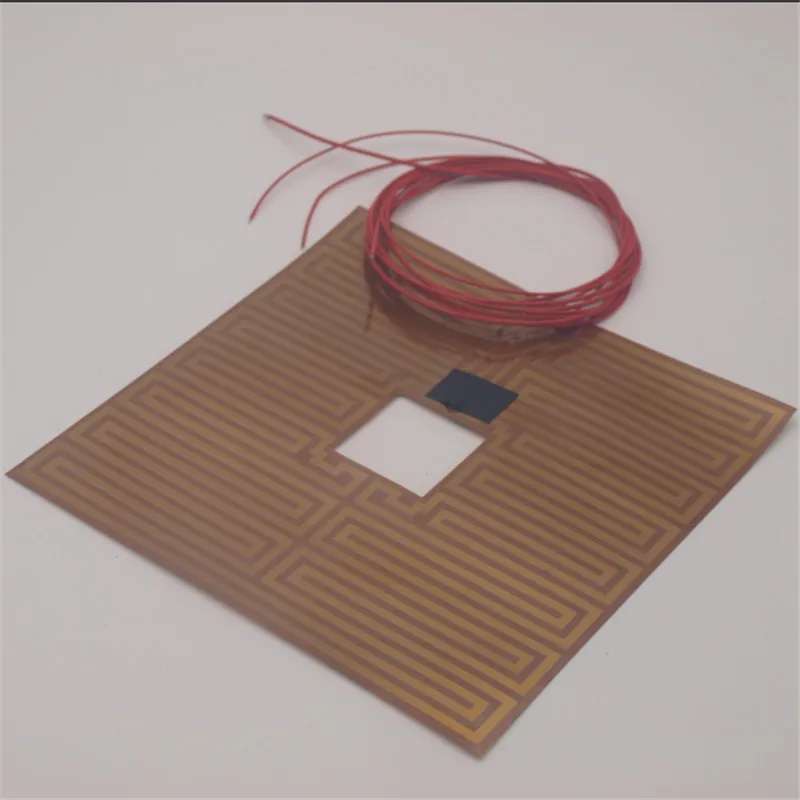

Bed heater 3d printer

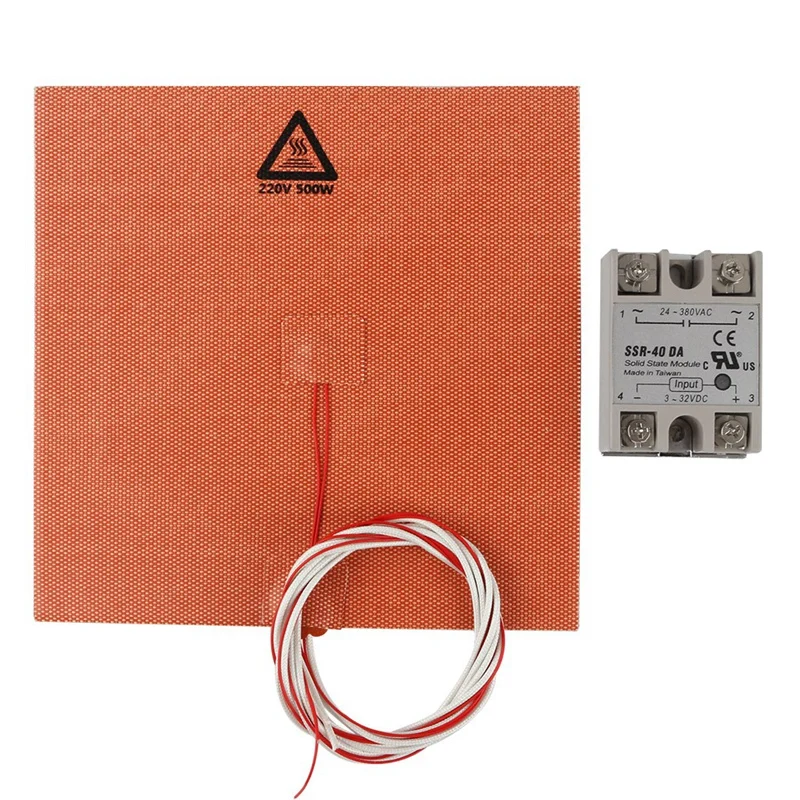

24V 250W Silicone Heater for 235x235mm Heated Bed Upgrade Creality End

- PRODUCT DETAILS

- REVIEWS

- SHIPPING & RETURNS

PRODUCT DETAILS

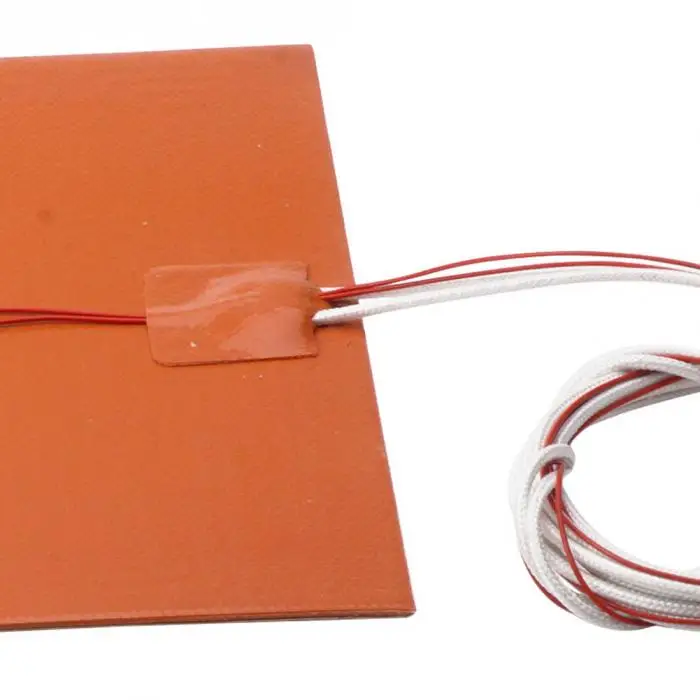

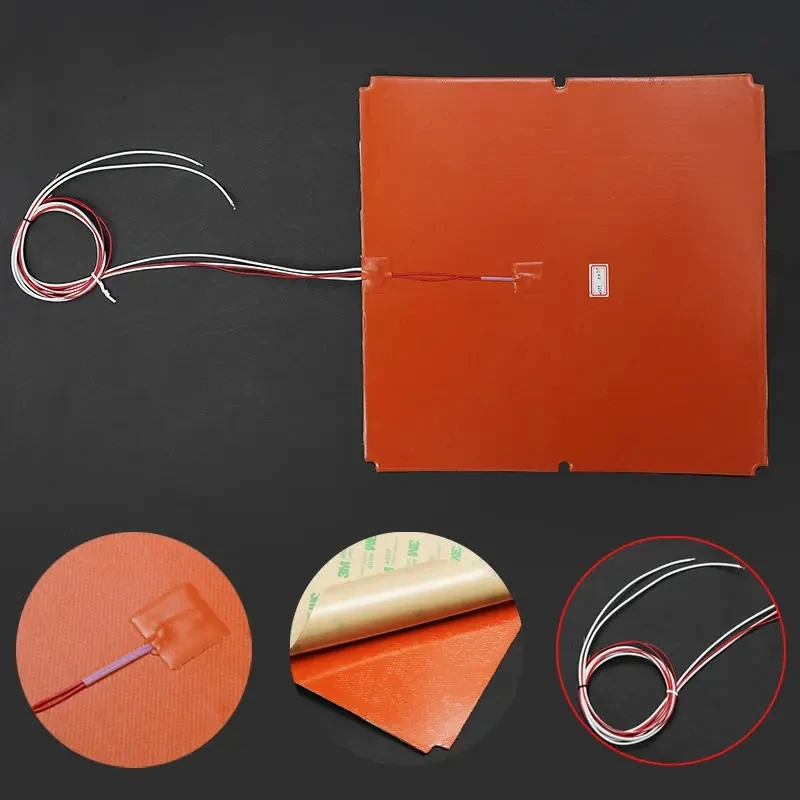

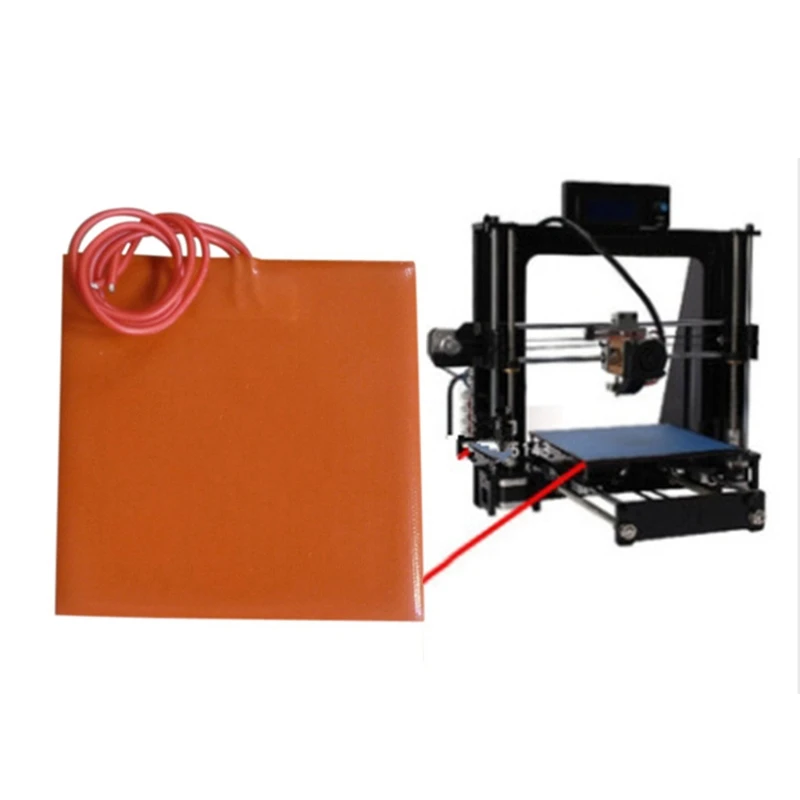

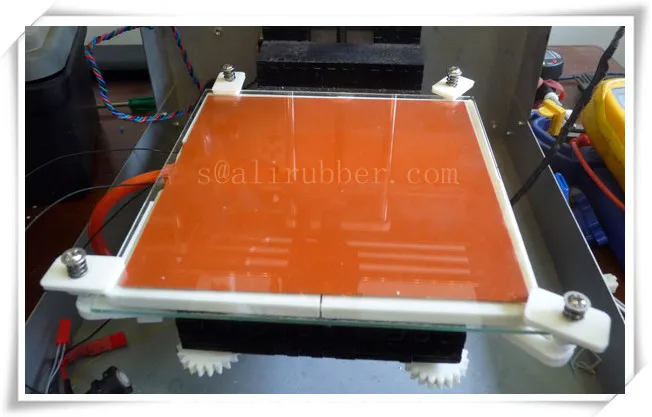

The 24V 250W Silicone Heater is designed for the Creality Ender 3 and Ender 5 series 3D Printers, intended to replace the traditional PCB board as a heating source. Compared to PCB, silicone heaters reach temperature faster and feature better heat distribution at the edges of the build plate. The new feature in the November 2021 revision is an internal over-temperature protection switch that will shut the heater OFF as soon as the temperature reaches 150C.

The included 3M 468MP adhesive backing comes pre-applied, is rated up to 150° C for extended periods of use, and bonds exceptionally well to metal surfaces. Just peel and press for a quick and painless installation on a new or existing heated bed.

The Silicone Heater comes pre-wired with power cables and thermistor, a drop-in replacement for the Creality boards. We also sell complete kits in our store, which include a new 6061-T6 aluminum build plate.

Silicone Heater Details

- Voltage: 24V

- Power rating: 250 Watts

- Wiring: 700 mm

- Mounting: 3M 468MP Adhesive Backing

- Dimensions: 235 x 235 mm

- Thermistor: NTC 3950 100K Thermistor

Thermistor Specifications

- TEMP_SENSOR id 11 in Marlin firmware (Default)

- High accuracy: 1%

- Resistance value at 25°C=100K

- Wiring length: 1 meter

Package Contents

(1) 24V 250W Silicone Heater (235 x 235mm)

REVIEWS

Love this upgrade

