Robot factory 3d printer

Robot Factory’s Conversion Kit Makes Continuous 3D Printing Attainable

Log inSign up

Please ensure that JavaScript is enabled in your browser to view this page.

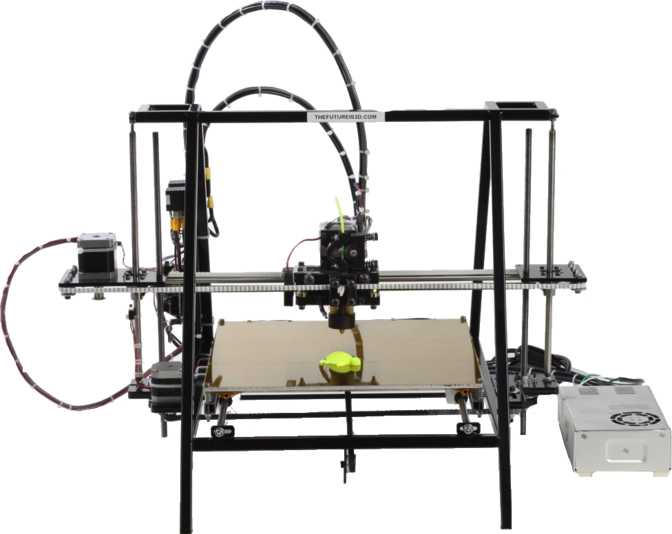

Robot Factory’s new conversion kit makes continuous 3D printing attainable and works with many Prusa i3-style 3D printers.

Everyone agrees that 3D printers are invaluable for prototyping, but there is a lot of debate about whether or not they’re practical for manufacturing at scale. The primary benefit of 3D printing is that you can immediately start producing new designs without the time or expense of retooling. But, if you need thousands of copies of the exact same design, injection molding is far more efficient. If you could print continuously without human intervention, you would narrow that gap between 3D printing and injection molding. Robot Factory’s new Steel Roller Kit can be used with many 3D printer models to enable continuous printing.

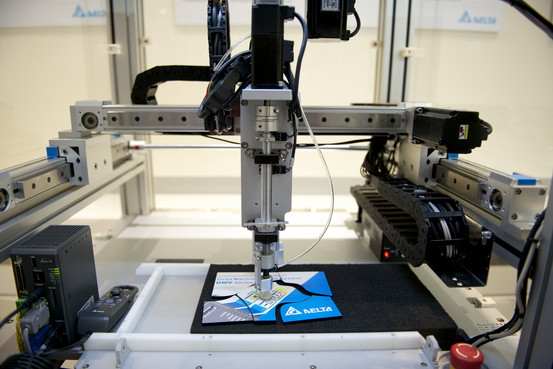

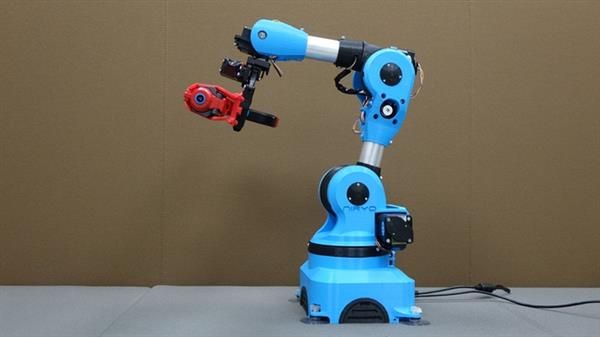

The fused-filament fabrication (FFF) 3D printing process is inherently inefficient, because parts have to be built up layer by layer. There isn’t much that can be done about that, but you can improve the situation by giving the printer the ability to work indefinitely without having to wait for a human operator to remove the completed part and start a new job. There have been many experimental efforts to achieve that, but it has proven to be difficult to actually remove the parts from the bed. That’s because we usually try to make filament adhere to the bed as strongly as possible. Robot Factory’s SilverBelt 3D printer solved that problem with the use of a conveyor belt-style bed, which easily ejects parts. Their new Steel Roller Kit brings that same principle to the 3D printer you already own.

