PETG filament is the dream filament for those of you looking to 3D print your own cookware. It’s highly durable and heat resistant while also being one of the most food-safe 3D printer filaments on the market.

It’s even been given the green light by the FDA as a safe material for clothing and household utensils due to its non-toxicity, lasting shelf-life, and high recyclability.

Most discussions regarding the food safety of PETG filaments take mainly food containment and storage into account. This means that it’s the safest available 3D printer filament for long-term exposure to food at room temperature or below. This makes it ideal for Tupperware replacements and transportation for things like potlucks and picnics.

Keep in mind, however, that these approvals only come from non-treated PETG. Some manufacturers include additional chemicals in the creation of their filaments for things like color and advanced durability. These chemicals may render the filament non-food safe, and should be avoided.

Some manufacturers include additional chemicals in the creation of their filaments for things like color and advanced durability. These chemicals may render the filament non-food safe, and should be avoided.

Always search for ‘Raw’ or ‘Clear’ PETG filament if you plan on using it with food, like the one here. This will tell you that it has not been treated with any chemicals and is safe to use.

Nylon Filaments – Food Safe

Nylon is considered a food-safe filament, but only at the highest grade of quality. While it’s best to avoid using nylon filament with food if you’re at all unsure, using filaments like nylon-9 are safe to use with food.

If you plan to use nylon filaments like this for kitchen utensils, be sure to follow the same advice we recommend when using PLAs.

Read more: the best Nylon 3D printers

Ceramic – Food Safe

If you’re lucky enough to have a 3D printer that can print ceramics, then you’ll be very glad to know that ceramic filaments like this are considered to have the same properties as traditionally made ceramic crockery.

This means that they are food safe and can be used as any regular cup, saucer, plate, bowl, or even cutlery.

Read more: ceramic 3D printing buyer’s guide

Dangers of Non-Food Safe Filament

There are plenty of reasons to double check that your 3D printer filament is food safe before using it for your culinary endeavors. Double-checking your filaments to make sure they’re food safe is of upmost importance when protecting yourself and your family from some very dangerous health risks.

Bacteria

Not all materials can be thoroughly cleaned with just hot water and a good scrub, and sometimes materials that appear clean and shiny are actually crawling with dangerous bacteria. Unfortunately for us humans, our eyesight is nowhere near good enough to detect such bacteria.

Allowing these germs to build up and thrive on any surface is hazardous enough, but the risk is further maximized with things that are going near your food. Think about it, raw chicken looks clean but you wouldn’t put it anywhere near your mouth!

All 3D printing filament will have grooves and notches that may be invisible to the naked eye where bacteria can build up. While this isn’t too much of an issue provided you clean your utensils regularly, crockery and cutlery left unchecked will soon end up crawling with germs.

While this isn’t too much of an issue provided you clean your utensils regularly, crockery and cutlery left unchecked will soon end up crawling with germs.

Even more food safe 3D printer filaments like PLA will degrade with prolonged exposure to heat, creating more grooves in which bacteria can thrive. So even diligent washing may render your utensils unsanitary over time.

Toxic Materials

It’s very important to remember that ABS filament is never food safe. ABS is a toxic filament that will leech into your food and make it unsafe to eat even if it tastes fine. Colored ABS is often made using additional chemicals like unsafe dyes which cause even more harm if eaten or used with food.

While PLAs tend to be non-toxic and generally food safe 3D printer filaments, be sure to check with the manufacturer or provider before you bring it into the kitchen!

Additional fact: Plastic utensils from takeaways and picnics are made of polystyrene, which are only safe to use at room temperature, but they become toxic with prolonged exposure to heat. As if we needed another reason to avoid those environment-destroying tools.

As if we needed another reason to avoid those environment-destroying tools.

Use a Stainless Steel Extruder – Avoid Lead

It’s not just filaments that can be non-food safe, sometimes it’s your 3D printer itself. Check your extruder’s specs before printing anything that’s to go near food.

Many extruders are made from brass, which contain lead. If used too much or worn away, particles of this lead will seep into your prints, rendering them unfit for ingestion and very dangerous to your health.

