Xyzprinting da vinci mini maker 3d printer review

XYZPrinting Da Vinci Mini Review 2022

Heard about XYZPrinting Da Vinci Mini 3D printer? We did as well and decided to test one of them to see if they're worth it. Here are our findings!

By Justin Evans

4

See Price

So you’ve decided to get into the world of 3D printing. Where do you begin? There are printers for every possible requirement, and there’s a lot of jargon floating around that makes it hard to accurately compare different models. Relax – we’re here to help.

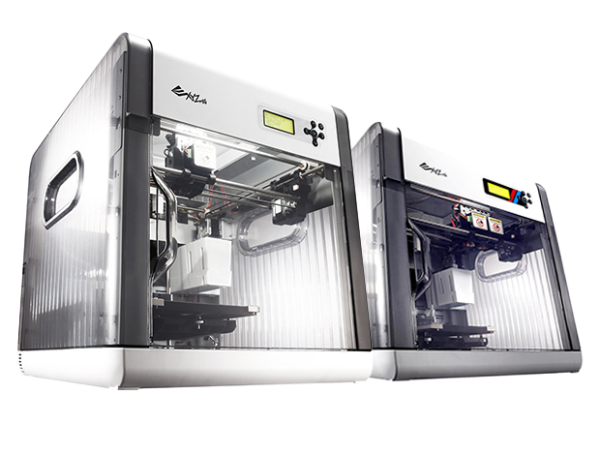

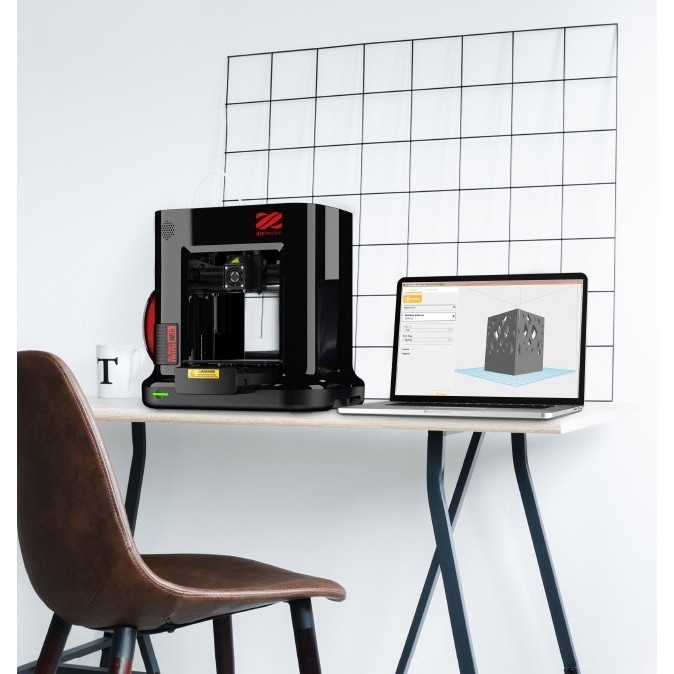

XYZPrinting is known for creating some of the best entry-level 3D printers around. Today, we’ll be looking for any strengths or weaknesses that the Da Vinci Mini might have– it’s a small printer, but it’s certainly capable. However, is it right for you and your needs? You’ll have to read on to find out.