The Steel Roller Kit should work with just about any Prusa i3 3D printer and the models derived from that design. Those include the Creality CR-10, Ender, Anycubic i3 Mega, Lulzbot TAZ, the official Prusa i3 MK3S, and many more. The kit contains the steel roller conveyor belt, which replaces the original bed and most of the Y axis assembly. Instead of the build platform sliding forwards and backwards, the conveyor belt will roll in the Y axis. When it comes time to eject a part, the bed simply rolls until the part is pushed off of the end of the conveyor belt. The conveyor belt is made of steel, but can be covered in Kapton, painter’s tape, and more.

The kit contains the steel roller conveyor belt, which replaces the original bed and most of the Y axis assembly. Instead of the build platform sliding forwards and backwards, the conveyor belt will roll in the Y axis. When it comes time to eject a part, the bed simply rolls until the part is pushed off of the end of the conveyor belt. The conveyor belt is made of steel, but can be covered in Kapton, painter’s tape, and more.

When you perform this conversion, you should be able to retain your 3D printer’s original bed heating element. That will be positioned beneath the steel conveyor belt to keep it heated — though I suspect thermal performance will be something of an issue. You’ll need to reprogram your 3D printer’s controller with the correct Marlin Firmware, and modify your slicing software to provide the G-code required to handle the part ejection. A Simplify3D profile is available to do that. There is no word on pricing yet, but you can contact Robot Factory to find out more information.

Cameron Coward

Writer for Hackster News. Maker, retrocomputing and 3D printing enthusiast, author of books, dog dad, motorcyclist, and nature lover.

Latest articles

Read moreRelated articles

robotfactory home website 3Dprinters

Robot Factory is "design, production and marketing" of electronic and mechanical devices...

Robot Factory is "3D Printing" and more!

Robot Factory is "design, production and marketing" of electronic and mechanical devices... Robot Factory is "3D Printing" and more!

BENCHTOP INJECTION MOLDING is the benchtop system...

Read more

Injection Molding System Robot Factory Srl has just...

Read more

Andrea Martini ‘on air’ – upgrade of a. ..

..

Read more

Upgrade kit for 45 degree tilted 3D printer...

Read more

BENCHTOP INJECTION MOLDING is the benchtop system...

Read more

Injection Molding System Robot Factory Srl has just...

Read more

Andrea Martini ‘on air’ – upgrade of a...

Read more

Upgrade kit for 45 degree tilted 3D printer...

Read more

FUTURE EVENTS

There are no scheduled events

THEY TALK ABOUT US

Sistema pneumatico da banco per stampaggio ad iniezione. ..

..

Read more

Pneumatic Injection moulding Sistema per lo stampaggio ad...

Read more

Plastic-Molding Benchtop Printersbenchtop injection molding

Read more

Desktop Injection Molding Now Available from Robot Factory

Read more

Sistema pneumatico da banco per stampaggio ad iniezione...

Read more

Pneumatic Injection moulding Sistema per lo stampaggio ad...