If your extruder is made of stainless steel, then you’re all good to go!

Maximize Safety When Using Food-Safe 3D Printer Filaments

Much like traditional metal utensils, how safe they are to use will always in some way depend on how you take care of them. As we’ve discussed, some filaments are generally safe for use with food, but there are some extra steps you should be taking to make sure your projects stay safe and you stay healthy!

Wash Efficiently

While the go-to rule for washing up is to get the water as hot as possible, this isn’t the case with 3D prints designed for food. A good scrub with warm water and anti-bacterial soap will clean out your 3D printed kitchen utensils well without exposing them to the kind of heat that will warp or damage them.

A good scrub with warm water and anti-bacterial soap will clean out your 3D printed kitchen utensils well without exposing them to the kind of heat that will warp or damage them.

This will protect the aesthetic of your creations as well as make them less likely to become bacteria havens in the future.

It may be tempting to opt for a dishwasher for these instances, but it’s best to avoid using them. Dishwashers run on higher temperatures and strong blasts of water that will damage your prints and make them less usable and more dangerous over time.

Ensure Everything is Food Safe

As we’ve mentioned before, it’s not just food safe 3D printing filament you need to consider. You need to make sure your 3D printer nozzle as well as any long-term chemical solutions you use in post-processing are also safe for ingestion even in small quantities.

Making sure every step in the printing process is as sanitary as possible is very important to ensure that what you’re putting in or near your mouth isn’t going to come back to bite you instead. Think about it, you wouldn’t want to mix cake batter with a freshly varnished wooden spoon, would you?

Think about it, you wouldn’t want to mix cake batter with a freshly varnished wooden spoon, would you?

Use Sparingly

It will be tempting to make something as special as a homemade utensil a go-to in your kitchen, but the more anything comes in contact with food, the more dangerous it could be.

While things like cookie cutters and cutting boards have limited contact with food already, 3D printed cups and bowls should only be used sparingly and washed immediately after use to ensure they stay food safe for a long time.

Because of this, it’s generally recommended that you don’t use any 3D printer filament to make crockery like cups, bowls, and plates. While one-time use may be safe, they will deteriorate and become toxic quickly regardless of whether or not your filament is food safe.

While it is possible to keep such things safe for a long time, the care required to maximize safety is often not really worth it. Instead, why not use your 3D printer to make safer items like this personalized cup holder? That way you’ll enjoy eating and drinking with things you’ve made yourself while avoiding the attached risks of unhygienic consumption.

Practice Food Safety

While it should go without saying, it’s still worth noting that you should be following all food hygiene standards alongside taking extra care with your 3D printed utensils.

Even after you’ve double-checked your equipment and ensured that you’re using a food safe 3D printer filament, keeping all workspaces clean and sanitary should take priority above all else. Prepare all your food as directed (wash vegetables, thoroughly cook white meats, etc.) and always put your health first.

Cooking tools you made yourself are fun to use, but getting to show off isn’t worth putting yourself, your family, and your friends at risk.

Other articles you may be interested in:

- The strongest 3D printer filaments

- The best 3D printer filament storage

- PLA vs PLA+ filament comparison

Consumables for FDM printing Plastic filaments

No matter how high-tech 3D printing is, 3D modeling is impossible without such an inexpensive component as consumables. Each 3D prototyping technology has its own pool of consumables - they are developed taking into account compatibility with printers, cost efficiency and quality of output 3D objects. Thus, industrial installations use powder materials, medical 3D printers are biocompatible and neutral, culinary ones work with a wide range of paste-like and viscous food compositions, and the most common in the segment of personal and semi-professional 3D equipment - with plastic thread and photopolymer resins. And since this segment is the most massive, it is on it that we will focus in the first place.

Each 3D prototyping technology has its own pool of consumables - they are developed taking into account compatibility with printers, cost efficiency and quality of output 3D objects. Thus, industrial installations use powder materials, medical 3D printers are biocompatible and neutral, culinary ones work with a wide range of paste-like and viscous food compositions, and the most common in the segment of personal and semi-professional 3D equipment - with plastic thread and photopolymer resins. And since this segment is the most massive, it is on it that we will focus in the first place.