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, WiFi |

| Printing Speed | 100mm/s |

| Build Volume | 5.91 x 5.91 x 5.91” |

Table of ContentsShow

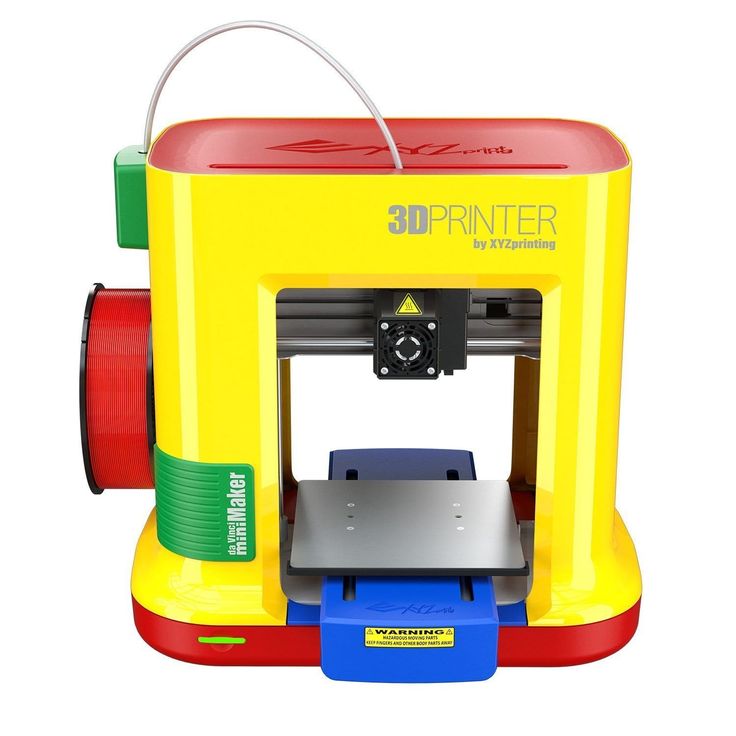

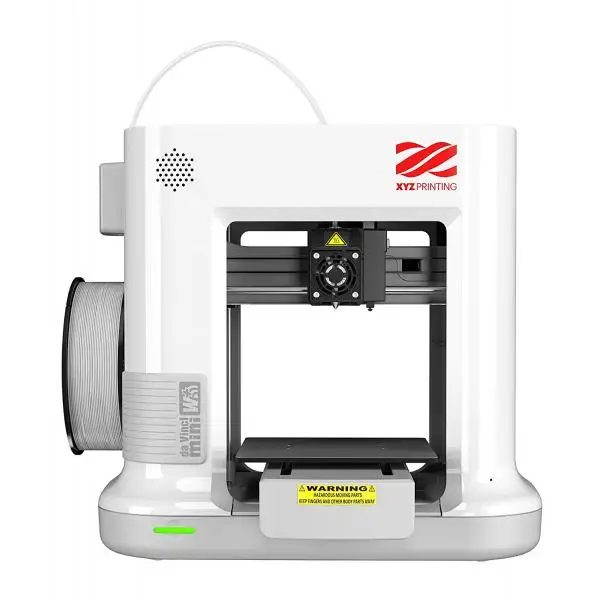

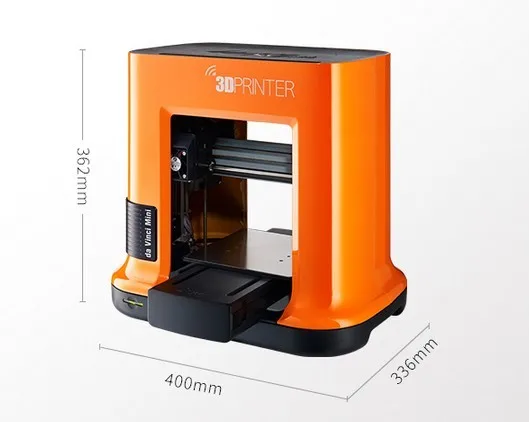

Design

The XYZPrinting Mini comes pre-assembled, so there’s no need to factor in build time. It’s a small-sized unit, perfect for sitting on your desktop, but this does mean that the build area is similarly restricted. Don’t get us wrong – you’ll be able to print decent-sized models, but nothing too huge.

Notice how there’s no enclosure? This means that it’ll be a little louder when you print, but all things considered, it’s still fairly quiet since the mechanical parts are mostly covered by the plastic frame. There are also implications for heat retention, but that’s not an issue, as we’ll explain later.

You get exactly what you’d expect from a low-end printer: there’s a single extruder and a maximum speed of 100mm/s. This is fairly standard and just means that you’ll take slightly longer to print. However, as the build area is only around 6” in each direction, you won’t be waiting hours unless you’re trying to print a large, solid cube.

Printing

There are three different speeds to choose from. As expected, the faster you print, the rougher the final quality. We found that the fastest setting resulting in significant stepping on curved surfaces, while if you allow it to take its time, your models look far better, but still not professional-level.

In an attempt to keep things as simple as possible for new users, XYZPrinting has limited the Mini to using PLA filaments. This removes the need for an enclosure but does restrict you somewhat in terms of the things you can build. Still, for beginners, PLA is more than enough to get you started.

The overall quality of the prints is too low for manufacturing, and the build volume too small for mass-production. However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

Features

So what other features does the Mini have to make things easier for beginners? Well, instead of adding things, XYZPrinting has removed components. There’s no heated bed, for instance, and no built-in screen. You do have a USB connection, though, and WiFi functionality, which is almost unheard of in low-budget printers.

We were pleased to see that drivers are available for both Windows and Mac computers. On the other hand, there’s no Linux support. It supports four different file types, though, so you’re not really limited to using a particular modeling program, which is great.

Even the interface is simplistic. There’s a single button for starting a print and a status LED that lets you know how your print is going. All in all, it’s easy to use even if you’re not particularly tech literate. Let’s be honest – that’s never a bad thing.

Let’s be honest – that’s never a bad thing.

Cost

Here’s the thing: the Da Vinci Mini isn’t available in the United States. You can buy it from several European locations, though. It costs around $700, which makes it among the cheapest, most robust 3D printers we’ve covered. Of course, you’ll have to find a company to ship it over if you’re in the US.

Running costs are minimal. PLA is among the least expensive materials you can use, and since while third-party filaments aren’t supported, you can easily mod it to accept them. Large spools of PLA often cost less than $20 so really, your monthly material costs will depend on how often you print.

We think that this 3D printer is appropriately priced. It’s clearly intended for novice users, and the price point helps it stay affordable, unlike more advanced printers that offer user-friendly features. You’ll likely outgrow it in a year or two, but until then, it’ll serve you well.

Support

XYZPrinting’s support section provides customer help telephone numbers for 11 different countries. Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

The limited warranty period is similarly outstanding. You’re covered from factory defects for up to two years at no extra cost, presuming you bought the printer from one of XYZPrinting’s recommended sellers. There’s no option to extend this warranty, though, which is a bit of a shame.

Customers can consult model-specific FAQs and tutorials in case they need any technical help. There are also different versions of the software, as well as documentation for each printer model here. All in all, it’s one of the most comprehensive support packages offered by any major 3D printing manufacturer.

Rapide Lite 200 Review

XYZ da Vinci Mini 3D Printer Review

Skip to main contentTom's Guide is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

Here’s why you can trust us.

The da Vinci Mini offers great performance for the price, but it is limited to using filament from XYZ.

Editor's Choice

Tom's Guide Verdict

The da Vinci Mini offers great performance for the price, but it is limited to using filament from XYZ.

Pros

- +

Low-cost, high-quality printer for PLA prints

- +

Easy-to-use software

- +

Quick printing at most settings

Cons

- -

Printing at highest resolution is very slow

- -

Failed prints on some complex 3D models

- -

Supports limited print materials

- -

Only works with filament from XYZ.

Why you can trust Tom's Guide Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best XYZ da Vinci Mini 3D Printer deals

No price information

For more information visit their website

Priced at $270, the XYZ da Vinci Mini is a small but well-equipped 3D printer that is aimed at 3D-printing newcomers and the casual consumer. It offers a lot of printing performance for the price, producing decent quality prints at an acceptable speed. But there are compromises: the highest-quality printing is very slow, and it works only with filament from XYZprinting. Since the filament isn't expensive and comes in a good range of colors, it's an acceptable compromise. So, for most users, the da Vinci Mini could provide a good intro to 3D printing.

It offers a lot of printing performance for the price, producing decent quality prints at an acceptable speed. But there are compromises: the highest-quality printing is very slow, and it works only with filament from XYZprinting. Since the filament isn't expensive and comes in a good range of colors, it's an acceptable compromise. So, for most users, the da Vinci Mini could provide a good intro to 3D printing.

With its bright orange plastic case, the XYZ da Vinci Mini certainly stands out from the crowd of me-too black printers. (If you really want to stand out, XYZ offers a $249 education-focused version called the da Vinci minimarket that is made of multicolored plastic, like the illegitimate offspring of a Lego factory and a Terminator.)

