Solid 3d print

solidprint3d, Orlando 3D printing, 3D scanning, and prototyping

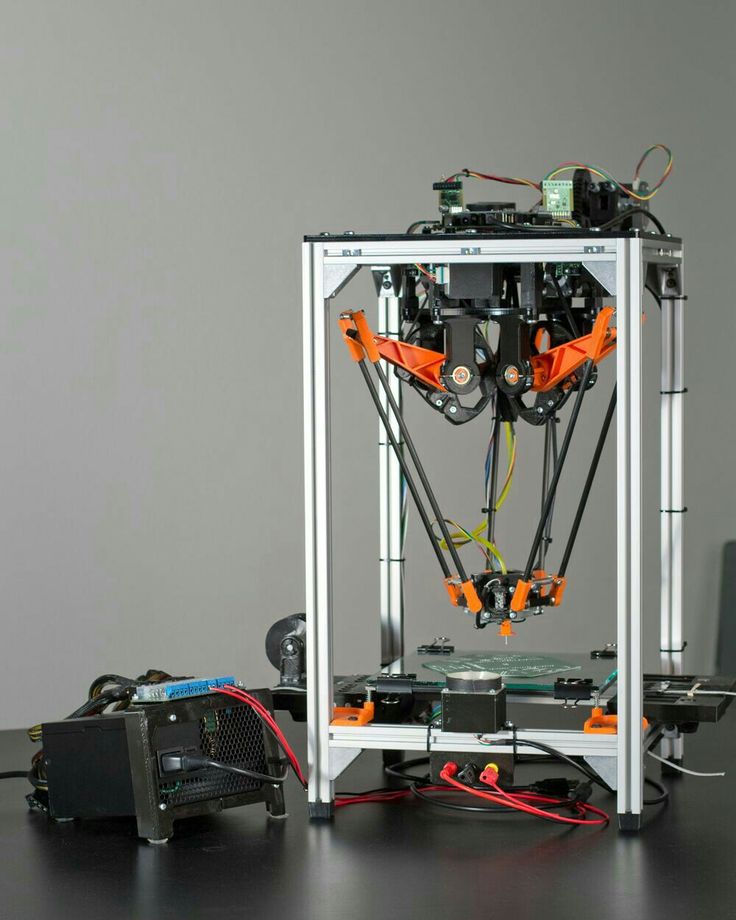

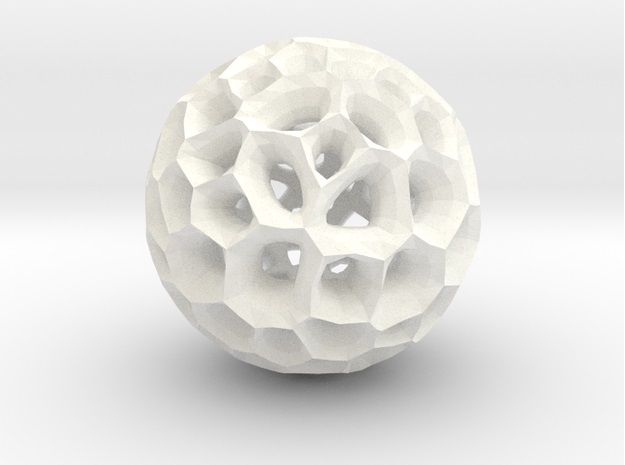

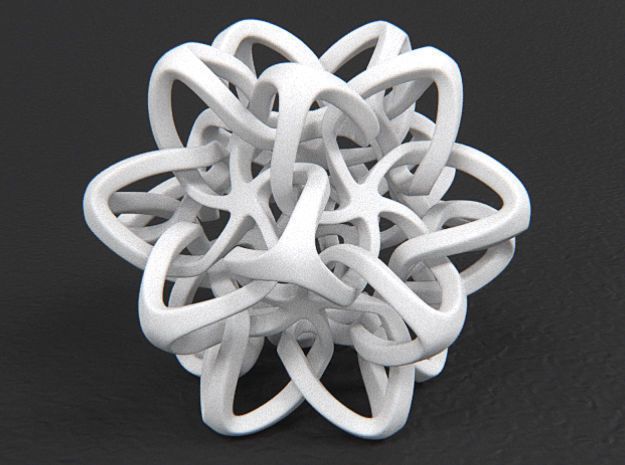

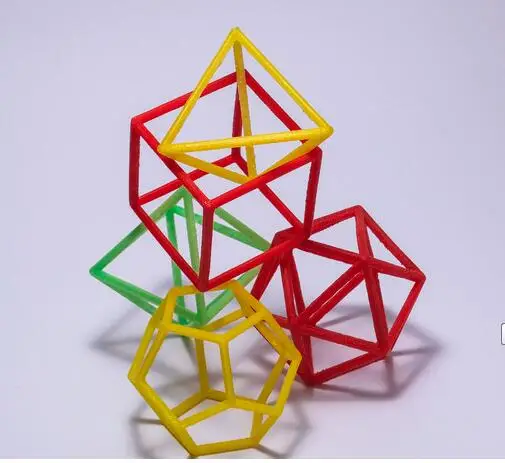

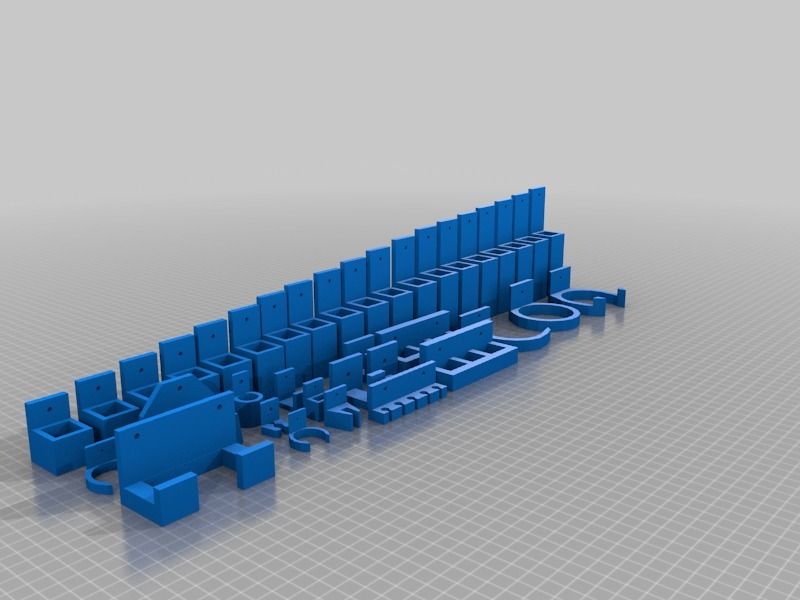