Of course, you have already studied our range of consumables - in the 3DMall online store it is rightfully considered one of the most worthy and affordable in the whole country. Here you can buy consumables for FDM and other types of printers inexpensively with delivery in Moscow and Russia, including the possibility of picking up at one of the many points of issue. And our Knowledge Base and prompt free consultations with our experts on all issues related to 3D printing will help you make the right choice.

FDM consumables

Most modern personal printers are FDM units, which, like their consumables, are more than affordable. Today, such printers are available not only in offices, design and engineering offices, but also in the homes of many fans of maker and 3D technologies.

There are many varieties of plastics for 3D printing - a far from exhaustive list of materials includes PLA, ABS, PVA, Nylon, PC, HDPE, PP, PCL, PPSU, Acrylic, PET, HIPS, imitation wood, sandstone or metals, the characteristics of which we consider in more detail.

PLA - polyaktide

The undisputed leader of the modern market of consumables for FDM printers - an environmentally friendly, biocompatible, thermoplastic composition. Its production is based on corn and sugar cane, thanks to which products from this type of plastic are successfully used in everyday life. It is used for the manufacture of toys, dishes, souvenirs, housing elements for household appliances, designer models, food packaging, medicines, surgical thread, and due to its affordability, it is also used for education and hobbies.

Despite the high quality of the surface of PLA products, it is a stretch to call them practical - the material is quite soft and short-lived. The melting temperature is 170-180 about C, the glass transition process begins when cooled to 50 about C.

PLA has proven to be the best type of material for 3D printers with an open build chamber and a heated worktable.

Benefits include low shrinkage so finished objects do not deform during curing, ease of handling and versatility.

ABS

ABS, or acrylonitrile butadiene styrene, is the most popular heat-resistant plastic in the field of 3D prototyping, which, however, cannot be considered one of the most popular due to the fact that printing with its use is quite problematic.

Advantages - durability, mechanical strength, resistance to moisture, oils, a wide range of acids and elevated temperatures (it withstands heat up to 100-110 about C, responds well to staining). At the same time, some varieties are destroyed by prolonged contact with direct sunlight, and the melting point is about 180 about C - considered low for industrial use. When cooling, the object is subject to significant shrinkage - the first layers can twist, deform and crack. To avoid such problems, the use of ABS is recommended for printing on 3D printers with a heated desktop and a closed body. For a more reliable grip on the work surface, you should also use adhesive tape.

At the same time, some varieties are destroyed by prolonged contact with direct sunlight, and the melting point is about 180 about C - considered low for industrial use. When cooling, the object is subject to significant shrinkage - the first layers can twist, deform and crack. To avoid such problems, the use of ABS is recommended for printing on 3D printers with a heated desktop and a closed body. For a more reliable grip on the work surface, you should also use adhesive tape.

ABS products are absolutely safe at normal air temperatures, however, heat releases toxic acrylonitrile fumes, so it should not be used for printing toys, household items, dishes and food storage containers.

PVA - polyvinyl alcohol

A truly unique material for special applications. Its main feature is the ability to dissolve in water, which allows it to be used to build support structures (support for particularly filigree elements of the main object) when printing on printers with 2 extruders. The finished model after separation of the support does not require mechanical post-processing - its surface is smooth and of high quality.

The finished model after separation of the support does not require mechanical post-processing - its surface is smooth and of high quality.

The mechanical properties of this type of plastic are also interesting - in conditions of low humidity it has amazing strength, and with increasing humidity it becomes elastic, however, with a loss of strength. The melting temperature is 165-175 about C, which allows it to be used in combination with PLA and ABS plastics.

Before using PVA, it is recommended to dry it additionally (for example, in an oven) at a temperature not exceeding 80 C for 6-8 hours, even if it was stored in an absolutely sealed dry container.

Nylon

The main advantage of this material is its resistance to wear due to friction, which makes it very popular in various industries, in particular for coating parts as an alternative to lubrication.

