3D print sliding parts

How to FDM Print for Part Sliding Clearance

How to FDM Print for Part Sliding Clearance | GrabCAD TutorialsLearn about the GrabCAD Platform

Get to know GrabCAD as an open software platform for Additive Manufacturing

Visit our new homepage

GrabCAD Tutorials

14 Jun, 2017 07:58 PM

If you are 3D printing parts that have to fit/slide together after printing, you will need to put some sort of clearance between those parts in your CAD system.

A good starting place is a clearance 2x the layer height you are going to print at, but you should make a few smaller test prints at different clearances to see if the 2x layer height rule holds for your particular situation and orientation.

Have fun and happy printing!

-

Step 1:

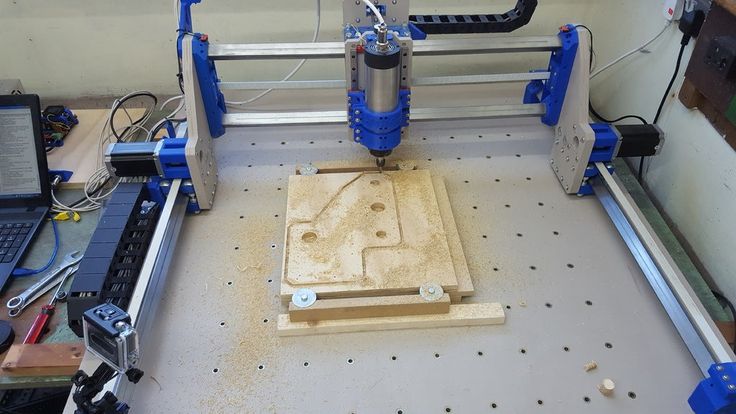

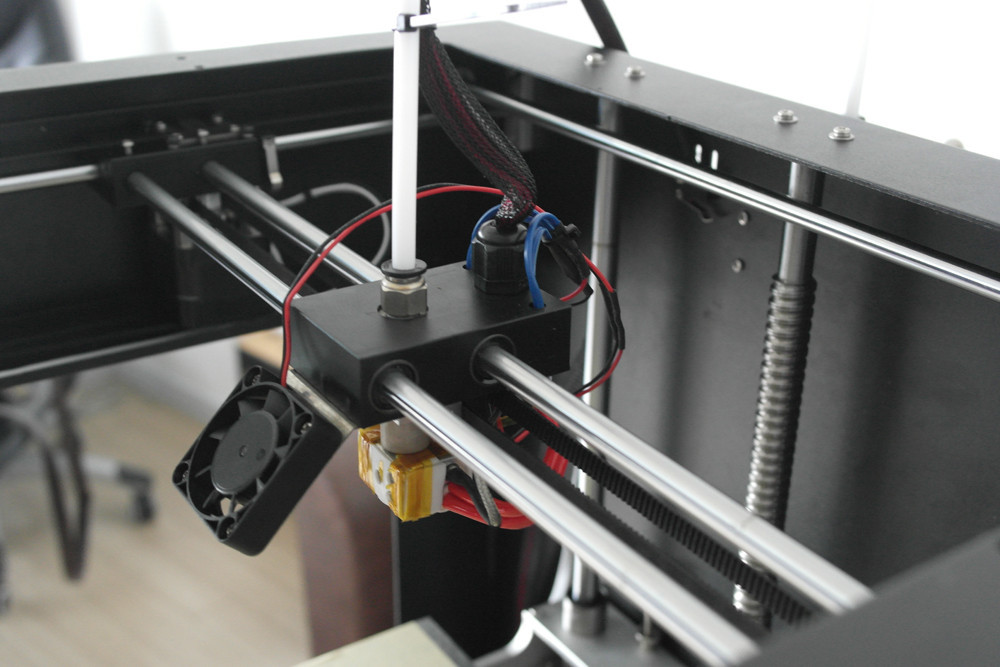

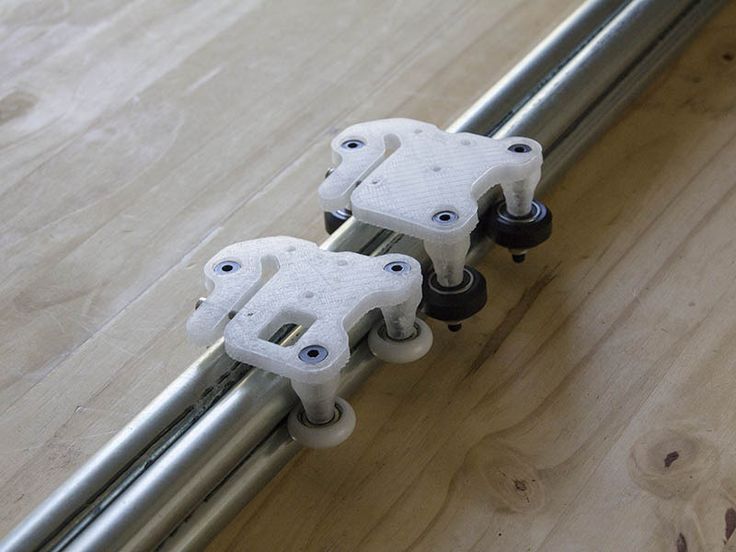

Step 1: Figure out your Z Layer Height. You probably know by now that most FDM printers lay out beads of molten plastic in an XY plane, then move the build platform or the head in the Z direction and start again with another XY layer.

What you may NOT know is that the beads are not the same wide as they are high (which is why they are ovals in the picture above, not circles). But there IS a relation between the height and the width, and the height is usually easier to figure out in most FDM systems.