Super fast heating and holds temp very well. I wish yall would make one for my 5 plus. But I would recommend this for anyone needing a replacement heater

SHIPPING & RETURNS

Shipping

Gulfcoast Robotics ships Monday through Friday, excluding holidays. The shipping cut-off time is 11 A.M. Eastern Standard. Orders placed after the cut-off time will be shipped the following business day. All orders are fulfilled by our warehouse located in North Port, Florida (US).

The shipping cut-off time is 11 A.M. Eastern Standard. Orders placed after the cut-off time will be shipped the following business day. All orders are fulfilled by our warehouse located in North Port, Florida (US).

Domestic Orders

Domestic orders are shipped via USPS using the service selected at checkout. Parcels that exceed the First Class weight limit of 15.9 oz will automatically use Priority Mail. Once your package has been processed, a Tracking Number will be provided. The Shipping Confirmation is sent via e-mail and/or SMS alerts, depending on the contact information specified at checkout.

International Orders

All orders shipped to a destination outside of the United States are subject to the import duties, fees and taxes of the destination country. Delays in delivery may occur if your package is randomly selected by the Customs Department for inspection.We have no control over the process or additional charges associated with the delivery and important of your package into your country. We do not benefit in anyway from these charges and work closely with our carriers to ensure as few delays as possible.We are not responsible for any duties, fees, or taxes that are incurred during the delivery of your order/package.