Nylon thread is represented by a fairly large assortment, each variety has its own advantages and disadvantages. The most popular and practical are traditionally considered the nylon-66 created by DuPont in 1935 and its later analogue produced by BASF nylon-6. Their melting points are respectively 265 and 220 about C, which determines the features of their application.

The most popular and practical are traditionally considered the nylon-66 created by DuPont in 1935 and its later analogue produced by BASF nylon-6. Their melting points are respectively 265 and 220 about C, which determines the features of their application.

Key features - easily absorbs moisture, fuses with polyimide, which requires special care when choosing a printer, for a more secure fixation to the desktop, use wax-impregnated adhesive tape. Recommended for refilling printers with studded traction mechanisms as part of extruders, as well as for printing solid models, since nylon parts stick together very poorly.

PC - polycarbonate

The main advantages of polycarbonate plastic filament are its high strength and temperature resistance, it can be cooled and heated without the risk of deformation of the finished object, which cannot be said about the printing process itself. The melting temperature of the material is 265 about C, the safety requirements and risks of deformation during model building will help to optimize equipment with a closed print chamber and a heated platform. You should immediately pay attention to the risks - printing these materials is harmful to health, since bisphenol A, a potentially carcinogenic and toxic substance, is used in the process of its production.

You should immediately pay attention to the risks - printing these materials is harmful to health, since bisphenol A, a potentially carcinogenic and toxic substance, is used in the process of its production.

Due to its high hygroscopicity, RS should be stored in dry and fully sealed containers.

HDPE - High Density Polyethylene

This is one of the world's most sought after plastics for 3D printing. The material melts very easily and hardens in record time - the temperature difference between these processes is only 20-25 degrees, the average melting point is 130-145 about C. (hardening too fast), high shrinkage and deformation activity. The optimal solution for high quality HDPE printing results is high speed prototyping and careful temperature control of the build chamber and work platform to slow down the process of layer curing. However, HDPE is in the category of the cheapest consumables. It is used for the production of plastic bottles and containers, disposable tableware.

An interesting fact is that this type of plastic thread can also be made from plastic waste, there are even 2 professional installations that can cope with this task (universal processing machines FilaBot and RecycleBot.

PP - polypropylene

A versatile and inexpensive material used for production a wide range of plastic products - from dishes and packaging to pipes and fittings.The advantages of PP include low specific gravity, chemical resistance, non-toxicity, moisture resistance, wear resistance and low cost.Unstable with constant contact with direct sunlight and temperatures below -5 o C.

Print shrinkage is as high as 2.4%, 3 times greater than with ABS. Molten material adheres well even to a cold surface, but for high quality printing it is recommended to use equipment with a heated bed.

More popular than the original polypropylene is its imitation, developed by the world famous company Stratasys - Endur.

PCL - polyaprolactone

This is a low temperature biodegradable polyester that melts already at 60 about C, which requires a careful approach when choosing equipment for PLC printing - not all 3D printer models support this mode. Non-toxic - used in the field of medicine, has excellent plasticity, so it can be used an unlimited number of times.

Non-toxic - used in the field of medicine, has excellent plasticity, so it can be used an unlimited number of times.

High viscosity and low temperature resistance make this material unsuitable for functional prototypes and objects, but it is ideal for printing food containers and various layouts.

PPSU - polyphenylsulfone

Thermoplastic material with outstanding strength characteristics, in demand in the aviation industry. Chemically and thermally resistant, does not burn, does not deform in a wide temperature range (-50 o C ... +180 o C). It is used in the production of food containers, dishes, household items. Resistant to corrosion from solvents and household chemicals.

With all the advantages, it is used infrequently, since the melting point is 370 o C.

Acrylic - Plexiglas

Durable, environmentally friendly, moisture resistant material, characterized by excellent adhesion of layers in the prototyping process. The objects have a homogeneous flat surface and excellent performance properties. It is rarely used for FDM printing, as it is difficult to store and requires the highest construction accuracy, which is very, very difficult to achieve on a classic personal printer.

