3D printed house 2023

2023 Could Be the Year of 3D Printed Homes in the US: Photos

2023 Could Be the Year of 3D Printed Homes in the US: Photos Search iconA magnifying glass. It indicates, "Click to perform a search". Insider logoThe word "Insider".US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right. Read in app Brittany Chang/Insider- Groundbreaking 3D-printed home construction projects are slated to finish in 2023.

- Using printers to build the walls of a home could reduce the project's build time, cost, waste, and required physical labor.

- The CEO of Alquist believes more homes will be printed than built traditionally by 2027.

Brick and wood framed homes are so 2022.

New US home sales dropped sharply in June, data showed on Tuesday. CHRIS DELMAS/Getty ImagesNext year, homes built using 3D printers could be the hottest trend in the home construction industry.

CPH-3D

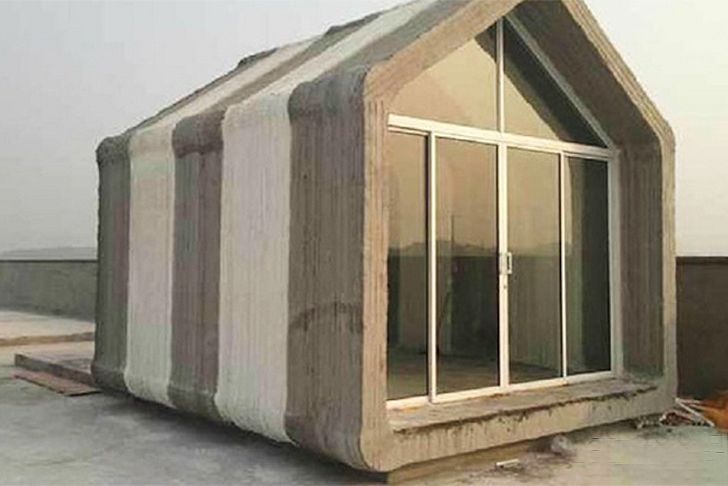

CPH-3D Throughout 2022, homes built using 3D printers have popped up across the world from a luxury house with printed walls in Austin, Texas …

Icon's over 2,000-square-foot House Zero in Austin. Brittany Chang/InsiderSource: Insider

… to a fully printed 400-square-foot concrete tiny home in Denmark.

3DCP Group

3DCP Group Source:Insider

And the momentum behind printed homes won't be slowing down in the new year.

3DCP GroupSeveral major 3D printing construction projects are slated to finish next year.

Azure Printed Homes

Azure Printed Homes And by the end of 2023, we could see people living in 3D-printed homes made of recycled plastic …

Azure Printed Homes… studying in printed schools …

BOTO FriddetThe housing market has been in flux over the last few years amid COVID-19, inflation, supply chain restraints, fluctuating demand, and rising interest rates.

People walk by a sold sign in front of a house along the Erie Canal in Pittsford, New York, on Monday, Sept. 6, 2021. Ted Shaffrey/AP Photo

People walk by a sold sign in front of a house along the Erie Canal in Pittsford, New York, on Monday, Sept. 6, 2021. Ted Shaffrey/AP Photo A 3D printer can't solve all of these problems.

Aiman HusseinBut proponents of the construction tech — like Zack Mannheimer, CEO of 3D printing construction startup Alquist — believe printing may alleviate some of the sore spots in the traditional home building process.

Alquist

Alquist Source: Insider

Using 3D printers to build houses reduces the time, cost, waste, and physical labor needed to construct a home.

The 3D printer. IconIn the future, these cuts will be more dramatic.

3DCP Group

3DCP Group But as of now, many companies have yet to achieve what they say will be the full potential of the nascent technology.

HannahAnd the majority of startups are only printing the layered walls, leaving the remainder of the home to be built "traditionally" …

The site of the 3D-printed home. Habitat for Humanity

Habitat for Humanity … although this is already making the building process "radically faster and meaningfully cheaper," Jason Ballard, the cofounder and CEO of 3D printing construction startup Icon, told Insider in March.

