Uc davis 3d printer

3D printing reaches new dimensions at UC Davis

The hottest engineering technology becomes available to all students

Last month, three UC Davis graduate students — Andrea Bledsoe, Randy Carney and Holly Abney — began working with a 3D printer in Sacramento’s Arcade library to create a prosthetic leg for Bledsoe’s dog.

However, not everyone who wants to use a 3D printer needs an extensive knowledge of materials science. Nor do they have to aim to build something as complicated as a prosthetic leg.

In fact, on Wednesday, a handful of undergraduate students walked into the Engineering Student Startup Center (ESSC) in Academic Surge 2060 for a free 3D printing workshop. They were greeted by a small 3D model of Yoda from Star Wars. The model was printed in a machine that is available for students of all majors to use free of charge.

“All students have to do to use the printer is to sign up for one workshop to learn about basic usage and safety,” said ESSC director Dr. Lucas Arzola. “We give them a quiz so they can be certified and prove that they have learned how to use it safely.”

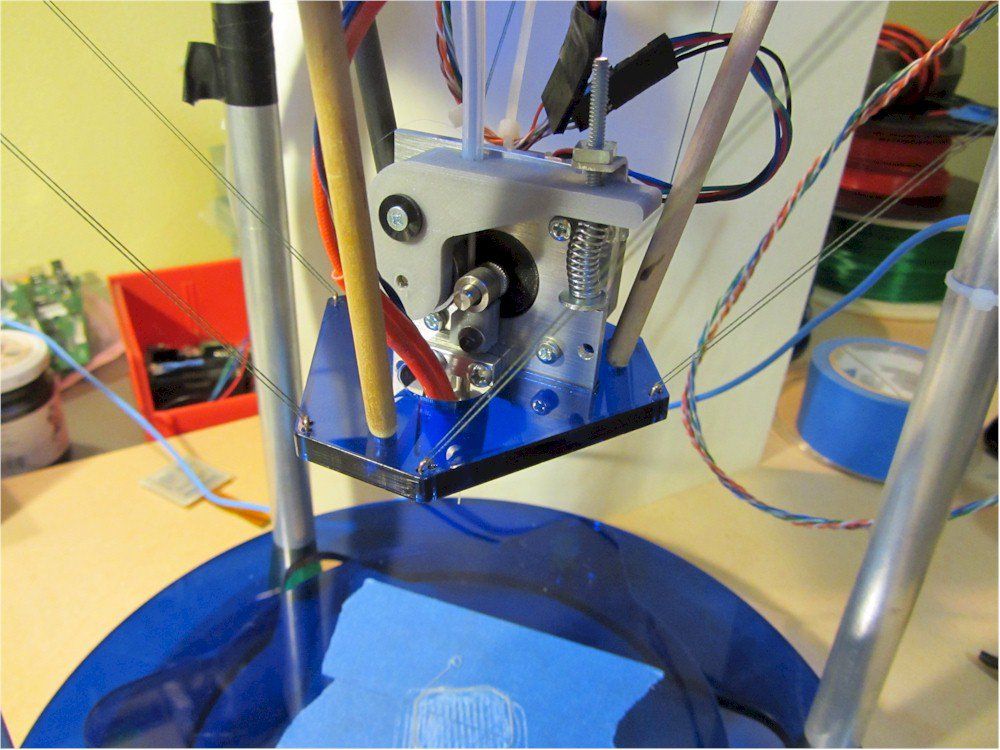

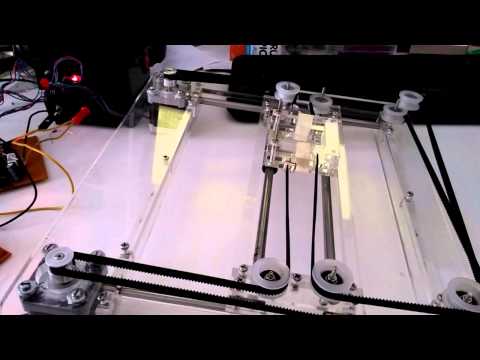

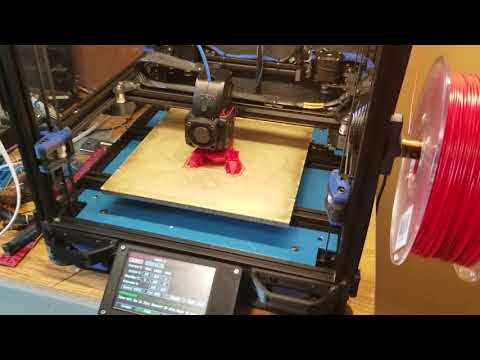

The goal of 3D printing, or “additive manufacturing,” is to create solid objects from a digital computer file. The process starts by slowly adding plastic volume layer by layer. With the machine, as plastic melts to form a new layer, previous layers begin to shrink as they cool down. Eventually, the successive layers add up to create the entire object.

According to Arzola, the ESSC is a leader in 3D printing safety. Research suggests that 3D printing generates nanoparticles by melting plastic. However, research about the dangers the nanoparticles pose is still ongoing, and there are currently no specific safety measures for a 3D printer. The ESSC has taken extra precautions and installed a fume hood above the printer to absorb nanoparticles.

“We’re very big on safety here,” Arzola said. “In that sense, we’d like to think that we’re a leader [in] safety. There are other 3D printers on campus, but to my knowledge, this is the only one with a fume hood and the only one available to all students. ”

”

The safety procedures used with the printer were developed in part by second-year mechanical engineering major Kendall Lui, who is also a student manager employed by the ESSC. Lui and his co-workers, including fourth-year aerospace engineering major Kevin Arcalas, will teach the safety and training workshops, held weekly throughout spring quarter.

The managers themselves are self-taught — Lui built his own 3D printer while still in high school, and Arcalas read manuals and experimented with the printer over the summer. Arcalas strongly believes in the trial-and-error process.

