Stratasys idea series 3d printers

| ||||||||||||||||||||||||||||||||||||||||||||||||||

Stratasys 3D Printers | Stratasys Materials & Service

A Trusted Partner

Since 1988, Stratasys has worked closely with thousands of companies around the world, helping them develop perfect 3D printing solutions.

Reimagine What’s Possible

3D printing solutions are about opening the minds of our engineers, educators, and medical professionals, creating limitless opportunity for our businesses and professions. Stratasys technologies helps you innovate new products, solutions, and techniques through design freedom, iteration, and ingenuity.

Rely on Performance

Stratasys 3D printing solutions elevate the quality, standards, and integrity of products so your customers delight in a great experience. They streamline workflows, inspire collaboration, and support end-to-end solutions so your organization delivers results through the best experience. Outperform the competition, increase ROI and, most importantly, create ideas that will shape the world.

-

FDM

-

PolyJet

-

SAF

-

P3

-

Stereolithography

FDM

Stratasys FDM 3D printers use production-grade thermoplastics to build strong, durable and dimensionally stable parts with the best accuracy and repeatability of any 3D printing technology.

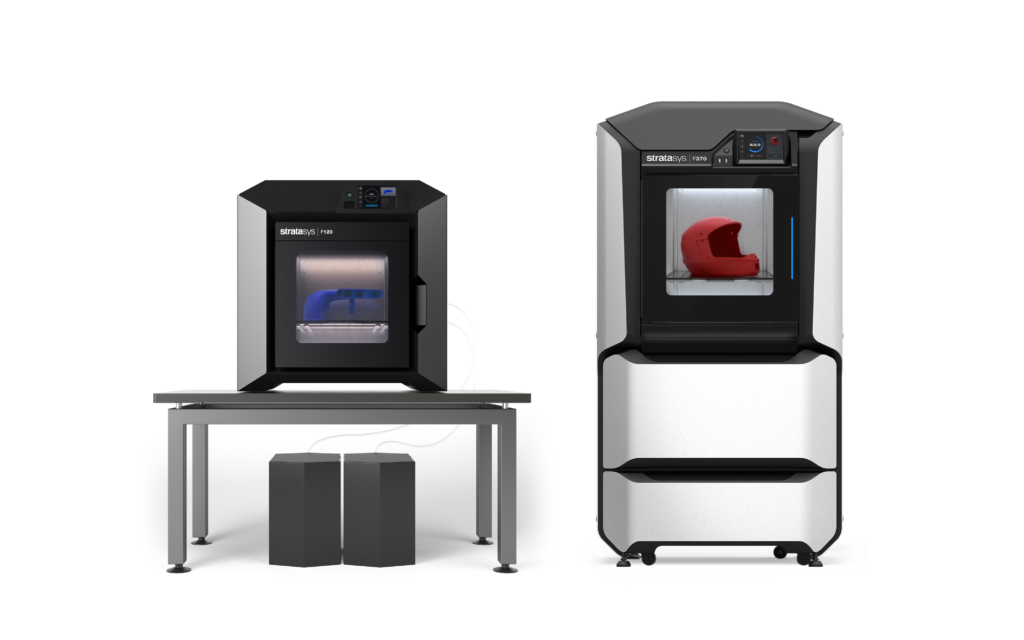

F123 Series Stratasys 3D Printers

Reliablity and simplicity in two affordable, industrial-grade, office-friendly 3D printers.

Learn More +

F123 Composite-Ready Stratasys 3D Printers

New!

Print stronger parts with carbon fiber 3D printers.