We do not benefit in anyway from these charges and work closely with our carriers to ensure as few delays as possible.We are not responsible for any duties, fees, or taxes that are incurred during the delivery of your order/package.

24V 250W Silicone Heater for 235x235mm Heated Bed Upgrade Creality Ender-3 / Ender-5 3D Printers

heated bed - PLA and bed heating?

$\begingroup$

I've read different things about PLA and heat-bed. Some say it is not needed, others recommend 60-70°C, but not for the first layers.

For larger objects I often have the problem that the object does not stick to the blue-painters-tape-covered aluminium print plate. Instead the print "curls" up on one or more corners. To reduce this effect, I'm using a brim between 5 and 10mm. Depending on the size of the object the brim works quite well. Will heating the bed also improve the print quality by reducing the amount of heat warping / curling?

- pla

- heated-bed

- warping

$\endgroup$

3

$\begingroup$

I actually find it's not needed for PLA. I generally have it heated to 40 °C and use blue painters tape along with some hairspray (I prefer Tresemme as it smells gorgeous).

I generally have it heated to 40 °C and use blue painters tape along with some hairspray (I prefer Tresemme as it smells gorgeous).

I've experimented with a glass bed, and Buildtak but I find blue painters tape is the key. I overlap the blue tape ends to the bed so it sticks, then spray the hairspray onto the tape. Also bed leveling is super important as are your print settings. What you want for the first layer is to have it essentially "pushing" into the bed. That way it gets good contact and wont curl up during the print, though it can be a challenge to get off later.

TL;DR for PLA you dont need a heated bed, its more about the surface and 1st layer height.