The objects have a homogeneous flat surface and excellent performance properties. It is rarely used for FDM printing, as it is difficult to store and requires the highest construction accuracy, which is very, very difficult to achieve on a classic personal printer.

Stratasys' VeroClear imitator, which is used in Objet Eden printers, is in much greater demand.

PET - polyethylene terephthalate

Food and medical containers are mainly made from this material with a very complex name. Its main advantage is its high chemical resistance, it is not subject to the damaging effects of a wide range of acids and alkalis, it is resistant to wear and a wide temperature range (-40 about C ... +75 about C). Shrinkage on cooling is about 2%, which, combined with a high melting point, reaching 260 about C, makes the printing process somewhat problematic. The transparency of the product is achieved by rapid cooling of the model to the glass transition threshold (+70-80 about C). In general, to obtain a consistently high-quality result, it is enough to create the same conditions as when printing ABS.

In general, to obtain a consistently high-quality result, it is enough to create the same conditions as when printing ABS.

HIPS Soluble Support Material

This is a polystyrene with amazing durability, used to produce real parts and components used in various industries in real use. It is also used for the manufacture of toys, disposable tableware, a number of building materials. In terms of physical properties (strength and durability), it is similar to ABS plastic, but it dissolves easily in limonene. This feature allows it to be used as a support material for printing ABS plastic products, in comparison with PVA it has a much lower cost and absolute insensitivity to water.

Printing is recommended in well-ventilated rooms, as toxic volatile substances may be released during melting.

Wood imitators

This category of consumables includes LAYWOO-D3 and BambooFill, products from which both visually and functionally are in no way inferior to analogues made of natural wood - the products even have a characteristic woody aroma. They do not deform and do not require the use of a heated platform. LAYWOO-D3, for example, is made from dusted sawdust and a non-toxic binder polymer, making it safe and highly post-processable.

They do not deform and do not require the use of a heated platform. LAYWOO-D3, for example, is made from dusted sawdust and a non-toxic binder polymer, making it safe and highly post-processable.

An interesting detail is that the use of nozzles with different heating parameters can achieve different decorative effects. For example, as the extrusion temperature increases, this type of material acquires a richer, darker hue.

The only negative is the high cost, which exceeds the price of PLA or ABS by almost 4 times.

Laybrick – sandstone simulant

We owe the appearance of this composite material with high aesthetic and performance characteristics to the inventor Kai Parti. By the way, LAYWOO-D3 is also his creation. The binder used as the basis for creating this type of material is mixed with a mineral filler - this explains the original texture of the resulting products.

Depending on the selected melting temperature, the surface of the products can be smoother or rougher (the higher it is, the greater the roughness).

One of the easiest materials to work with - it does not need a heated platform, it practically does not shrink or deform. The only drawback is the high cost compared to other filaments.

BronzeFill - metal simulant

Metal is the foundation of additive manufacturing, its use in 3D printing opens up almost unlimited possibilities for mankind. If not for the high cost, of course. Therefore, it is not surprising that a high-quality imitator, BronzeFill, has also been created for the followers of FDM printing. Products printed from it are not inferior to metal ones either visually or operationally.

This is an almost transparent PLA-based plastic, which also contains a bronze filler. Finished 3D objects respond well to post-processing - grinding, polishing - and visually look like all-metal, but you should not forget that thermoplastic is based on it.

How to choose printing plastic?

The choice of filament for printing should be determined by the following several parameters:

- the capabilities of the 3D printer at your disposal;

- requirements for surface quality, detailing accuracy and performance of finished products;

- color;

- scope.

We offer you a small comparison table on the key characteristics of the most popular types of plastic in personal 3D printing, which will help you choose the best option.

layer, °С

threads, mm

An important component when working with 3D printers and 3D pens are consumables.

An important component when working with 3D printers and 3D pens are consumables. The modern market offers a wide variety of 3D consumables. 3D plastic printing has become the most widespread in the world. All polymers differ in their technical characteristics and appearance, have their pros and cons. We will consider their advantages and features.

