2Nd dynasty 3d print

2nd Dynasty - Tabletop Analytics

2nd Dynasty

| Activity | Projects | Revenue | Pledges | Avg. Pledge | Links |

|---|---|---|---|---|---|

| 2017 - 2022 | 8 | $414,809 USD | 4,529 | $92 USD | |

| 2nd Dynasty focuses on bringing our original, nostalgic-inspired sci-fi designs to life on your 3D printer! We got our start in 3D animation and visualisation using Maya, and now continue that tradition through hand-crafting our ships and terrain for home 3D printing. | |||||

Projects

Free Trader Beowulf Starship

A project in Vänersborg, Sweden by 2nd Dynasty 8 created

AccessoryMiniaturesSTL

Officially licensed Deck Plans and 3D printable 28mm starship from the Traveller RPG universe

Duration: 2022/10/22 - 2022/11/18 (26 days)

67,392 EUR

of 25,000 EUR Goal

629

Backers

107 EUR

Avg. Pledge

View Stats

Visit Project

| 67,392 EUR of 25,000 EUR Goal | 629 Backers | 107 EUR Avg.Pledge |

View Stats Visit Project

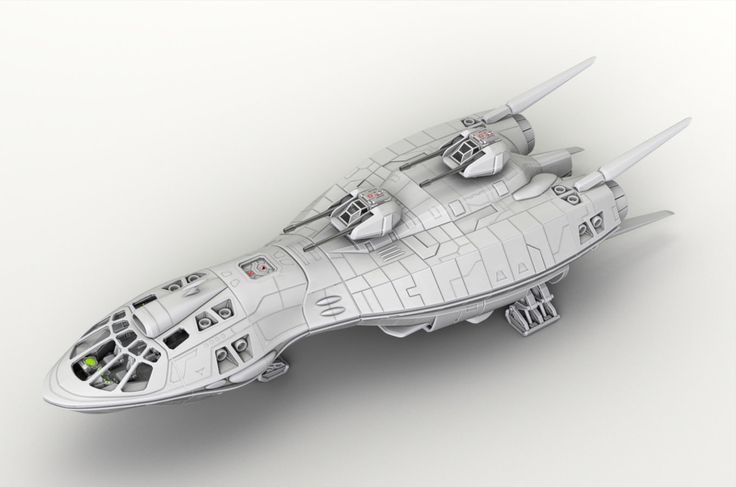

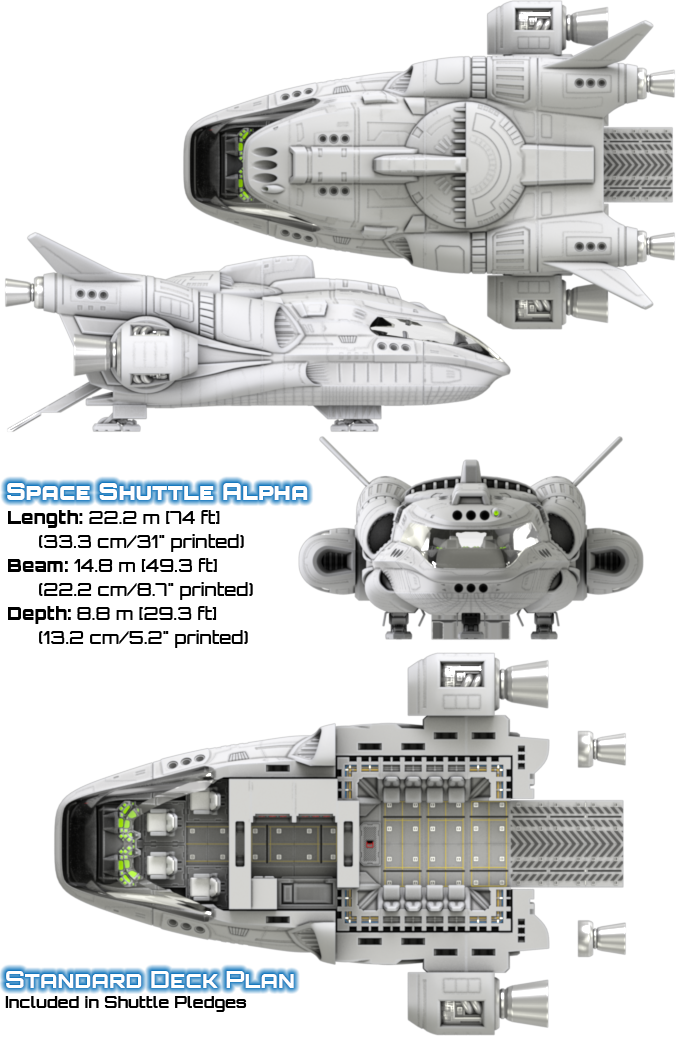

Shuttle Alpha Mk IV

A project in Vänersborg, Sweden by 2nd Dynasty 8 created

AccessoryMiniaturesSTL

2022 edition of our flagship 28mm OpenLOCK-compatible 3D printable aerospace vehicle

Duration: 2022/07/04 - 2022/07/18 (13 days)

19,161 EUR

of 5,000 EUR Goal

539

Backers

36 EUR

Avg.Pledge

View Stats

Visit Project

| 19,161 EUR of 5,000 EUR Goal | 539 Backers | 36 EUR Avg.Pledge |

View Stats Visit Project

Traveller RPG Starship Miniatures

A project in Trollhattan, Sweden by 2nd Dynasty 8 created

AccessoryMiniaturesSTL

Officially Licensed 3D-Printable Miniatures for the Traveller Universe. Ideal first time 3D printing project for Starship fans.

Ideal first time 3D printing project for Starship fans.

Duration: 2021/11/02 - 2021/11/22 (19 days)

63,638 EUR

of 4,500 EUR Goal

780

Backers

82 EUR

Avg.Pledge

View Stats

Visit Project

| 63,638 EUR of 4,500 EUR Goal | 780 Backers | 82 EUR Avg.Pledge |

