3D print vertical garden

Make All the Things Part 3: Vertical Garden - 3DPrint.com

Pumping Station One

Hello everyone! After finishing our first project within the Make All Things series, I was taking a break and looking for some new projects to make. Within the environment of my makerspace, Pumping Station One, the tools to make anything are endless. I have been working on building up the Pumping Station community and I just recently became a board member and the head of Public Relations. I think this space will benefit from the ability of us to showcase different projects we can do as a community. It will also be awesome to involve the Chicagoland area with different things we create.

With that being said, a new project idea was presented to me by a member of the PS1 community. A member wants to lead a project for a vertical garden. It is important to know a couple of things. Firstly, this member has no ideas whatsoever about vertical gardens. Neither do I. Neither do a good amount of the PS1 community. That is the fun part though. Again, being in a makerspace inspires people to try and fail within areas that are outside of their comfort zone. These are the experiences that push us to learn that we have more ability than we can imagine. The goal of this project is to build a vertical garden for someone who lives in a city like Chicago. Living in a larger city typically keeps people away from nature. Topics like botany are very foreign to a majority of city dwellers like myself. It will definitely give myself and anyone else a new mindset and consideration for plant life. We also want to build a system that will grow edible crops that people would use for their own nutrition. This will be a large scale project that will utilize CNC machines, arduinos, rapid prototyping, as well as 3D printing.

We will have different phases of this project. We have been working on our first phase of the project which is dedicated to design research and user research. We are taking a design approach to this project so that this could be a viable option for a large amount of people in terms of implementation. Most of us have no inherent biases about building a vertical garden because we have no understanding of botany, farming or gardens. We are looking to build crops and a garden that would be beneficial to the common person. Having no skills within this field allows us to quickly ask a bunch of questions. This will come before the actual building of the project, and that is key. It forces us to have deliberate consideration of the user. In the previous project I created, the product I built was a ring design that I personally liked. Instead of keeping an insular approach to product design, it is important to gain outside perspective.

Most of us have no inherent biases about building a vertical garden because we have no understanding of botany, farming or gardens. We are looking to build crops and a garden that would be beneficial to the common person. Having no skills within this field allows us to quickly ask a bunch of questions. This will come before the actual building of the project, and that is key. It forces us to have deliberate consideration of the user. In the previous project I created, the product I built was a ring design that I personally liked. Instead of keeping an insular approach to product design, it is important to gain outside perspective.

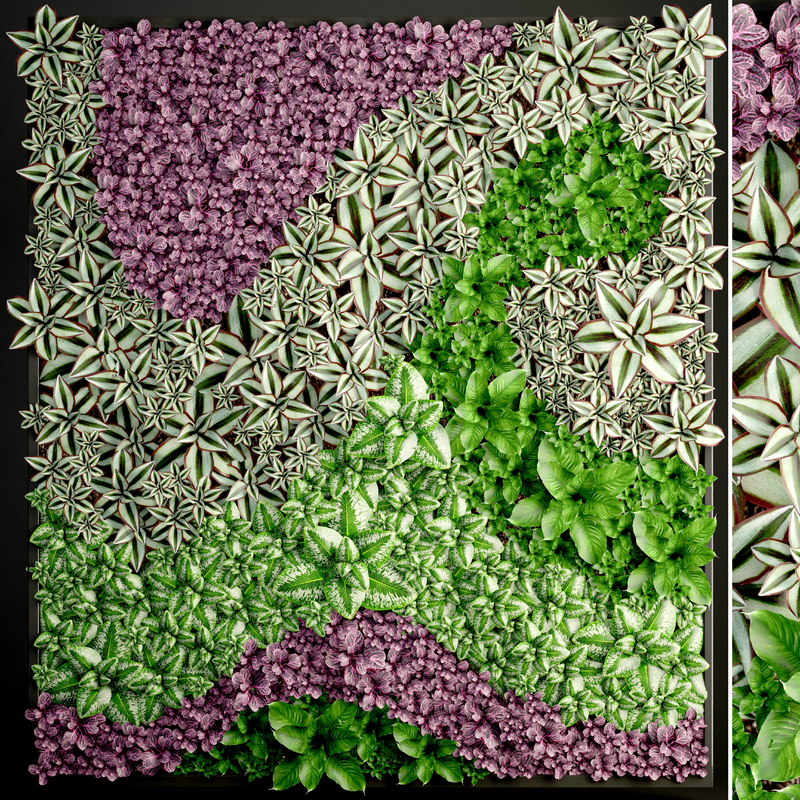

An Example of a Vertical Garden

Some of the questions already built by the group of organizers we have for this project are the following:

- How loud would this be in someone’s house?