Main types of 3D plastics

PLA (Polylactide, PLA). One of the most famous types of plastic for 3D printing, which is made from raw materials of plant origin. The advantages include high environmental friendliness, no smell, smooth surface, stable dimensions. It has a low melting point and a low coefficient of interaction between various rubbing surfaces. Well suited for products that do not need to be used for a long time, decorative detailed objects.

ABS Inexpensive common impact-resistant material, which has excellent moisture resistance, heat resistance, good compatibility with all kinds of 3D printers. It has a fairly low stickiness, while being ideal for drawing on paper. This is what Lego bricks are made of. It is best to work with it in well-ventilated areas. Plastic is not suitable for food storage.

It has a fairly low stickiness, while being ideal for drawing on paper. This is what Lego bricks are made of. It is best to work with it in well-ventilated areas. Plastic is not suitable for food storage.

PET (Polyethylene terephthalate, PET, PET). Widely used in the food industry, especially in the production of plastic bottles. Strength and flexibility are similar to ABS plastic, however, it can shrink, which can deform the final product over time. The plastic is readily available, moreover, with the help of certain home processing machines (eg FilaBot) you can use the materials at hand to create your own thread.

PETG (Polyethylene glycol terephthalate). The most used plastic in the world: in clothing, food vessels and containers, industrial sheets and technical resins. Recently, 3D printing has become popular. It combines the properties of ABS (Strength, Heat Resistant, Durable) and PLA (Ease of Printing), the layers fuse very well and there is almost no distortion. In addition, this plastic is considered food safe. However, it scratches quite easily, and under the influence of ultraviolet light, its structure becomes slightly weaker.

In addition, this plastic is considered food safe. However, it scratches quite easily, and under the influence of ultraviolet light, its structure becomes slightly weaker.

PVA (Polyvinyl alcohol). Water soluble consumable. It is not suitable for durable products, however, it can help as a support material when printing models of complex geometric shapes. Its use is especially relevant for 3D printers with a dual extruder. The final product from 2 types of plastic can be placed in water for several hours, after which the PVA plastic will dissolve, and only a mold made from another insoluble plastic will remain. Plastic is quite expensive.

HIPS (Polystyrene, HIPS). Advanced polystyrene-based high-impact plastic. The main characteristics of plastic for 3 D printer include moisture resistance, high resistance to mechanical shock, acids and alkalis. The consumable is widely used for the manufacture of housings for household appliances, stationery and toys. It is recommended to print in a well-ventilated area, although it is quite safe and can even be used for food containers.

The consumable is widely used for the manufacture of housings for household appliances, stationery and toys. It is recommended to print in a well-ventilated area, although it is quite safe and can even be used for food containers.

NinjaFlex . Elastic modern material from the company Fenner Drives, which allows you to create quite flexible, elastic, deformable products. The most commonly used plastic for 3 D printer is used in the construction industry for the production of high quality seals. It is similar in structure to rubber or silicone, but is very tear-resistant and wear-resistant. Causes no difficulty in printing.

Laywoo - D3. Thermoplastic is interesting in that it is able to imitate wood when printed, thanks to the addition of microscopic wood particles, the volume of which is about 40%. The extrusion temperature ranges from 185°C to 230°C. At the same time, extrusion at low temperature gives light shades of wood, and at high temperature - dark colors. Finished products can be drilled, sanded, painted, varnished. There is no characteristic "plastic" smell and harmful fumes, which allows you to print food containers and toys. Produced by the German company RepRap GmbH, but it costs much more than PLA or ABS.

At the same time, extrusion at low temperature gives light shades of wood, and at high temperature - dark colors. Finished products can be drilled, sanded, painted, varnished. There is no characteristic "plastic" smell and harmful fumes, which allows you to print food containers and toys. Produced by the German company RepRap GmbH, but it costs much more than PLA or ABS.