View Stats Visit Project

13741% |

Starship V - Sleipnir, Crew Miniatures and Deck Designer

A project in Vänersborg, Sweden by 2nd Dynasty 8 created

AccessorySci-fiMiniatures

A highly detailed 28-mm-scale 3d-printable spaceship, crew miniatures and print planning tools for your home 3D printer

Duration: 2020/09/08 - 2020/10/04 (25 days)

687,067 SEK

of 5,000 SEK Goal

921

Backers

746 SEK

Avg. Pledge

Pledge

View Stats

Visit Project

| 687,067 SEK of 5,000 SEK Goal | 921 Backers | 746 SEK Avg.Pledge |

View Stats Visit Project

11669% |

Starship IV Chimera - Modular 3D Printable 28mm Spaceship

A project in Trollhattan, Sweden by 2nd Dynasty 8 created

AccessorySci-fiMiniatures

Complete 28mm scale 3D printable spaceship for tabletop play or display, including full OpenLOCK-compatible modular interiors

Duration: 2019/10/22 - 2019/11/22 (30 days)

583,493 SEK

of 5,000 SEK Goal

554

Backers

1,053 SEK

Avg.Pledge

View Stats

Visit Project

| 583,493 SEK of 5,000 SEK Goal | 554 Backers | 1,053 SEK Avg.  Pledge Pledge |

View Stats Visit Project

12214% |

Starship III - Fully 3D Printable 28mm Spaceships

A project in Trollhattan, Sweden by 2nd Dynasty 8 created

AccessoryMiniaturesSTL

Complete 28mm scale 3D printable spaceships for tabletop play or display, including full OpenLOCK-compatible modular interiors.

Duration: 2019/01/15 - 2019/02/15 (30 days)

610,723 SEK

of 5,000 SEK Goal

606

Backers

1,008 SEK

Avg.Pledge

View Stats

Visit Project

| 610,723 SEK of 5,000 SEK Goal | 606 Backers | 1,008 SEK Avg.Pledge |

View Stats Visit Project

Starship II - 3d printable OpenLOCK-compatible Deck Plans

A project in Trollhattan, Sweden by 2nd Dynasty 8 created

AccessoryMiniaturesTerrain

Build your own Starship layout using OpenLOCK-Compatible parts. Ideal for tabletop wargames and RPGs such as Starfinder, etc.

Ideal for tabletop wargames and RPGs such as Starfinder, etc.