Read more

Plastic-Molding Benchtop Printersbenchtop injection molding

Read more

Desktop Injection Molding Now Available from Robot Factory

Read more

KUKA engineers improve industrial robots with 3D printers

News

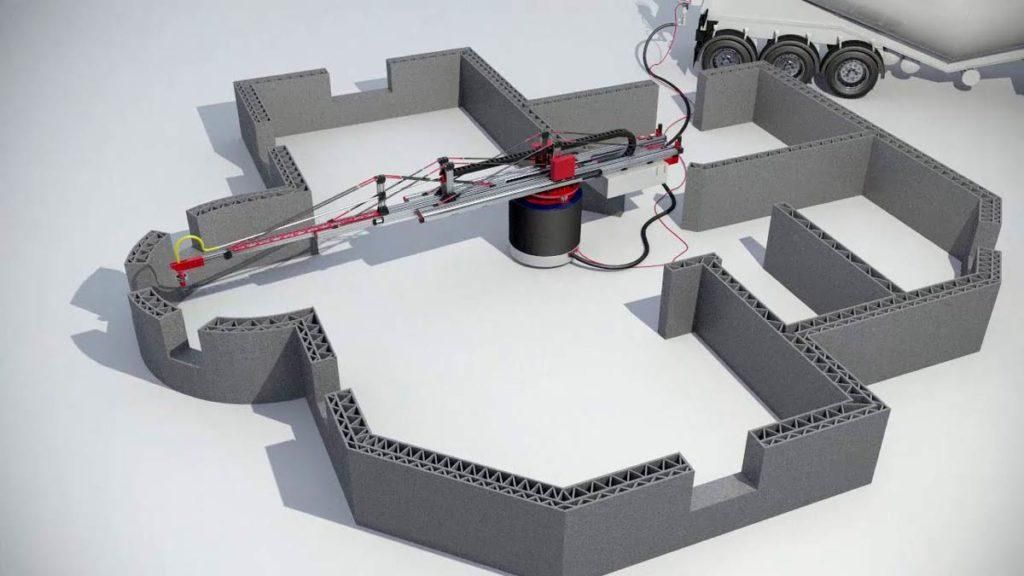

Robotics and 3D printing go hand in hand, because any 3D printer is, in fact, a robot.

Robotic arms often serve as the basis for industrial and construction additive systems that print polymers, fuse metals, and even apply layers of cement and concrete mixtures. But industrial robots themselves are increasingly being developed and improved using additive technologies. We explain using the example of the famous company KUKA. nine0003

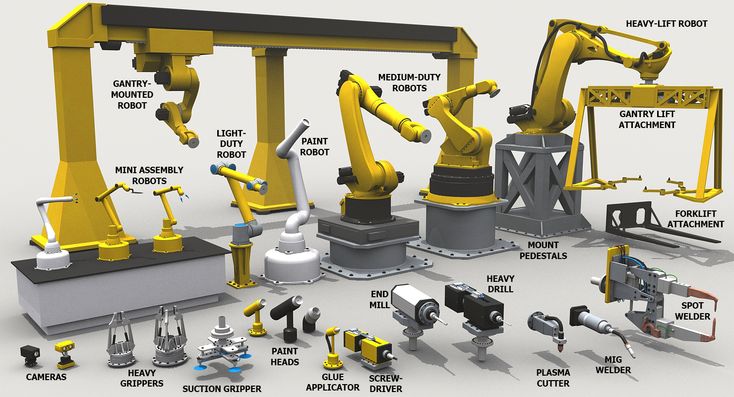

Robotic arms often serve as the basis for industrial and construction additive systems that print polymers, fuse metals, and even apply layers of cement and concrete mixtures. But industrial robots themselves are increasingly being developed and improved using additive technologies. We explain using the example of the famous company KUKA. nine0003 One of the most famous brands in industrial robotics is the German company Keller und Knappich Augsburg or simply KUKA. KUKA engineers are constantly improving their creations, including experimenting with different manipulators and nozzles, because such six-axis machines work in a variety of industries, performing a variety of tasks - unloading and loading pallets, assembly, welding, and so on and so forth. Over the past few years, the company's specialists have been teaching robots new skills and "professions", experimenting with machine learning and equipping robotic arms with new tools. nine0003