The case covers the workings of the printer, but the print bed and hot extruder are still open to the world. A cheap fold-it-yourself plastic cover is included, but this won't stop curious fingers for long, so some caution is required with younger users.

On the left side of the printer, a fold-out hook that holds the filament reel also contains an NFC card reader that identifies the filament reel to the device. This allows the printer to track both the color and how much of the printer filament is left on the reel.

At the bottom of the open space in the middle of the Mini is the print bed, a 6 x 6-inch aluminum slab covered with a sheet of tape that the PLA print material sticks to. This sheet can be easily swapped out if it is damaged while removing a print. The Mini ships with three, and replacements cost less than a dollar each.

With its bright orange plastic case, the da Vinci Mini certainly stands out from the crowd of me-too black printers.

This print bed means the da Vinci Mini can build prints up to 5.9 x 5.9 x 5.9 inches, or a little more than 205 cubic inches. That's a good size for a small printer, but it comes with one caveat: there is no heating on the print bed, so larger prints may not always stay stuck to the bed. XYZ recommends that you should apply a bit of white glue to the print bed before starting on a large print.

XYZ recommends that you should apply a bit of white glue to the print bed before starting on a large print.

Above the print bed is the extruder assembly, hidden in a black box that snaps into place when you put the printer together. This print head moves left to right and up and down, while the print bed moves forward and backward to provide the full range of movement. On the right side of the print head is a single button that lowers the bed sensor. The filament feeds through the top of the frame in a plastic tube that routes it to the mechanism that pushes the filament into the extruder.

MORE: Top-Rated 3D Printers on the Market Now

Controls: Stick with Software

The da Vinci Mini has no controls on the printer itself. Instead, everything's located in the XYZware program, available as a free download for Windows and Mac. This program is straightforward and simple to use, presenting you with a rotatable preview of the 3D model. You can scale, shift or load multiple models to print at once, but you can't edit the models.

Setup: Auto-Calibration Is Key

The da Vinci Mini is a fairly simple printer to set up, with most of the time taken up removing the multiple pieces of tape holding the various parts in place during transit. This does involve some hassle: the arm that the print head sits on has a couple of plastic tubes holding it in place that you have to yank out, making an alarming cracking noise that initially made me think I had broken something. Once I concluded that I had not, the next steps involved installing the filament spool, feeding the filament into the print head and starting the printer up.

Once you install the XYZware, the Mini can be calibrated. This is a mostly automated process: you select the calibration option in the software, and press a button on the print head when requested. This lowers a small sensor, which the printer uses to detect the print bed and ensure it is level.

That's a lot simpler than printers like the Monoprice MP Select that ask you to calibrate things manually; thus, the Mini is less prone to user error. Auto-calibration also works well: we found that we needed to recalibrate the printer only when it was moved from one location to another.

Auto-calibration also works well: we found that we needed to recalibrate the printer only when it was moved from one location to another.

Materials: Pretty Restricted

The da Vinci Mini works only with PLA filament from XYZ: if you try to install a reel of third party filament without one of the NFC tags that accompanies a reel of XYZ’s own filament, the printer will refuse to accept it. As well as authorizing the filament for use, these tags contain the color of the filament, plus a running total of the amount used.

MORE: How to Buy the Right 3D Printer

XYZ currently charges $27.99 for a reel of PLA filament that holds 600 grams of material, which is comparable to the cost of most third-party filaments.

Print Process: Sticky Business

We did have some issues with prints not sticking to the print bed: we found that moderate-size prints tended to peel a little at the edges, even with the addition of white glue as recommended by XYZprinting and its software. However, we found that, if the print was built on a raft — a latticework of printed material laid underneath the print to help it stay stuck to the print bed — it succeeded most of the time.

However, we found that, if the print was built on a raft — a latticework of printed material laid underneath the print to help it stay stuck to the print bed — it succeeded most of the time.

In our tests, we found that our standard gears print failed without a raft, because the parts were too small to stick to the print bed. However, the gears printed without problems when the raft was added.

Print Speed: Setting Determines Speed

Depending on the setting you use, the da Vinci Mini can be both a very fast and a very slow printer. Printing at the Normal quality preset (which uses a 0.4mm layer height), it could crank out a 4.5-inch-high print of our Thinker model in a little less than 4 hours. That's impressively fast, especially for a printer at this price, and it's significantly faster than more expensive printers like the da Vinci Pro.

(Image credit: Richard Baguley)But when you raise the print quality, things slow down. Using the Good setting increased the print time to 6 hours and 43 minutes, and at the Excellent quality print setting, this printer took more than 12 hours to produce the same sized print. This setting uses a 0.2mm layer height and slows down the movement of the print head to improve the print quality.

Using the Good setting increased the print time to 6 hours and 43 minutes, and at the Excellent quality print setting, this printer took more than 12 hours to produce the same sized print. This setting uses a 0.2mm layer height and slows down the movement of the print head to improve the print quality.

To be fair, we should point out that the Mini achieves its fast speeds by having a slightly larger layer size than most 3D printers. It uses a layer height of 0.4mm for the Normal preset, while the da Vinci Pro uses a 0.2mm layer height for its Normal preset. Think of it as trying to paint a wall with a brush that is 4 inches wide, or one that is 2: the larger brush spreads more paint, so it will go quicker.

Print Quality: Clean and Smooth, But Some Flaws

We were impressed with the print quality of the da Vinci Mini: it produced clean, smooth prints with acceptable detail in most of our tests, with only a few glitches.

(Image credit: Richard Baguley)The Normal quality preset produces the quickest prints, but that comes at the cost of visible layering and some glitches, such as the odd misjoined layer that produces a visible gap in the print, which looks like a layer of filling in a cake. On our gears test model (which creates a set of planetary gears that fit together), we found that this layering produced some malformed parts that didn't fit together.

On our gears test model (which creates a set of planetary gears that fit together), we found that this layering produced some malformed parts that didn't fit together.

Switching to the Good preset gets rid of these gaps, and produced gears that fitted together nicely. On our Thinker test print, the layers are still visible close up, though. The Excellent preset lives up to the name: The prints produced using this are very smooth and clean, with very nice curves and sharp edges. There are still some slight glitches, though: the top of the Thinker’s head had a few lumps and strands of filament on it that looked like a bad comb-over.

(Image credit: Richard Baguley)The only model that the da Vinci Mini failed to print properly was our geometric sculpture. The printer failed to print parts of the flat faces that form the core of the sculpture, so the print fell apart when we removed the support material.

MORE: How 3D Printers Work

The da Vinci Mini offers a lot of printing performance for its $270 price, producing clean, attractive prints with only a few glitches. The Good preset provides the best balance between speed and quality.

The Good preset provides the best balance between speed and quality.

What you don't get with the Mini is the flexibility of other 3D printers: it can print only with ABS filament bought directly from XYZprinting. This material isn't any more expensive than others (and comes in a good selection of colors), but it means you can't experiment with different types of filament, such as wood and nylon, that are now available and that can be used with printers like the $399 Printrbot Play.

That may not be a problem for most users, though, and the da Vinci Mini offers value for money that is hard to beat.

Today's best XYZ da Vinci Mini 3D Printer deals

No price information

For more information visit their website

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Tom's Guide is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

XYZ Da Vinci mini. The last three letters of the alphabet.

Together with the Ultimaker 2 Go, the guys from IGo3D sent me and this little one for review. The kid, made specifically for all sorts of TsMIT, that is, for children's creativity, therefore, should be as simple as slippers, but nevertheless be able to print honestly, so as not to be rejected by the young generation of makers who Marco Bruni brings up so diligently. True, offering his version of Prusa.

Is he as screwed up as he is painted?

Let's do a little unpacking. A neat box with a picture of the printer and the model name.

Inside - a complete set of various necessary devices for printing.

This is a scraper/palette knife. If sharpened, it is convenient to pick off the part from the table. Although, I prefer a clerical knife.

USB cable - USB type B, for connection to a computer.

Sheet of paper tape. In general, there should be 3 of them. One is glued on, one is a spare, and another piece was on the Ultimaker table when it was delivered to me. Unheated table, designed for PLA printing only. The knights of the cold table will appreciate this miracle, costing less than $300. Particularly hard-nosed citizens manage to print on drygostols with nylon. As you know, everyone has their perversions.

Interesting brush. Designed to clean the feed gear of the extruder from plastic chips, if it suddenly feeds poorly. I used this to wash baby bottles and nipples. :D

Such a funny aluminum record. As the manual says, it's a Leveling tool. The level, then, will expose them.

As the manual says, it's a Leveling tool. The level, then, will expose them.

And spare fitting PC4-01.

Of course, the power supply, 24V and 2.5A.

The printer itself is so shiny and glamorous. Purebred pryuche-shaped drygost. I myself played enough of this at one time, I bought an acrylic dry-table on aliexpress at the dawn of sales on Ali. The printer is made in a beautiful glossy case of bright colors, which undoubtedly attracts the attention of children.

Of course, for the sake of caring for the environment, and minimizing the possible risks of electrical and thermal injuries - there is no heating of the table. Printing is offered with polylactide (PLA) only. All possible moving and rotating and heating parts are covered with protective casings and provided with warning labels.

Just the right time to stick a large sheet of paper tape from the ZIP on the table, for better adhesion of the plastic to the table.

The most important thing is the simplicity of the design. XYZ decided to go the easy route, like inkjet printers, using rolled aluminum in the form of a beam and a second rail. The first is the shaft. Belts are applied closed, thin.

Z-axis coupling made of pipes, with screw holes. No split joints. And just one pin.

The classic scheme for most inkjet printers is a stamped aluminum sheet, with shaft and motor mounts, attached to a molded plastic part, with bearings installed in Z. studs M5. Simple and no frills.

Head feed - classic bowden. Attached is a picture of how to refill the plastic. A little lower is a folding reel seat.

We press the pressure lever from below and insert the plastic into the extruder.

Even with bearings. The coil rotates freely. This option is ideal for flex printing.

This option is ideal for flex printing.

The carrier structure of the printer is based on an aluminum profile. Reliable, beautiful, easy to install.

Optical limit switches are located at the bottom of the housing for precise positioning of the extruder.

On the back, on the panel, there is a power connector and a connector for connecting to a computer.

The top of the printer is closed with a lid, with a slot for a Bowden tube, with a company logo.

The printer is quite compact, its table, when installed against the wall, does not rest against the wall. And it fits easily on the windowsill.

What about software?

The manufacturer supplies a simple and understandable software for children - slicer XYZware.

We connect the printer to the computer, select our printer, upload the model and print. Everything seems to be simple.

Everything seems to be simple.

In addition to printer management and print preparation software, XYZ distributes its free 3D modeling software, XYZmaker.

Download utilities on the official website.

The printer, in addition to simulating a COM port, has a fully functional Wi-Fi.

Select our printer from the list.

Connect it via USB.

It is then defined in the program.

In the settings, you can set up a Wi-Fi connection and safely cut off the USB cable. Since they were already printed in IGo3D, 33 meters out of 100 remained from the complete coil. Not a lot. Okay, let's load what we have.

In the thread menu, select boot.

Follow the instructions on the screen.

Here we either wait until he pulls the snot out of the nozzle and press ready, or wait until he spit out a little more of it (he knows the length of the tube) and turn off the flow himself.

Now let's calibrate the plane of the table. This can be done in the settings menu.

Select calibration.

We press the magic button, and a probe comes out from below, which will measure the surface of the table in 9 currents, in order to map the surface of the table. That is, when the table is curved, it will bypass this curvature and print smoothly.

And after measurements, he asks to remove the probe by pressing the button.

Excellent, surface calibrated. Now let's calibrate the offset.

This is the calibration of the optical limit switch in Z. It must be done if the first layer does not lie flat, that is, either the nozzle is imprinted on the table (and you need to press the button with the up arrows) or the thread from the extruder lies on the table freely and does not stick (then press down arrow). Each press makes a change in 0.05 mm increments. This is usually not required before the first print.

Each press makes a change in 0.05 mm increments. This is usually not required before the first print.

All calibrated, start printing.

To load and slice a model, it must be loaded into the program in STL or OBJ format.

For the test, I decided to print the head of some alien humanoid, which was shared with me here. With the thinnest layer of 0.1 mm and high speed.

Select settings. And press print. Slicing starts.

After that, you can save to your g-code format - 3w.

Regarding the size, you can scale it with standard tools.

I selected based on the amount of free time and the remaining filament.

Press print and the g-code file is transferred to the printer's internal memory.

Then it warms up the nozzle and starts printing. During printing, any actions with the printer are not available, only pause and stop printing.

During printing, any actions with the printer are not available, only pause and stop printing.

Since I have less than a third of the reel left, I periodically got such messages.

Printing starts in Makerbot style - 2 lines are drawn on the edge to ensure plastic feed.

And then - the brim ordered in the settings.

The first layer is printed very thick and is not adjustable. But filling at high speed (which is not the maximum, but still about 70 mm / s) works out disgustingly. Outlines draw well. But it prints in a strange way, apparently very large jerks (Jerk) at small accelerations, so at first it moves smoothly and slowly, and then when switching to idle, it slowly accelerates, and in the end it just flies at high speed to the desired coordinate.

Conclusions

We must pay tribute to the developers, they minimized the cost of the printer so much that from there is the maximum that can be pulled out to the organs - steppers, limit switches and an extruder with a cooler. All.

All.

Regarding noise - it prints comparable to inkjet MFPs and the like, there is a rattling backlash of plastics, a few melodies of steppers. In principle, this is what everyone is striving for, to make a super-cheap printer and get the main profit from consumables. But, not only in the Russian Federation, this idea seems ridiculous, filament counter resetters are already being sold on Ebay.

If you judge by the ease of working with a printer specifically for children, then this is the undoubted leader, everything is intuitively simple, and no intervention with a screwdriver is required. There is no need to understand how a stepper motor works and how to determine the sequence of its connection to the printer board, you do not need to understand the firmware settings and learn the basics of C ++. Just turn it on and follow the instructions on the screen.

The print quality is quite decent for this price category, and the presence of an auto-level table is an undeniable advantage over all sorts of plush-shaped designs in the form of a whale for twice the cost of this baby.

This is the head. The printing is accurate, for this kinematics it is a masterpiece.

No wobble, the plastic feeds evenly and neatly.

As you can see, the biggest mistake of the company is the lack of blowing of the part, despite the fact that the print is blocked only by PLA. But despite this, many hanging elements turned out just gorgeous.

And now the guts...

And inside it has one board of its own design.

Accurate wiring, there is only one ground for the entire printer, and it is displayed on the frame from the profile.

The heart of the printer is a 32-bit processor from Atmel. Approximately, as in Arduino Due. With support for 1 device with SD / eMMC memory, one USB and ethernet port occupied by Wi-Fi.

Memory - Kingston 4 GB, eMMC. The g-code file is loaded there after slicing. It is likely that after the start of printing, you can generally cut off the cable from the PC and printing will not stop. This is probably why, during printing, there are no flow and speed settings.

The g-code file is loaded there after slicing. It is likely that after the start of printing, you can generally cut off the cable from the PC and printing will not stop. This is probably why, during printing, there are no flow and speed settings.

Toshiba drivers, micro-stepping up to 1/32.

The best 3d printer - a device that quickly builds a given part. The device allows you to create cases for your smartphone, toys, dishes, etc. Suitable for home and business use.

Review of the best budget 3D printers for the home

These are inexpensive models with a minimum set of options. Create elements from different materials using different technologies.

Wanhao Duplicator i3 mini

Compact device with small print area. Can be used immediately after unpacking. To do this, just install the device, perform calibration. Compatible with various operating systems. Quickly creates the given element. Monochrome screen for easy parameter setting. The display shows information about the current process - nozzle temperature, percent complete, etc. Good cooling system.

Quickly creates the given element. Monochrome screen for easy parameter setting. The display shows information about the current process - nozzle temperature, percent complete, etc. Good cooling system.

Characteristics:

- technology - FDM, FFF, PJP;

- design - open chamber;

- raw material - PLA;

- connection - USB, SD;

- speed - 70 mm/s;

- OS compatible - Windows, MAC, Linux, Unix;

- dimensions - 325x380x240 mm;

- weight - 7 kg;

- price - from 14900 rubles.

Advantages:

- is completely ready for operation;

- easily connects to the operating system;

- securely holds the model;

- Glue stick included.

Disadvantages:

- freezes periodically;

- poor quality screw table levelers;

- no Russian menu.

Creality Ender-3

Easy-to-operate device with high model creation speed. Sturdy platform with even heating. Allows you to work without an adhesive coating. Printing can be paused with saving the settings, then resuming the process. Power supply with active cooling.

Sturdy platform with even heating. Allows you to work without an adhesive coating. Printing can be paused with saving the settings, then resuming the process. Power supply with active cooling.

Characteristics:

- technology - FDM, FFF, PJP;

- design - open chamber;

- raw materials - ABS, PLA, Wood;

- connection - USB, micro SD;

- speed - 180 mm/s;

- dimensions - 440x465x420 mm;

- weight - 6.9 kg;

- price - from 16900 rubles.

Advantages:

- prints well;

- ease of use;

- wear parts;

- compact.

Disadvantages:

- noisy;

- is obsolete and needs to be upgraded.

TEVO Tornado

Repairable and upgradeable model. Suitable for use by beginners. Easy control, simple settings. Can be used daily. Creates smooth elements of different dimensions. Large print volume. The titanium extruder ensures the high performance of the printer. Installed on any surface. Well implemented cooling system.

Installed on any surface. Well implemented cooling system.

Characteristics:

- technology - FDM, FFF, PJP;

- design - open chamber;

- raw materials - ABS, Flex, PLA, PVA, Wood, PETG;

- connection - USB, SD;

- speed - 150 mm/s;

- OS compatible - Windows, MAC, Linux, Unix;

- dimensions - 560x620x600 mm;

- weight - 11 kg;

- price - from 31700 rubles.

Advantages:

- quick assembly;

- easy to set up;

- strong, stable frame;

- can create large elements;

- is easy to reflash.

Disadvantages:

- airflow is poorly implemented;

- some accessories are made of plastic;

- The work table has a poor adhesive coating.

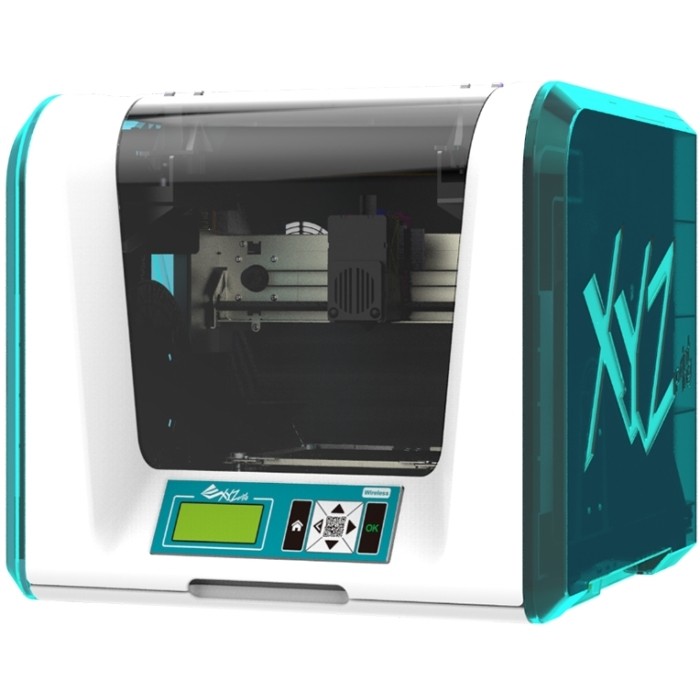

XYZPrinting da Vinci Junior Pro

A simple but functional device. Supplied with a memory card containing the software. If there is no suitable output on the computer, the software can be downloaded from the official website of the manufacturer. The backlight of the camera allows you to see the internal components. Ready for use immediately after unpacking. No manual calibration required. The cooling system works well, so the device does not overheat during operation.

The backlight of the camera allows you to see the internal components. Ready for use immediately after unpacking. No manual calibration required. The cooling system works well, so the device does not overheat during operation.

Characteristics:

- technology - FDM, FFF, PJP;

- design - open chamber;

- raw material - PLA;

- connection - USB, Card Reader;

- speed - 40 mm/s;

- compatible with OS - Windows, MAC;

- dimensions - 420x430x380 mm;

- weight - 12 kg;

- price - from 38400 rubles.

Benefits:

- easy cartridge replacement;

- safety;

- ease of operation;

- compact;

- no assembly required.

Disadvantages:

- limited type, material manufacturers;

- small screen.

Prusa i3 Steel

Easy to set up model. Small size allows you to install it on the desktop. The steel frame ensures accurate printing. Possibility of modernization. A clear step-by-step guide helps to quickly assemble the device. High quality cooling system. The medium print area allows you to make souvenirs, small toys, etc.

Possibility of modernization. A clear step-by-step guide helps to quickly assemble the device. High quality cooling system. The medium print area allows you to make souvenirs, small toys, etc.

Characteristics:

- technology - FDM;

- raw materials - ABS, PLA, PVA, HIPS;

- connection - USB, SD;

- speed - 200 mm/s;

- compatible with OS - Windows, MAC, Linux;

- dimensions - 410x480x450 mm;

- weight - 11 kg;

- price - from 44800 rubles.

Advantages:

- low vibration;

- creates smooth models with a homogeneous structure;

- rich equipment;

- clear instructions;

- ease of use;

- rigid stable frame;

- good airflow.

Disadvantages:

- difficult to fix bar, SD card;

- The work surface takes a long time to heat up.

Geetech A10M

Multicolour maker. The mixer allows you to mix material of different shades to simulate elements with gradients. Can be used by beginners at home. Firmware update via internet. High print speed. The finished part fully complies with the specified parameters. Convenient control panel with source open source. System for resuming an interrupted process.

Can be used by beginners at home. Firmware update via internet. High print speed. The finished part fully complies with the specified parameters. Convenient control panel with source open source. System for resuming an interrupted process.

Characteristics:

- technology - FDM, FFF;

- raw materials - ABS, HIPS, PETG, PLA, PVA, Rubber;

- connection - USB, SD;

- compatible with OS - Windows, MAC, Linux;

- dimensions - 530x470x230 mm;

- weight - 8.8 kg;

- price - from 27000.

Advantages:

- wide platform;

- print precision;

- ease of use;

- large touch display;

- forms products from different materials.

Disadvantages:

- components fail quickly;

- slow operation.

FlyingBear Ghost 4S

High performance device. Uninterrupted supply of plastic. Connecting to a computer via Wi-Fi. In the event of a power outage, the settings are saved. The process is resumed with the given parameters. Automatically deactivated after completion of work. Forms elements with complex geometry. Smooth surface details. Wear resistant components. The all-metal frame provides stability on the basis.

The process is resumed with the given parameters. Automatically deactivated after completion of work. Forms elements with complex geometry. Smooth surface details. Wear resistant components. The all-metal frame provides stability on the basis.

Characteristics:

- technology - FDM;

- raw material - PLA, ABS, TPU, Wood, HIPS;

- connection - Wi-Fi, USB, SD;

- speed - 150 mm/s;

- compatible with OS - Windows, MAC;

- dimensions - 392x342x420 mm;

- weight - 15 kg;

- price - from 35000.

Advantages:

- ease of operation;

- large touch screen;

- many functions;

- simple setting.

Drawbacks:

- mediocre assembly;

- Poor blower system.

Anycubic I3 Mega

Compact device suitable for creating flexible elements. The heated work surface allows you to easily remove finished products after cooling. The material feeds smoothly for accurate printing. Can be used immediately after unpacking. Solid, secure platform. Rigid metal frame guarantees stability. Good adhesion of the first layers ensures a clear creation of figures. The touch display displays the set parameters. The screen provides access to settings, real-time operation control. Power failure protection system.

The material feeds smoothly for accurate printing. Can be used immediately after unpacking. Solid, secure platform. Rigid metal frame guarantees stability. Good adhesion of the first layers ensures a clear creation of figures. The touch display displays the set parameters. The screen provides access to settings, real-time operation control. Power failure protection system.

Characteristics:

- technology - FDM/FFF/PJP;

- design - open chamber;

- raw materials - ABS, PLA, Wood, HIPS;

- connection - USB, SD;

- speed - 100 mm/s;

- dimensions - 405x453x410 mm;

- weight - 11 kg;

- price - from 23800 rubles.

Advantages:

- accurate printing;

- works out of the box;

- color screen;

- updated table;

- good adhesion to the substrate;

- ease of use;

- easy setting.

Disadvantages:

- start-up squeak;

- smell of plastic;

- noisy.

Tevo Tarantula Pro

Budget model that works with different materials, including soft ones. Quickly forms an element. Smooth uninterrupted supply of plastic. Wide opportunities for modernization. Original design. Small dimensions, so the installation of the device does not require a lot of space. Suitable for creating large figures. The frame is not strong enough. This suggests that problems may arise during operation. To avoid their appearance, you need to securely fix the device on the countertop.

Characteristics:

- technology - FDM, FFF, PJP;

- design - open chamber;

- raw material - ABS, Flex, Nylon, PLA, PVA, Wood, ASA, HIPS, PETG, PP, SBS, POM;

- connection - USB, USB Type A, SD;

- speed - 150 l/h;

- compatible with OS - Windows, Linux, Unix;

- dimensions - 434x504x333 mm;

- weight - 8.5 kg;

- price - from 18900 rubles.

Benefits:

- large print area;

- compact;

- powerful power supply;

- quick work;

- uniform platform heating;

- well implemented cooling system.

Drawbacks:

- cheap material parts;

- requires hard surface mounting.

Top of the line models for small and medium businesses

These devices help organizations increase productivity, increase revenue. High speed, advanced functionality.

Zortrax M200

Semi-professional instrument with open housing. Platform with auto-calibration, uniform heating. The built-in Wi-Fi module allows you to connect devices without the use of wires. Large print area. Additional features to improve the product forming process. Automatic deactivation of the device when the material runs out.

Advanced cooling system. The built-in camera allows you to watch the creation of figures from a computer. You can use immediately after unpacking. No assembly or calibration required. Automatic firmware update via Wi-Fi allows you to improve the interface.

Characteristics:

- technology - FDM, FFF, PJP;

- raw materials - ABS, PLA, Nylon, PC;

- speed - 100 mm/s;

- compatible with OS - Windows;

- dimensions - 345x360x430 mm;

- weight - 13 kg;

- price - from 138200 rubles.

Advantages:

- is completely ready for operation;

- accurate, fast printing;

- silent operation;

- well implemented cooling system.

Disadvantages:

- problems with the creation of large products;

- poor quality components.

Ultimaker 3

Professional, reliable device. Choice of preset, program settings. Automatic material feed. Suitable for creating elements with complex geometry. Built-in camera for monitoring work remotely. Uniform platform heating. You can work with different materials. Allows you to make shapes with two colors. Automation of the process eliminates the occurrence of errors during operation. Consumables recognition system, selection of suitable settings. No manual calibration required.

Characteristics:

- technology - FDM, FFF, PJP;

- raw material - ABS, PLA, PVA, NEYLON, HIPS, Flex, CPE;

- connection - Wi-Fi, Ethernet;

- compatible with OS - Windows, MAC;

- dimensions - 357x338x338 mm;

- weight - 13 kg;

- price - from 330,000 rubles.

Advantages:

- adjustable;

- the presence of a second switchable nozzle;

- variety of materials;

- white recessed light;

- high print volume;

- fast product forming.

Disadvantages:

- motors get very hot;

- balancing difficulty;

- noisy work.

Picaso Designer X Pro

The model is made of reliable, durable, wear-resistant materials. Platform with uniform heating. Creates elements of different thicknesses. Convenient control, setting. Solves problems of any complexity. The process control system allows you to monitor the supply of plastic, the uniformity of the applied layers. The display reports the status of the current job. The device is suitable for the production of industrial parts. Automatic calibration sets up the platform in seconds.

Characteristics:

- technology - FDM;

- raw materials - PLA, ABS, PLA Flexible, PVA, PC, Hips, Nylon, Laywood, FilaFlex, Filamentarno;

- connection - USB, Ethernet, USB Flash;

- speed - 30 cm3/hour;

- compatible with OS - Windows;

- dimensions - 492x390x430 mm;

- weight - 22 kg;

- price - from 149000 rubles.

Advantages:

- printing accuracy;

- easy calibration;

- easily removable magnetic table;

- directional material feed;

- fast work.

Disadvantages:

- constantly clogs the nozzle;

- when a new layer is formed, a void is formed.

Tevo Nereus

Low cost, easy to use device. Suitable for personal use, custom printing. Wi-Fi module for wireless synchronization with devices. The process can be controlled remotely from a smartphone. Large touch screen for easy setup. Built-in uninterruptible power supply in case of a power outage. Durable aluminum frame provides stability. Open source.

Characteristics:

- technology - FDM;

- raw materials - ABS, HIPS, Nylon, PETG, PLA, PVA, Rubber;

- connection - Wi-Fi;

- speed - 150 mm/s;

- weight - 13 kg;

- price - from 30900 rubles.

Advantages:

- color touch display;

- surface heats up quickly;

- wide print area;

- backlash-free assembly;

- option to restart the process after a power outage.

Weaknesses:

- loud power supply fan;

- "raw" firmware.

Artillery Sidewinder X1

A model that can be used right out of the box. Wide work surface. Almost instant heating of the platform. High positioning accuracy. Wear-resistant materials of increased strength. The table cover is perforated glass with good adhesion to all types of plastics used. After the process is completed, the figures are easily removed from the surface. Powerful, directional material flow.