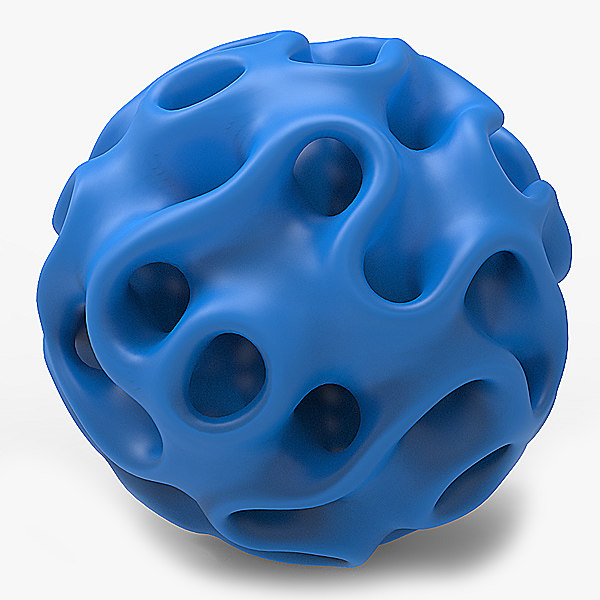

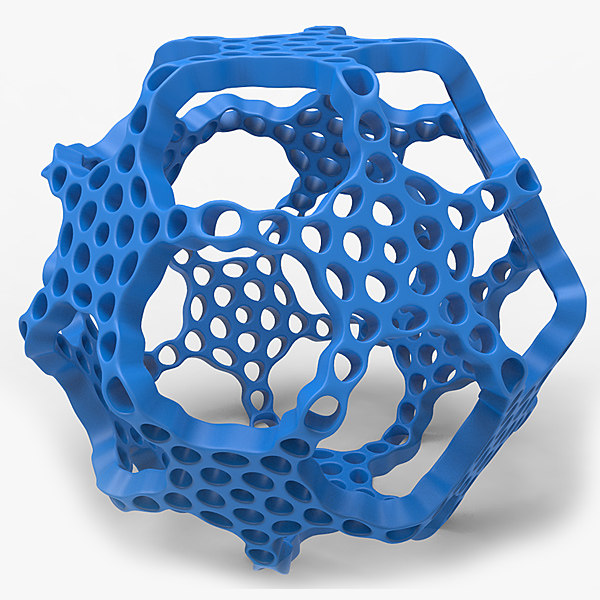

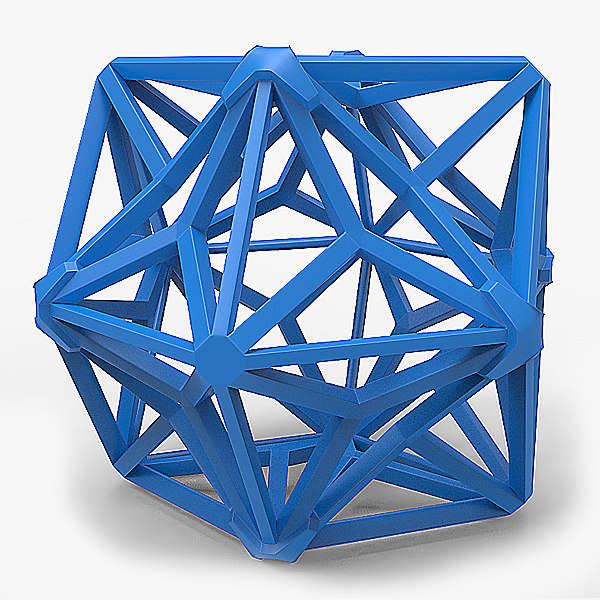

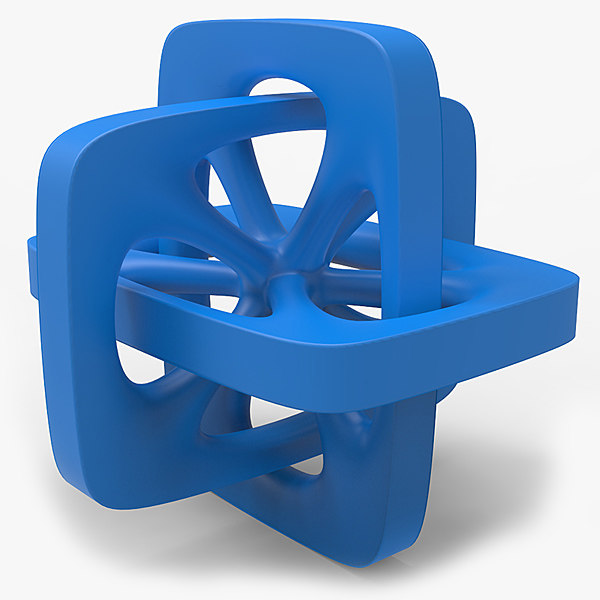

3D Printing

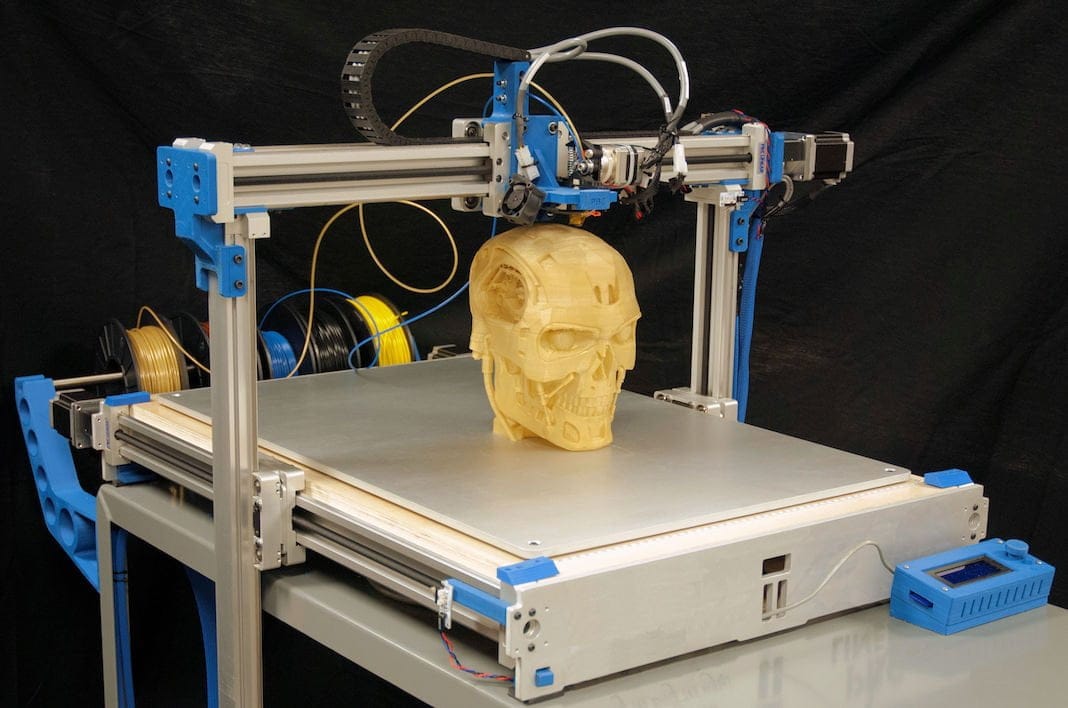

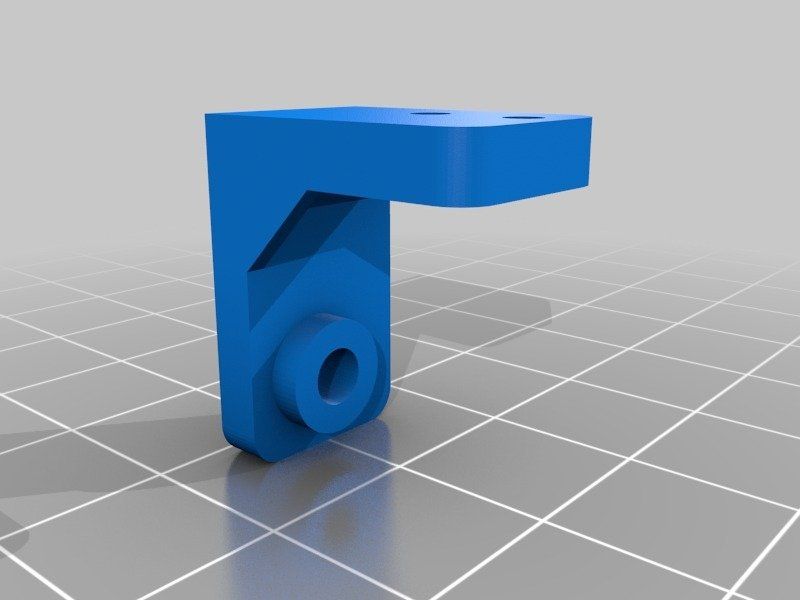

From figurines to working prototypes, our 3D printers provide endless possibilities and applications. We offer custom 3d printing in a wide range of materials and colors. Our printers print at a resolution as fine as 20 microns giving you a crisp detailed print.

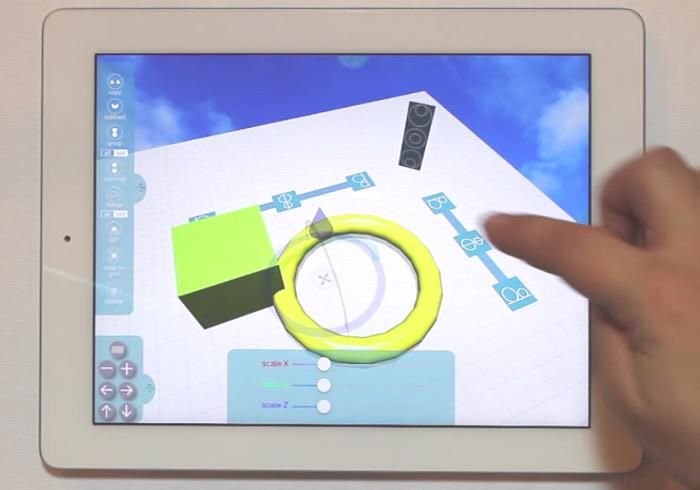

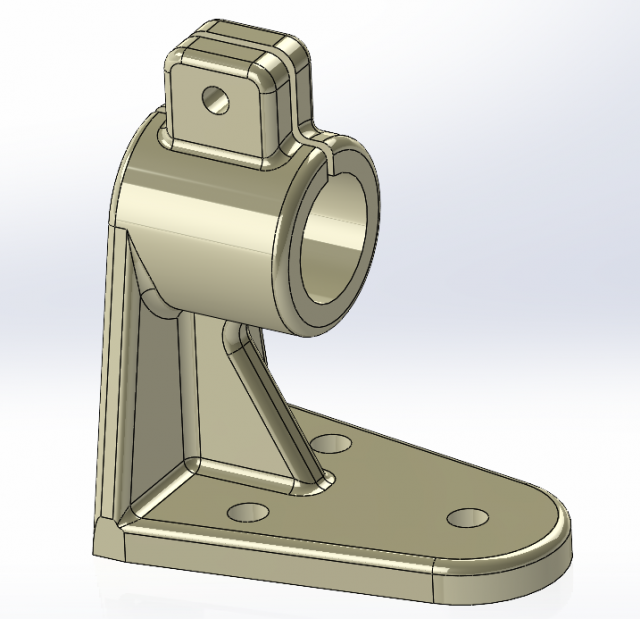

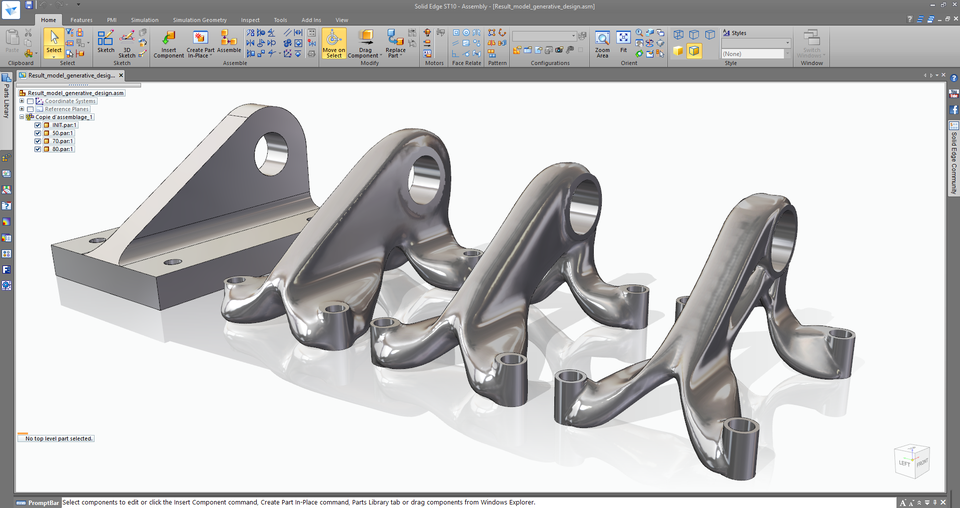

Learn MoreRapid Prototyping

Let us help make your ideas come to life. With over a decade of CAD and 3D modeling experience, we can provide you with everything you need to turn your idea into a reality. We will also design your file according to machine shop specifications.

Learn MoreReverse Engineering

Need something reproduced but don't have the skills to do so? Give us your item and we can reverse engineer it. Have a broken part but can't get a replacement? We also reverse engineer hard to find items. Just bring it in and we can do the rest, even 3D print it.

Laser Cutting and Engraving

Need something reproduced but don't have the skills to do so? Give us your item and we can reverse engineer it. Have a broken part but can't get a replacement? We also reverse engineer hard to find items. Just bring it in and we can do the rest, even 3D print it.

Learn More3D Scanning

We offer professional 3Dscanning services at affordable prices. We can 3D scan up to 15 feet in a single session with extreme accuracy. Bring your part in today to have 3D scanned today.

Learn MoreMold Making

Need something reproduced but don't have the skills to do so? Give us your item and we can reverse engineer it. Have a broken part but can't get a replacement? We also reverse engineer hard to find items. Just bring it in and we can do the rest, even 3D print it.

3D printed Busts

Send us images of you or your loved ones and we will 3D print a bust and post process it to make it look like a bronze or stone statue.

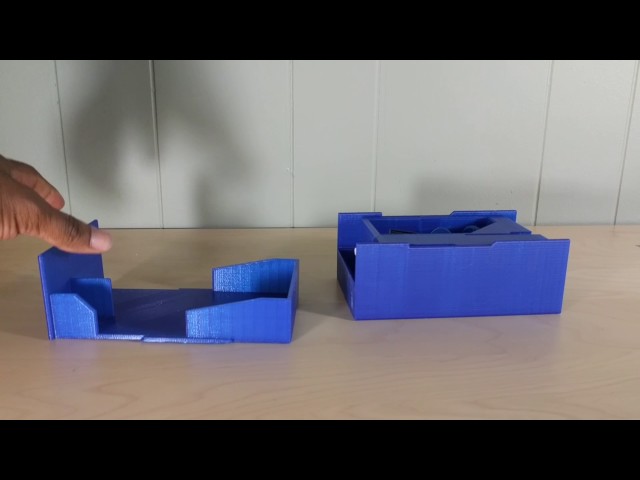

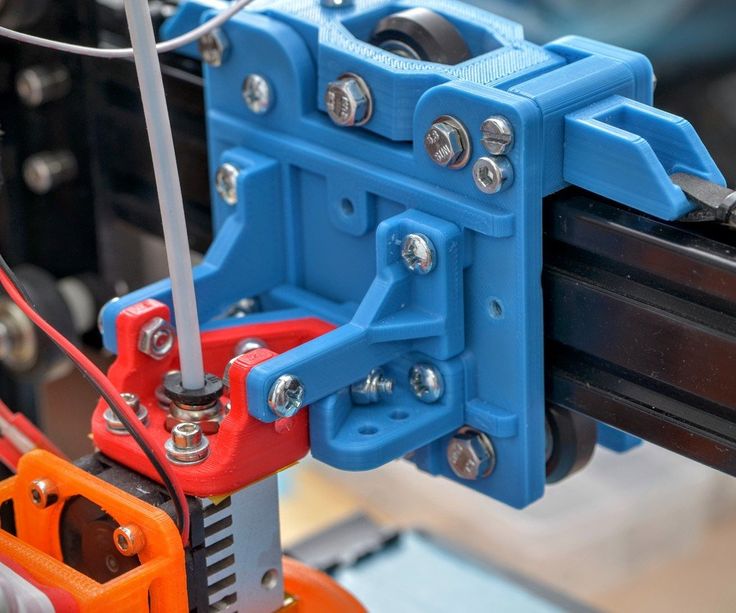

Learn MoreCustom Electronic Enclosures

>From small camera boards, to PC's, we can design, and create custom, unique enclosures for just about everything. Our High Resolution 3D printers can produce your Custom electronic Enclosures in as little as one day..

Learn MoreScale Replicas

A lot of companies make large products that are too large to bring to trade shows. We makle scale replicas of your product so you can bring them to trade shows and conventions with ease, eliminating the hassle and even saving money.

Learn More3D Printers, 3D Scanners, Supplies & Support

Best In Class Dental Scanners, Software & 3D Printers With

UK Based Support

Request DemoRequest a Free Sample

We use Reviews. co.uk to gather certified genuine reviews from our customers. We continually use customer feedback to improve the service that we offer to our customers and to motivate our team.

co.uk to gather certified genuine reviews from our customers. We continually use customer feedback to improve the service that we offer to our customers and to motivate our team.

Read Reviews

Let’s Find You The Right Dental 3D Printers

& Scanners Today

Talk to us today and we'll provide

Free Sample

Request Demo

Chat Now

Introducing the Amazing Formlabs 3D Dental Range

Formlabs have developed a new range of 3D dental printers, resins, and consumables to help increase the workflow and accuracy of operations in the dental industry. Adopting Formlabs into the process has meant dentists can now complete most procedures on the same day as their clients’ appointments. They have also benefited from the following:

Reduced Cost

Printing in-house means you are no longer required to depend on secondary companies for tooling etc.

Client Satisfaction

Shorter wait times, quicker operations and better results.

Ease of Use

Formlabs printers are user friendly and easy to use. Also have a look at Solid Print3D support

Increased Output

Dentists have the ability to print in-house and preform same day operations. No more delays from secondary suppliers.

And the Incredible 3DISC Scanning Range

3DISC offers innovative, ergonomic 3D intraoral scanning solutions that offer more accurate scanning for dentists while enhancing patient comfort.

Increased Output

These lightweight scanners feature rotating, easy to sterilise tips provide full manoeuvrability to create accurate 3D images fast.

Client Satisfaction

Fast scanning means less time in the chair and altogether a less intimidating experience for patients.

Reduced Cost

A one-off capital expenditure with no ongoing licensing fees or subscriptions, and free software updates forever. Reduce lab fees with the 3DISC scanning range.

Ease of Use

Intuitive software preinstalled on a supplied, optimised pc so dentists can begin scanning from day one.

Integrate Into Your Workflow

Designed with Dentists in Mind

Formlabs have analysed and studied the Dental industry to ensure that the printers integrate well into the workflow. At Formlabs they understand that Dentists aren’t engineers, so the printers have been designed in such a way to be intuitive for those using it.

At Formlabs they understand that Dentists aren’t engineers, so the printers have been designed in such a way to be intuitive for those using it.

Formlabs also offer an abundance of online training and teaching. Check out Formlabs Dental Youtube page to receive step by step tutorials of how to design and print each resin.

Formlabs Dental Youtube Page

Support and Training

Setup your printer and start printing

Formlabs supply all their customers with access to helpful webinars, useful information packs and free advice over the phone. Check out our webpage were all these resources can be found in one place.

Formlabs also offers a specialised ‘Dental Service Plan’ with each 3B or 3BL printer. Have that peace of mind that you are always covered, no matter what happens. Check out the service plan here.

Formlabs Webinars and Training

Let’s Find You The Right Dental 3D Printers

& Scanners Today

Talk to us today and we'll provide

Free Sample

Request Demo

Chat Now

One Stop for All Your 3D Dental Needs

Check out our range of Formlabs dental 3D printing machines that are compatible with the Formlabs Dental Resins.

-

Formlabs Form Wash L

£2,399.00EX.VAT Add to cart -

Formlabs Model Resin 1L

£120.00EX.VAT Add to cart -

Dell Precision 7560 15" Laptop-All Rounder Plus

£2,235.00EX.VAT Add to cart - Sale!

3DISC - Heron Intraoral Scanner

£10,500.00 EX.VAT Add to cart -

Formlabs Draft V2 Resin 1L

£120.00EX.VAT Add to cart -

Formlabs Form Cure L

£2,399.00EX.VAT Add to cart

-

Dental Resin Range

Have a look at the specific use for each 3D Printing Dental Resin and how it could help your business.

Shop Dental Resins -

Formlabs BioMed White Resin | 1L

BioMed White Resin Formlabs is committed to ensuring every…

-

Formlabs BioMed Black Resin | 1L

BioMed Black Resin Formlabs is committed to ensuring every…

-

Formlabs Castable Wax 40 Resin 1L

Formlabs Castable Wax 40 Resin Castable Wax 40 Resin…

-

Formlabs Castable Wax Resin 1L

Formlabs Castable Wax Resin offers smooth surface finish for…

-

Formlabs Model Resin 1L

Formlabs Model v2 Resin Formlabs Model v2 Resin is…

-

Formlabs Surgical Guide Resin 1L

Formlabs Surgical Guide Resin Formlabs Surgical Guide Resin is…

-

Formlabs Temporary CB Resin 0.

7L

7LFormlabs Temporary CB Resin Our range of Dental Resins…

Need more information?

Frequently Asked

Questions

Here, you'll find answers to the most common questions we are asked. If your question isn't

answered here, contact us.

01926 333 [email protected]

What is a dental 3D scanner?

+

-

An intraoral scanner is a handheld electronic device which can be inserted into the patient’s mouth to map the anatomical structures within the buccal cavity. The images are sent to a PC where they give a 3-dimensional visual representation of the patient’s mouth, teeth, roots, gums and bones, as well as the nerves and airways. Scans can be sent in an instant to your dental laboratory if required, meaning the whole process is quicker, safer, more efficient and more comfortable for the patient than traditional x-rays or modelling.

What are the common uses for a 3D printer in dentistry?

+

-

3D printing has revolutionised many industries, but it has perhaps been most valuable in the medical fields, including dentistry, where every patient is unique so there can be no ‘one-size-fits-all’ approach. 3D printing can be used to produce physical models for orthodontics prosthodontics and surgery; to make dental, orthopaedic and craniomaxillofacial implants; to produce frameworks and copings for implant and dental restorations; and to create drill guides to be used when fitting dental implants. 3D printers reduce the need for manual modelling, saving time, labour and money.

3D printing can be used to produce physical models for orthodontics prosthodontics and surgery; to make dental, orthopaedic and craniomaxillofacial implants; to produce frameworks and copings for implant and dental restorations; and to create drill guides to be used when fitting dental implants. 3D printers reduce the need for manual modelling, saving time, labour and money.