Learn More +

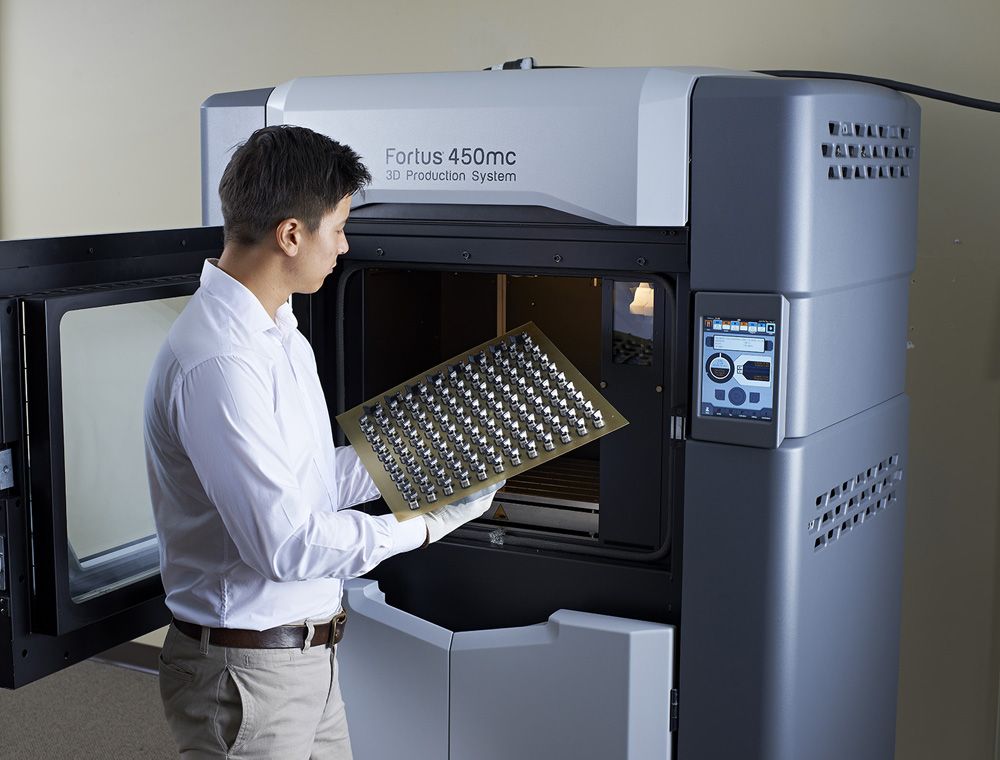

Fortus 450mc Stratasys 3D Printer

Built for streamlined manufacturing.

Learn More +

F770 Stratasys 3D Printer

Print large on a small budget.

Learn More +

F900 Stratasys 3D Printer

The largest-capacity FDM printer, delivering remarkable agility, sharp accuracy and high return on investment.

Learn More +

PolyJet

Stratasys' PolyJet is a powerful 3D printing technology that produces smooth, accurate parts, prototypes and tooling. With microscopic layer resolution and accuracy down to 0.1 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.

With microscopic layer resolution and accuracy down to 0.1 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.

Objet30 Stratasys 3D Printer

Precision prototyping on your desktop.

Learn More +

J35 Pro Stratasys 3D Printer

New!

The versatile multi-material office printer.

Learn More +

J55 Prime Stratasys 3D Printer

New!

Amazing possibilities at every turn.

Learn More +

J5 DentaJet Stratasys 3D Printer

New!

A small but powerful tool for dental labs.

Learn More +

J5 MediJet Stratasys 3D Printer

New!

The economical, compact, all-in-one medical modeling printer.

Learn More +

J850 Digital Anatomy Stratasys 3D Printer

New!

Proven anatomical realism.

Learn More +

J8 Series Stratasys 3D Printers

Realize and hone your design ideas more quickly, precisely and reliably, and be able to combine up to seven materials at one time.

Learn More +

J4100 Stratasys 3D Printer

Create large or small production tools and full-scale prototypes.

Learn More +

SAF

SAF technology empowers a powder-based additive manufacturing process that employs industrial-grade technology to achieve higher levels of production of end-use parts.

h450 Stratasys 3D Printer

Grow your business through volume production with consistent end-use functional parts.