Icon's over 2,000-square-foot House Zero in Austin. Brittany Chang/InsiderSource: Insider

A traditional construction project that takes six to seven months to build can currently be completed in five to six months using a printer, Mannheimer told Insider in May, noting that the goal is a four-month timeline.

Alquist

Alquist And as of now, printed homes are only marginally more affordable than traditionally built homes.

IconBut these prices could continue to drop as more construction companies scale the use of 3D printers, Mannheimer said.

3DCP GroupAnd if his projections are correct, we could see 3D printers at every construction site by 2025.

3DCP Group

3DCP Group As of now, the industry-wide integration of 3D printing construction tech may be hard to believe.

3DCP GroupBut in 2023, we could begin to see the start of this rapid shift toward printed buildings.

Icon's over 2,000-square-foot House Zero in Austin. Brittany Chang/Insider

Icon's over 2,000-square-foot House Zero in Austin. Brittany Chang/Insider Alquist has plans to build 200 concrete homes in southwest Virginia within the next five years.

AlquistSource: Insider

And the company is working with Muscatine, Iowa, and the city's local organizations to print a collection of 10 homes next year, Marci Clark reported for KWQC.

Alquist

Alquist Source: KWQC

On the West Coast, Los Angeles-based Azure will begin delivering its accessory dwelling units (ADUs) printed using recycled plastic in 2023 …

Azure Printed HomesSource: Insider

… which will include 10 rental homes throughout California's Los Angeles and Orange County.

Azure Printed Homes

Azure Printed Homes Source: Insider

Similarly, Tampa, Florida startup CPH-3D (Click, Print, Home) and Alquist will begin construction on a home that's been listed at nearly $600,000.

CPH-3DSource: Insider

The project has yet to find a buyer. But Matt Gibson, the listing agent and founder of CPH-3D, says the home will be sold and completed in 2023.

CPH-3D

CPH-3D And reservations for these homes — which will start in the mid-$400,000s — will open in 2023 as well.

A rendering of the upcoming 100-home community. Icon, Lennar, BIGSource: Insider

But this printing application is slated to extend beyond homes in the new year.

Thinking Huts

Thinking Huts Nonprofit Thinking Huts is using 3D printers to build schools in countries that need them the most.

Thinking HutsSource: Insider

In 2022, seven years after the nonprofit was founded, the team completed its first prototype school in Madagascar.

Thinking Huts

Thinking Huts Compared to traditional homebuilding, this construction technology is still relatively nascent.

3DCP GroupBut with all these projects slated to enter the market in 2023, it seems like we're at the precipice of a 3D-printed home boom.

Alquist

Alquist And by 2027, Mannheimer believes more homes will be printed than built traditionally.

Icon"I don't want to build a worse world faster and cheaper," Ballard said. "I want to build a better world faster and cheaper.

" Icon

" Icon Source: Insider

Read next

3D Printing 3d printed home Real EstateMore...

The Genesis Collection – ICON

Homes at Wolf Ranch

Built by ICON and Lennar, one of the nation’s leading homebuilders, and co-designed by BIG-Bjarke Ingels Group, the innovative community of one hundred 3D-printed homes feature eight floorplans, 24 elevations, and will be powered by the sun with rooftop solar panels.

03 Bedrooms | 02 Baths | 1,574 Sq Ft

This stylish single-story home located in the incredible community of Wolf Ranch has 3 bedrooms, 2 bathrooms, and boasts more than 1,500 square feet of living space, a rear patio and an open floor plan for entertaining. The primary suite sits off the living area, and includes a beautiful walk-in closet, a double vanity, a standalone tub and shower.

Learn More

03 Bedrooms | 02 Baths | 1,781 Sq Ft

The perfect home for entertaining, Genesis 02 has an open floor plan that allows you to see your guests or family across the kitchen, living and dining spaces. This spacious 3-bedroom, 2-bathroom single-story home features a large walk-in closet in the primary suite, as well as a double vanity, a standalone tub and shower.