- How much energy does it require?

- What’s the upkeep for the plants ? (can it be automated)

- What plants do we actually need to grow?

- How seamless can the process be?

- How much light do we need?

- How much water do we need ?

- How large is the system?

- How do the plants intake the nutrients?

- How do plants get from a seed to a plant?

- How does the location of the plant affect its growth?

- What are the things people need to know in order to manage the vertical farm?

- How much produce per person do you need to sustain yourself?

- How do we prevent infection in a small space?

- How safe can it be if it’s at home?

- How often can you update your plants and what is the cycle of growth?

- How many can you grow at once?

- What can move people from buying produce to growing their own ?

- How easy is it to set the system?

- How can we control the system?

- What are the parameters that we need to control?

- Can you transfer it to an outdoor environment? ( How can you transfer it?)

- How cheaply can this be made?

- What is the life cycle that we want to set for this?

- What are the materials for that lifecycle?

- How does the system interact with the materials?

- What is our form of energy?

Bulbasaur Plant Potter

Our core audience will be vegetarians, vegans, and healthy lifestyle individuals as they are the most likely to implement this kind of product readily. Our secondary audience of users include farmers, restaurant chefs, and people with dietary restrictions. A lot of our research will be focused on gaining insight from industry experts. These experts would include home food – growers, agricultural engineers, farmers, restaurant chefs/restaurant owners/catering companies, organic chemistry scientists, bio engineers, and individuals from the nonprofit Plant in Chicago. Once we have done proper research over a month period, we will then be able to build out a prototype product that will utilize various machines including some 3D printing. It will be a fun experience, so watch out for some updates on this project on a weekly basis.

Our secondary audience of users include farmers, restaurant chefs, and people with dietary restrictions. A lot of our research will be focused on gaining insight from industry experts. These experts would include home food – growers, agricultural engineers, farmers, restaurant chefs/restaurant owners/catering companies, organic chemistry scientists, bio engineers, and individuals from the nonprofit Plant in Chicago. Once we have done proper research over a month period, we will then be able to build out a prototype product that will utilize various machines including some 3D printing. It will be a fun experience, so watch out for some updates on this project on a weekly basis.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d design • botany • farming • makerspace • organic chemistry • plants • product development • user experience • user research • vertical garden

Please enable JavaScript to view the comments powered by Disqus.

3D G-Tower - Vertical Gardening Perfected

Skip to content

Changing the face of vertical gardening as we know it!

Get Started Go To Forums

Step 1: Print Your Parts

Print your tower segments, bases, and caps in any color you like!

Step 2: Assemble Your Towers

No tools necessary, all tower parts stack together just like Legos!

Step 3: Plant Your Towers

Tower segments accept plant starter plugs or netpots!

About 3D G-Tower

The 3D G-Tower is the smartest vertical grow tower design ever made for hydroponics & aquaponics growers!

It’s the very first tower of its kind and has the lowest total cost of ownership since any novice can 3D print their own!

“The 3D G-Tower by Panhandle Ponics is the most affordable, most efficient, and easiest to use vertical gardening tower for hydroponics or aquaponics.”

— Hooked On Ponics Magazine

The 3D G-Tower overcomes the shortcomings in the ZipGrow tower design and is twice as productive with multiple planting planes! Allows you to grow twice as many market-size plants per foot than the ZipGrow tower in a smaller form factor.

Easier to plant because no media is required to hold your plants in the tower. The 3D G-Tower also requires no special tools to plant it. Supports standard 1.25″ plant starter plugs or 2″ netpots depending on which tower format you choose. Just drop in your plants and you’re off to the races!