Learn More +

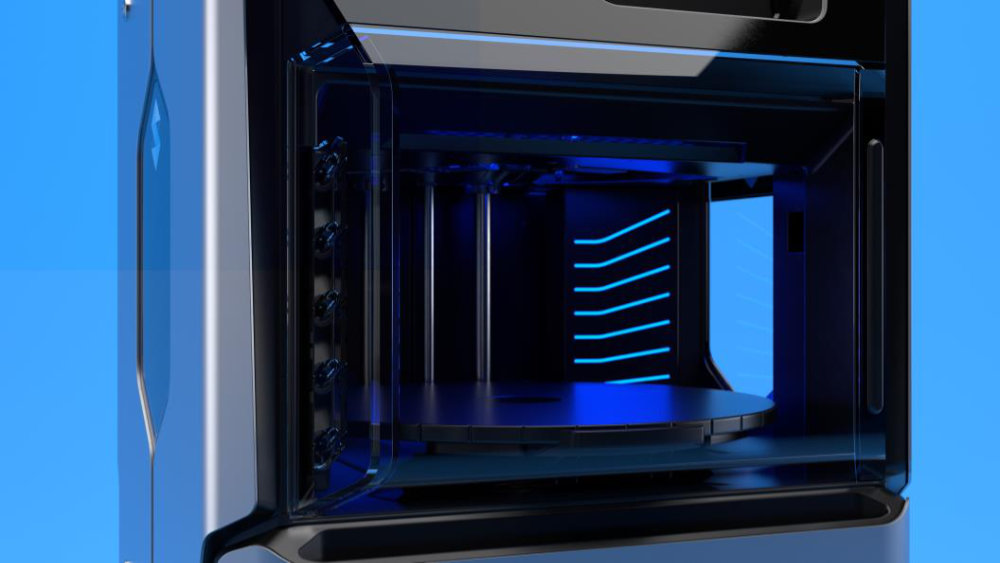

P3

P3™ Programmable Photopolymerization technology is a tightly synchronized print process that includes pneumatic controls to reduce pull forces during the print process, resulting in exceptional surface quality, without sacrificing speed or isotropy.

Origin One Stratasys 3D Printer

Achieve mass production of end-use parts in a diverse range of high-performance materials.

Learn More +

Origin One Dental Stratasys 3D Printer

New!

An industrial production solution for dental applications.

Learn More +

Stereolithography

The result of over four years’ testing, Stratasys' Stereolithography technology delivers outputs unfailingly, time after time with game-changing advances in speed, accuracy and reliability to the established capabilities of Stereolithography. creating smooth-surfaced prototypes, master patterns, large concept models and investment casting patterns more quickly and more precisely than ever.

creating smooth-surfaced prototypes, master patterns, large concept models and investment casting patterns more quickly and more precisely than ever.

Neo Series Stratasys 3D Printers

A versatile stereolithography printer with flexible options to suit all needs.

Learn More +

Stratasys 3D printers Overview of the entire line from 3DMALL

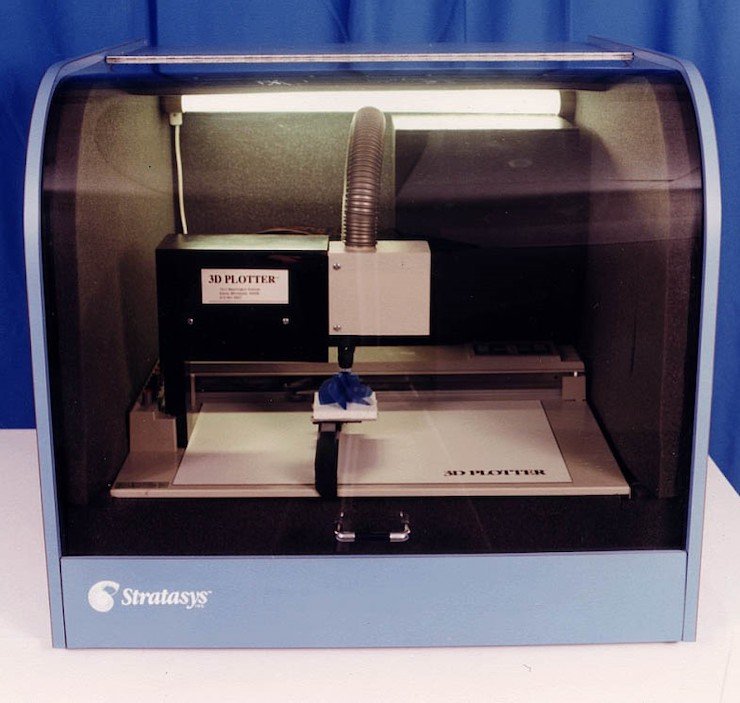

It's hard to believe, but 3D printing as a phenomenon is about to change its 4th decade. Technologies for 3D prototyping are developing more dynamically than any other industry. They are becoming more affordable, productive, their areas of application are expanding, and today it is difficult to imagine what would have happened to the modern world if in 1988 Scott Crump, one of the founders, inspirers and engines of the future world famous brand Stratasys, had not invented on his own kitchen FDM printing.