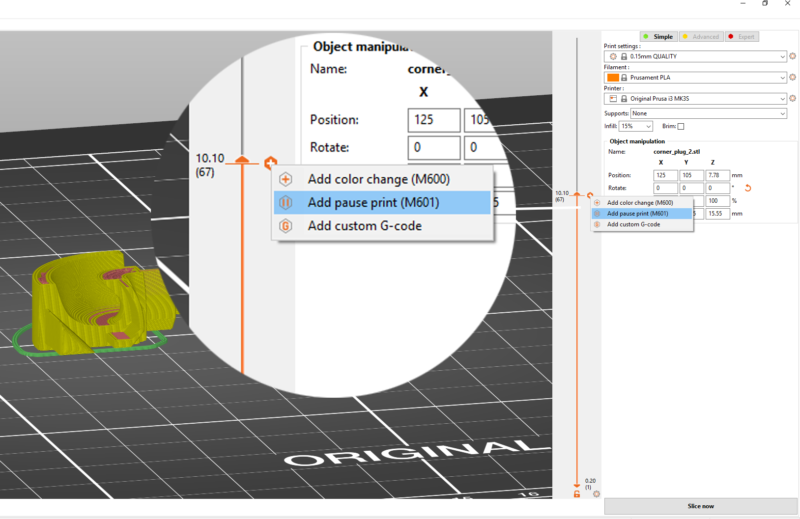

If you’re using GrabCAD Print, this is easy to find. Choose your printer in the bottom right, and then hit your “Print Settings” panel to see your slice heights. In the picture below, I’ve highlighted that I’ve chosen one of our Boston area F370’s, and that it gives me four possible slice heights (0.005, 0.007, 0.010 or 0.013 inches).

The point here is to choose ONE of those slice heights and continue.

-

Step 2:

Step 2: Convert that Z Layer Height into an XY bead width. This can either be the hardest or easiest step.

Now, typically, (let the record show that I said ‘typically’, AND stressed it), for Stratasys printers, your XY width was 2 times your Z height, because the nozzle squished down the bead, to make it stick to the previous layers.

So, if I chose a Z height of 0.005” to print at, my typical (let the record show…) XY layer thickness would be 0.010 inches. Thus, when designing my sliding components in CAD, I would start by leaving 0.010” clearance between those moving parts.

Of course, many printers have different values for this conversion (typically…) so make sure to check this for your own system. But 2x the Z height is a decent place to start.

-

Step 3:

Step 3: Test the fit with a small, 35-minute print, BEFORE making your HUGE, 27-hour print.