Duration: 2018/04/10 - 2018/05/11 (30 days)

256,329 SEK

of 5,000 SEK Goal

248

Backers

1,034 SEK

Avg.Pledge

View Stats

Visit Project

| 256,329 SEK of 5,000 SEK Goal | 248 Backers | 1,034 SEK Avg.Pledge |

View Stats Visit Project

Starship - 3d printable OpenLOCK-compatible Deck Plans

A project in Trollhattan, Sweden by 2nd Dynasty 8 created

AccessoryTerrain

Build your own Starship layout using OpenLOCK-Compatible parts. Ideal for tabletop wargames and RPGs, etc.

Duration: 2017/09/05 - 2017/10/06 (30 days)

141,377 SEK

of 5,000 SEK Goal

252

Backers

561 SEK

Avg.Pledge

Visit Project

| 141,377 SEK of 5,000 SEK Goal | 252 Backers | 561 SEK Avg.  Pledge Pledge |

Visit Project

Facebook Feed

Terms & Conditions - Contact Us - Advertise - Widgets - Facebook

Powered by The Hive

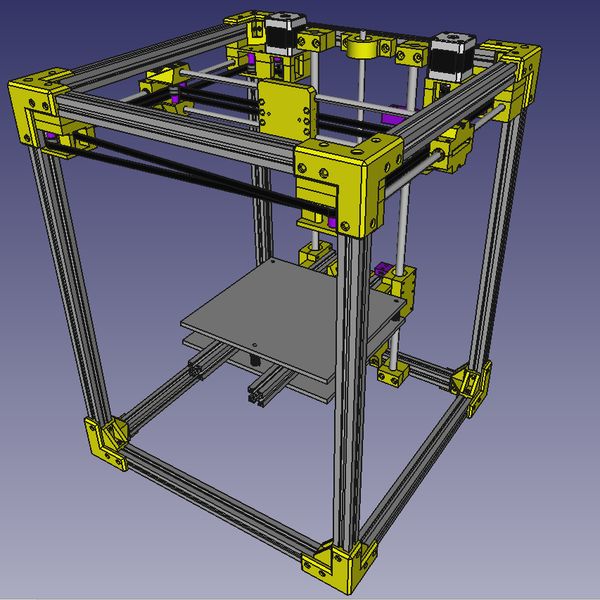

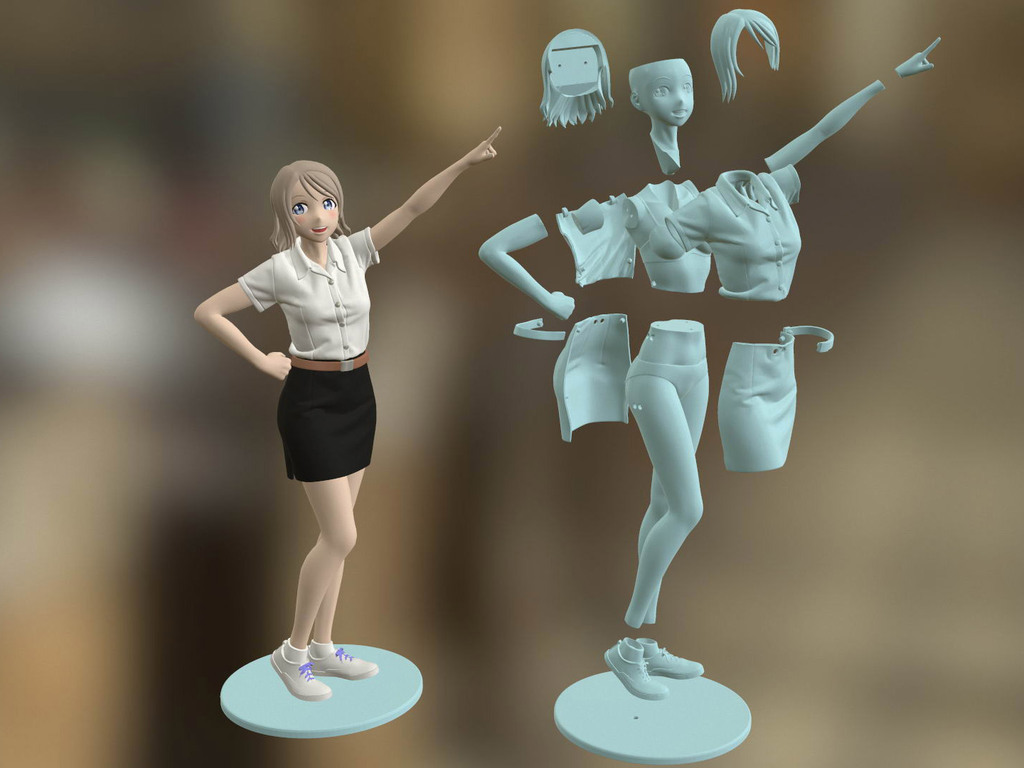

3Dio by 2nd Dynasty

3Dio is the must have 3D printing helper. Plan out and get print lists and assemble for your next game!