The 3D G-Tower uses a Vertical NFT method which has been tried, tested, and proven in a production environment since 2018. Two different cap models, one for hydroponics and one for aquaponics. Precision 360 degree water delivery system guarantees that all plants receive water equally no mater how they are oriented.

Unlike project listings on hobbyist 3D printing sites, the 3D G-Tower is actually used in commercial production environments and has been fine-tuned for that purpose. The 3D G-Tower system is the smartest grow tower choice if you fully intend to maximize your grow space in any hydroponics or aquaponics operation.

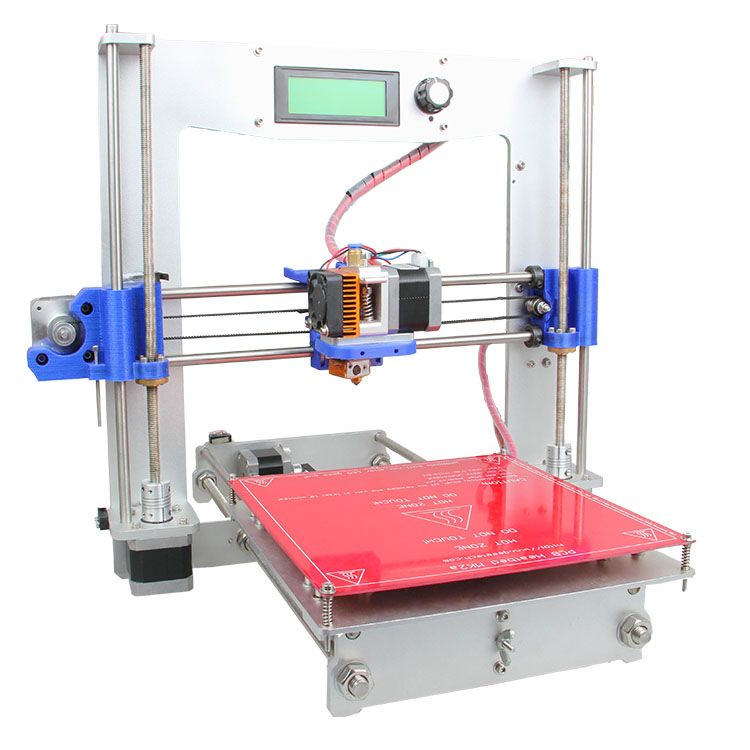

The 3D G-Tower has the lowest total cost of ownership since they can be 3D printed with any FDM type 3D Printer. You just print them as needed for nothing more than the cost of the 3D printer filament and the minimal electricity costs to run your printer.

Please see the Product Information page for more technical information on the 3D G-Tower and what makes it better than any other grow tower design on the market.

3D G-Tower Assembly & Usage

Buy Them Premade Or 3D Print Your Own

Ordering Options

Subscription Services

Patreon has been replaced by members-only features on this website in order to provide a more useful service.

More Info →

Got An Order Related Question?

Send A Message

Use the forums for all non-order-related questions.

Application of 3D technologies in landscaping

News

Subscribe to the author

Subscribe

Don't want

4

3D printing has been around for more than a decade, but its use has recently become affordable and inexpensive. Let's talk about how this technology helps to save resources and reduce the carbon footprint, save ecosystems and create greenery.

Let's talk about how this technology helps to save resources and reduce the carbon footprint, save ecosystems and create greenery.

How does 3D printing work? She creates three-dimensional objects using a special printer that applies the material in layers. In order to print an object, you first need to create its digital model. The technology was developed back in the early 80s, but for a long time 3D printers were too expensive for everyday use. The first affordable models appeared in the mid-2000s, and since the early 1910s, 3D printing has become more common: a 3D printer costs about the same as a home computer and does not take up much space. nine0003

Almost anything can now be printed with 3D printers, from aircraft parts, houses and bridges to food and, in the near future, human organs. This technology saves resources: 3D printing consumes up to 100% of the material used, while carbon dioxide emissions are quite large compared to, for example, casting technology.

