3D jet printer

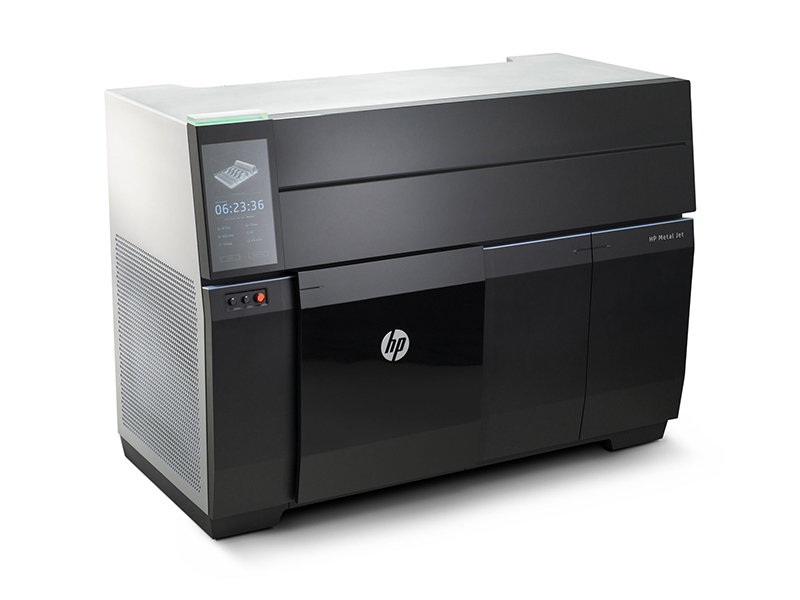

Industrial 3D Printer – HP Jet Fusion 5200 Series 3D Printing Solution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Expand and scale into volume production with HP industrial 3D printers

Enhanced manufacturing predictability

Breakthrough productivity and automation

Expand into new applications and markets

See how the HP industrial 3D printer works

Explore the complete HP Jet Fusion 5200 Series Industrial 3D Printing Solution

HP 3D High Reusability PP

1enabled by BASF

Chemical resistant,2 weldable, low moisture absorption, functional parts

Data courtesy3

HP 3D High Reusability PA 11

4Ductile,5 quality parts

Data courtesy6

HP 3D High Reusability PA 12

7Strong, low cost,8 quality parts

Data courtesy9

HP 3D High Reusability PA 12 GB

10Stiff, dimensionally stable, quality parts

Data courtesy11

BASF Ultrasint® TPU01

Flexible, functional parts.

HP Jet Fusion 5200 Series 3D Automatic

Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

HP 3D API

12Streamlined data access and automation across industrial management systems.

HP 3D Center

13Dashboard view into production data and remote monitoring for greater efficiency and agility.

Learn

Watch

HP 3D Process Control

14Dimensional accuracy and repeatability—faster—for manufacturing predictability.

HP SmartStream 3D Build Manager

Quickly and easily prepare your jobs for printing with all the elements you need.

Download

Autodesk® Netfabb® with HP Workspace

Provides advanced software for the additive manufacturing of production quality parts.

HP Build Processor

The industry standard software for professional 3D Printing, to unlock the full potential to manage every step in your production process.

Siemens NX AM

Combine design, optimization, simulation, preparation of print jobs, and inspection processes all in a single managed environment and with minimal steps.

HP Jet Fusion 5200 3D Natural Cooling Unit

Designed to remove and cool each build naturally, thereby enabling continuous production.

Hovmand Forklift 5200

HP recommended accessory to remove and place the HP Jet Fusion 5200 3D Natural Cooling Unit from the processing station.

HP 3D Solution Services

Explore new opportunities to scale production and accelerate growth with support and consultancy from HP.

HP 3D Professional Services

Expert guidance to help you and your customers identify viable strategic opportunities, optimize design for breakthrough applications, and streamline manufacturing processes.

Data courtesy15

HP 3D as a Service

Pay based on usage: Gain new levels of cost predictability and the flexibility to scale your business as you grow.

HP Integrated Financial Solutions

Accelerate your time to value. Enjoy the flexibility to meet both your technology and financial plans while allocating your cash to other priorities.

Data courtesy16

Expand your offering with quality white applications

Achieve consistent white - part after part, with the HP Jet Fusion 5420W 3D Printing Solution that delivers enhanced manufacturing predictability and outstanding part quality at the right cost.

Disclaimers

The content of this site is for information purposes only and it is showing the product configuration for the US market only.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Based on internal HP testing, May 2020.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use. - Based on internal HP testing, May 2020, with tests for mechanical property retention, dimensional stability, and weight change after 7- and 30-day immersion with acids, bases, organic solvents, and aqueous solutions. Due to the material characteristics, extra tuning is required in part design and printing, compared to other rigid HP 3D Printing materials.