3D printing is supposed to be all about the testing and iterating, right? So we’d be foolish not to iterate and test on this key idea too before printing your masterpiece of sliding motion.

-

Step 4:

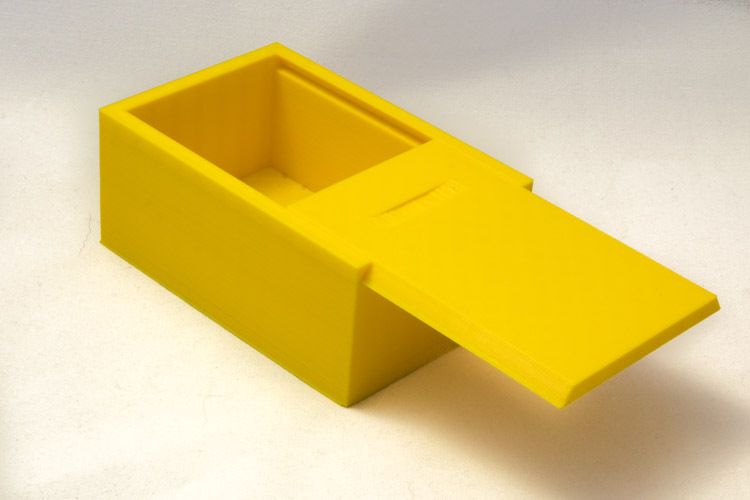

So, here is me, trying to fit a base and cover together with NO gap between the parts in my CAD

Unsurprisingly, they don’t fit.

-

Step 5:

Now here’s me, putting together a base and cover with 0.

010” gap in my CAD files.

010” gap in my CAD files.And with 2x the Z height gap, the parts fit great!

-

Step 6:

And just for one last sanity check, if I printed these parts at 0.020” or 0.030” clearance, they fit, but the fit is loose and sloppy.

If you look closely at the picture, you can even SEE the gap between the parts, which is too much.

Was this tutorial useful?

Sliding best STL files for 3D printer・Cults

sliding puzzle Game of 15

Free

Optimum sliding closet door roller - Model 11.20.01

€5

plastwood cutting board and sliding cut

€8

Fridge sliding doors stopper

€1

Storage Cabinet with sliding door

€4 -70% €1. 20

20

Sliding Door Handle - Flat

Free

Sliding Door Handle

Free

Spider-Man Box

€2.73

ALLIGATOR 2 tuning plate throwing arm + 1 joule

Free

USB - SD - Micro SD box

€1.25

Bogota Mini Case

Free

Cybertruck with sliding bed cover (4x4 & 6x6 versions)

€3.56

Door lock

€0.50

Concealment garage door opener keychain.

€0.90 -33% €0.60

Baby Yoda sliding keychain

€0. 50

50

End cap for pipe to secure a sliding glass door

Free

Rabbit keychain

€2.62

Sliding Door Guide

Free

Sliding Dodecahedron Puzzle Easy

Free

Sliding Patio Door Roller Adjustment Access Hole Covers / Caps

Free

ALLIGATOR 2 AR15 stock

€3

ALLIGATOR 2 Pikatinny rail extension

€0.50

Sliding Door Lock

Free

Modular Cable Holder

Free

Door Guide

Free

ALLIGATOR 2 Thumb Release

€0. 50

50

Sliding Valve Air Engine

Free

2 Cylinder Sliding Valve Engine

Free

Sliding glass patio door plug

Free

SIKU front adapter for tractors

€1

spare part for PERALU bay window

Free

Camera cover for laptop camera

€0.50

Kingdom Builder organizers

€5.98

Sliding legolini double rubber mod

Free

Curtain rail slider/holder hook sliding

€0.50

Sunroof Sliding Part for BMW 10007576B

€9

Subaru cup holder shutter

€5. 66

66

Garden shed door handle

Free

Double-sided sliding puzzle

Free

AA 18650 Battery Tray

Free

Crocodile kind mobile

€1.31

Sliding closet door guide

€3.90

Pocket Door Slide Adjustment Lock

Free

Box with Sliding Lid with Hole

Free

Headset Locking Clips

€1.90

Baily Sliding Door Fix Kit

€3.06

sliding door stop clips

€1

Speedloader for Mini ADDER v3, Alligator 2

€2

3D printing with Formax plastic on order in Moscow, promptly, delivery

Engineering thermoplastic based on ABS with the addition of carbon fibers (up to 15%), capable of withstanding heavy loads and high temperatures.

Ideal for printing almost anything: functional models, prototypes, high art, decorative items, drone parts, gears, molds and more.

high strength and resistance to mechanical damage

wide operating temperature range

finished products are very light despite the size

excellent for printing large items and complex shapes

uniform, even, matte surface

suitable for moving parts

water and humidity resistance

high abrasion and wear resistance

Formax is an engineering thermoplastic made from ABS with carbon fiber. The popular print formax is characterized by resistance to high loads, temperature and no shrinkage. Plastic is great for making prototypes, functional models, gears, moldings, drone parts. Finished structures can be used in a wide range of temperatures.

Compared to other plastics printed carbon filled abs has the following advantages:

- Dimensionally stable.

- High rigidity, strength.

- Lightweight.

- Excellent surface quality.

The material is a worthy competitor to industrial designs. It is used for the production of technical products and devices where strength is needed.

Formax filaments are brittle compared to their ABS counterparts and should be printed by professionals. nine0003

Carbon fiber is made of tiny fibers that are added to the base material to improve its performance. Such fibers are very strong, contribute to increasing the strength and rigidity of the plastic, but because of this, the threads become more abrasive and brittle.

Thermoplastic is UV resistant and has low hygroscopicity. It is advisable to store the threads in containers or sealed plastic bags with silica gel.

Material application:

Formax plastic is ideal for all types of products:

- Prototypes.

- Functional models.

- High art.

- Gears.

- Molding products.

- Drone elements, etc.

The material responds well to increased printing speed, can easily undergo mechanical and chemical processing, and respond to the use of many solvents. It dissolves quickly in acetone, which can be used to bond individual elements or smooth surfaces. nine0003