This spacious 3-bedroom, 2-bathroom single-story home features a large walk-in closet in the primary suite, as well as a double vanity, a standalone tub and shower.

Learn More

03 Bedrooms | 02 Baths | 2,014 Sq Ft

A private primary bedroom retreat anchors this home and provides a sanctuary with its own patio. The focal point of the home is the open kitchen, which connects to both the living and dining spaces—a host’s dream. The 3-bedroom, 2-bath home offers ample closet space, large windows and a spacious kitchen island.

Learn More

03 Bedrooms | 02 Baths | 1,977 Sq Ft

Genesis 04 is a 3-bedroom, 2-bath home with nearly 2,000 square feet of living space, in addition to a 385-square-foot outdoor patio. Large sliding doors off the living room allow you to bring the outdoors in. The primary bedroom offers a large walk-in closet.

Large sliding doors off the living room allow you to bring the outdoors in. The primary bedroom offers a large walk-in closet.

Learn More

04 Bedrooms | 02 Baths | 1,993 Sq Ft

This 4-bedroom, 2-bathroom home is perfect for those looking for larger space. It boasts more than 2,000 square feet of living space and flex spaces that could be used for a home office—or even two. The primary suite sits towards the rear of the house, offering privacy for its occupants. The gorgeous en-suite bathroom features a large walk-in closet.

Learn More

03 Bedrooms | 02 Baths | 2,010 Sq Ft

Genesis 06 has an open-concept living room attached to a spacious patio, allowing for both indoor and outdoor entertaining. Large glass sliding doors allow the space to fill with natural light or close out the outside world. The home offers 2,000+ square feet of living space with an open-concept kitchen.

Large glass sliding doors allow the space to fill with natural light or close out the outside world. The home offers 2,000+ square feet of living space with an open-concept kitchen.

Learn More

04 Bedrooms | 03 Baths | 2,031 Sq Ft

Genesis 07 is a 4-bedroom, 2.5-bath with ample living space for homeowners. The open kitchen sits between living and dining spaces, allowing for seamless transitions and entertaining.

Learn More

04 Bedrooms | 03 Baths | 2,112 Sq Ft

A 4-bedroom, 3-bathroom home, The Genesis 08, offers over 2,000 square feet of living space. The front door allows for side entry and greater privacy in the home. Upon entering the foyer, there is a separation between living and dwelling spaces. This home offers a large, open kitchen and dining space with an adjacent living room and access to the outdoors.

The front door allows for side entry and greater privacy in the home. Upon entering the foyer, there is a separation between living and dwelling spaces. This home offers a large, open kitchen and dining space with an adjacent living room and access to the outdoors.

Learn More

Reservations Begin 2023Get On The List

CyBe will build a four-story 3D printed building

News

Subscribe to the author

Subscribe

Don't want

Dutch construction company CyBe Construction intends to build a four-story house using a 3D printer of its own design. The project is being implemented in Eindhoven, a kind of European capital of building additive technologies.

Apparently, this building will not become a record. The tallest building printed directly on top of the foundation is a recently completed three-story villa in Saudi Arabia built by Danish company COBOD. CyBe is going to build a four-story building, but with workshop 3D printing and subsequent assembly of blocks on the construction site. In this direction, the record belongs to the Chinese company WinSun, which demonstrated a prefabricated five-story house back in 2015. nine0003

CyBe is going to build a four-story building, but with workshop 3D printing and subsequent assembly of blocks on the construction site. In this direction, the record belongs to the Chinese company WinSun, which demonstrated a prefabricated five-story house back in 2015. nine0003

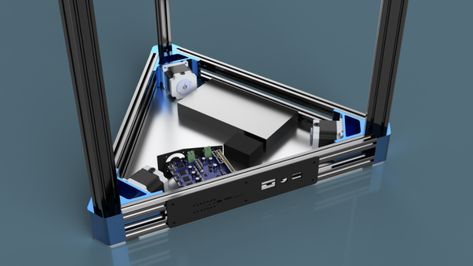

The blocks are planned to be made on the CyBe G portal additive system, although the company has much more original solutions like the CyBe RC mobile 3D printer, a robotic arm on a caterpillar platform that allows you to move from place to place after the completion of the next 3D printed block.