$\endgroup$

1

$\begingroup$

Heating the bed helps me, even with PLA. I print with a 60 °C bed. The bed is 3/8" 6061 alloy aluminum, sanded with 600 grit sandpaper, coated with Elmer's purple glue stick, and dried.

The brim will help. You might make the brim thicker than one layer (like 2-3 layers).

If you look at the bottom of your print, are there large gaps where the PLA doesn't touch the bed? If so, you could zero the head closer to the bed, or increase the flow for the first layer.

I haven't set up a cooling fan, although many praise the results. It is an experiment for a future day.

$\endgroup$

3

$\begingroup$

Heated beds can help, but you have to be careful using too much heat. If you go above the glass transition temperature (about 60 °C for PLA), the stresses of the upper layers cooling will warp the bottom, because above the glass transition temperature, the PLA can deform.

For example, I was making very tall and skinny parts, a recipe for warping. At 65 °C, I had a bit of the bottom corners curling, but the part finished. I turned the heat up to 80 °C, and the parts warped so much they came off the build plate. I ran the exact same parts at 58 °C, and they came out beautifully every time.

I turned the heat up to 80 °C, and the parts warped so much they came off the build plate. I ran the exact same parts at 58 °C, and they came out beautifully every time.

A higher bed temperature can aid adhesion, (see Effect of the printing bed temperature on the adhesion of parts produced by fused filament fabrication), but if the temperature is above the glass transition, the parts can and will deform much more easily.

$\endgroup$

1

$\begingroup$

This is fundamentally a heat transfer problem. As a large print is being made, it is very thin. Thin things cool off quickly, especially when no new hot material is being placed on top in the meantime. A heated bed will only help for a time, depending on the print size, before it starts to actually contribute to warping due to rapidly cooling upper layers and still- heated lower layers.

A hack can be found by improving bed adhesion, but this leaves the underlying problem of thermal stresses intact. Only through better 3D printing thermal properties design or through better object design will the warping problem be solved rather than mitigated.

$\endgroup$

$\begingroup$

It really depends on your formulation. 70 °C would be on the higher end. I think I do between 70 °C - 75 °C. Not any higher.

Add a glue from a glue stick to help with keeping it on the bed.

Use a raft to reduce the issue as well.

A fan is the number one thing you can do.

The last solution is to build a heat enclosure. They are not on every 3D printer because of patents blocking them. You can easily make your own.

Technically it is not 100 % needed, i.e. the MakerBot does not use it, but the guys at MakerBot have PLA down to a science.

Also I thought Kapton is not for PLA usually. .. see these MatterHackers articles:

.. see these MatterHackers articles:

- How to succeed when printing with ABS;

- How to succeed when printing with PLA.

From RepRap Wiki - Glossary:

Raft

A technique used to prevent warping. Parts are built on top of a 'raft' of disposable material instead of directly on the build surface. The raft is larger than the part and so has more adhesion. Rarely used with heated build surfaces. For the small area models, it is very useful to prevent warping via adding a raft for the model before slicing it. It can also help with with precision parts by removing the slight first few layer distortion caused by the heated bed.

$\endgroup$

2

$\begingroup$

For printing PLA you can manage to succeed without a heated bed. You can use blue painting tape on any platform. It will help a lot. But sometimes the tape itself curls up and you end up with a bad print. Heated bed helps here for better adhesion of the blue tape to the bed. You can also use hair sprey to ensure that the blue tape sticks to the bed.

You can use blue painting tape on any platform. It will help a lot. But sometimes the tape itself curls up and you end up with a bad print. Heated bed helps here for better adhesion of the blue tape to the bed. You can also use hair sprey to ensure that the blue tape sticks to the bed.

Hair sprey is pretty effective on ABS. If you use a heated bed + glass + hair sprey ( Akat Gardi is the best brand) you will never have any problem with your prints.

$\endgroup$

$\begingroup$

I can only go with my own experiences; a Printrbot simple metal originally with no heated bed and blue tape was fine for small parts if printed with a reasonable brim and rafts when needed (Slic3r does that) but larger prints tended to warp and curl. I upgraded to a heated bed, which I run at 55 - 60 °C for every print. Additionally, I now use Kapton tape on the bed and glue stick. I have recently reprinted a part for my printer, an LCD housing, to replace the badly warped original, which is my benchmark print. I have no warping/curling problems to the point that I have reduced the standard brim from 5 mm to 2 mm to save some material. Some additional detail - only PLA at present from a 0.4 mm extruder at 205 °C in 0.2 or 0.3 mm layer height for the finer detail. Takes longer but the results are worth it.

I have no warping/curling problems to the point that I have reduced the standard brim from 5 mm to 2 mm to save some material. Some additional detail - only PLA at present from a 0.4 mm extruder at 205 °C in 0.2 or 0.3 mm layer height for the finer detail. Takes longer but the results are worth it.

$\endgroup$

$\begingroup$

The answer depends a bit on the type of PLA (supplier of specific filament), type of machine, type of build platform, size of model and ambient temperature.