Our Park of equipment allows you to make a wholesale order of any complexity

Decor

is perfect for printing unique decorative and art products

Consciousness of mobile models and prototypes of future concepts

industry

manufacture parts, equipment boxes, protective structures

Examples of work

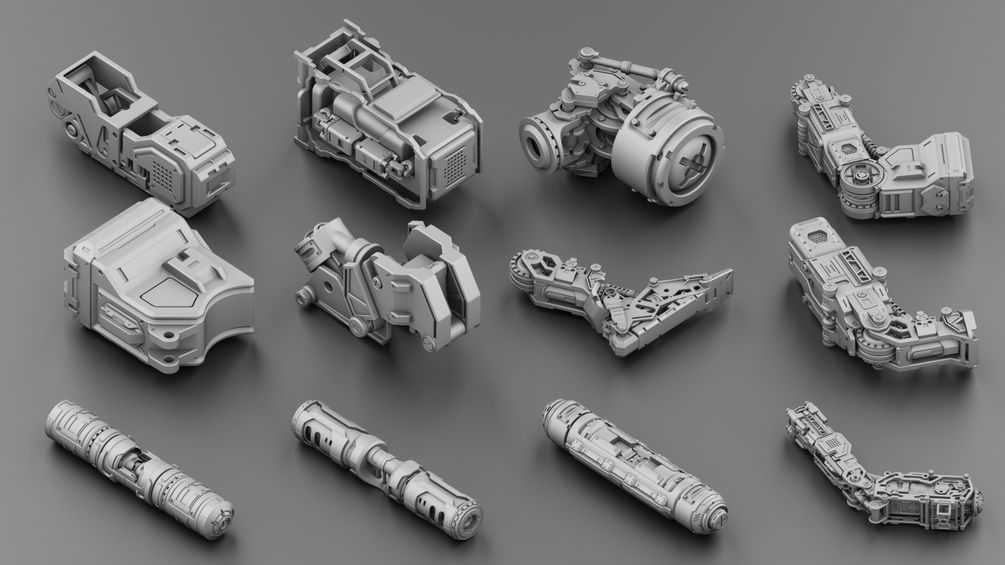

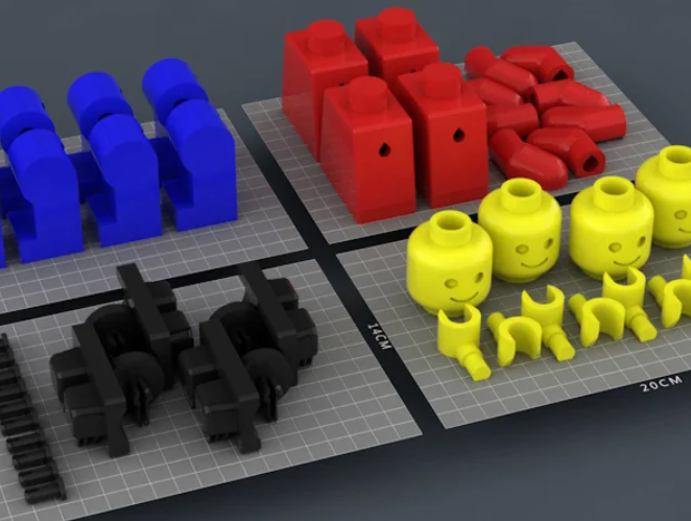

Possibilities of 3D printing: art, fashion, medicine

Expressive sculptures by contemporary artists, dresses for fashion shows, architectural models and parts of the human body - a short guide on how to use 3D printing was compiled by Artyom Dezhurko.

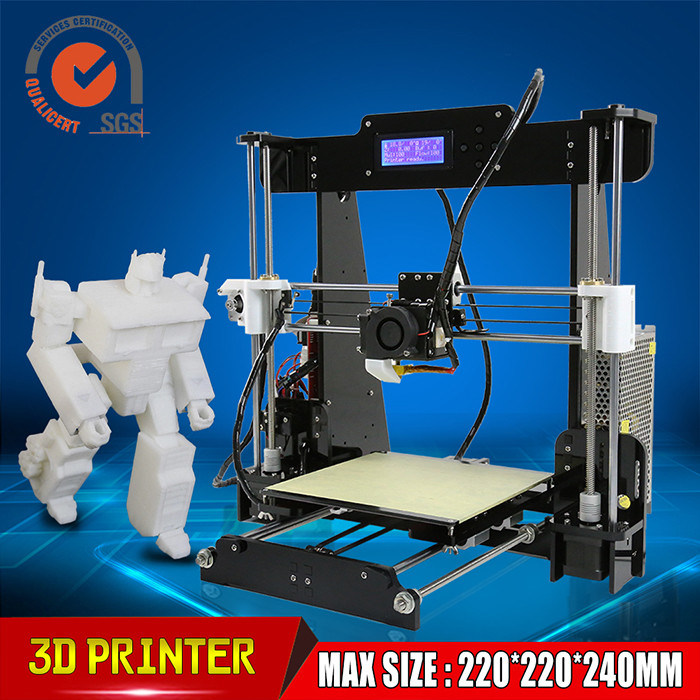

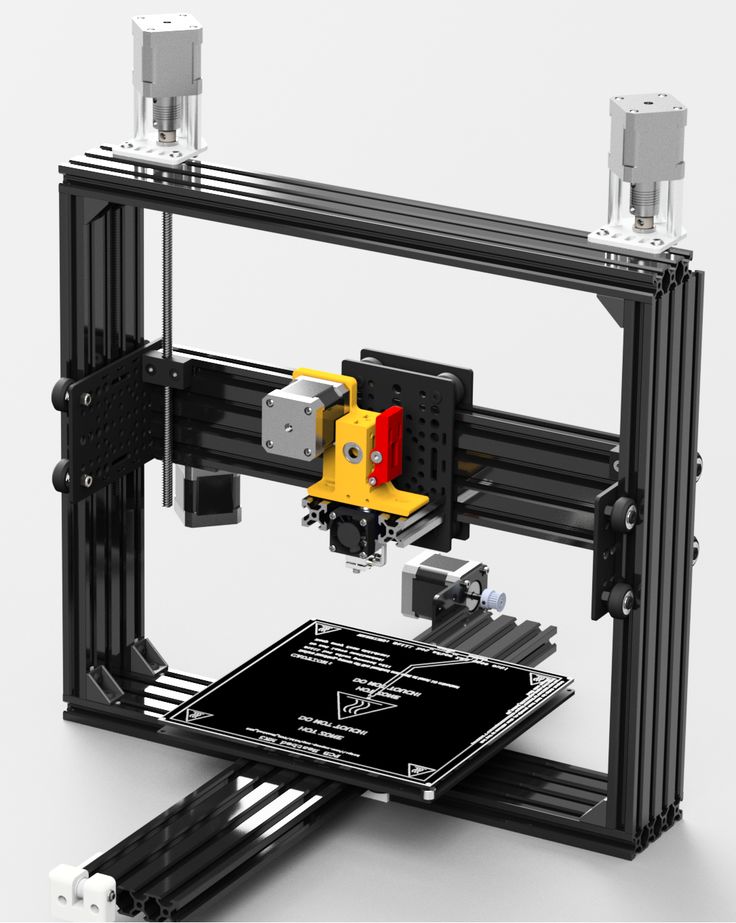

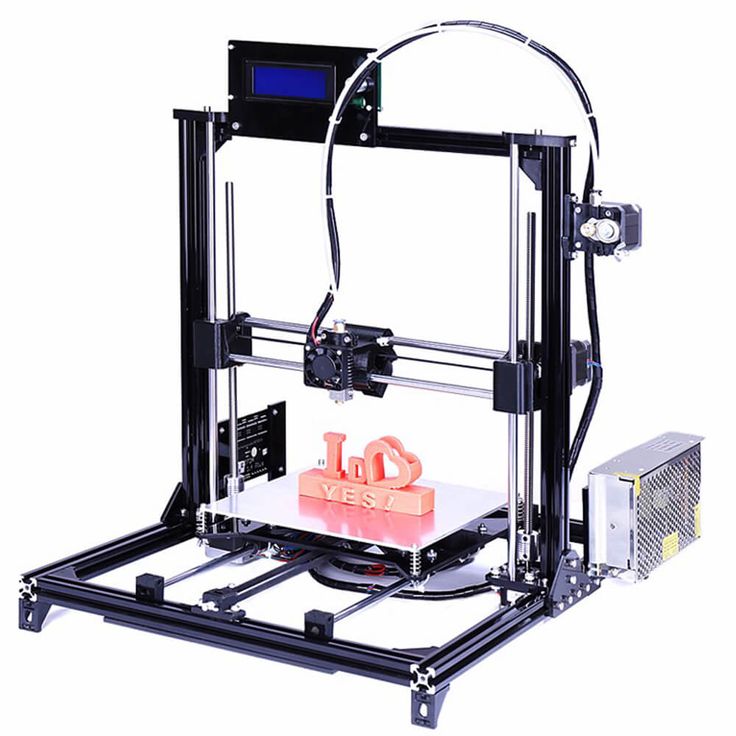

3D printing was invented by American Chuck Hull in 1984. Modern 3D printers are capable of printing large objects, up to a car body; and use different printing techniques (stereolithography invented by Chuck Hull is just one of them). However, whatever the technique may be, the essence is the same: the printer creates an object by building up the material in layers. Thus, you can create an arbitrarily complex shape. 3D printers print from different materials: plastic, cellulose, ceramics, metals, sugar. nine0003

Modern 3D printers are capable of printing large objects, up to a car body; and use different printing techniques (stereolithography invented by Chuck Hull is just one of them). However, whatever the technique may be, the essence is the same: the printer creates an object by building up the material in layers. Thus, you can create an arbitrarily complex shape. 3D printers print from different materials: plastic, cellulose, ceramics, metals, sugar. nine0003

This material is an illustrated overview of how 3D printing is currently used in various fields: art, architecture, technology, fashion, medicine.