Characteristics:

- technology - FDM, FFF, PJP;

- design - open chamber;

- raw material - ABS, Flex, Nylon, PLA, Wood, HIPS, PETG, PC;

- connection - USB, SD;

- speed - 150 mm/s;

- OS compatible - Windows, MAC, Linux, Unix;

- dimensions - 780x250x540 mm;

- weight - 16.5 kg;

- price - 36900 rubles.

Advantages:

- high print speed;

- process control system;

- easy setting;

- touch control.

Disadvantages:

- short USB cable;

- inconvenient port layout;

- noisy fans.

Two Trees Sapphire S

Unit with stable aluminum frame. Option to resume operation after a sudden power outage. Fast uniform heating of the platform with three leveling points.

Features:

- technology - FDM;

- raw materials - PLA, ABS, PETG, Wood;

- connection - USB;

- speed - 180 mm/s;

- compatible with OS - Windows;

- dimensions - 450x450x320 mm;

- weight - 12 kg.

Advantages:

- easy assembly;

- Russian language menu;

- convenient touch screen;

- forms elements quickly;

- creates parts with complex geometries.

Disadvantages:

- few settings;

- incomprehensible interface;

- inconvenient way to fasten straps;

- Firmware failed.

Elegoo Mars

Compact model with no backlash assembly. Accurate, clear printing at high speed. High resolution color touch screen. Wide plotting area along the XY axis. Compatible with many materials. The smoothing function reduces the effect of stairs on the product.

Accurate, clear printing at high speed. High resolution color touch screen. Wide plotting area along the XY axis. Compatible with many materials. The smoothing function reduces the effect of stairs on the product.

Features:

- technology - DLP;

- design - closed case;

- raw material - 405NM UV resin;

- connection - USB;

- weight - 6.8 kg;

- price - from 31500 rubles.

Benefits:

- easy to calibrate;

- ease of use;

- high speed;

- original slicer;

- consumable savings.

Faults:

- noisy fan;

- inconvenient port layout.

The best SLA models for small and medium businesses

Printing using laser stereolithography technology - the formation of elements with high resolution, accuracy, the smallest deviation of details from the specified parameters. Wide working area. SLA 3D printers are suitable for use at home, in small workshops, and in large-scale production.

WANHAO DUPLICATOR 8

Model with simple, user-friendly operation. The print speed can be adjusted. Material - photopolymer resin. It allows you to create complex geometric shapes with a smooth surface. Cures quickly with LED light. There is a viewing window on the side of the table to monitor the process.

Characteristics:

- design - closed chamber;

- raw material - photopolymer;

- connection - USB, Wi-Fi;

- speed - 30 mm/hour;

- OS compatible - Windows, MAC, Linux, Unix;

-

price - from 92000 rubles.

- Advantages:

- compact dimensions;

- light weight;

- works fast;

- forms several products at the same time;

- high performance;

- automatic leveling mechanism;

- high capacity resin tank;

- convenient touch screen for operation;

- no special conditions for installation, operation.

Disadvantages:

- no on/off button on front panel;

- custom design.

Formlabs Form 2

Intuitive instrument. Forms elements with a smooth surface. Stable operation with uniform material feed. Suitable for forming large products. Good cleaning system - foreign particles are regularly removed from the construction, mixing area to create parts with a uniform structure. The platform heats up evenly.

Characteristics:

- technology - SLA;

- design - closed chamber;

- raw material - photopolymer;

- connection - USB, WI-FI, Ethernet;

- compatible with OS - Windows, MAC;

- dimensions - 350x330x520 mm;

- weight - 13 kg;

- price - from 259000.

Advantages:

- convenient touch screen;

- smooth surface of figures;

- automatic material volume control;

- clear print;

- ease of use;

- You can create multiple elements at the same time.

Disadvantages:

- defects in the formation of small parts;

- expensive consumables.

B9 Creator

Precision print model. Wide working area. Suitable for creating products with complex geometry. A high resolution. You can make figures in a thin layer. Flat, smooth surface. Application of material without voids. Suitable for jewelry production. Works with cured epoxy.

Characteristics:

- raw material - liquid photopolymer;

- connection - USB, SD;

- speed - 12-20 mm/hour;

- compatible with OS - Windows, MAC;

- dimensions - 790x470x305 mm;

- weight - 13.5 kg;

- price - from 337250 rubles.

Benefits:

- fast printing;

- finished items match the specified parameters;

- simple design;

- maintainability;

- you can make complex parts.

Disadvantages:

- fine tuning required;

- Resin reservoir builds up solid particles preventing uniform flow of material;

- firmware problems.

Premium 3D printers

High performance expensive models. Extended functionality. Suitable for professional use.

Formlabs Form 3

Low power laser 3D printer. Quickly creates features with complex geometry. Reproduces the smallest details. Built-in sensors control the process, support printing conditions, notify about changes in the state of the device. Can be used immediately after unpacking. Does not require complex assembly.

Characteristics:

- technology - SLA;

- design - open chamber;

- raw material - liquid photopolymer;

- connection - Wi-Fi, Ethernet, USB;

- dimensions - 405x375x530;

- weight - 17.5 kg;

- price - from 336600 rubles.

Advantages:

- ease of replacement of consumables;

- ease of use;

- automated work;

- free software included in the kit;

- X, Y accuracy;

- layer thickness can be adjusted;

- wide range of materials;

- maintainability.

Disadvantages:

- print speed dependent on resin viscosity;

- risk of product deformation;

- high price.

Raise3D Pro2

Closed case model for low volume production. Sturdy aluminum frame provides stability. Large print area. Suitable for simultaneous creation of several products at once. Allows you to form complex shapes with fine details. Works at high speed. Convenient touch panel for process settings. Intuitive interface with a wide range of features. Complies with environmental safety standards, therefore suitable for the home. A silicone coating is applied to the surface of the working area, which allows you to remove the finished product without damaging it.

Characteristics:

- technology - FDM;

- design - closed chamber;

- raw materials - ABS, HIPS, Nylon, PETG, PLA, PVA, Rubber;

- connection - LAN, USB, Wi-Fi;

- speed - 30-150 mm/s;

- compatible with OS - Windows, MAC, Linux;

- dimensions - 620x520x760;

- weight - 44 kg;

- price - from 371000.

Learn more