Success story

The company Stratasys needs no introduction - even a layman who is remotely familiar with 3D printing technologies knows perfectly well that we owe its appearance to this brand.

Despite the fact that fusing technology, or FDM printing, is the first in the field of 3D modeling, the dynamic development and improvement of not only the method itself, but also the evolution of 3D printers, consumables, allows it to hold a leading position in the industry for more than 25 years.

Stratasys work tirelessly to expand the horizons and possibilities of 3D printing, to provide a solution to the current user problems, the complexity of which increases every day.

Today, this brand has the most complete list of innovative products and solutions in the field of 3D:

- constantly developing FDM and PolyJet technologies;

- many generations of 3D printers that make it possible to realize a project of any complexity without exaggeration in any industry from education, design and architecture to medicine, automotive and aerospace;

- a wide range of innovative printing consumables;

- professional additive manufacturing and 3D printing services available to everyone;

- popularization of 3D technologies by providing consultations;

- participation in the development of Thingiverse and GrabCAD specialized communities, which today offer free access to more than 2 million 3D models of various levels of complexity.

In three decades of manufacturing experience in technologies ranging from stereolithography to CNC modeling, there has not been a single year that has not been marked by iconic innovations from Stratasys, among which we would like to highlight the following developments:

- 1994 - presentation of the world's first thermoplastic for printing, which became the basis for the development and production of a wide range of consumables on the modern market;

- 2002 - Stratasys introduces the first desktop 3D printer under $30,000, increasing the number of pioneers in the personal 3D printing and maker segment;

- 2007 - the first 3D printer in the Objet equipment line was released, supporting several types of consumables;

- 2008 - the first industrial 3D printer appears;

- 2012 - Objet releases the first desktop device that supports 7 materials and the world's first machine that can combine 100 or more materials;

- 2014 - Stratasys introduces the first color printer.

And we are sure that this is far from the end - the brand Stratasys will continue to create new technologies, not only expanding the possibilities of 3D prototyping, but also making them, without exaggeration, limitless.

3D printing technologies. 3D Printer Stratasys

As a true pioneer in the field of 3D printing, Stratasys is actively developing in all its areas, including the continuous improvement of its own FDM and PolyJet technologies.

FDM is rightfully considered one of the most popular 3D modeling methods in modern conditions due to the simplicity and safety of the method. Layer-by-layer fusing of a thermoplastic thread makes it possible to work with objects of various complexity, including those with a complex or filigree shape. It is this technology that opens up new horizons for designers, architects, constructors and engineers, and at the same time is quite simple so that a child can easily master it.

PolyJet - a later development of the brand's specialists, which is based on the use of liquid photopolymers and growing a model by layer-by-layer deposition. The layer thickness is only 16 microns, during the prototyping process, polymers of various colors and textures can be used, due to which objects can have different physical and mechanical characteristics. It is the ideal solution for small-scale prototyping and mold casting for the production of urethane products.

The layer thickness is only 16 microns, during the prototyping process, polymers of various colors and textures can be used, due to which objects can have different physical and mechanical characteristics. It is the ideal solution for small-scale prototyping and mold casting for the production of urethane products.

Recently, Stratasys has also been actively involved in creating innovative solutions in stereolithography, direct and laser metal sintering, offering optimized designs and technologies also for industrial 3D modeling.

Consumables

Since 1994, Stratasys has been one of the world's most renowned manufacturers of consumables, the quality of which exactly meets the high requirements for 3D printers manufactured by this brand. The product line of this company is considered to be one of the richest in the segment. It includes high-tech thermoplastics of all available modifications, as well as photopolymer resins with unique characteristics, biocompatible and dental materials.

Additive Manufacturing

Stratasys not only leads the way in innovative solutions and the development of increasingly efficient technologies, the brand now offers professional additive manufacturing services.

Stratasys Direct Manufacturing is a unique service for single and serial production of parts, spare parts, structural elements of various products, which any business can use.

3D printers

With Stratasys 3D printers, without exaggeration, any idea is guaranteed to go through a difficult path from inception to implementation. Each model, regardless of size and purpose, is a professional product. All equipment manufactured by this company is united by the impeccable quality of not only the devices themselves, but also the modeling. Intuitive ease of use, the most functional software, efficiency of modeling and high quality of detailing - these qualities are inherent in each model, both budget personal and expensive industrial installations.

Among the most famous and sought after brands, Stratasys products are represented by a huge number of product lines, including the world famous Objet, Dimension, Fortus and Connex. It is no coincidence that this particular brand classifies its products not so much by lines, but by purpose, combining devices from different series into one of the subcategories - Idea, Design, Production and Dental.

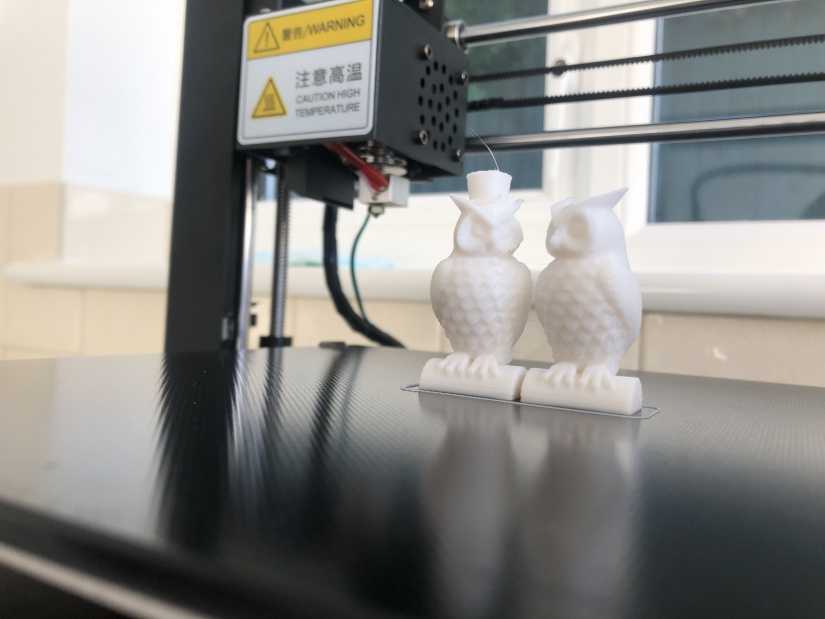

Idea

Idea is a series of truly affordable compact desktop printers for learning and creativity, featuring three Mojo printers and uPrint. Despite the very compact size, these kids allow you to model objects of varying complexity and large enough volume - this is a real opportunity to "feel" your idea and improve it already according to quite understandable, tangible criteria.

At a low cost, printers of this series can become indispensable assistants for designers, fashion designers, architects, constructors and researchers. Another advantage of all Idea devices is their pronounced simplicity, which allows them to be used to engage in the basics of 3D printing.

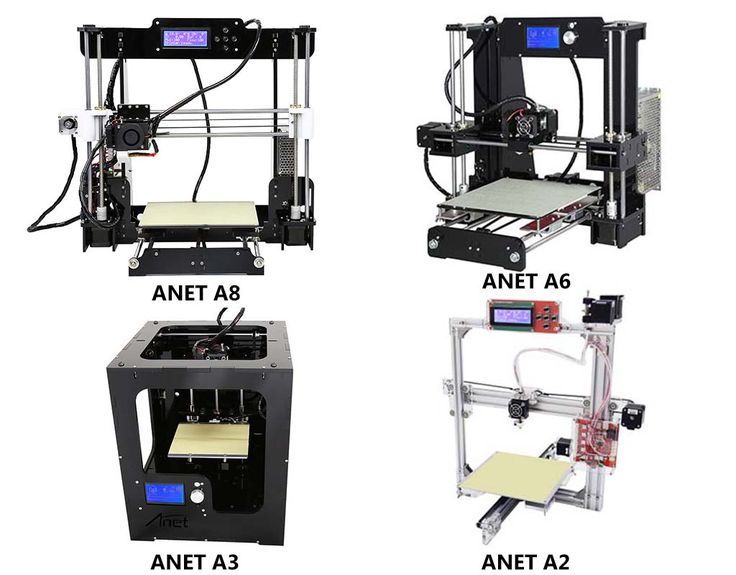

Design

The Design series of printers is still compact, but more productive units designed to make design and modeling processes faster and more efficient. These include most Objet, Dimension, and even the high-end Fortus 250mc 3D printers.

The innovation of each device in this series is not only in the best quality of prototyping, but also in the possibility of collaboration, a more advanced system of information exchange, improved parameters for protecting your intellectual property.

Use them to create monochrome and color objects, experiment with different types of consumables, modeling objects with different degrees of elasticity or different purposes. All devices of this series are characterized by high accuracy and detail, reliability.

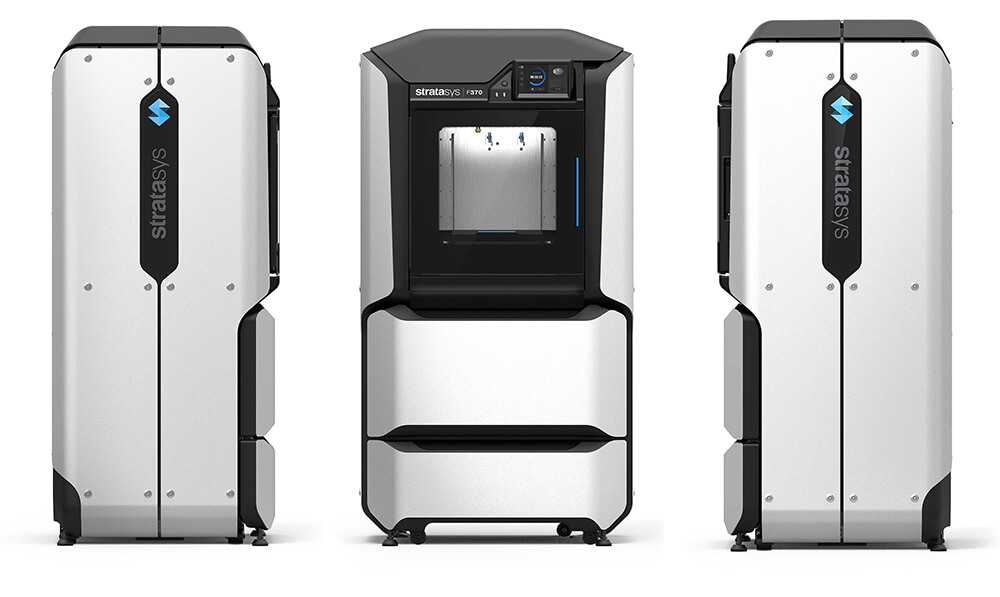

Production

The 3D Production series is a cost-effective and high-tech solution with an open production cycle, which can be changed at any stage of printing. In the additive manufacturing segment, Fortus, Objet and Connex 3D printers are rightfully considered leaders in the field of FDM and PolyJet technologies. Each of the units in this series is a high-performance device that works with a wide range of consumables and allows you to create durable and, importantly, accurate prototypes and fully functional parts with defined thermal, physical and chemical properties with the highest precision of detail and near-perfect visual characteristics.

Each of the units in this series is a high-performance device that works with a wide range of consumables and allows you to create durable and, importantly, accurate prototypes and fully functional parts with defined thermal, physical and chemical properties with the highest precision of detail and near-perfect visual characteristics.

Dental

It's no secret that 3D technologies are in great demand in medicine, in particular, in dentistry. Dental printing equipment is a high quality of service, a guarantee of an individual approach, the efficiency of manufacturing biocompatible prostheses and implants.

Digital Dentistry is one of the youngest and most promising trends of today, the development of which was made possible by the introduction of high-performance and amazingly accurate printing presses from Stratasys in the Objet line of equipment - OrthoDesk, Dental Selection, Dental Prime and Dental Advantage.

4D technologies

In recent years, the attention of leading developers of Stratasys has been focused on creating an even more innovative product in the field of already 4D modeling - yes, yes, that's right, the presentation of the first innovative products in the field of 4D printing is just around the corner.

According to some sources, one of the latest Connex printers could be the first 4D prototyping test machine. One of the features of the printers of this line is the ability to convert formats, transform the surface. This allows researchers to program different material properties in different components of the same model and activate the process of self-assembly of the finished object, which is of no small importance for the aerospace, automotive, and construction industries.