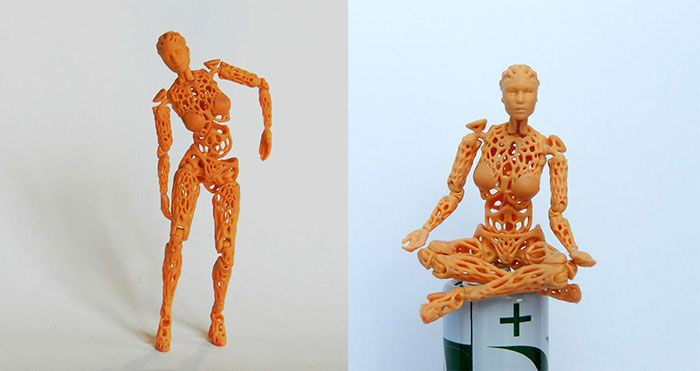

Richard DuPont, USA

Nick Erwink, USA

"Princess", Eric van Straten, Netherlands

A modern 3D printer prints layers so thin that they can no longer be seen with the naked eye. Therefore, sculptors love it: 3D printing is the same casting, but technologically simplified and allowing endless replication of the object. Sculptures with her help are very different: from photographically accurate images of famous football players to the vicious postmodern statuettes of Eric van Straten. nine0003

nine0003

Michael Hansmeyer and Benjamin Dillenburger. Digital Grotesque, 2015

Study paper by Andy Zheng and Christina Eromenok at RPI School of Architecture

PTW Architects. Model of the Beijing National Water Sports Center, 2007

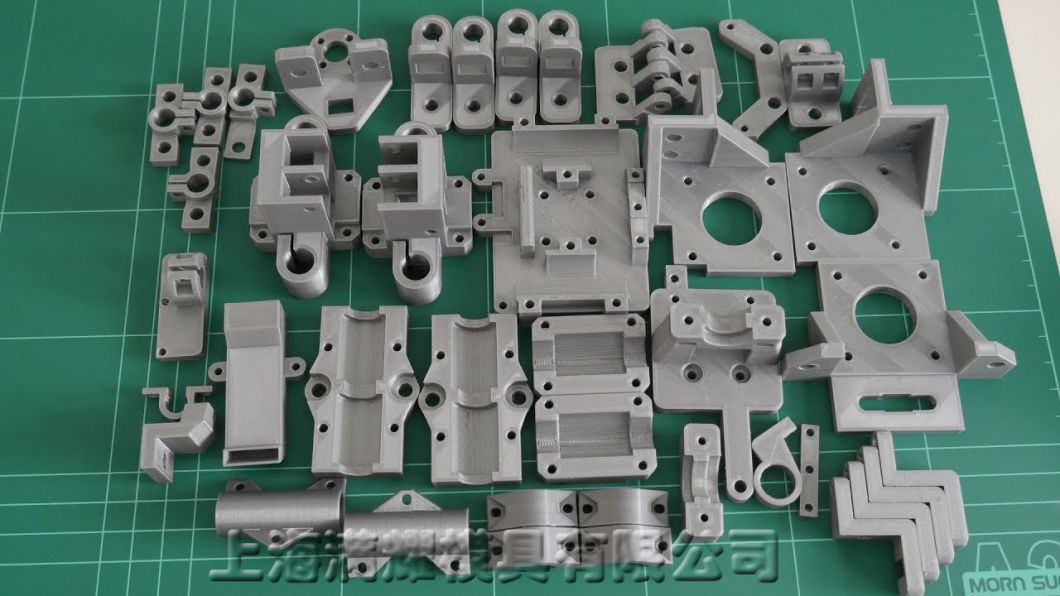

Most often, 3D printing is used for rapid prototyping - creating models of mechanisms and, especially often, architectural models. In addition, now 3D printers have begun to be used to produce large parts from which prefabricated houses are created. The Chinese company Winsun is experimenting with this technology. nine0003

In the automotive industry, 3D printing scale model production is widespread and seems to have completely supplanted the old plasticine sculpting technique. A model of James Bond's car from the movie "Skyfall" was printed on a 3D printer. And in 2010, a prototype of the Urbee car was created, the entire body of which was printed on a 3D printer.