Laybrick. Sandstone (chalk) imitation, similar to wood imitation in Laywoo-D3. The material is also unpretentious, does not require a high melting temperature with minimal shrinkage. The higher the melting temperature, the more rough the surface of the product will be. Very light weight and perfect for decoration. Easy to machine and paint. Non-toxic and safe for health. Requires long curing after printing (2-3 hours). The threads themselves can be quite fragile and require careful handling.

PC (Polycarbonate). 3D printing is just starting to gain popularity as technology improves. It has a high hygroscopicity, so before printing it is better to dry the thread for 8-10 hours at a temperature of 70 ° C to eliminate the risk of product deformation. The material itself is transparent and is often used as a substitute for ordinary glass. Pretty picky when printing. It's safe on its own, but it's best to print in a well-ventilated area.

It has a high hygroscopicity, so before printing it is better to dry the thread for 8-10 hours at a temperature of 70 ° C to eliminate the risk of product deformation. The material itself is transparent and is often used as a substitute for ordinary glass. Pretty picky when printing. It's safe on its own, but it's best to print in a well-ventilated area.

Nylon PA (Nylon). The use of nylon itself in simple 3D printing is difficult due to technological difficulties, however, special nylon filaments for 3D printers are already appearing (for example, from Taulman and Stratasys), which have high wear resistance and elasticity. The consumable has poor viscosity. It is recommended to dry the filaments before printing. Virtually ungluable.

SBS (SBS). Innovative copolymer model with high heat resistance and low stiffness. It is used in prototyping and designing light-transmitting products. Possesses high adhesion to pure glass and has excellent weldability of layers among themselves. There is no smell when printing, does not absorb moisture, low shrinkage, flexibility, almost completely transparent.

Possesses high adhesion to pure glass and has excellent weldability of layers among themselves. There is no smell when printing, does not absorb moisture, low shrinkage, flexibility, almost completely transparent.

POM (Polyformaldehyde). Features high strength, rigidity and good stability. Well transfers shock loadings, attrition, influence of organic solvents and oils. At the same time, it is quite well amenable to processing. Due to its physical harmlessness and resistance to disinfection and sterilization, it is often used in the production of food equipment and some types of dentures.

PMMA (Polymethyl methacrylate, or Acrylic glass). Industrial grade plastic. Most often used to create blanks in instrumentation, for theater and cinema scenery, art installations. To work with this plastic, you will need a special 3D printer with Binder Jetting printing technology - layer-by-layer bonding of plastic powder with a binder. After printing, plastic requires additional processing: drying in an industrial oven, blowing glue and impregnating with special substances.

After printing, plastic requires additional processing: drying in an industrial oven, blowing glue and impregnating with special substances.

When selecting plastic for 3 D -pen or printer, it is necessary to take into account both the features of the device itself and the operating conditions of the future 3D model. When starting work with 3D equipment, many people use ABS or PLA plastic. These are the most popular, budget consumables. To teach children how to work with a 3D printer or 3D pen, PLA plastic is most often used because of its cheapness, environmental friendliness and lack of smell when melted.

What can you create with 3D printer plastic?

- Toys for children and teenagers. Ideal for preschools where kids learn to make their own models of various cars, dolls and cartoon characters;

- Household items. Modern models of plastics allow you to create various finishing products that are widely used in the manufacture of furniture and in construction;

- Details of objects and parts of mechanisms.

With the help of 3D printing from the appropriate types of plastic, you can create various fasteners, locks and other small details of clothes, things and mechanisms that are sometimes difficult to just find and buy;

With the help of 3D printing from the appropriate types of plastic, you can create various fasteners, locks and other small details of clothes, things and mechanisms that are sometimes difficult to just find and buy; - Training layouts. With the help of modern devices and innovative consumables, you can create a variety of devices. This allows you to significantly save financial resources and increase the efficiency of the educational process.

Modern types of plastic products are widely used in 3D printing in the manufacture of advertising, souvenirs. Consumables can be presented in various designs: thermoplastics, plastic threads, granules, powders and all kinds of composite elements.

When ordering plastic for 3D printing, pay attention not only to the technical characteristics, but also to the safety and harmlessness indicators of , especially if you are going to purchase plastic for 3D printing for children.

Learn more