“To really learn about this machine, the students that come to the workshops actually have to use it,” Arcalas said. “There’s always a student manager watching, and of course we’ll approve what they want to print before they begin. But sometimes things can happen during the process.”

Lui roughly estimates that the printer has a 20 percent success rate and that 80 percent of projects experience small problems. The ESSC printer lacks a heating bed, a component that other 3D printers often have. The printing process warps the object and can cause it to remove itself off the printing bed, and a heating bed would keep layers consistently warm.

The ESSC printer lacks a heating bed, a component that other 3D printers often have. The printing process warps the object and can cause it to remove itself off the printing bed, and a heating bed would keep layers consistently warm.

3D printing also requires a lot of patience. The entire process can take several hours to complete — the Yoda model took 16. Since the printer in the ESSC does not have the capacity to manufacture multiple copies of the same product, it is mainly used for smaller projects and prototypes.

“Many students use the printer for their senior project, and need to build brackets for whatever they are building. I’ve also seen some cool things like a small whistle or a nametag,” Lui said. “What they build doesn’t necessarily have to be something that’s useful in the long run. Part of our goal is just to give these students exposure to 3D printing.”

Arzola believes that this exposure will allow people to see that 3D printing and self-manufacturing can become commonplace.

“The 3D printer is the hottest technology around right now. It used to be really difficult to manufacture a product that was tangible, and it was also really expensive,” Arzola said. “What 3D printing is doing is making manufacturing more accessible to everyone. In the future you might imagine that 3D printers will become so cheap and commonplace that even little kids can have it in their houses and make their own toys.”

Photos by Ciera Pasturel.

3D printing helps complex surgery and medical education at UC David Health

0Shares

UC Davis Health’s surgeons are using 3D printing to assist them in complex surgical procedures. Part of the University of California, Davis, the faculty believes that in the long term this technology will remove barriers to understanding in medical surgery and medical education.

David Lubarsky, vice chancellor of human health sciences and CEO of UC Davis Health, said, “3D printing, which for us means manufacturing that’s accurate, affordable and on-site, can be a game changer in health care. ”

”

The UC Davis Health complex. Image via UC Davis.“By enabling intricate anatomy to be translated from computerized data into life-like replicas that clinicians can actually hold, analyze and work with means that challenging medical puzzles will become that much easier to solve.”

3D printing for facial reconstruction

In recent years, 3D printing technology has proved its usefulness in the biomedical field. Primary examples of this include the use of the technology in cancer research, patient-specific spinal and dental implants and pre-surgery planning.

UC Davis Health is using an Ultimaker 3 printer to make a difference.

With the help of 3D printed anatomical models, Joseph Michael went through a surgical procedure which restored his eyesight. Michael, whose orbital socket (the circular cavity in which the eye rests) was damaged after an assault, received treatment at UC Davis Health. Dr. E. Bradley Strong, a professor of otolaryngology and a facial reconstruction surgery specialist, performed the surgery.

Dr. Strong explained, “Facial reconstructive surgery involves intricate anatomy within an extremely narrow operative field in which to maneuver our instruments […] Being able to print out a high-resolution 3D model of the injury, allows us to do detailed preoperative planning and preparation that is more efficient and accurate.”

“We can also use these patient specific models in the operating room to improve the accuracy of implant placement.”

On the benefit that 3D printing brings to surgery planning, Dr. Strong further added, “[…] the accuracy of pre-surgical planning and the precision of implant bending and placement were greatly improved. It saves time and enables me to be more efficient and make critical decisions before entering the operating room.”

Sharing 3D printing space

The 3D printing amenity is shared among UC Davis and UC Davis Health’s four departments, which includes the School of Medicine, Betty Irene Moore School of Nursing, Practice Management Group, and Medical Center.

The technology is currently being employed for cancer research at the UC Davis Department of Radiation Oncology, attempting to 3D print boluses for radiotherapy, an application also explored by other institutions.

Furthermore, the Translating Engineering Advances to Medicine (TEAM) lab of the Biomedical Engineering department is 3D printing body parts of animals for veterinary surgery.

Professor of small animal orthopedic surgery, Denis Marcellin-Little, said, “There is great value in working together because veterinary medicine is a bit more ‘nimble’ on the development and application side, but the patient needs are very similar.”

For more news on how 3D printing is changing the biomedical field, subscribe to our 3D printing newsletter. And follow us on Facebook and Twitter for live updates.

We also have exciting careers in the industry, visit our 3D Printing Jobs site to learn more.

Featured image shows the UC Davis Health complex. Image via UC Davis.

Image via UC Davis.

Tags David Lubarsky Denis Marcellin-Little UC Davis Health University of california Davis

Umair Iftikhar

| [Dec. 6th, 2012| 10:51 am ] PCRD | |

| A very good article by Ilya Kalashnikov, lecturer at the HSE Faculty of Business Informatics, about 3D printing. And here you can get acquainted with the implemented projects of the PTsRD prototyping studio.

Technologies of the future. Printers have learned to print food, houses and weapons Nowadays, with the help of 3D printing, a variety of things are created: from sneakers to parts of combat robots. And recently, scientists from the University of Southern California developed a Contour Crafting system that can print a two-story residential building in 20 hours! Remember the saying: "What does it cost us to build a house: let's draw - we will live?" Today it is already a reality. The prospects for 3D printing are amazing. Just a few years ago, 3D printers seemed like a lab curiosity of mad scientists and daring engineers. And this year, the media have given birth to literally an avalanche of messages on the topic where they are being applied in practice today. New technology is used more and more massively, becoming more accessible and interesting. Take at least the same Contour Crafting. Imagine a huge printer the size of a crane. He is able to perform up to 90% of all construction work, including concrete walls, piping and electrical wiring, ceiling installation, roof decking and wall painting. The machine will do all this. People here will only have interior decoration. Well, even windows and doors and put. A promising production method has already been adopted by the US military. For example, the Pentagon is using 3D machines to produce the missing elements of individual soldier equipment, as well as spare parts for robots, such as rods and gears, at the forefront.

Gunsmith enthusiast, known as HaveBlue, made an AR-15 automatic rifle using a 3D printer. The weapon has successfully passed tests with several hundred shots, though so far only in the .22 LR version. In the "native" .223 caliber, the design does not work yet.