Several bicycle frames have been 3D-printed (and even an entire Airbike bike - developed by EADS), but in their case, we are not talking about mass production yet. More promising is the printing of couplings made of durable plastic, with the help of which in small "garage" bicycle workshops it is possible to assemble frames from factory metal tubes. nine0003

More promising is the printing of couplings made of durable plastic, with the help of which in small "garage" bicycle workshops it is possible to assemble frames from factory metal tubes. nine0003

Chair Gaudi (Bram Genin)

A mold is printed on a 3D printer, which is then used to cast the supporting structure of the chair.

Hot Pop Factory

Sculpture of Charles and Ray Eames DSW chairs scanned and 3D printed.

LINK system

Christian Sjöström, Sweden, 2015.

Prototype Node

Modeling in Grasshopper. Charles Freed, UK, 2015.

3D printed as whole furniture (e.g. Gaudi chairs, designed by Bram Genen, 2009) and piece by piece (designed by Benjamin Vermeulen), as well as connections with which prefabricated furniture can be assembled without using bolts and nuts. Such joints have been made before, but 3D printing has greatly simplified their production.

Noah Raviv. Hard copy collection. 2014

Noah Raviv. Hard copy collection. 2014

2014

Chromat. Formula 15 collection. Spring-summer 2015

Michael Schmidt, Francis Bitonti. Dita Von Teese dress. Laser printing (SLS). 2013

Iris van Herpen, Julia Koerner, Voltage Show. Print materialize. 2013

Iris van Herpen. Crystallization Collection. Summer 2010

Iris van Herpen. Autumn-Winter 2013-14

3D printers can print elements from which plastic fabric is then woven. Either from this fabric, or directly from plastic, dresses, bathing suits, shoes are created. Iris van Herpen has released several collections of 3D printed dresses and shoes. United Nude prints shoes designed by famous designers and architects: Zaha Hadid, Rem Koolhaas, Ross Lovegrove. But the most famous piece of clothing created using this technology is Dita Von Teese's mesh nylon dress. nine0003

#Cast is a custom tire consisting of the letters that the patient most often typed on Twitter. Manufacturer FATHOM, designer Eva DeCapri (USA). 2014

Prosthesis on the model of the patient's skull. Photo from Walter Reed Hospital in Washington

Photo from Walter Reed Hospital in Washington

Arm splint. The developers are UCLA School of Architecture and Urban Planning students Nicholas Solakian, Peter Nguyen and Derek Buell. 2013

Medicine is the most promising application for 3D printing. By scanning the surface of the body, it is possible to create fixation bandages that exactly match the anatomy of a particular patient, “custom” prostheses and implants that reproduce lost parts of the skeleton. One unfortunate man who lost half of his face had the missing half printed on a 3D printer. There is no photo of this person here, but you can easily find it if you wish. nine0003

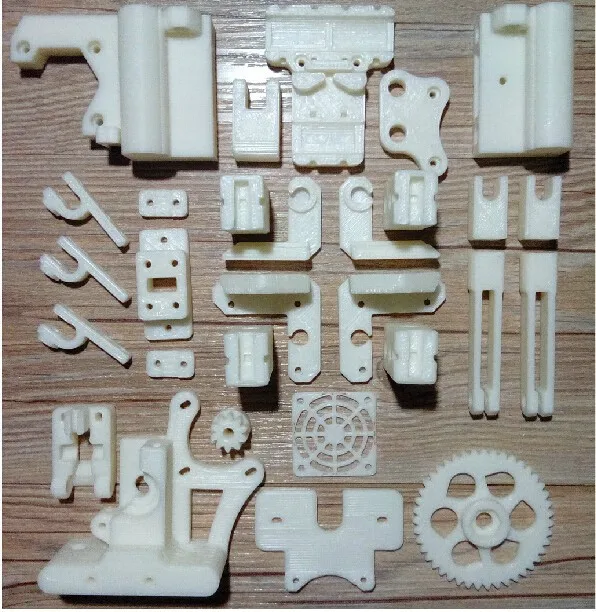

Printer self-reproduction

There are printers that can print parts of themselves. Undoubtedly, in the coming years they will learn to breed.

Growing donor organs

3D printing technologies for living tissues and organs are being developed. Living cells are used as the material, with which the printer "seeds" the matrix.