The new project will use a manufacturing method called Prefabricated Prefinished Volumetric Construction, which involves shop-floor fabrication, finishing, and fitting out modules—from individual blocks to entire rooms—before being sent to the construction site for assembly into the building. While the CyBe G 3D printer can be set up outdoors, the company prefers shop floor 3D printing as it makes it easier to work in harsh environments and thus helps to achieve higher quality and productivity. nine0003

nine0003

CyBe Construction boasts several projects including the first 3D printed residential building in Saudi Arabia, a 3D printing and robotics lab for the Dubai Electricity and Water Authority, and a showcase building at the Salon Internazionale Del Mobile Milan furniture show ( in the picture above ).

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected]. nine0028

building CyBe

Follow author

Follow

Don't want

Article comments

More interesting articles

nine

Subscribe to the author

Subscribe

Don't want

Students-teachers, psychologists, engineers and designers together with the prototyping laboratory of Novgorod. ..

..

Read more

7

Subscribe to the author

Subscribe

Don't want

What do plastic fish eat? Plastic, of course. British student Eleanor McIntosh won...

Read more

59

Follow the author

Subscribe

Don't want

The 3Dtoday portal, supported by Creality and Bestfilament, invites everyone to participate in...

Read more

Read blogs

Building 3D printing in anticipation of a breakthrough / Habr

Technology -printing originated in the 80s of the 20th century, but construction 3D printing appeared much later. The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003

They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003 Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

nine0003

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0003

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now? nine0096

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself. The issue of regulation and certification also plays an important role - this process is long and creates an additional lag. nine0107

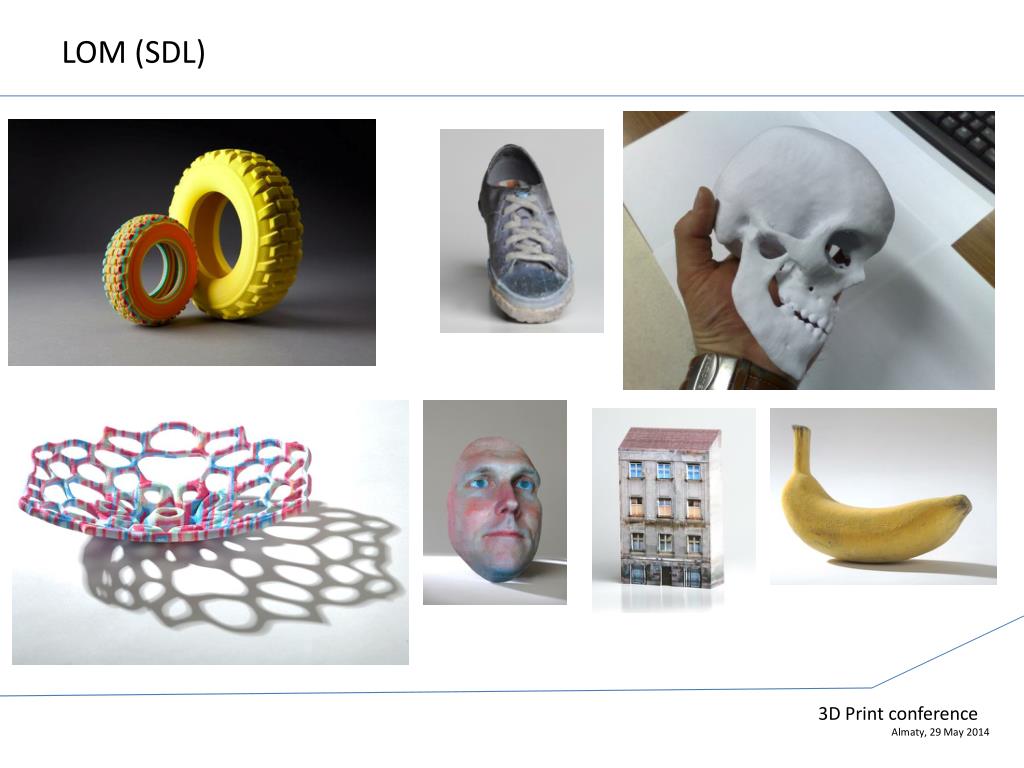

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared.