Hollywood also keeps its nose to the wind. In Peter Jackson's recently released film The Hobbit: An Unexpected Journey, the lion's share of the props was created using 3D printing. Among the objects that were born in this way are linings that give volume to the hands, feet and ears of the actors, elven swords, helmets and axes. The filmmakers joke that if actor Ian McKellen hadn't shown up on set, his face would probably have been printed and someone else would have played him as the wizard. [ Read more ] Powder printing. This is implemented as follows: the printer pours a layer of powder onto the platform and pours it with a binder or sinters it with a laser beam, then pours the next layer and re-fastens it with glue or a laser - and so on until the desired object is formed. Powders are used in a variety of compositions: synthetic mixtures, gypsum, ceramics, metal, etc. Printing with molten material. The printer "draws" layer after layer of molten material that is extruded from the print head nozzle. In this case, mainly various plastics are used, for example, the very common ABS or PLA. But this spring, the British company Choc Edge introduced a 3D printer that prints . Printed with photopolymer. A photopolymer is poured into the cuvette, and a cut of the model is projected onto its surface - the illuminated area of the material immediately freezes. You can also draw a contour with an ultraviolet beam. Then another photopolymer is added to the cuvette, the next layer is projected, etc. Various light-sensitive resins act as a photopolymer. Compared to traditional printers, 3D machines are much slower – it takes hours or even days to produce one object. But in many cases, it still turns out much faster than if you had to grind a model out of wood or metal. 3D printers create real objects based on their 3D digital models. But where do these patterns come from? Firstly, they are built using special programs (for example, AutoCad) based on drawings, sketches, photographs of the desired item. And secondly, they are obtained by 3D scanning of existing objects. 3D scanners come in contact and non-contact types. The high demand for 3D printing is driving the industry at a furious pace. Its main area of application today is industry. Thanks to 3D prototyping, it is possible to produce prototypes of a new product without the involvement of special equipment and the launch of new lines, significantly reduce the time for pre-production, and minimize the cost of things produced in small batches. Often "printed" prototypes are workable, that is, they allow you to evaluate not only the design, but also the functionality of the future product. In addition, 3D printing is actively used in education - for the implementation of concepts developed by students, in medicine - in the manufacture of dentures and other implants, in architecture - with its help, models of future structures are created, in art, in the entertainment field . Science is trying to use 3D printers, in particular, for such an important task as the creation of living tissues and organs. The first mass-produced biological 3D printer, born from the collaboration of the American company Organovo and the Australian Invetech, was introduced in 2009year. This device has two printheads: one is filled with the cells of the desired organ, the second - with auxiliary materials (collagen, growth factors, etc.). In order to lay out the cells in the correct order, a laser calibration system and a super-precise robotic head positioning system are used. There are already examples of the successful use of this technology (for example, "printing" and insertion of the liver of a laboratory mouse), which means that we can hope that soon humanity will completely abandon the institution of donation. Today there are also 3D food printers - devices that can be used to print a particular dish. These machines work on the same principle as the others, only instead of plastic or metal, they use liquid "food inks", flavors and dyes. For example, the Burritob0t 3D machine, built by NYU graduate Marco Manriquez, is loaded with melted cheese and beans to produce delicious Mexican burritos. The Digital Chocolatier, assembled at the Massachusetts Institute of Technology, can print sweets from three components, say, chocolate, fruits and nuts. That is, today 3D printers play the role of food assemblers rather than cooks, and work with natural ingredients. In the future, the food obtained by 3D printing will no doubt become synthetic, with all its inherent advantages and disadvantages. But, if you do not succumb to skepticism about the usefulness of exclusively organic products, you can find a lot of advantages in synthetic food over traditional food. Thus, scientists note that in artificial food it will be possible to easily regulate the amount of proteins, fats and carbohydrates, if necessary, enrich it with vitamins and microelements. In addition, the production of synthetic products does not require any pastures or fields, no need to harvest and transport livestock to the slaughterhouse, no need to pack, deliver, cook, etc. The evangelists of this technology assure that in the very near future artificial food will not differ in taste, color and appearance from natural food - unless you find unnecessary bones, seeds, shells and scales in it. Unfortunately, at the moment, an overwhelming minority of citizens can afford to buy a 3D printer and provide it with the necessary materials, because we are talking about tens of thousands of dollars. But the “locomotive flies forward”, and there are already more than one project of budget 3D printers (the price of which starts at about $550) and dozens of ideas to reduce the cost of consumables (for example, it is proposed to use plain paper and glue). 3D prototyping services are offered today in our country. At the same time, you can order not only the printing of an existing digital model, but also 3D modeling. They print from plastics, from powders, from photopolymers, they make both monochrome and color models. As for the price of the finished product, it is determined by its volume, or rather, by the volume of material used. In Belarus, according to experts, 1 cm3 of gypsum powder costs about 1.5 dollars, plastic - 2.5 dollars. The future of 3D printing doesn't just look good for manufacturers, scientists, medical professionals, it looks good for all of us. Broke a cup? Did you like the neighbor's shoes? Craving strawberry ice cream? Instead of wasting time and effort looking for all the right things, just download the desired 3D model from the Internet and load it into your home 3D printer. Do you still shop? 3D printing is coming to you! | |

UC Davis - Davis | Cost | Admission

UC Davis or University of California Davis ( UCD ) - state higher education institution in the United States. UCD began its academic activities in 1908. Due to the favorable location of the university within Davis, students can take advantage of all the advantages of both city and country life.

UCD began its academic activities in 1908. Due to the favorable location of the university within Davis, students can take advantage of all the advantages of both city and country life.

University ranking. The University of California Davis is one of the top 30 universities in the United States. The university is included in the top 5% of the best universities in the international ranking. The university is known for the high quality of education in the following areas: "Arts and Humanities", "Engineering and Technology", "Life Sciences and Medicine", "Natural Sciences", "Social Sciences and Management", "Mathematics", "Physics" , "Chemistry", "Informatics", "Economics and Business". In terms of the quality of education, the university occupies a leading position and is on the 100th line in the world ranking. Given that the university enjoys an impeccable reputation among employers, its graduates should not have problems finding employment after graduation.

Admission and tuition fees. The selection committee selects applicants based on the exams passed and the applicant's previous performance. The admission process is not complicated by the competition, for example, no more than 2 applicants apply for one place at the university. The academic year at the university is divided into quarters. The cost of studying at the university is quite high and amounts to 36,773 USD per year. Those wishing to get a master's degree in this university should expect to spend 13,000 USD per year of study. Given the high cost of tuition, students can participate in scholarship programs. You can get knowledge in this university not only in person, but also in a remote format. To plan your education at UCD, you should check the cost information on the official website http://www.ucdavis.edu.

University staff. The University of California at Davis can be considered a large educational institution with over 39,000 students. Both citizens of the country and foreign citizens can apply for admission to the university. Among students, every 5th student is a foreigner. More than 3 thousand teachers are teaching at the university. Most of the teachers at UCD are foreign specialists. The university cooperates with other international universities on student exchange issues. You can learn more about student life on the social pages of the university: iTunes, Twitter, Youtube, Facebook.

Both citizens of the country and foreign citizens can apply for admission to the university. Among students, every 5th student is a foreigner. More than 3 thousand teachers are teaching at the university. Most of the teachers at UCD are foreign specialists. The university cooperates with other international universities on student exchange issues. You can learn more about student life on the social pages of the university: iTunes, Twitter, Youtube, Facebook.

University infrastructure. The infrastructure of the educational institution includes its own library. The university offers its students accommodation in a student hostel.

UC Davis - Official Description

UC Davis, set in a small traditional college town, is justly famous for its outstanding programs in the biological and agricultural sciences. In addition, its programs in engineering, the social sciences, physical sciences, mathematics, and the arts and humanities are also popular and highly prestigious. Graduate Studies oversees more than 80 graduate degree programs, giving UC Davis the most diversified teaching faculty and curriculum in the nine-campus system. The quality of life on campus is enhanced by its proximity to the state capital and the San Francisco Bay Area, sites that offer a wealth of additional cultural, political, and social opportunities. There are currently 30,229students, of whom 6,720 are in graduate and professional programs. UC Davis faculty and graduate programs attract highly qualified students from diverse educational, social, ethnic and cultural backgrounds. It is this global mix that contributes to the character of both the campus and the city of Davis. The campus has a tradition of close association between students and faculty, and the style is one of informality and congeniality. The campus itself is about 5,500 acres, including the experimental agriculture plots, a central quadrangle, hundreds of beautiful old shade trees, and an arboretum on the banks.