Customer satisfaction is enhanced as services can be delivered faster and more accurately, reducing time spent ‘in the chair’ and therefore cost too.

How do 3D dental scanners work?

+

-

An intraoral dental scanner records the 3D geometry of the mouth and associated structures accurately and precisely by casting structured light on the area to be mapped. The handheld device uses image sensors to capture areas of interest which are sent to and processed by associated software. A point cloud is constructed which is then further interpreted by the software to create a virtual 3-dimensional surface model which is typically called a ‘mesh’.

How do I choose a 3D dental printer for my practice?

+

-

One of the most important considerations must be the accuracy and precision of the printer. This goes beyond simply analysing a machine’s technical specifications. You must also evaluate the 3D printer’s quality, the technology it uses, the materials utilised for printing, the software settings, and options for post-processing. One sure way to determine the quality of a particular printer is to combine examination of the technical specifications with a sample part created by it. We are happy to send you such a sample so you can evaluate the quality for yourself.

Other important factors to take into account include how easy the machine is for you and your staff to use; how much your initial investment will be in the technology and how quickly you’ll receive a decent return on that investment (including upfront and running costs), and what materials you can use (notably, whether you’re tied to a particular manufacturer’s materials or can use those made by third parties. Speed of printing is also important to consider, as is the ability to scale up in future as demand increases.

Speed of printing is also important to consider, as is the ability to scale up in future as demand increases.

What should I look for in an intraoral scanner?

+

-

The obvious factors are accuracy, speed, flexible workflows and an open system. But just as important is the quality of the software and the options it presents in terms of how scanned images are displayed – can they be easily understood by patients for educational purposes and to enhance customer satisfaction and approval of treatment options? You should also make sure your scanner is fully integrable with other technologies you use in your practice and with any external lab you use. Factor ongoing maintenance and repair costs into your budget; and ensure your staff on board with the technology and willing to learn how to use it before investing in an intraoral scanner.

How much does a 3D dental printer cost?

+

-

As an example, the best selling Formlabs Form 3 complete packages is £4,299 excluding VAT. This includes all you need to manufacture high-quality and precise parts and start printing right away: as well as the printer, you will also receive a resin tank, a platform, a finish kit, the Preform software, a Form wash and a Form cure. The Form 3 uses low force stereolithography to produce retail-grade models and end-use parts from a variety of materials. If you wish to print with medical grade resins, the Form 3B may be more suitable.

This includes all you need to manufacture high-quality and precise parts and start printing right away: as well as the printer, you will also receive a resin tank, a platform, a finish kit, the Preform software, a Form wash and a Form cure. The Form 3 uses low force stereolithography to produce retail-grade models and end-use parts from a variety of materials. If you wish to print with medical grade resins, the Form 3B may be more suitable.

All Form 3 and 3B printers are compatible with consumables used by the Form 2, and if you are looking to upgrade to the Form 3 or 3B, for a limited time, you will receive a £500 credit to use against future consumables.

Contact us today for a free quote.

Let’s Find You The Right Dental 3D Printers

& Scanners Today

Talk to us today and we'll provide

Free Sample

Request Demo

Chat Now

Get Advice On The Right 3D Printer For Your Business

Contact 3D Dental today for a quick response – we are happy to help with any enquiry.

Let's Talk

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0053

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0053

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0053

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0053

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0053

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0053

nine0053

Pros:

Cons:

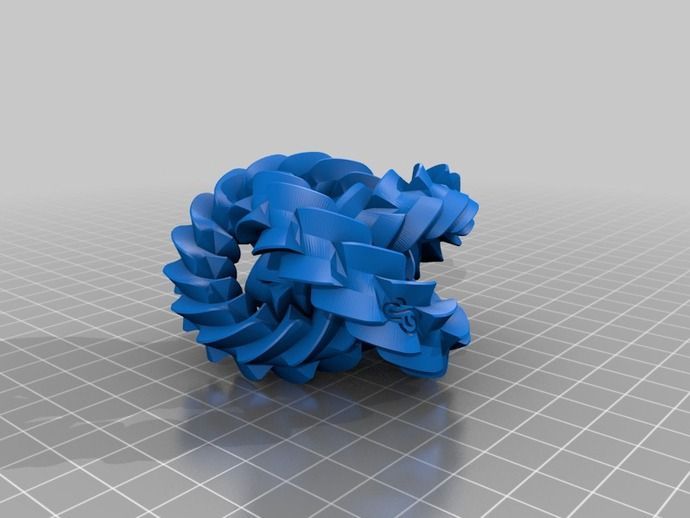

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0053

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0053

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0053

nine0053

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0053

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0053

nine0053

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0053

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0053

nine0053

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0053

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0053

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0053

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0053

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

nine0113 Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you! nine0053

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

INSTAGRAM nine0053

In contact with

Two-color irradiation makes 3D printing continuous

German engineers have developed a 3D printer for 3D printing. It uses two light sources with different wavelengths, located perpendicular to each other: a flat source puts the molecules in the liquid polymer precursor layer into an active state, and the projector causes this layer to polymerize, and only in the right areas. This greatly speeds up the printing process, and also allows you to print objects with separate internal inclusions, for example, a sphere with a ball inside. An article describing the method and prototype of the printer was published in Nature , and the description of the commercial printer is published on the website of the Xolo company, where some of the authors work.

It uses two light sources with different wavelengths, located perpendicular to each other: a flat source puts the molecules in the liquid polymer precursor layer into an active state, and the projector causes this layer to polymerize, and only in the right areas. This greatly speeds up the printing process, and also allows you to print objects with separate internal inclusions, for example, a sphere with a ball inside. An article describing the method and prototype of the printer was published in Nature , and the description of the commercial printer is published on the website of the Xolo company, where some of the authors work.

Classic fused deposition or laser stereolithography 3D printers create objects in separate layers, and inside the layer the print head or laser beam slides along the surface and creates solid areas. This process takes a long time, so engineers have begun to improve methods to speed up work within a single layer, mainly in methods for working with liquid photocurable materials. The simplest method that speeds up the printing process is that the beam does not slide over the surface of the liquid, passing one line after another, but is immediately applied to the entire surface through a liquid crystal stencil. In recent years, methods have also begun to appear that allow printing over the entire volume at once. They can be divided into two types. In one, light is supplied from three sides at once, and solidification occurs at the intersection of the rays. Another uses the tomographic principle, which uses only one projector, and in front of it is a rotating cuvette with a liquid precursor. Superposition of projections allows you to create a given level of irradiation from the desired areas of the liquid and solidify them. nine0053

The simplest method that speeds up the printing process is that the beam does not slide over the surface of the liquid, passing one line after another, but is immediately applied to the entire surface through a liquid crystal stencil. In recent years, methods have also begun to appear that allow printing over the entire volume at once. They can be divided into two types. In one, light is supplied from three sides at once, and solidification occurs at the intersection of the rays. Another uses the tomographic principle, which uses only one projector, and in front of it is a rotating cuvette with a liquid precursor. Superposition of projections allows you to create a given level of irradiation from the desired areas of the liquid and solidify them. nine0053

The tomographic method can print an entire centimeter-scale object in about a minute, but due to light fluctuations caused by rotation, the printing accuracy is hundreds of micrometers - less than other light-based 3D printing methods. German engineers led by Martin Regehly from the Brandenburg University of Applied Sciences and Stefan Hecht from the Humboldt University of Berlin have developed a method that allows you to quickly and continuously print volumetric objects using irradiation, but with a higher resolution - at the level of tens of micrometers. nine0053

German engineers led by Martin Regehly from the Brandenburg University of Applied Sciences and Stefan Hecht from the Humboldt University of Berlin have developed a method that allows you to quickly and continuously print volumetric objects using irradiation, but with a higher resolution - at the level of tens of micrometers. nine0053

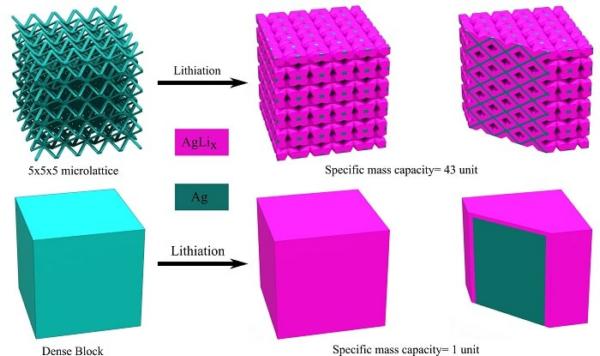

The new printing method is based on the earlier two-color photopolymerization method. It uses a photoinitiator that is sensitive to two wavelengths: when irradiated with light of one wavelength, it passes into a short-lived activated state, and when irradiated with a second wavelength, it initiates polymerization of the precursor. The design of the new printer uses its own source for each of the wavelengths. In order to activate the photoinitiator at each point of the liquid only once, the engineers used a laser source of ultraviolet radiation with a length of 375 nanometers, the light from which, using an optical circuit, is “stretched” to a line as high as the working area of the printer. During printing, a transparent cuvette with a precursor moves along this line in one direction, so activation for each photoinitiator molecule occurs only once. nine0053

During printing, a transparent cuvette with a precursor moves along this line in one direction, so activation for each photoinitiator molecule occurs only once. nine0053

A projector with a resolution of 3840 by 2160 pixels and a pixel size in the plane of the ultraviolet band from the laser of 21 by 21 micrometers is installed on the perpendicular side. It studies light with a peak intensity at a wavelength of 550 nanometers, which coincides with the absorption peak of an activated photoinitiator.

During printing, the laser creates an ultraviolet-irradiated plane that activates the photoinitializer, the projector focuses a layer of the 3D model in this plane, the cuvette gradually moves, and the projector displays new layers. After that, a liquid precursor and a solid 3D model remain in the cuvette. nine0053

Tests have shown print speeds of 55 cubic millimeters per second, or approximately one minute per centimeter-wide cuvette. The print resolution on the test samples was 25 micrometers in the UV plane and 50 micrometers in the perpendicular direction.