The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared. nine0107

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations.

In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry. nine0107

Thus, I believe that the specified time period is a fairly natural cycle of the formation of technology, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, an increase of 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

nine0003

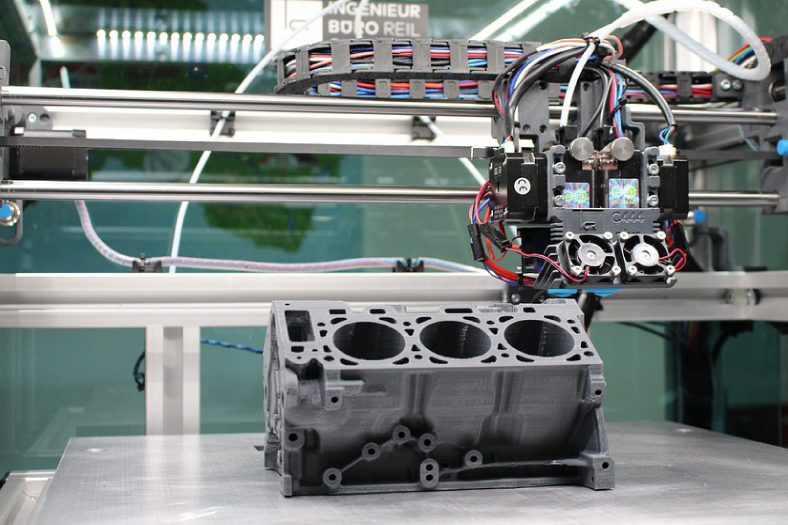

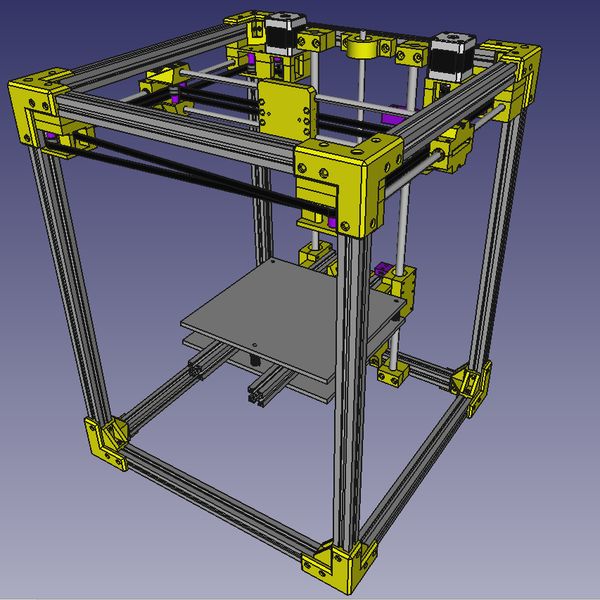

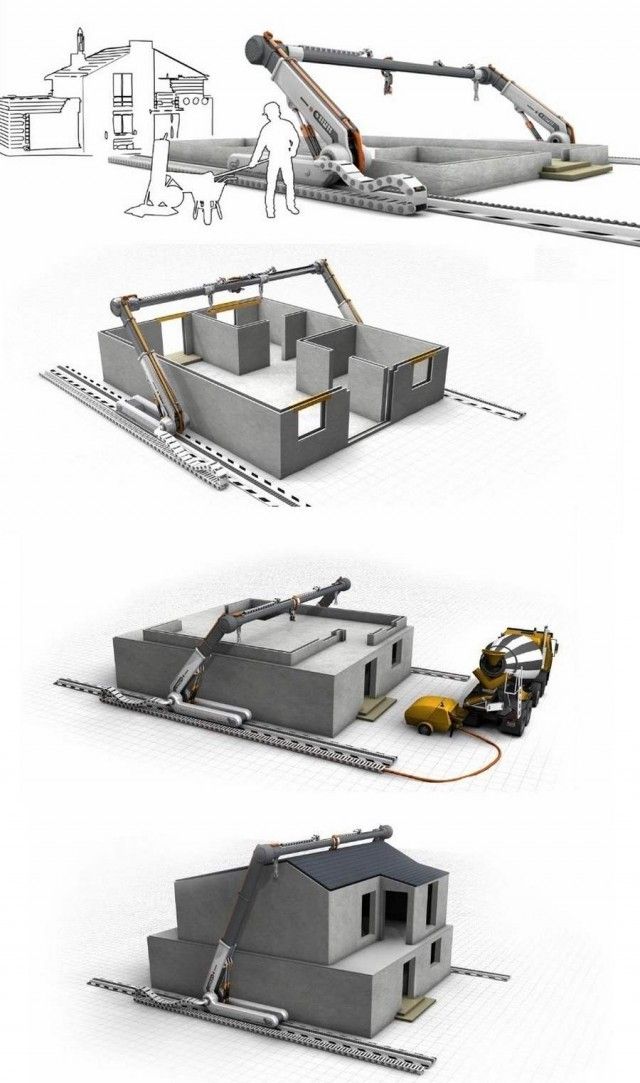

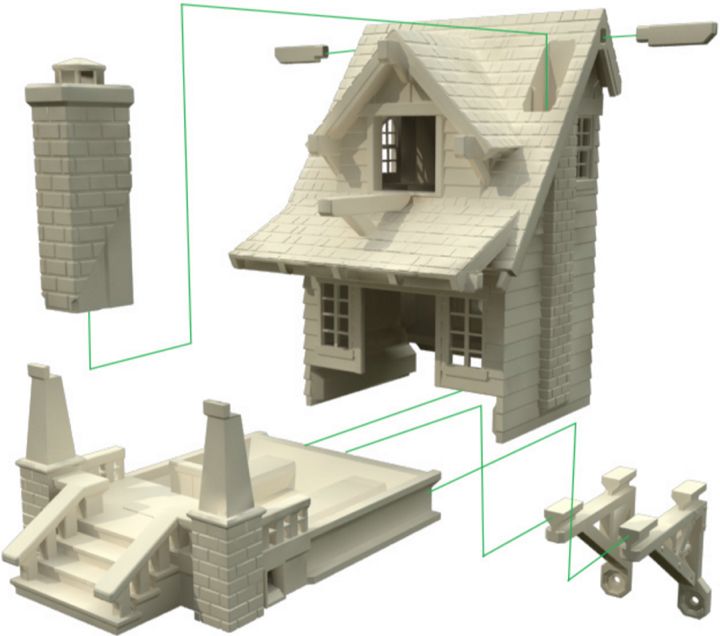

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds. nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but The lack of affordable housing is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

At the same time, the trend towards “green agenda ”, CO2 emission reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0003 3D printed walls.

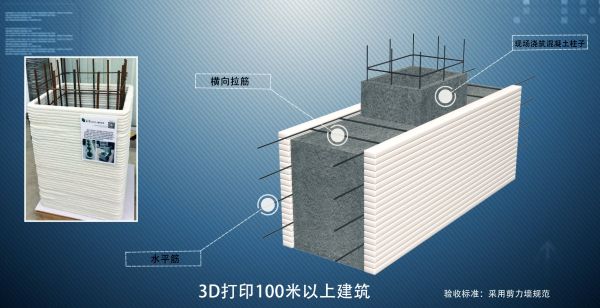

Today, when we talk about 3D printing of houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used, which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

eco-concrete with the addition of polymers is currently being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds. nine0003

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany. nine0003

"There are spots on the sun." Despite all the advantages of building 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0003

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

nine0003

nine0003

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0003

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop.