Shanghai 3d printer

China’s first 3D printed retractable bridge unveiled in Shanghai

0Shares

A 3D printed retractable bridge has been unveiled in Shanghai, China, that is capable of unfurling in less than one minute.

Reportedly the first of its kind to be built in China, the Bluetooth-controlled bridge spans nine meters long and is located in the city’s Wisdom Bay Innovation Park.

The successful manufacture of the bridge is seen as a step towards further advances in 3D printing technology for retractile architecture.

The 3D printed retractable bridge in Wisdom Bay, Shanghai. Photo via Yu Xi / Global Times.Wisdom Bay’s 3D printing credentials

Shanghai’s Wisdom Bay is built on the former site of a wool textile mill and is home to more than 300 global companies that engage in 3D printing, intelligent micro-manufacturing, virtual reality (VR), augmented reality (AR), and artificial intelligence (AI) robotics projects. The site is also supposedly home to the world’s only 3D printing museum.

Wisdom Bay has played host to several innovative 3D printing projects in recent years. In 2019, a 26.3 meter-long and 3.6 meter-wide 3D printed concrete bridge was installed in the park. Hailed the world’s largest at the time, the bridge was 3D printed by Tsinghua University in 450 hours.

At the beginning of this year, another project carried out by Tsinghua University saw the successful construction of a 3D printed concrete bookstore in the park. The bookstore was printed on-site in three weeks using “fiber concrete” to withstand compression and earthquake effects and has a floor space of 30 square meters.

Rendering of the 3D printed bookstore. Image via Wisdom Bay Innovation Park.The 3D printed retractable bridge

Weighing just 850 kilograms, the retractable bridge is nine meters long, 1.5 meters wide, and 1.1 meters high. The structure has been installed over a small pond in Wisdom Bay and is reportedly capable of holding up to 20 people at a time.

The bridge is made up of 36 3D printed triangle panels, each of which features a different design resembling ripples spreading outwards. Printed over three days, the panels are made from a composite carbonate polyester material that is claimed to be environmentally friendly.

The bridge is divided into nine segments. The retractile element of the bridge is operated via Bluetooth, with the structure unfurling across the water in a spiral shape in less than one minute. The bridge is also equipped with a gravity-sensitive automatic warning system to prevent over-loading.

The bridge is reportedly due to open to the public at the end of July.

The 3D printed retractile bridge in operation. Video via Global Times.

Video via Global Times.Bridging gaps with 3D printing

Thanks to its ability to yield improved material efficiencies, cost reductions, and time savings, additive manufacturing is being increasingly utilized for the construction of bridges, viaducts, and other civil engineering projects across the globe.

Elsewhere in Shanghai, a 15.25 meter-long pedestrian bridge has been 3D printed as part of a project carried out by Chinese construction firm Shanghai Mechanized Construction Group Co and 3D printing filament manufacturer Polymaker. The bridge was created as a demonstration of pollution-free construction and the use of “smart” technology.

Europe is also leading the way in leveraging 3D printing’s architectural potential. Last year, global nutritional science firm and materials producer DSM was involved in a project to 3D print a footbridge from recyclable source materials. Installed in the heart of Rotterdam’s Kralingse Bos park district, the bridge was the first to utilize fiber-reinforced thermoplastics.

Meanwhile in Paris, a consortium including large-scale 3D printing firm XtreeE was awarded a design-build contract for a 40-meter pedestrian footbridge made from 3D printed structural concrete in preparation for the 2024 Olympic Games.

Most recently, construction firms BAM and Weber Beamix announced they had begun building the world’s longest 3D printed concrete pedestrian bridge in the Netherlands, which will stand at a length of 29.5 meters once complete.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the 3D printed retractile bridge in Wisdom Bay, Shanghai. Photo via Yu Xi / Global Times.

Photo via Yu Xi / Global Times.

Tags BAM DSM Polymaker Shanghai Mechanized Construction Group Co Tsinghua University Weber Beamix Wisdom Bay Innovation Park XtreeE

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Arburg Opens Shanghai 3D Printing Center to Expand Chinese Presence - 3DPrint.com

German machine construction company Arburg opened a new Prototyping Center (APC) at its Shanghai site on March 2021, strengthening its presence in China and offering prospective additive manufacturing customers the chance to witness its plastic Freeformer machines live. The almost century-old company has four locations in China, from technology centers in Pinghu and Shenzhen to commercial offices in Hong Kong and Shanghai. This latest addition is considered a significant stepping stone for Arburg since the APC could eventually cater to the growing demand for 3D printing technologies in the entire Asian market.

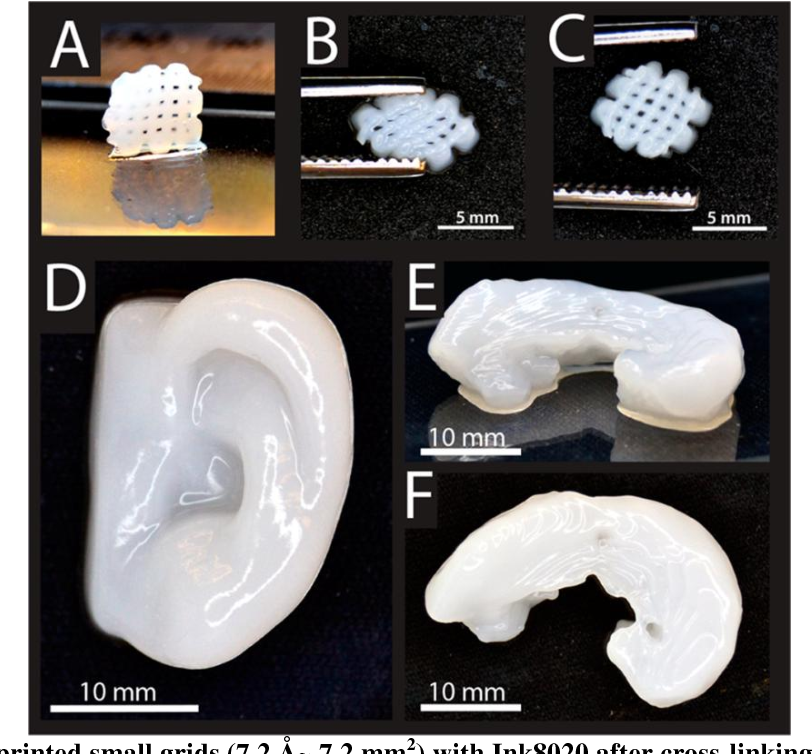

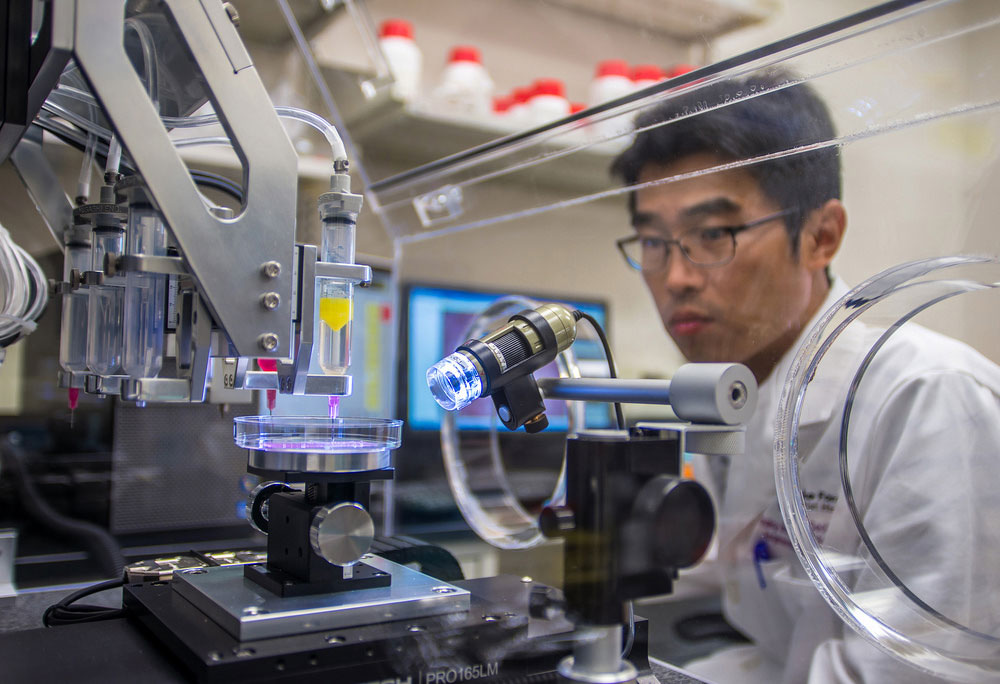

The new additive manufacturing hub at Arburg Shanghai (which has been Arburg’s main site in China since 2004) is expected to satisfy a particularly high demand from the medical technology and packaging industries, which is why news of the opening was announced during a medical seminar. With its industrial Freeformers – designed for the mold-free 3D printing of plastic parts as one-off items or in small batches – production at this APC will be somewhat smaller than the original Arburg prototyping center at the company’s headquarters in Lossburg, Germany, but comparable in terms of its capability.

The medical FDA-approved material TPE Medalist MD 12130H is suitable for producing flexible, customized hand orthoses with Freeform. Image courtesy of Arburg.

As the third Arburg Prototype Center in the world, the investment builds on the group’s plan to have dedicated prototyping centers available to customers in each of the company’s key market regions. Just like the first two facilities in Germany, and Rocky Hill, Connecticut, the new APC will use a vast array of original materials to produce benchmark parts using AM techniques, working round the clock where necessary to meet demand.

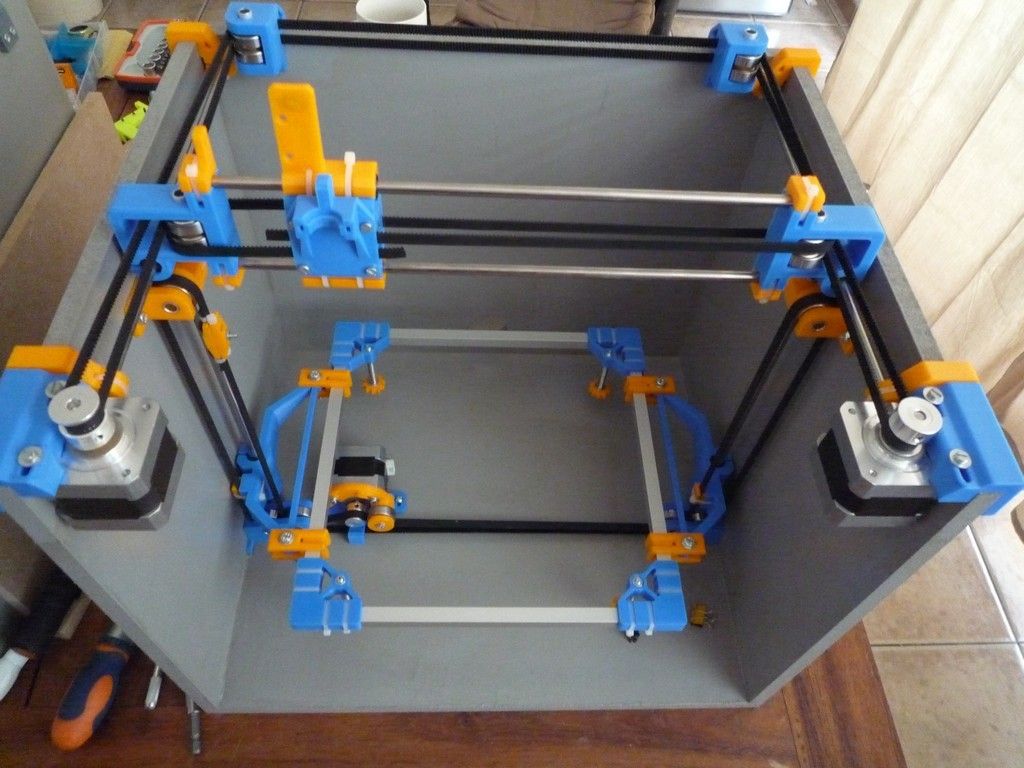

Operating a total of four Freeformers, two 200-3X and two 300-3X will allow preliminary trials to be conducted so that potential customers can determine whether Arburg Plastic Freeforming is suitable for their desired parts, materials, and applications before they commit to a purchase.

Industrial AM with the Freeformer uses plastic granules processed in injection molding and is capable of 3D printing objects without support structures. The open system is suitable for very soft and certified original materials and is particularly suitable for demanding applications in the medical and automotive industries. However, to help current and prospective customers become more familiar with the technology, they will be given the opportunity to participate in Freeformer training courses and work with the machines on site.

The Freeformer 300-3X and Freeformer 200-3X from Arburg. Image courtesy of Arburg.

Arburg Managing Director of Sales and Services, Gerhard Böhm, said the company in Asia is experiencing growing demand for the Freeformer machines in applications that involve additive manufacturing of functional components made from original materials. He also considered the new Arburg Prototyping Center in Shanghai would enable a wider expansion and a better way to respond specifically to the local needs of the Chinese market.

He also considered the new Arburg Prototyping Center in Shanghai would enable a wider expansion and a better way to respond specifically to the local needs of the Chinese market.

The investment builds on the firm’s strong position in China, a country that has truly adopted 3D printing technology. In the last ten years, AM has thrived, heavily promoted by the government and local companies. It is becoming one of the largest AM manufacturing markets in the world. In 2017, the Chinese government issued the “Additive Manufacturing Industry Development Action Plan,” trying to make a national AM industry worth $3 billion by 2020. Just a year later, China’s 3D printing market was estimated to be worth $1.8 billion, and according to a report by Ernst and Young, 78% of surveyed Chinese companies in 2019 had already adopted 3D printing.

Arburg’s Freeformer system. Image courtesy of Arburg.

Arburg’s presence in the Chinese marketplace spans more than 25 years. During this time, the family-owned business has installed service technicians and sales along the entire “plastic belt” of the Pacific coast and the country’s center around Chengdu and opened its subsidiaries in Shanghai in 2004 and Shenzhen in 2006. During the Chinaplas 2021 trade fair, the Managing Director at Arburg China, Zhao Tong, said that industrialization is an important topic. Still, digitalization is a key harbinger in increasing production efficiency and offers an enormous potential far from exhausted.

During the Chinaplas 2021 trade fair, the Managing Director at Arburg China, Zhao Tong, said that industrialization is an important topic. Still, digitalization is a key harbinger in increasing production efficiency and offers an enormous potential far from exhausted.

The new Arburg Prototyping Center will initially serve customers from China, but plans are in place to add more machines and staff capacity so that availability can gradually be offered to the whole of Asia. The service team at the Shanghai site also undergoes training to keep enhancing their additive manufacturing expertise.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing centers • 3d printing facility • Arburg • Arburg China • Arburg Freeformer • Arburg Prototyping Center (APC) • china • prototyping • Shanghai

Please enable JavaScript to view the comments powered by Disqus.

3D Printed Pedestrian Bridge was unveiled in January 2019 in Shanghai

2952 views Posted on: 03/28/2019

Author: 3D4U.COM.UA

Smart City in Shanghai unveiled China's first 3D printed footbridge, a 15-meter structure that spans a small lake in a park.

A 3D printer helps make ideas that seemed impossible just a short while ago come true. If you have not purchased a 3D printer yet, then custom 3D printing at 3D FOR YOU will make your idea come true. nine0003

"Many people have never touched a 3D printed object and still consider it part science fiction, part technology of the future," said Polymaker, a 3D printing plastics maker that supplied the materials and developed the plastics used in the 3D printing. construction.

“Therefore, projects like this bring a lot of value in terms of educating the public about the reality and possibilities of 3D printing,” added Polymaker.

The bridge is located in the Taopu Smart City complex in Putuo District and is strong enough to support the weight of four adults per square meter. Shanghai Machinery Construction Group created the printer, and Coin Robotic created the extruder system.

Shanghai Machinery Construction Group created the printer, and Coin Robotic created the extruder system.

They invested about $2.8 million in the design of the printer.

“This is both an everyday, practical app and an interactive one where people can touch and even rely on… a 3D printed thing,” Polymaker said of the bridge. nine0003

Before 3D printing came along, the construction team spent a year and a half researching and planning. The result was "the world's largest plastic 3D printer".

It then took 450 hours for this device to print a plastic bridge 3.8 meters wide, 1.2 meters deep and weighing about 5800 kg. Polymaker provided acrylonitrile styrene acrylate (ASA) or plastic combined with fiberglass for construction.

3D printer plastic has a wide range of parameters and technical characteristics, which allows you to use it according to your needs. nine0003

The company chose ASA because it is weather resistant, strong and provides heat and chemical resistance. Fiberglass has reduced the warp effect of 3D printing, which is noticeable when creating large projects. It also added strength to the bridge, which its engineers predict will last about 30 years.

Fiberglass has reduced the warp effect of 3D printing, which is noticeable when creating large projects. It also added strength to the bridge, which its engineers predict will last about 30 years.

The Shanghai government said the bridge is "an innovative way to promote 3D printing technology and popularize it in urban construction." nine0003

While this bridge is cause for celebration, it is not the world's first 3D printed bridge. The world's first 3D printed pedestrian bridge was made in Madrid in 2016.

Related Products

-

CR-10S PRO 3D printer Creality

Price: 30 600 ₴

Creality CR-10S PRO is a 3D printer with a large printable area (300x300x400),...

-

3D Printer Flashforge Guider II

Price: 70 800 ₴

FlashForge Guider II is an improved version of the popular 3D printer Guider with...

Related articles

- Top 20 interesting toys for children on a 3D printer.

Category: 3D printing

02/15/2022

11712 views

What kind of toys can be created with a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more - 12 common 3D printing mistakes to avoid. nine0004 5009 views

As an industry, 3D printing is evolving every day, so it's important to know all aspects of this technology today. In this...

Read more - 9 romantic 3D printed gifts for Valentine's Day.

Category: 3D printing

02/09/2022

1924 views

3D printing can help you create unique and personalized gifts for your significant other. Compilation 9...

Read more - What can be printed on a 3D printer? nine0004 Category: 3D printing

03.02.2022

2609 views

When hearing about a 3D printer for the first time, most people are interested in the question of what can be printed on a 3D printer.

Read more In this article...

In this article... - Why Succeeding With a 3D Printer Is Easier Than You Think.

Category: 3D printing business ideas

02/01/2022

1978 views

Arguments in favor of a business with a 3D printer. Why the first steps in such a business are much easier to take than in any other. nine0003 Read more

Record-breaking 3D printed concrete bridge erected in Shanghai

News

Shanghai has the largest 3D printed bridge to date. The design of the building is inspired by the historic Anji Bridge, the oldest surviving bridge in China.

The fourteen-meter construction very, very approximately repeats the appearance of the historical 1400-year-old bridge in Hebei province, called the “Anji Bridge” or “Big Stone Bridge” [ not to be confused with the bridge of the same name across the Moscow River - approx. ed. ]. The modern version has dispensed with masonry in favor of steel, concrete and additive manufacturing.

As you can see in the illustration below, the problem with reinforcement was solved very simply: 3D-printed elements play a rather decorative role and rely on a steel arch that acts as a supporting structure. The structure is 14.1 meters long and 4 meters wide, making it the longest 3D printed concrete bridge in the world. nine0003

There are already examples of such structures: in October last year, Dutch builders completed work on a pedestrian and bicycle bridge, in principle capable of supporting the weight of a truck and connecting the suburb of Gemert with the ring road. The project was carried out by the Technical University of Eindhoven with the support of the construction company Royal BAM Group. But this eight-meter design was not the first.

The championship belongs to the Institute of Modern Architecture of Catalonia, which in December 2016 built a crossing over the canal in Alcobendas, a suburb of Madrid. Both the Spanish and the Dutch bridge also consist of separate 3D printed blocks assembled into a single structure, but with built-in tie cables. nine0003

Both the Spanish and the Dutch bridge also consist of separate 3D printed blocks assembled into a single structure, but with built-in tie cables. nine0003

It was not possible to find out exactly who was responsible for the production of 3D-printed blocks of the new bridge, but it can be assumed that the well-known company WinSun, which managed to mark a number of demonstration projects using building additive technologies, completed the contract.

Meanwhile, local construction company Shanghai Construction Group is working with 3D printing materials manufacturer Polymaker and large-format additive systems developer Coin Robotics to decorate the city with its own record-breaking fifteen-meter-long plastic bridge, the world's largest plastic bridge. nine0003

Acrylonitrile-styrene-acrylate structure with fiberglass reinforcement has already been printed and will soon be installed in the Taopu Smart City technology park during the renovation of Shanghai's Putuo district.