PLA has less issues with warping compared to ABS or Nylon, but can still warp depending on everything mentioned. My usual first try to minimize warping is to heat the bed. 60 - 70 °C works well but I'll also go up to 100 depending on a variety of factors. If still not having any luck, generally on larger parts I try adding a raft. If I STILL have issues after that I'll add 'helper disks' (small quarter dollar sized disks) around the part to increase the surface area of the raft. The disks will add more material but I have about a 99 % success rate using these.

The disks will add more material but I have about a 99 % success rate using these.

If a part is going to take more than about 3 hours and I can't have any warping at all, I always use a heated build plate and place the discs all the way around the part. Generally will add about a hour or more, but well worth the extra time.

$\endgroup$

2

$\begingroup$

A lot depends on exactly which PLA you use and the build surface. I'm using one of those new-fangled high-temperature PLA's (MakerGeek's Raptor PLA, black) and a BuildTac surface on a MonoPrice Select Mini v2. From my experiments, I believe that the biggest influence in preventing warping is the BuildTac.

My slicer is Simplify3d, so the settings may be in a different format than yours. I use a hot-end temperature of 240 °C, a bed temperature of 40 °C, layer height of 0. 0875 mm, a first-layer modifier of 1.5, an extrusion modifier of 0.95, and a retraction distance of 3 mm.

0875 mm, a first-layer modifier of 1.5, an extrusion modifier of 0.95, and a retraction distance of 3 mm.

I've never had a problem with warping, but these settings prevent stringing and allow me to more easily remove parts after printing. And yes, I wait until the bed gets to room temperature before removing the part.

$\endgroup$

$\begingroup$

Heated bed definitely helps with PLA adhesion, it also helps depending the surface, for example PEI offers better adhesion than glass. Another option is to try to overextrude the first layer (125 %) and make sure it is squeezed out, so basically you get a wavy effect on the first layer. This should help a bit even in the curly corners. Another thing I have noticed from experience is the PLA itself, not all PLAs are the same so you could try another manufacturer or try your PLA in a friend's printer to see if you get the same effect. Generally on PLA we do not expect any warping, but the reality is that some do have.

Generally on PLA we do not expect any warping, but the reality is that some do have.

$\endgroup$

$\begingroup$

Heating the bed helps with adhesion to the bed, but can seriously interfere with cooling of the layers just above the bed that are in contact with large amounts of material touching the bed. I've found that, if I have a model with a flat region touching the bed and walls leaning outward from it (overhangs) as they go up, any corners will curl upwards before they can cool if the bed is 60 °C or above - it's effectively a heat bath at the glass transition temperature that's going to be hard for a fan to overcome.

At 50 °C the effect is almost gone, and at 40 °C and below it seems entirely gone, but the exact temperature that's safe is going to depend on ambient room temperature, cooling fan power, and effectiveness of the fan duct. I've just found this as a solution to my curling-corner problems, so I might end up tweaking things more, but I think I'm going to try printing PLA without heating the bed at all unless I have trouble with adhesion.

An example showing slightly warped vertex/edge from curling corners at 50 °C vs good ones at lower temperatures:

$\endgroup$

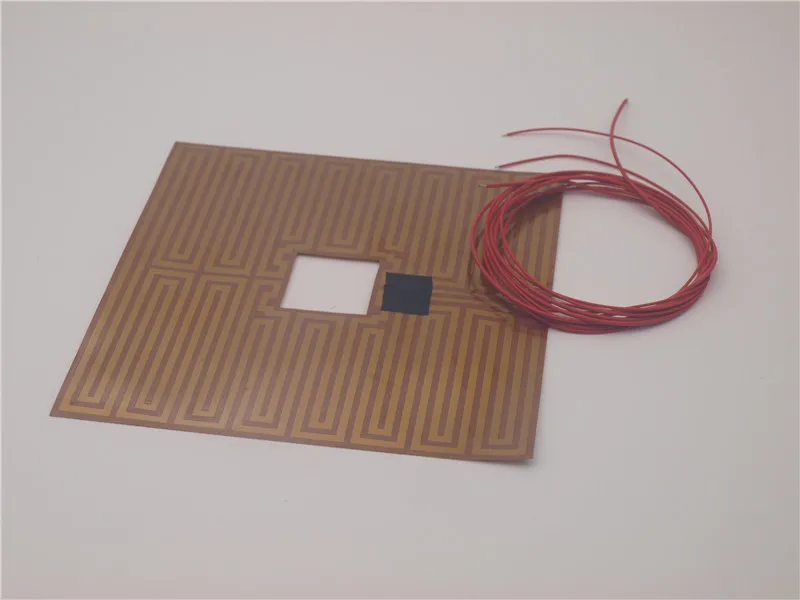

China Customized 3D Printer Heated Beds Manufacturers, Suppliers - Free Sample

Introducing

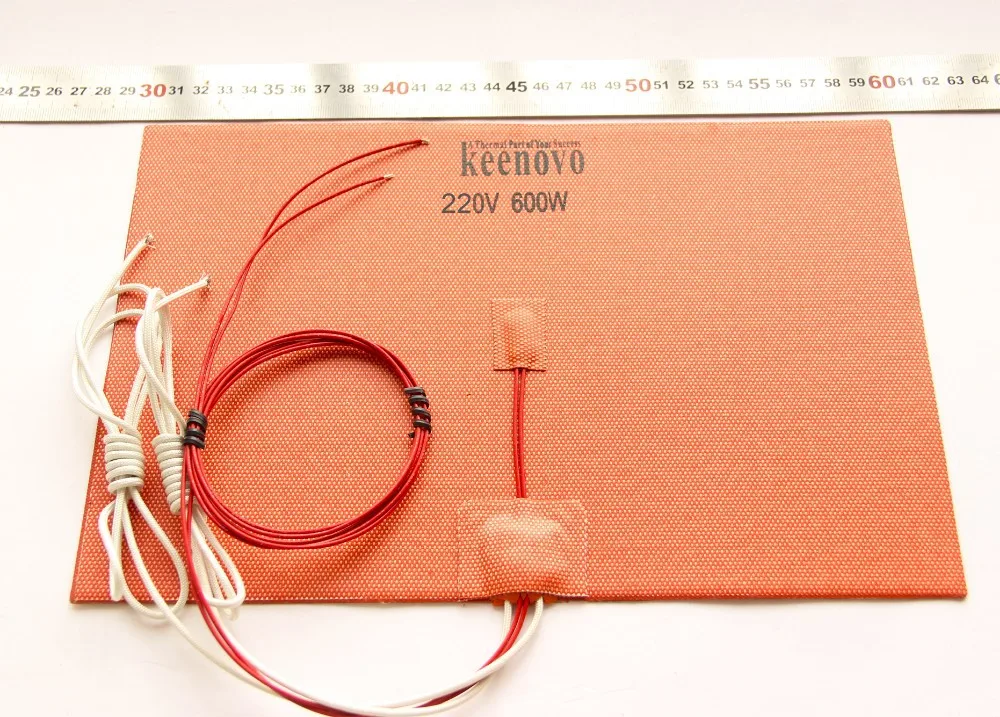

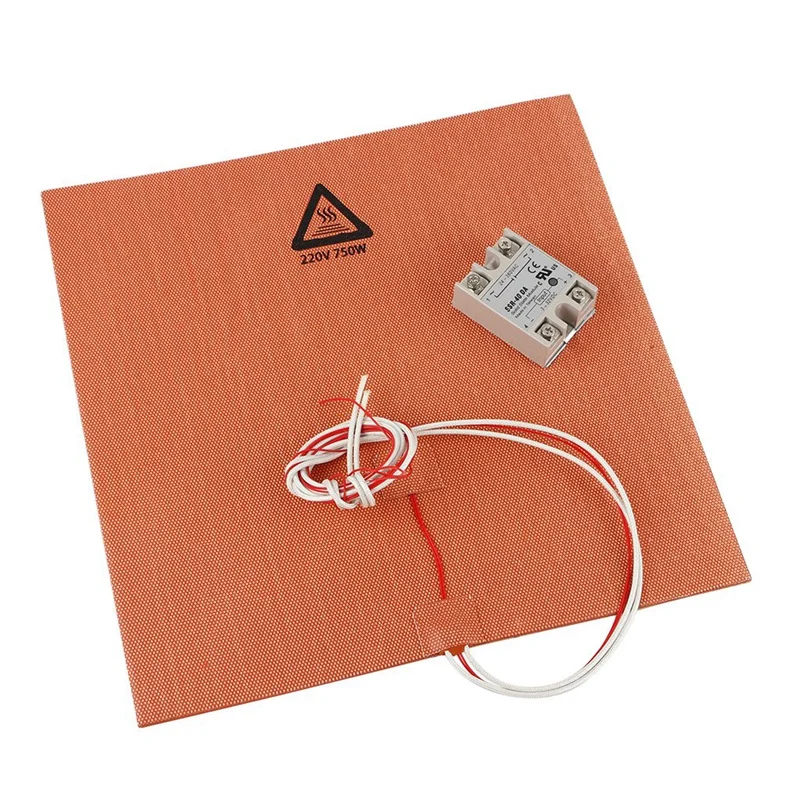

3D Printer Heated Beds is specially for 3D Printer Heated Beds printer hot heating bed product. Use nickel-chromium alloy electrical wire or nickel-chromium foil etching circuit. The thermal insulation material of silicone rubber and glass fiber cloth is formed by high temperature molding and aging heat treatment. Therefore, it has high reliability. It is soft, fast heating, uniform temperature, high thermal efficiency, long life safety, double-sided addition back, easy to install, can be in close contact with the heated object. we can customize for clients. The product can also set temperature protection. Temperature controller and other accessories. It is more convenient and safe to use. nine0005

nine0005

Quick Details

Applicable Industries: Manufacturing. Petrochemical. Energy. New Energy.

Condition: New

Type: GP-016

Power Source: Electric

Place of Origin: Jiangsu, China

Brand Name: G P

Name:

heated bed 3D printer Dimension (LZWEH): 30WEH 250-1.5 MMM

Voltage: 110V

Power: 400 W

Wire type: Silicone braided wire. 300MM

Accessories: overheat protection switch, digital display temperature control, aviation plug, 3M double-sided tape

Certification: CE, UL, ISO9001, ROHS

SH: 8516800000

After-sales Services Provided: Video technical support, Online support .

Warranty: 1 year

Specifications

| 0052 | Power deviation speed | ± 5% |

| High voltage resistance | > 5 kV |

2. Heating plates can be installed with different heat probes.

3. The heater can be installed with various plugs or connectors. nine0005

4. An aluminum plate can be installed on the back of the heating plate for more even heat dissipation.

5. Temperature control knob, digital display temperature distortion, high power temperature warped system.

6. Heating plates can be installed with an insulating layer.

7. The heater can be equipped with a spring buckle.

8. The heater can be fixed with Velcro. nine0005

The company was founded in early 1990 in Jiangsu, China, specializing in research and development, production, sales of silicone rubber heaters, silicone rubber electric heating plate, silicone rubber electric heating belt, silicone rubber electric heating film and other silicone rubber electric heating series products. Products through the international certification of UL, CE, ROTH. The company has complete production equipment, perfect process technology, strong scientific and technological force, excellent product development and design capabilities, and rich production experience. After many years of hard work, our products have been exported to Southeast Asia, Europe, America, South America, the Middle East, Africa and many other countries. nine0005

After many years of hard work, our products have been exported to Southeast Asia, Europe, America, South America, the Middle East, Africa and many other countries. nine0005

Supply Ability:

50000 Piece/Pieces per month industrial cabinet heater.

Packing details:

Boxes, also we can pack as your request.

Port:

Shanghai

Lead time:

Example: 2-5 working days.

Production time: 15 days.

FAQ

Question 1: Why do you choose?

A: 1. Export standard

2. Reasonable price

3. Timely delivery

4. Excellent quality

5. Good service

Question 2: Can I get product samples?

Answer: Yes, of course. Our stock sample is free, but personalized sample has to pay for it and you pay shipping.

Question 3: Do you have a catalog?

Answer: Yes, we have a catalogue. Feel free to contact us to ask us to send you one. nine0005

Feel free to contact us to ask us to send you one. nine0005

Question 4: When and how can I get a tracking number?

A: As one as we do shipping, I will tell you the tracking number. If you want to know something about the goods along the way, I am please to help you.

Question 5: Are you a factory or trading company?

Answer: We are factory and trading company, we are direct seller, so we can give you the cheapest price than anyone else.

Question 6: Where are you located?

A: Our factory is located in Wuxi, Jiangsu Province. nine0005

hot label : 3D heated bed printer, China, manufacturers, suppliers, customized, wholesale, cheap, low price, buy discount, free sample

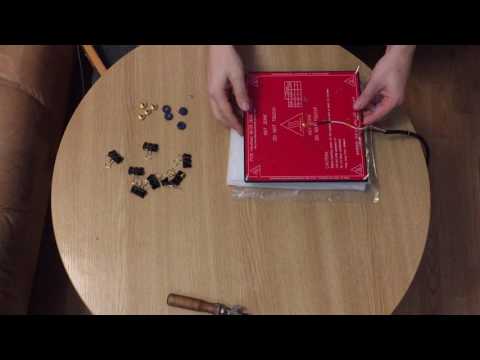

hot bed. Don't try to sleep on it

Technician

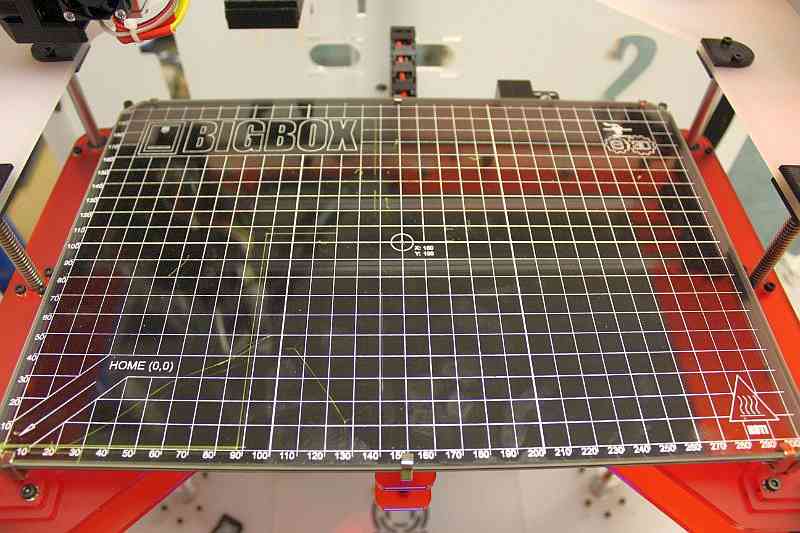

Today I would like to talk about such a popular and, at the same time, vague topic as a hot bed. I will not talk about all types of heaters, otherwise we will be discussing here until the morning, but I will dwell on the most popular type of 'Hot Bed' - a bed made on the basis of a printed circuit board.

nine0005

nine0005 In general, when I hear the phrase 'hot bed', something like this appears before my eyes (see above). It is much more pleasant to call it a hot table or a heating platform, but here it’s as convenient for anyone. But I got carried away ... As always, I'll start with - 'why is it needed at all?'.