- HP 3D High Reusability PA 11 image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 11 provide up to 70% powder reusability ratio, producing functional parts batch after batch.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy. - Testing according to ASTM D638, ASTM D256, and ASTM D648 using HDT at different loads with a 3D scanner for dimensional accuracy. Testing monitored using statistical process controls.

- HP 3D High Reusability PA 12 image is data courtesy of Addit.ion

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- Supplies price, and maintenance costs recommended by manufacturer. Cost criteria: printing 1.4 full build chambers of parts per day/5 days per week over 1 year of 30 cm3 parts at 10% packing density on Fast print mode using HP 3D High Reusability PA 12 material, and the powder reusability ratio recommended by manufacturer, and printing under certain build conditions and part geometries.

- HP 3D High Reusability PA 12 GB image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 Glass Beads provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- BASF Ultrasint® TPU01 image is data courtesy of Kupol.

- Supported industrial management systems for HP Jet Fusion 5200 / 4200 Series 3D Printing Solutions : 3D Control Systems, AMFG, LINK3D, Siemens NX AM, Siemens Opcenter. Access to additional data modules available only for the HP Jet Fusion 5200 Series 3D Printing Solution. Additional purchases required. Supported industrial management systems for HP Jet Fusion 5420W 3D Printing Solution : 3D Control Systems, AMFG, LINK3D. Access to additional data modules available only for the HP Jet Fusion 5420W 3D Printing Solution.

Additional purchases required.

Additional purchases required. - Available only for the HP Jet Fusion 5420W 3D Printing Solution and HP Jet Fusion 5200/4200 Series 3D Printing Solutions. Compatible software. Additional purchase required.

- Available only for the HP Jet Fusion 5200 Series 3D Printing Solution. This software is sold as an HP 3D Solution Service. For more information visit https://h30195.www2.hp.com/v2/GetDocument.aspx?docname=4AA7-7931EEW

- Data courtesy of Meidai

- Data courtesy of Invent Medical

HP Industrial 3D Printers - Leading The Commercial 3D Printing Revolution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Data courtesy1

Integrity.

Adaptability. Innovation.

Adaptability. Innovation. Production ready

and reliable

Together, we can take revolutionary designs seamlessly from prototype to production grade.

Ability meets

agility

Let’s implement production processes that allow you to rapidly develop unique solutions while remaining flexible.

Reimagining

realities

Now we have the power to customize like never before and produce wherever, whenever your product is needed.

The possibilities are endless

Partnership makes anything

possible

Breakthrough digital technology alone isn’t enough. Today, you need a trusted partner who knows how to apply it effectively to help solve your specific supply-chain challenges.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Data courtesy of Bastian Solutions & Fast Radius, Heygears, Avular, Breezm, Volkswagen and Cupra Racing

- Data courtesy of GoProto and Ropes Edge

- Data courtesy of Gimatic

- Data courtesy of SmileDirectClub

- Data courtesy of Volkswagen

- Data courtesy of Invent Medical

- Data courtesy of Cobra Golf

- Data courtesy Addit.ion

- Data courtesy of Hopkins, J., Lobete, A., Remacha, C.

- Data courtesy of Lumenium

- Data courtesy of Breezm

Archive

Subscribe to the author

Subscribe

I do not want

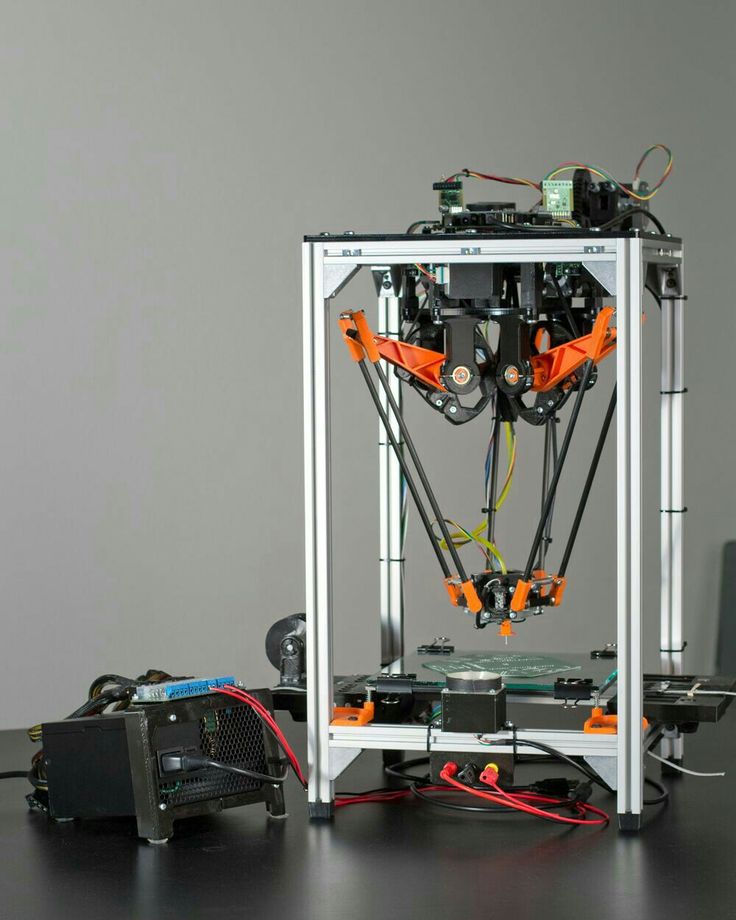

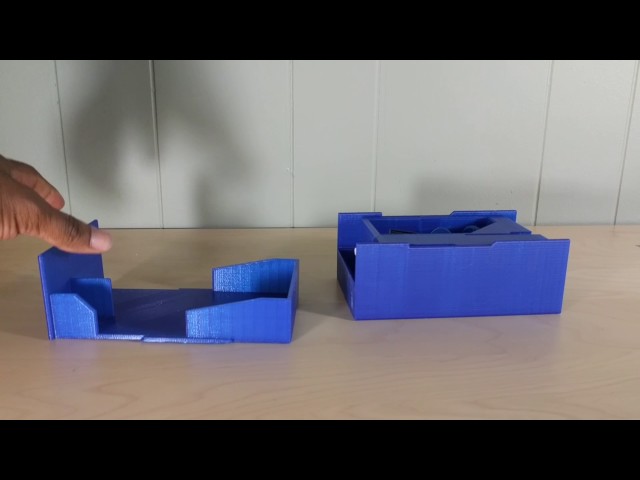

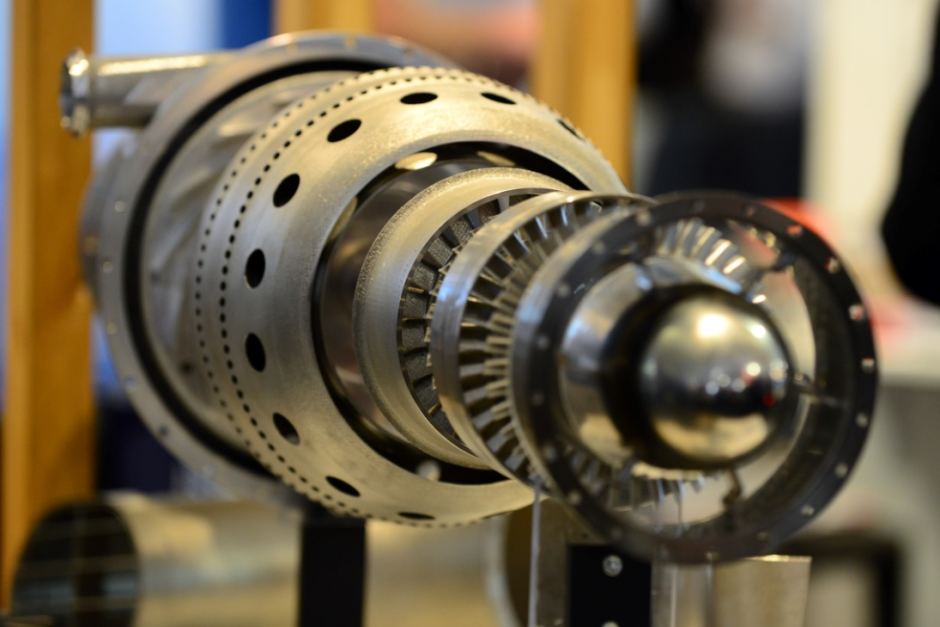

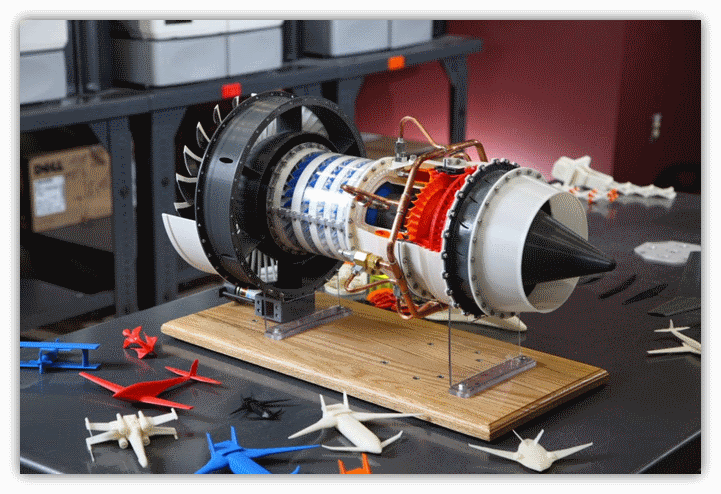

Product, printed on the 3D printer Plan B

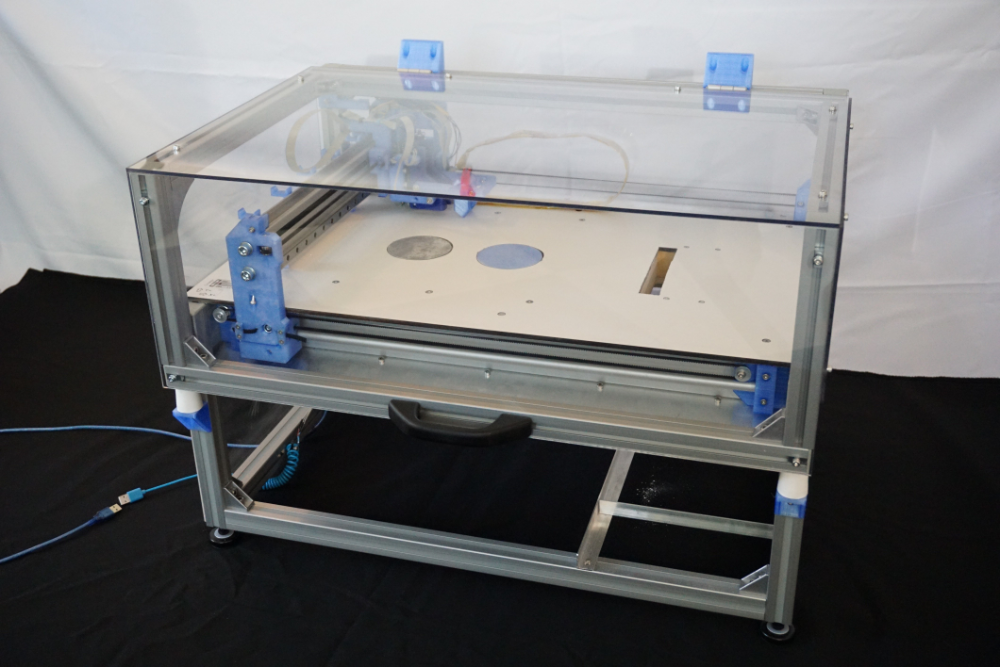

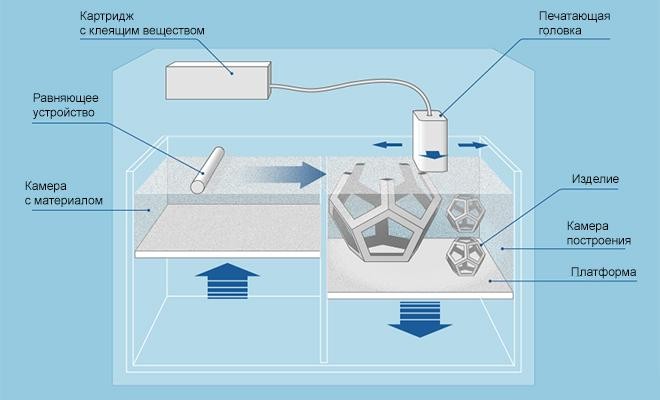

, 22-year-old engineer Ivo de Haas developed An open source Plan B 3D printer that's far from ordinary. It uses a technology that is fundamentally different from the method of layered deposition and stereolithography. This printer prints products from fine powder, which sticks together layer by layer under the influence of a special binder. nine0003

It uses a technology that is fundamentally different from the method of layered deposition and stereolithography. This printer prints products from fine powder, which sticks together layer by layer under the influence of a special binder. nine0003

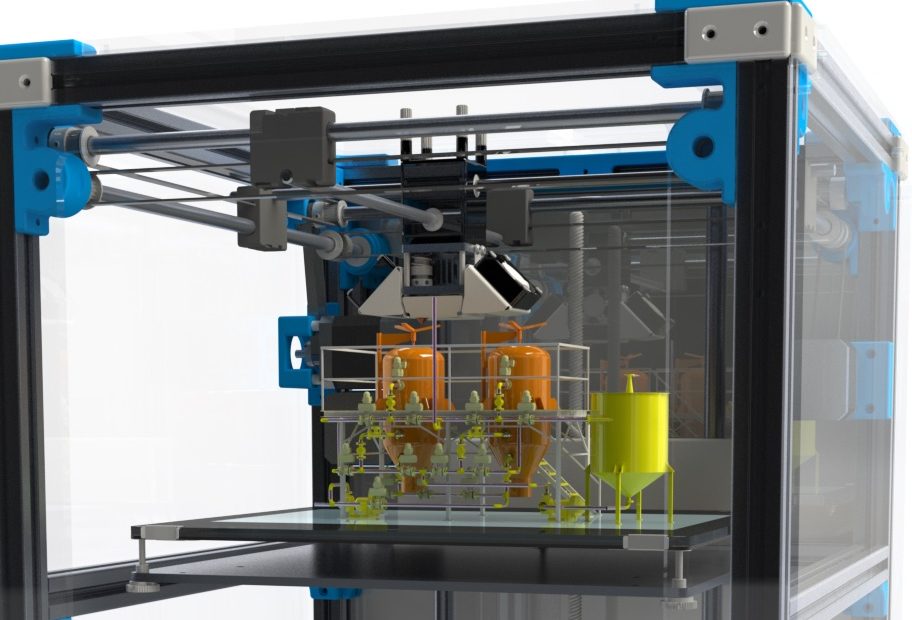

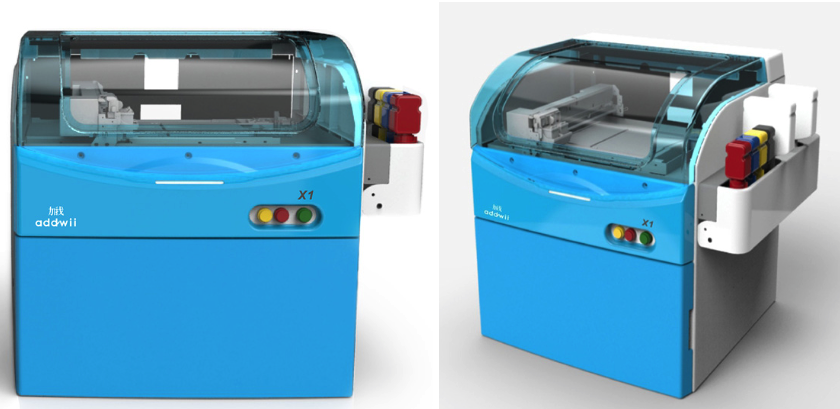

Plan B 3D printer

“3D printing differs from conventional inkjet printing only in its three-dimensionality,” explains Haas. – My 3D printer has several powder containers and a binder cartridge. First, he applies a thin layer of powder to the platform. The head sprays the binder, bonding the powder in the right places. When the layer is ready, the platform drops a little lower. This process is repeated until the product is finished.

Plan B 3D printed product

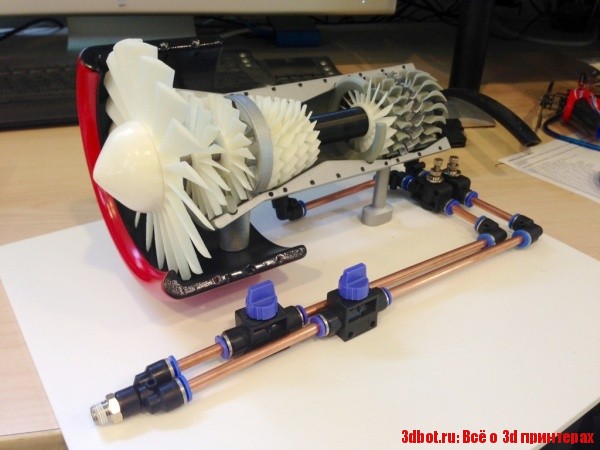

In general, this method is similar to selective laser sintering, but instead of a laser that sinters the powder, it uses a special adhesive that resembles glue. Haas claims that the Plan B prints much more accurately than fused deposition 3D printers. In addition, no support material is required when manufacturing products with a complex design, since the powder itself serves as a support. nine0003

In addition, no support material is required when manufacturing products with a complex design, since the powder itself serves as a support. nine0003

Plan B may not be one of the world's fastest 3D printers, but it prints faster than Cartesian 3D printers because the nozzle doesn't have to move as much as the print head normally does. While stereolithography and fused deposition 3D printers are limited in materials (usually plastic-based substances), Plan B is capable of printing virtually any powder material, including ceramic, stainless steel, graphite, and etc. nine0003

Plan B in action

Sounds great, doesn't it. However, there is a fly in the ointment in every barrel of honey. First of all, it is worth remembering that a very fine powder is used for work, which means that it will contain both the platform and the product itself. Also, the 3D printer's containers must always be filled with powder for it to function properly. But, perhaps, the most unpleasant can be considered the post-processing of products. Printed products are quite fragile, so they should be handled very carefully. First you need to brush off the remnants of the powder from them, then cover them with cyanoacrylic or epoxy glue to give them strength. Another way to fasten the product is to burn it in the oven. Agree, not everyone has a personal kiln at hand. nine0003

Printed products are quite fragile, so they should be handled very carefully. First you need to brush off the remnants of the powder from them, then cover them with cyanoacrylic or epoxy glue to give them strength. Another way to fasten the product is to burn it in the oven. Agree, not everyone has a personal kiln at hand. nine0003

The Plan B 3D printer cost Haas about 1,000 euros to build. Main features:

- Working volume: 150 mm x 150 mm x 100 mm.

- Layer thickness: 0.1-0.25 mm.

- Resolution: 96 dpi (HP C6602).

- Printing material: currently Zcorp gypsum powder and colorless binder (this list will be updated).

- Positioning accuracy (X/Y): 0.05 mm.

- Speed: 60 mm/sec (will be higher with future hardware update). nine0040

- Print speed: up to 30 mm/h (will be faster with a future hardware update).

- Power consumption: up to 160 W (about 90 W on average).

- Printer dimensions: 550 mm x 350 mm x 450 mm.

- Printer weight: 16 kg.

- Frame material: aluminum and plastic.

- Linear guides: LM8UU on steel rods 8 mm thick.

- Number of motors: 6 NEMA17 motors. nine0040

- Extras: LCD screen, rotary keypad, SD card reader.

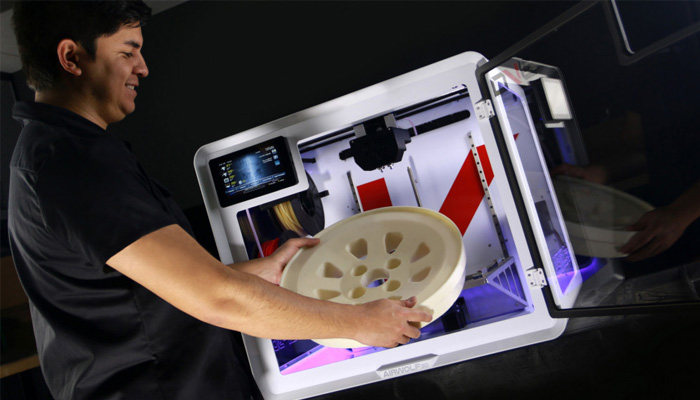

3D printer loaded with powder

All instructions for building the Plan B 3D printer can be found on the Haas website.