Graduate Studies oversees more than 80 graduate degree programs, giving UC Davis the most diversified teaching faculty and curriculum in the nine-campus system. The quality of life on campus is enhanced by its proximity to the state capital and the San Francisco Bay Area, sites that offer a wealth of additional cultural, political, and social opportunities. There are currently 30,229students, of whom 6,720 are in graduate and professional programs. UC Davis faculty and graduate programs attract highly qualified students from diverse educational, social, ethnic and cultural backgrounds. It is this global mix that contributes to the character of both the campus and the city of Davis. The campus has a tradition of close association between students and faculty, and the style is one of informality and congeniality. The campus itself is about 5,500 acres, including the experimental agriculture plots, a central quadrangle, hundreds of beautiful old shade trees, and an arboretum on the banks. ..

..

Description - University of California Davis

The University of California, Davis, makes a difference in the lives of people every day. Fueled by learning and energized by discovery, the UC Davis tradition of engagement with the local community, the nation and the world guides all that it does. The university's commitment to providing an attentive and research-enriched education creates a supportive learning environment for both students and faculty. UC Davis is a pioneer in interdisciplinary problem-solving, and its four colleges, five professional schools, more than 100 academic majors and 86 graduate programs make it the most comprehensive of all the University of California campuses

Read more

Your score has been saved.

Tell us what we can improve.

Your score has been saved.

Tell us what we can improve.

Thank you for your feedback.

UniPage Admission to University of California Davis

Entering a university is an important and responsible step in everyone's life. UniPage Experts:

- advise you on education abroad;

- select universities for your profile and budget;

- prepare the necessary set of documents;

- send applications to educational institutions;

- apply for internal university scholarships;

- help you get a student visa.

Free consultation Why UniPage

Universities Similar to University of California Davis

Universities in this city

Information is for guidance only. For exact information, refer to the official website of the educational institution.

Advanced Search

Showing records 1-1 of 1 .

The US Air Force is using a 3D printer to create mock-up drones, and the US ECBC is using mine detector parts. The plans of the US military are to produce spare parts for spacecraft, backpacks and vests, as well as individual prostheses through volumetric printing.

The US Air Force is using a 3D printer to create mock-up drones, and the US ECBC is using mine detector parts. The plans of the US military are to produce spare parts for spacecraft, backpacks and vests, as well as individual prostheses through volumetric printing.

.. with melted chocolate!

.. with melted chocolate!  The former work in direct contact with the object under study, while the latter analyze the radiation reflected from the object (visible light, x-rays, ultrasound). Based on the file obtained as a result of scanning, the corresponding software collects a three-dimensional image. The 3D model is edited, if necessary, "cut" into the thinnest transverse layers and sent to print.

The former work in direct contact with the object under study, while the latter analyze the radiation reflected from the object (visible light, x-rays, ultrasound). Based on the file obtained as a result of scanning, the corresponding software collects a three-dimensional image. The 3D model is edited, if necessary, "cut" into the thinnest transverse layers and sent to print.  .. You can list for a long time.

.. You can list for a long time.  In addition, the arsenal of such devices includes heating and cooling elements, as well as a mixer. In theory, a hungry user decides what he would like for lunch today, presses the desired button - and the printer, according to the recipe, mixes the necessary ingredients and prints layer by layer, say, borscht, or cutlets, or ice cream. In practice, food printers can do little so far.

In addition, the arsenal of such devices includes heating and cooling elements, as well as a mixer. In theory, a hungry user decides what he would like for lunch today, presses the desired button - and the printer, according to the recipe, mixes the necessary ingredients and prints layer by layer, say, borscht, or cutlets, or ice cream. In practice, food printers can do little so far.