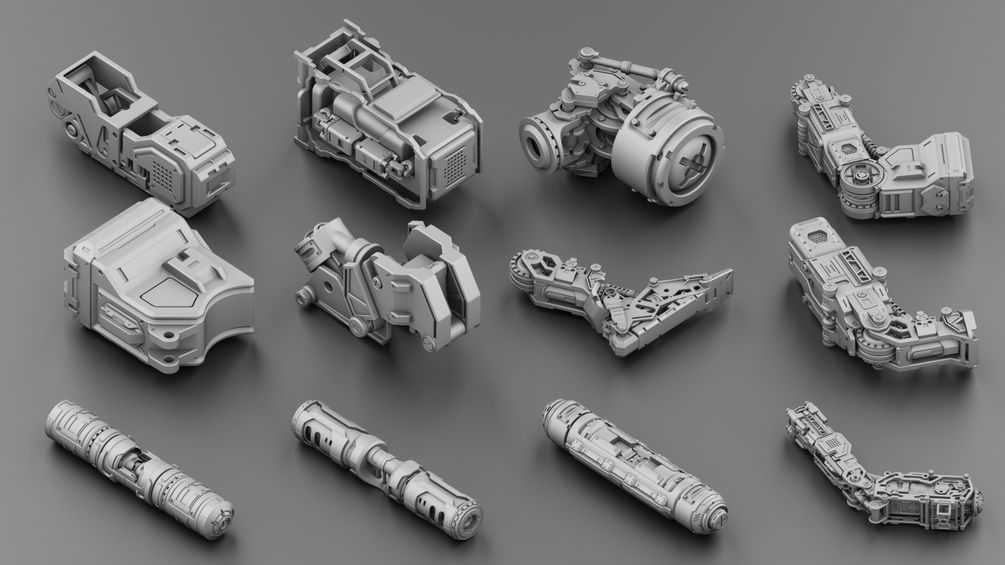

This tool is also perfect for 2ND Dynasty 3D printable spaceships with hundreds of individual 3D model files. With so many parts it can be difficult keeping track or customizing your own ship. 3Dio will help you along the way and includes 3d animated build instructions that let you pause and hover items to get what the parts are. Plus the File>Export command automatically moves the STL files to a ready to prep folder.

Type S ship from 2ND DynastyVisualize your print builds and plan with both 2ND Dynasty and other STL models.

- Easy-to-use animated build instructions for ships

- Plan out your own ship

- Import your own STL models with easy snapping helpers for open lock.

3Dio is NOT a slicer or 3D modelling program. It takes existing models and creates print lists you can use as a guide for printing.

Built in are hundreds of STL files grouped into bundles, some bundles have various ships, and some are still in progress. Refer to the table below to learn if your favorite items are available.