The heated bed is needed to compensate for uneven cooling of the part during printing and, thereby, to partially overcome the uneven shrinkage of the part during cooling. nine0005

The question arises - 'why partially?'. But because this is just a local effect, and the actual size of the effective zone where the heating platform can help maintain the temperature of the part is measured by a few millimeters above its surface. For full control, you need an isolated thermal chamber, or you can still print the part along with a kind of cocoon. Well, why is he then? And then, that these few millimeters are enough to keep the base of the printed model heated and not to deform. That is:

That is:

The hot bed serves to ensure good adhesion to the work table surface and reduces the chance of plastic delamination from the work platform.

This is achieved by heating the table just above the glass transition temperature of the plastic from which the print is made. For PLA this is 50 degrees. But for him you can do without a hot table. Some PLA printers dedicate their lives to serving the Cold Table, but we won't talk about them. Let's discuss the heating table device in more detail. nine0005

The first heating table was designed and built by Josef Pruscha, an engineer from Prague.

It was a board made of ordinary foil textolite, on which tracks of a certain width were cut. From the physics course, we know that knowing the resistivity, length and area of \u200b\u200bthe conductor, we can calculate its resistance. And we know the thickness of the copper on the surface of the board, the length of the track and the resistivity of the copper. Therefore, we can calculate the resistance of the entire conductor cut on the board. Knowing this, we can already calculate the thermal power of such a conductor if a current of a certain magnitude is passed through it. It is on this simple principle that the heater on the hot table board works. nine0005

Therefore, we can calculate the resistance of the entire conductor cut on the board. Knowing this, we can already calculate the thermal power of such a conductor if a current of a certain magnitude is passed through it. It is on this simple principle that the heater on the hot table board works. nine0005

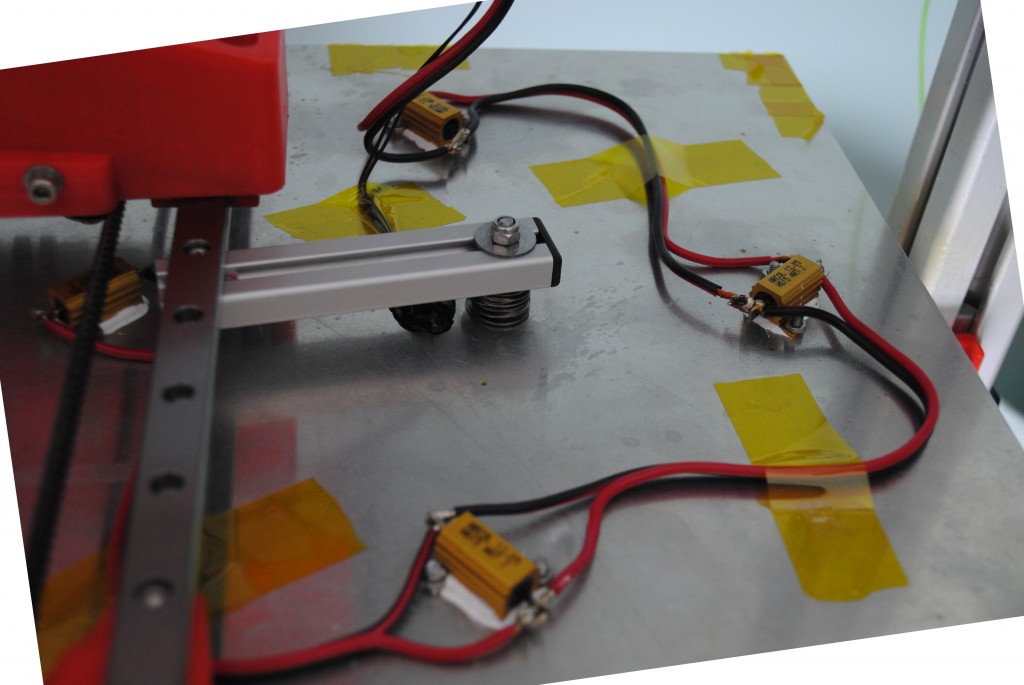

Since then, a whole bunch of different models of heating tables have been produced. One thing - 'but', their production was also established by our Chinese brothers. But these cunning guys sometimes save on milling and make the table etched. Why is it bad? Well, how do you say? Due to the peculiarities of the etching process, it is not possible to maintain the same thickness of the conductor along the entire length. If it is not possible to maintain the same thickness of the conductor, then this will entail a change in the resistance of the entire heater, and therefore it will be far from the calculated one. If it is less than necessary, then the table will overheat, if it is more, then the table will heat up badly. nine0005

nine0005

Be aware of where you buy! The table must be engraved directly from copper with a thickness of 35 microns! Please ask your seller before placing an order. A strong deviation from the reference value is a reason to demand an exchange or refund.

You can fix a table with too much resistance and I already wrote about how (link, link). So let's not talk about it. Let's move on to an overview of what popular PCB heating tables are out there besides the one designed by Joseph Pruscha (MK1). nine0005

MK2, MK2a:

There is very little intelligible information on it, and it is not often found. But I managed to find something. Supply voltage - 12V. Resistance - from 1 to 2Ohm. The oldest table, which is hardly worth taking now, and it can be found on sale less often than the rest.

MK2b Dual Power:

This table is much more common in stores. I would even say that he is the most popular.