Stratasys Inc. - 3D printers and systems

| Stratasys Inc. USA. GEO-NDT LLC supplies 3D printers manufactured by Stratasys in Russia. Anything you can imagine, Stratasys Inc. can build! Stratasys Inc. provides a wide range of services including custom manufacturing, low cost 3D printers and high performance 3D manufacturing systems. For 2009Stratasys ranks #1 in the world in terms of total units sold. In 1988, Stratasys invented and patented FDM (Fused Deposition Modeling) technology. This method marked the beginning of the development and formation of the company. Stratasys continues to use FDM to this day. In 2003, FDM ranked #1 in sales among other rapid prototyping technologies. Stratasys uses FDM technology in its Dimension 3D Printers and Fortus 3D Production Systems lines, which are designed for direct digital manufacturing and precision rapid prototyping. The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row. In early 2010, Stratasys entered into an agreement with HP. Under the agreement, Stratasys designs and manufactures an exclusive line of 3D printers based on FDM technology for HP. Rapid prototyping technologies are currently in demand by both large industrial companies and small businesses. Systems Stratasys Inc. used by manufacturers to create models and prototypes to assist in the design process of a new product. And they are becoming widely used for low volume finished products. Systems range from low cost desktop 3D printers to large production systems for direct digital manufacturing. Stratasys Inc. units. are actively used by the world's leading manufacturers in the automotive, aviation, medical, radio-electronic industries, manufacturers of household appliances, helping to significantly reduce the time required to update the product range and ensuring competitive success. These are the leading companies in their industries: Boeing, Lochheed Martin, Raytheon, Toyota, Volkswagen, BMW AG, Cummins-Allison, Honda, Harley-Davidson, Sony, Panasonic, Hewlett Packard, Xerox, IBM, Canon, Lexmark, Texas Instruments, Bosch, Lego, etc. If you want to order and buy a 3D printer of the Idea, Design and Production series, please call the numbers listed in the "contacts" section of our website. |

|

|

Stratasys Inc. USA.

USA.

GEO-NDT LLC supplies 3D printers manufactured by Stratasys in Russia.

Anything you can imagine, Stratasys Inc. can build!

Stratasys Inc. provides a wide range of services including custom manufacturing, low cost 3D printers and high performance 3D manufacturing systems. For 2009, Stratasys ranks #1 in the world in terms of total units sold. The growing popularity of Stratasys machines is explained by such qualities as a large selection of modeling materials, a reliable design, a wide range of models and an affordable price.

In 1988, Stratasys invented and patented FDM (Fused Deposition Modeling) technology. This method marked the beginning of the development and formation of the company. Stratasys continues to use FDM to this day. In 2003, FDM ranked #1 in sales among other rapid prototyping technologies. Stratasys uses FDM technology in its Dimension 3D Printers and Fortus 3D Production Systems lines, which are designed for direct digital manufacturing and precision rapid prototyping. The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row.

The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row.

In early 2010, Stratasys entered into an agreement with HP. Under the agreement, Stratasys designs and manufactures an exclusive line of 3D printers based on FDM technology for HP. In one year, HP will begin a phased rollout of mechanical design (MCAD) 3d printers to select country markets with the right to expand the distribution of 3d printers globally.

Rapid prototyping technologies are currently in demand by both large industrial companies and small businesses.

Systems Stratasys Inc. used by manufacturers to create models and prototypes to assist in the design process of a new product. And they are becoming widely used for low volume finished products. Systems range from low cost desktop 3D printers to large production systems for direct digital manufacturing.

The growing popularity of Stratasys machines is explained by such qualities as a large selection of modeling materials, a reliable design, a wide range of models and an affordable price.

The growing popularity of Stratasys machines is explained by such qualities as a large selection of modeling materials, a reliable design, a wide range of models and an affordable price.  In one year, HP will begin a phased rollout of mechanical design (MCAD) 3d printers to select country markets with the right to expand the distribution of 3d printers globally.

In one year, HP will begin a phased rollout of mechanical design (MCAD) 3d printers to select country markets with the right to expand the distribution of 3d printers globally.

And if you need an even larger product, it is enough to “grow” its parts, and then glue it together. Combined with powerful control software and hardware, this increases productivity, accuracy, repeatability and reliability.

And if you need an even larger product, it is enough to “grow” its parts, and then glue it together. Combined with powerful control software and hardware, this increases productivity, accuracy, repeatability and reliability.  There is no need to wait for anything - the parts can be released from the support material immediately after the completion of the building process.

There is no need to wait for anything - the parts can be released from the support material immediately after the completion of the building process.  ..

..  The system has many flexible settings for specific tasks, and is able to print assembled parts of different colors.

The system has many flexible settings for specific tasks, and is able to print assembled parts of different colors.  The thickness of one printed layer is only 0.178 mm.

The thickness of one printed layer is only 0.178 mm.