| Bundle | Sample Levels | Animated Instructions |

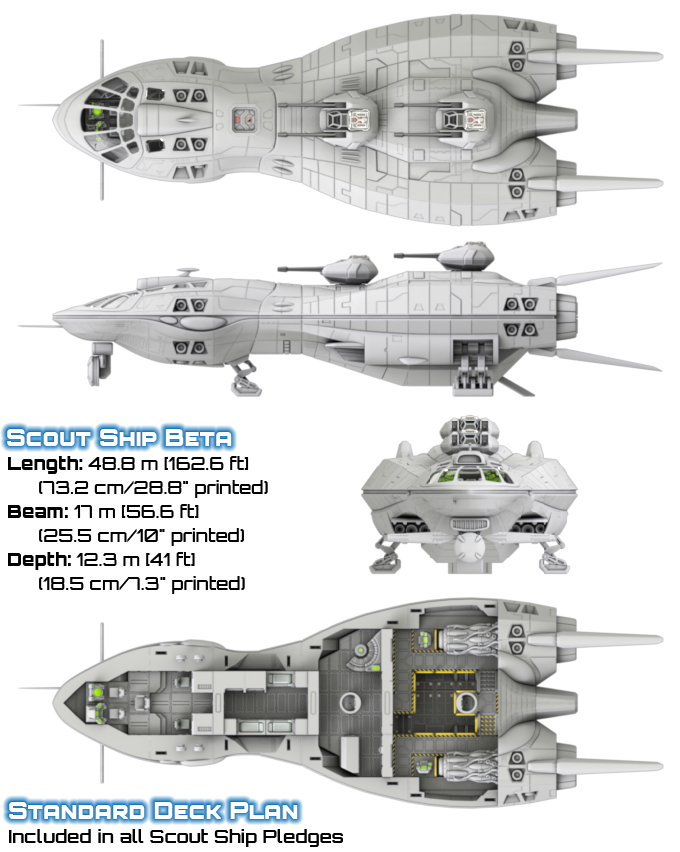

| Scout Ship Beta Centauri | 1 | ✔ |

| Chimera Cerberus | 1 | ✔ |

| Chimera | 1 | ✔ |

| Chimera Pegasus | 1 | ✔ |

| Sleipnir | 10 | ✔ |

| Alpha Shuttle MKIV | 1 | ✔ |

| Starfighter Modular System | 9 | ✔ |

| Starship Tiles TNG | ||

| Transport Delta | 1 | ✔ |

| Type J Seeker | 1 | ✔ |

| Type S | 1 | ✔ |

| Quest Dungeon Preview |

3Dio is still in Development

Currently, many aspects of the interface are still in flux. We appreciate feedback and are still working on this software. Right now, it works best with bundles downloadable inside the program.

We appreciate feedback and are still working on this software. Right now, it works best with bundles downloadable inside the program.

All versions require the internet to download bundles, but will happily work offline for as long as you need.

Mac has a known bug that prevents it from launching. Here is the work around:

- Download and install the itch app: https://itch.io/app

- Open and use it to launch 3Dio.

Need help? Get Support through Discord or Email

Purchase

In order to download this tool you must purchase it at or above the minimum price of $19.50 USD. You will get access to the following files:

Development log

- More Bundles coming your way

55 days ago

- Recover Mode and Linux Bug Fixes

69 days ago

- Auto Save and UX changes.

91 days ago

- 3D Gizmo and Rotation Sensitivity

Sep 19, 2022

- Fix for asset importer and UI freze.

Sep 12, 2022

- Moving from ".json" to ".3Dio" (1.238.3216)

Aug 31, 2022

- Reorderable Collections (1.238.3216)

Aug 27, 2022

- 1.234.4647 Bugfix

Aug 23, 2022

View all posts

90,000 Qin Dynasty 3D Printing, MakerBot's New Adventures, and More News of the Week!News

Subscribe to the author

Subscribe

I do not want

7

Makerbot to the production of 3D printers

Until recently, in 2013, the legendary company Makerbot bathed in the rays of Glory and rested on the laurels. With the successful Replicator 2 3D printer on hand and a growing stream of orders, MakerBot opened its own factory in Brooklyn. Then disaster struck: the scandal with the raw fifth generation seriously tarnished the company's reputation, and its founder, Bree Pettis, moved to Stratasys, and then completely left the big stage. MakerBot began reshuffles and mass layoffs. Now the company has broken another bottom, announcing the cessation of production of "replicators" in New York. nine0003

MakerBot began reshuffles and mass layoffs. Now the company has broken another bottom, announcing the cessation of production of "replicators" in New York. nine0003

Like a true manager, MakerBot CEO Jonathan Jaglom keeps a good face on a bad game. The 3D printers will be manufactured by the international company Jabil Circuit, which provides contract manufacturing services for electronics. According to Jaglom, “Working with Jabil will enable us to better position ourselves in a rapidly changing marketplace and reduce production costs in order to become more competitive on the global stage. We expect that a more flexible manufacturing model will allow us to quickly change production volumes based on current demand and without the constant costs of running a factory in New York.” nine0003