Article prepared for 3DToday.ru

nine0003

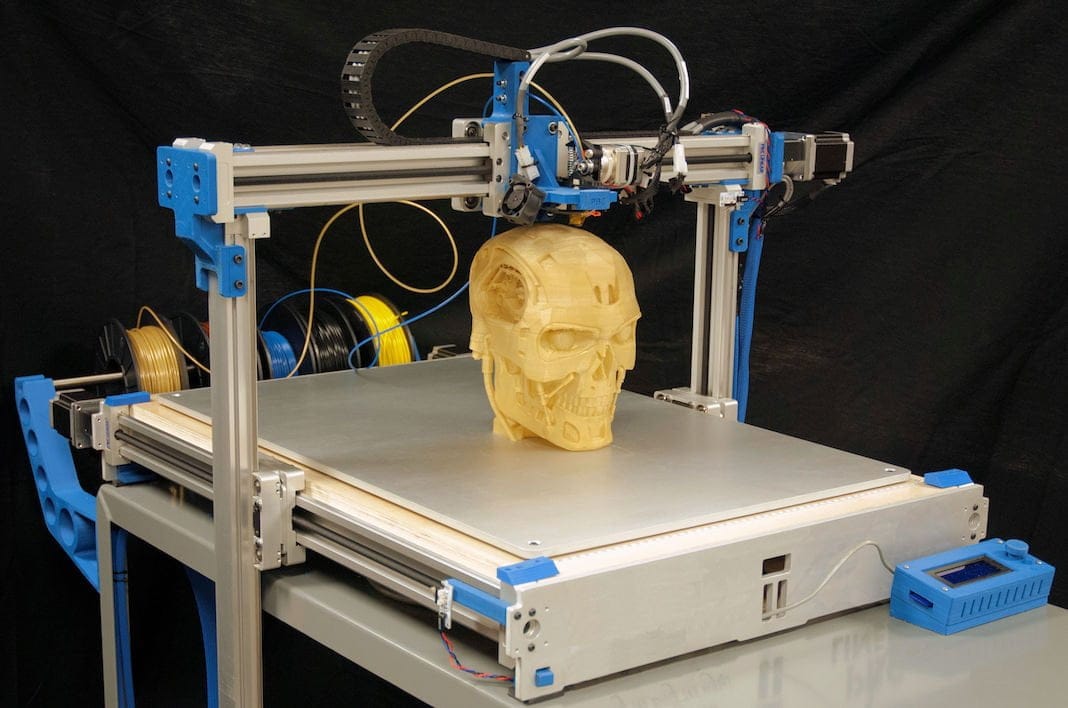

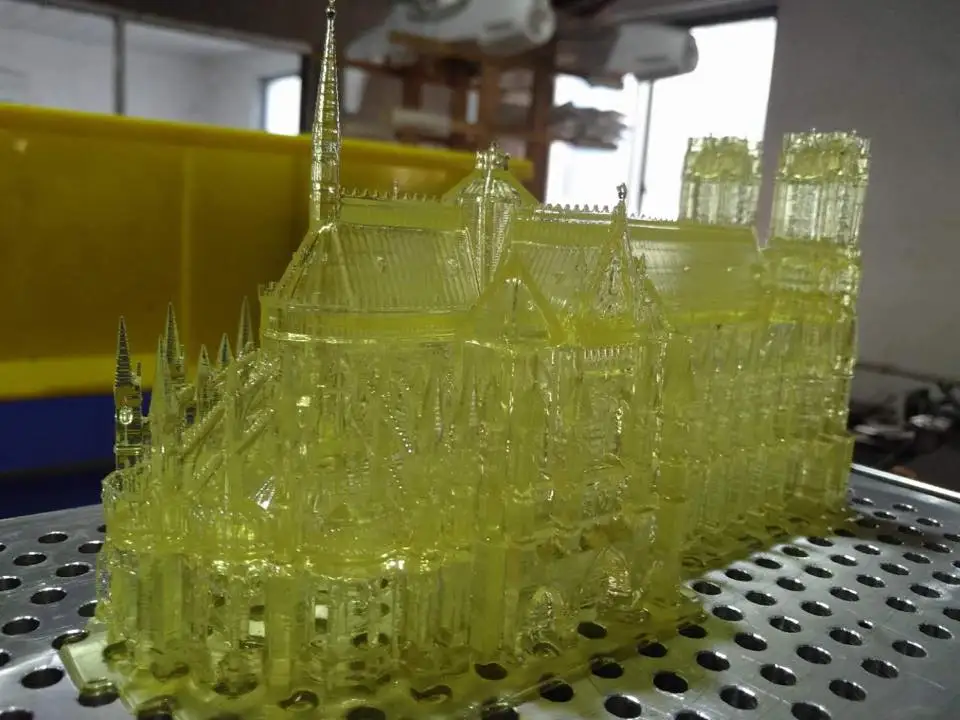

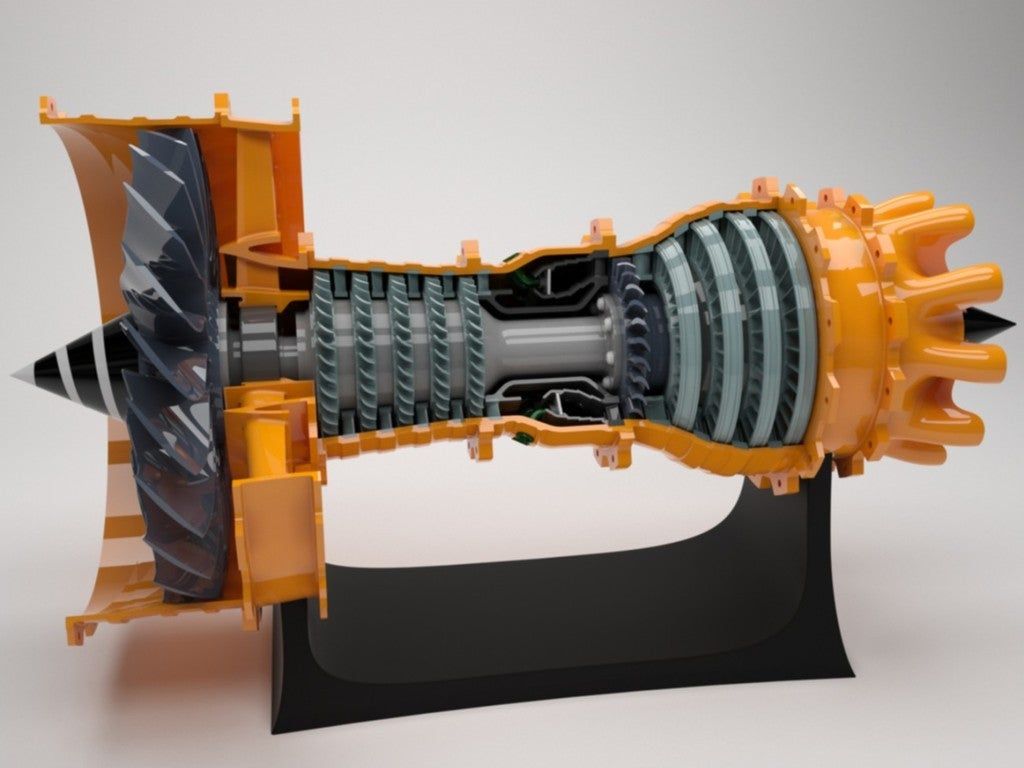

3DP stands for Three-Dimensional Printing , and translates as three-dimensional printing. This technology is one of the varieties of systems for the additive construction of a product according to its CAD model and differs from numerous similar schemes in that the process is carried out according to the principle of a conventional printer - through print head nozzles. Thus, 3D inkjet printing is a natural continuation of the development of conventional 2D printing technologies. To date, it has achieved fairly good results, such as color printing. nine0003

To date, it has achieved fairly good results, such as color printing. nine0003

Products printed on the Z Corp's Spectrum Z510 color 3D printer

The history of the emergence and development of 3DP

The idea of implementing equipment using this printing scheme was first proposed by two students at the Massachusetts Institute of Technology Tim Anderson and Jim Bredt in 1993. It is thanks to them that the term 3D printing has spread around the world. And this is quite fair, because the first model of the device was a modification of a conventional 2D printer. Instead of ink, he used a special adhesive composition, which applied layer by layer to the surface of the bonded substance, the boundaries of the future three-dimensional product. nine0003

In 1995, Tim and Jim formed the Z Corporation, which brought this technology to market, improving it to such an extent that in 2012 3D systems Corporation wished to acquire it along with the company. Under her brand, former Z Corporation models are now sold worldwide.