On the other hand, 3D printing helps to reduce the weight of the final product, and for example, reducing the weight of an aircraft by 100 kg saves up to 1.3 million tons of carbon dioxide throughout its life cycle. nine0003

3D printing can not only reduce your carbon footprint, but also save entire ecosystems. Coral reefs are dying due to the climate crisis, and this in turn causes an imbalance of life in the ocean, which could eventually lead to the extinction of most life on earth. Scientists partner with 3D printing companies to create tiles that mimic coral reefs and allow new corals to grow while keeping organisms associated with the ecosystem alive. nine0003

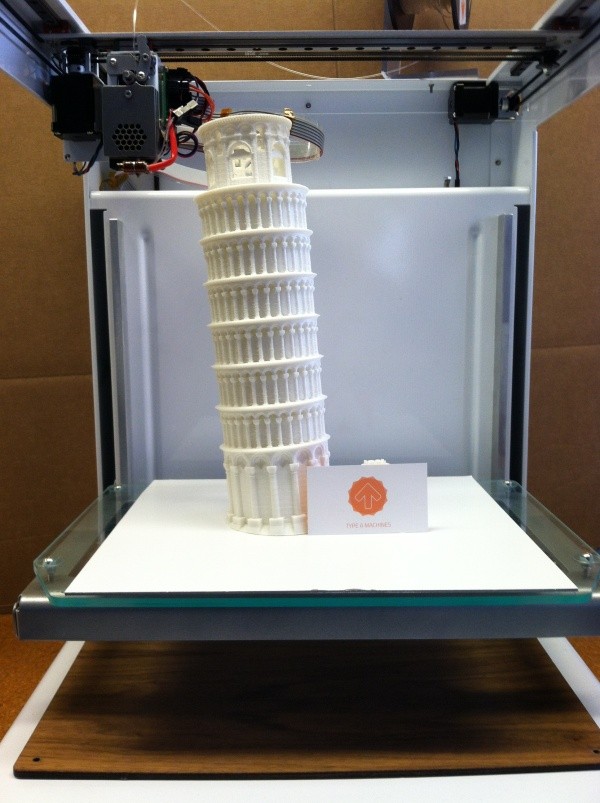

3D printing is also used in landscaping, which is also important for the improvement of ecosystems: for example, in China, in the city of Shenzhen, a huge park was created using this technology. Of course, the plants there are real, but all the benches, borders and flower beds are printed on a 3D printer. This approach reduced construction costs and shortened the project time: it took only two and a half months.

This approach reduced construction costs and shortened the project time: it took only two and a half months.

Development on printing the environment for the plants themselves is also underway: back in 2014, the programmer Yushiro Takeuchi proposed the technology of printing a "lawn" with seeds that then germinated. Such a technology would make it possible to create vertical gardens of any shape, easy to operate and with significant water savings, but the project was put on hold. nine0003

3D printed planters, plant care tools and imitation trees. Until recently, the value for money of such products was not suitable for large-scale landscaping projects, but the situation is changing. Work is currently underway on several vertical gardens that grow in 3D printed planters.

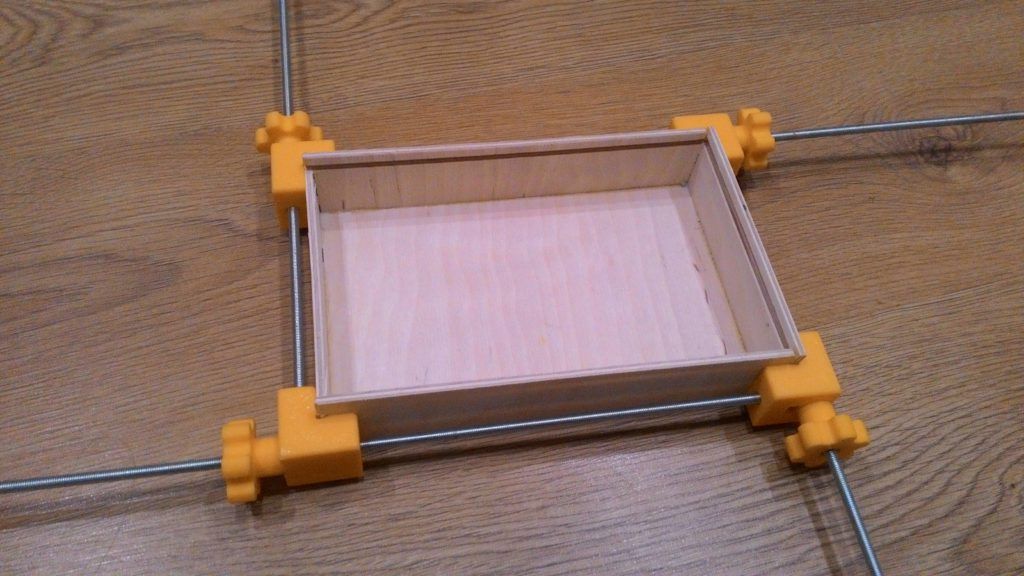

3D printing can also be useful at the stage of preparing a landscaping project. An example is the work of the Ficus company for the airport in Simferopol in 2017-2018. The terms of reference included the creation of the largest green wall in Europe: 15 meters high and consisting of 30,000 plants. Especially for the project, Ficus developed a new system with automatic watering, which reduces the risk of plant death in the event of unforeseen events. nine0003

Especially for the project, Ficus developed a new system with automatic watering, which reduces the risk of plant death in the event of unforeseen events. nine0003

However, before investing the customer's resources in the construction of such a complex and expensive facility, it was decided to test the prototype. 3D printing helped: with its help, glass modules were quickly made, a plywood wall structure with an area of two square meters was mounted, and the functionality of the new development was tested on it. Six months later, the prototype turned into a real vertical garden, which became the main distinguishing feature of the airport.

Yes, the 3D printing process is often still energy intensive, which contributes to increased emissions. Therefore, it cannot be argued that its role in sustainable development is decisive at the moment, but now the industry is using 3D printing from recycled materials, including plastic found in the ocean or wood waste, and the prospects for technology are huge. This is perhaps the most efficient way for every industry to eventually become sustainable.

This is perhaps the most efficient way for every industry to eventually become sustainable.

Author: Alexander Dvoeglazov, General Director of Ficus Company

Do you have any interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

ficus phytodesign landscaping

Follow the author

Subscribe

Don't want

4

Green garden 3D printer

The roofs of urban houses are generally not distinguished by bright colors, they are too gray and boring. Programmer Yushiro Takeuchi, who works with Sony Computer Science Laboratories, Inc., decides to change the city's shabby picture with his own efforts. Takeuchi found a way to print verdant gardens filled with vibrant flowers and herbs. Such gardens can be planted on rooftops or wherever your heart desires. nine0003

Takeuchi found a way to print verdant gardens filled with vibrant flowers and herbs. Such gardens can be planted on rooftops or wherever your heart desires. nine0003

It uses a 3D printer and software specially created by it to print a user-selected shape. The material used is twine, it contains plant seeds, from which a full-fledged garden grows in just a few weeks. With its 3D printing technology, gardens of any desired shape can be printed: triangular, rectangular, or even panda-shaped, like this:

The process of obtaining the finished product takes place in stages: first of all, you need to create the desired shape on the computer. Then load the given model into a 3D printer, which, using twine, will print the shape selected by the user. nine0003

Once the 3D printer has finished its work, an additional device will place tiny seeds in the twine.

Takeuchi's approach is based on a method called hydroponics (Facepla.net has talked a lot about different setups) where you grow plants using different nutrient material instead of soil.

The hydroponics method is used to grow vertical gardens. The image below shows a garden in France designed by French botanist Patrick Blanc. nine0003

Such installations can cost a pretty penny and cost $ 1,000 per square meter. And although it is much cheaper to build such a garden by hand, it will take a huge amount of time. High prices and long hours of manual labor are two factors that hinder large-scale adoption and development of green cities. In this case, 3D printing may be the solution.

"Printing solves all of these problems, and also provides a high degree of flexibility (you can print whatever size of your garden you want), which will hopefully make hydroponics a more attractive type of gardening for people living in dense cities with limited space," says Takeuchi.