In simple terms, this means that MakerBot is shutting down facilities in an area of 20,000 square meters. meters and transfers production abroad - where exactly, you have to choose Jabil. Most likely to China or Malaysia. For the company's employees, this means another wave of mass layoffs, but apparently, MakerBot has no other choice. Despite the company's claims of commitment to the "Brooklyn culture", localized production can not afford it, and the company somehow needs to be saved. At least, there should be no problems with production in China, because craftsmen from the Celestial Empire have been successfully stamping clones of "replicators" for so long and successfully. nine0003

Most likely to China or Malaysia. For the company's employees, this means another wave of mass layoffs, but apparently, MakerBot has no other choice. Despite the company's claims of commitment to the "Brooklyn culture", localized production can not afford it, and the company somehow needs to be saved. At least, there should be no problems with production in China, because craftsmen from the Celestial Empire have been successfully stamping clones of "replicators" for so long and successfully. nine0003

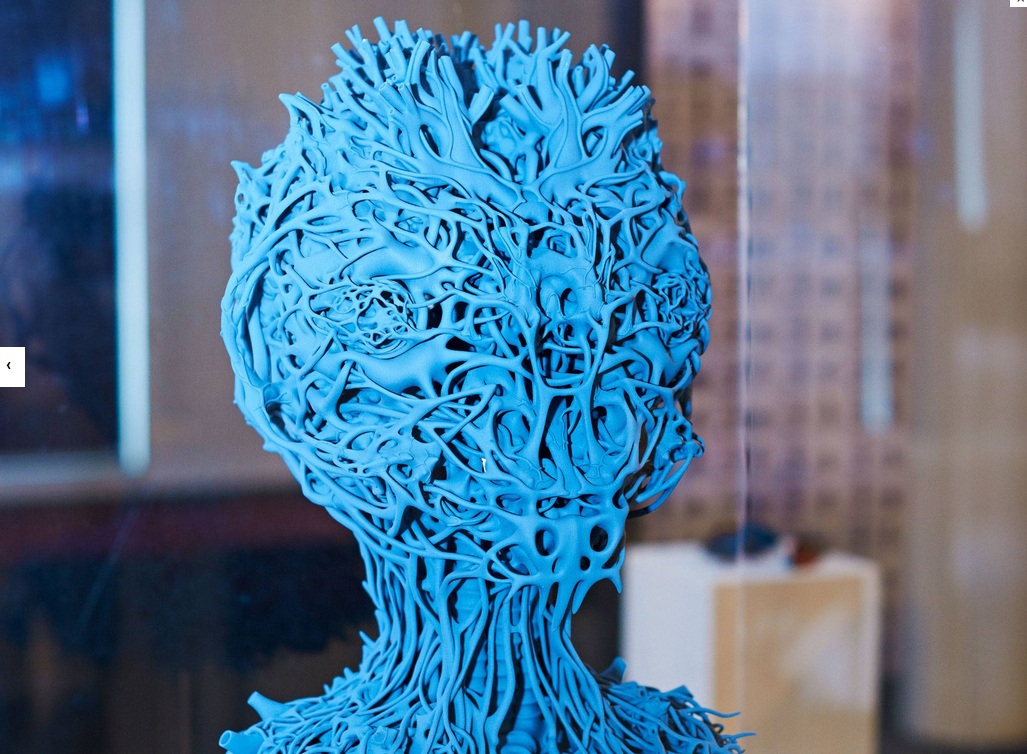

In the best imperial tradition

Polymaker has come up with a great demonstration of what Polysher can do, a 3D printed aerosol smoothing machine. To do this, the developers invited an artist named Tian Tian. The object of the demonstration was a 3D printed vase processed with Polysher and hand painted by the artist in the style of the Qin Dynasty.

School of Design and Digital Arts at Shanghai Aurora College. The artist has a particular fondness for antique vases. The vases of the Qin Dynasty date back to the 13th century, and the delicate decorations were created with careful strokes of a fine brush. The smoothness of the vessels is of great importance, since any irregularities can distort the movement of the brush and ruin the drawing. Of course, in the case of raw 3D printed models, layering leads to just such difficulties, but after smoothing the vase in Polysher, the artist managed to achieve the desired result. nine0003

The vases of the Qin Dynasty date back to the 13th century, and the delicate decorations were created with careful strokes of a fine brush. The smoothness of the vessels is of great importance, since any irregularities can distort the movement of the brush and ruin the drawing. Of course, in the case of raw 3D printed models, layering leads to just such difficulties, but after smoothing the vase in Polysher, the artist managed to achieve the desired result. nine0003

What's more, Tian Tian liked the idea of creating art with 3D printing: "When I decorate a vase created by another designer, there always comes a point where I can't fully express myself in the drawing." Very Zen, Tian. However, the popularity of Polysher is also ensured in the Russian market. Read more about Polysher here.