One of the directions of the ExOne company (USA) is the production of 3D printers that use the same technology. This firm was founded in 2005 as a subsidiary of the Extrude Hone Corporation. Using the patents obtained by Anderson and Bedt, they launched a line of printers that even print metal products today. nine0003

3D inkjet printing technology

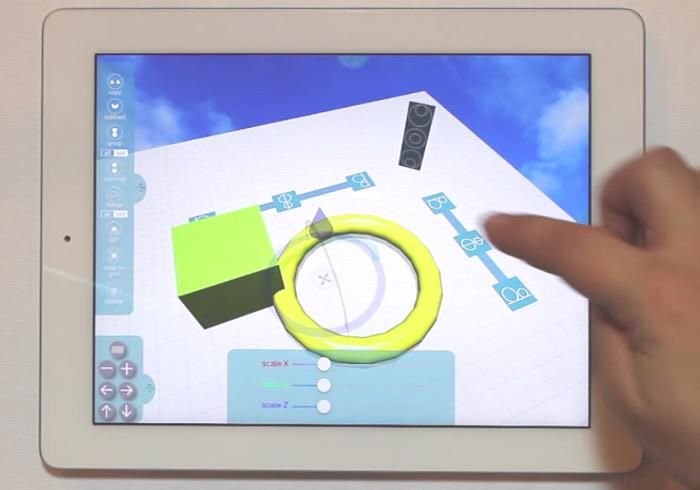

Today there are more than thirty 3D printing technologies, which in one way or another duplicate each other, although each has its own characteristics. The American Society for Testing and Materials (ASTM International) has divided 3D inkjet printing technologies into two categories:

- Material jetting - material splattering.

- Binder jetting Binder jetting. nine0040

In the first case, the building material itself is fed directly through the nozzles, which hardens after application. In the second, an adhesive is sprayed onto a thin layer of gypsum, polymer or metal powder. 3DP technology in its original form represented exactly the second method.

3DP technology in its original form represented exactly the second method.

If we consider it in more detail, then printing occurs in the following way:0003

- To begin with, a CAD model is loaded into a computer connected via an Ethernet cable to the printer, which is “cut” into layers, about 0.1 mm thick.

- Next, a thin layer of powdered material (gypsum, polymers, sand, metal) is applied with a roller on a special platform.

- Using the print head, a binder (glue, water, special mixture) is sprayed along the coordinates of the boundaries of the first layer received from the computer. nine0039 After that, the platform with the model is lowered by the thickness of the layer down, and the chamber with the building material is lowered by the same distance.

- Next, the roller unrolls the next layer and the process repeats.

- After the end of 3D printing, the product is removed from the powder layer and thoroughly cleaned of its residues.

When making models from metal powder, a firing process in a special furnace is added. Let's take a closer look at this process.

The figure above shows 4 stages of his stage:

- First, according to the above scheme, the so-called "green model" is formed from the matrix powder and binder (1,2).

- Next, the product is placed in an oven filled with a protective gas, usually nitrogen.

- When the temperature rises to 1000-1100 degrees, the binder is removed, and the free space around the powder particles is impregnated with bronze (or other metal) previously placed next to the "green" model. This process is called infiltration. nine0067

Materials used for 3DP printing and their cost

Gypsum has traditionally been used in 3D printing, and water played the role of a binder in this case. However, technology has stepped forward and, as is clear from the previous section, metals (bronze, copper), sand and polymer mixtures are now also used. Dyes are mixed into the binder, which makes it possible to carry out color printing on such a 3D printer.

Dyes are mixed into the binder, which makes it possible to carry out color printing on such a 3D printer.

The cost of the simplest powders is on average 600-700 euros for a 10 kg bucket (8200 cm3), the price of the binder is about 660 euros for 3.8 liters. nine0003

Characteristics of finished products and their application

Models made of gypsum and polymers are not too strong to be used in the production cycle as a mold, however, they are quite suitable for rapid visualization of prototypes of various parts and products . It can also be used in various architectural and design works or in the manufacture of souvenirs.

Products using metals have better properties, however, their strength is still at an average level: tensile strength 610 MPa, hardness HRC = 10-20. nine0093 Such characteristics are quite suitable for the manufacture of plastic injection molds, which can withstand from 200 to 500 thousand production cycles. They are also used to make parts that work under friction conditions - shafts, bushings, gears, etc.