With the breeze and without the cortege

Holland is remarkable not only for its love of bicycles and 3D printing, but also for the fact that all segments of society are exposed to this love. So Economics Minister Henk Kamp could not resist the opportunity to ride a 3D printed bike. A two-wheeler called Arc Bicycle was printed by a team of students from the Delft University of Technology with the help of technical experts from MX3D. nine0003

So Economics Minister Henk Kamp could not resist the opportunity to ride a 3D printed bike. A two-wheeler called Arc Bicycle was printed by a team of students from the Delft University of Technology with the help of technical experts from MX3D. nine0003

The run-in took place during the Innovation Expo in Amsterdam, where more than two hundred innovations were showcased. More than 4,000 entrepreneurs and academics, as well as about 70 ministers from all over the European Union, came to the exhibition. MX3D, a start-up that builds the world's first 3D printed bridge and, at its leisure, helps students make bicycles with its 3D printed welder robot, was also featured.

The bike weighs about the same as a regular steel frame version. “It was important for us to create a functional object that people use on a daily basis. Since we are students in the Netherlands, the idea of a 3D printed bicycle came to our minds. The bike frame serves as a good demonstrator due to multidirectional loads,” explains one of the designers, Stef de Groot. Someone who, but Minister Kamp appreciated the project at its true worth. As for MX3D, their project to 3D print a canal bridge in the center of Amsterdam is due to be completed in 2017. nine0003

Someone who, but Minister Kamp appreciated the project at its true worth. As for MX3D, their project to 3D print a canal bridge in the center of Amsterdam is due to be completed in 2017. nine0003

REC takes Europe by storm

The Russian company REC signed an agreement to supply consumables to the German retailer iGo3D. The agreement was reached at the Hannover Messe industrial fair taking place these days. This time we are talking about 20 tons of branded filament, which is very popular in the domestic market.

“Due to the popularity of the brand and the high quality of the products, demand is growing rapidly. Today, together with German partners, we are signing an agreement for the supply of our products. This contract and the growth of the market as a whole will allow our company to expand production and increase its share in the European market,” commented Nikita Gavrilov, CEO of REC. nine0003

nine0003

Subscribe to the author of

Subscribe

labor-intensive process with a rather high rejection rate, but its efficiency can be improved with the help of 3D printing technologies. We share an example.

Chinese porcelain is known throughout the world for its beauty, and elegant Song Dynasty style ceramics made in "official" kilns are especially prized. The first such ovens were personally designed and financed by Emperor Zhao Ji of Song, who himself was fond of art and was known as a good artist, musician, calligrapher and master of the tea ceremony.

Today, porcelain is made by several classical and modern methods, including hand and potter's wheel molding, casting and semi-automatic molding. Chinese ceramic artist Xiao Heqing went even further and introduced 3D printing technology into the process of making porcelain from Song Dynasty kilns. nine0003

The use of 3D printing is intended to simplify somewhat the complex process at the pen stage - mold making. Hollow porcelain products are often made by casting: slip, that is, liquid porcelain mass, is poured into a plaster mold, then the workpiece is removed and, after drying, sent for firing, and then covered with glaze and painting. The quality of the blanks directly depends on the quality of the slip and the accuracy of the molds, so the first stage plays a key role.

Hollow porcelain products are often made by casting: slip, that is, liquid porcelain mass, is poured into a plaster mold, then the workpiece is removed and, after drying, sent for firing, and then covered with glaze and painting. The quality of the blanks directly depends on the quality of the slip and the accuracy of the molds, so the first stage plays a key role.

Plaster molds are removed from the master models, and the models themselves are traditionally made from clay or plasticine. Such models are not durable, so you need to work with them carefully, especially since the manufacture of a master model is a very laborious process, usually done manually. This is where digital design and 3D printing technologies come in handy.

3D printed molds

Solid Edge Design nine0094

In the new process, master models are first digitally created using CAD systems and then printed with photopolymer resin on a SHINING 3D AccuFab-L4K stereolithographic 3D printer.