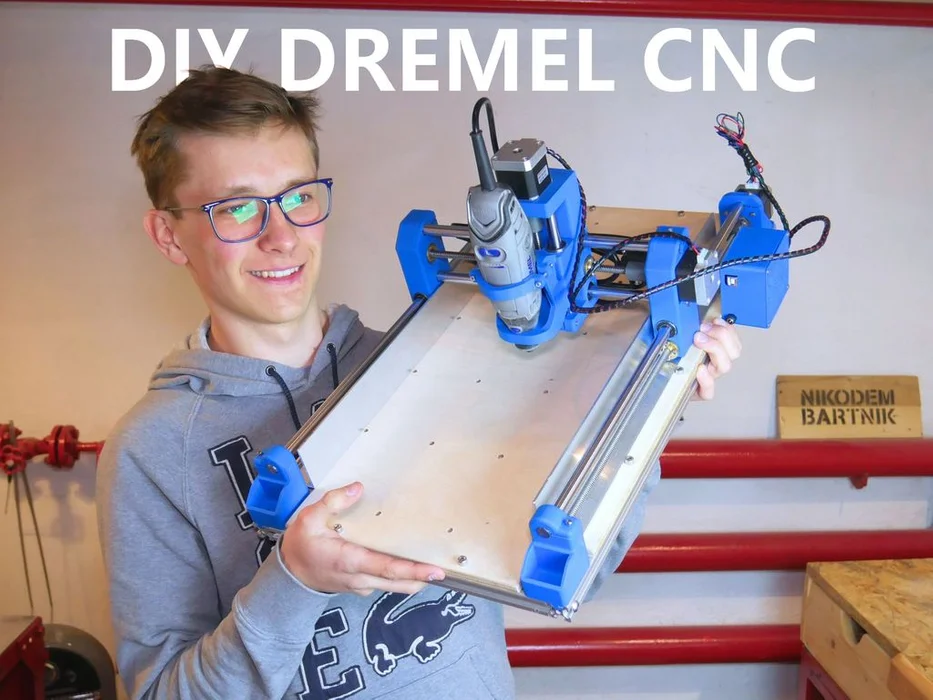

For prototyping new nozzles and improving the design of manipulators in general, fairly modest desktop 3D printers manufactured by the American company MakerBot are used, which work according to the technology of layer-by-layer deposition of a polymer rod (FDM / FFF), which is well known to all amateur printers. The choice of German engineers fell on the Replicator Z18 model - the largest version capable of growing products up to 305x305x457 mm in size.

The choice of German engineers fell on the Replicator Z18 model - the largest version capable of growing products up to 305x305x457 mm in size.

The Replicator Z18 3D printers are used in part for the production of customized parts such as cladding, but mainly for the production of prototype mechanisms, nozzles and assembly tooling. Then, the digital models used in rapid prototyping serve as the basis for the production of final metal parts using casting, forging and milling, and, if necessary, “metal” 3D printing. nine0003

While there have been a lot of complaints about the reliability of MakerBot 3D printers lately, especially due to the dampness of early batches of fifth-generation printers, engineer Thomas Schmidberger claims that in 92 percent of cases the print results are satisfactory, despite the “replicators” being used almost around the clock. ". The main thing is savings, because 3D printing allows you to quickly and inexpensively work out different iterations of the required parts. How to do it, see the video:

How to do it, see the video:

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Subscribe to the author

Subscribe

0003

3D printing opens up new design possibilities | Simplicity. Convenience. Creativity | Gradual implementation | Appearance matters | Reliable partnership as the basis for success

Labman has been the market leader in customized laboratory automation products and solutions for nearly 30 years. Labman robots operate in 42 countries and serve their purpose both in prestigious research institutes and in the development departments of major manufacturers. The company focuses on innovation and always firmly believes in results. That is why Labman is often approached to solve problems that at first glance seem impossible. Increasingly, additive technologies are used to solve such problems. nine0003

That is why Labman is often approached to solve problems that at first glance seem impossible. Increasingly, additive technologies are used to solve such problems. nine0003

Just three years ago, Labman didn't use 3D printing at all, but now 3D printed parts are present in almost every system developed by the company. This helped bring about significant change. How? The thing is that the introduction of additive technologies in this British company in collaboration with Materialize helped her save her most valuable resource - time. By simplifying the prototyping and fabrication of complex parts and components—processes that traditionally require significant costs, time, and labor—Labman can now:

- reduce design time by whole days;

- quickly work out changes in customer requirements;

- to produce spare parts while developing new solutions.

3D printing opens up new design possibilities

Labman has been designing and manufacturing custom laboratory automation since 1979. Applications for robotic solutions include liquid handling, powder handling, sample preparation, weighing and labeling, sample testing, titration, and more. The industries that use these solutions vary, but there are common challenges that the team faces day in and day out. It was these complexities that prompted Labman to turn to 3D printing technology. nine0003

Applications for robotic solutions include liquid handling, powder handling, sample preparation, weighing and labeling, sample testing, titration, and more. The industries that use these solutions vary, but there are common challenges that the team faces day in and day out. It was these complexities that prompted Labman to turn to 3D printing technology. nine0003

“We constantly have to run complex and precise processes in tight spaces,” explains Sean Devereux, Labman Mechanical Design Engineer. – Often, this requires inventing unusual and strange fixtures and fittings that make the impossible possible. The freedom of design that 3D printing offers attracted us - we knew we could create new shapes, combine parts into a single structure, and combine different methods and materials to reduce the overall weight, which is very important, for example, for mechanical manipulators. Ultimately, we realized that additive technologies would help us complete our portfolio with new non-standard solutions. nine0003

nine0003

iQB Technologies experts recommend article: 3D printing with metal vacuum gripper: 94% lighter, 2 times cheaper

We had a project in which the samples had to be placed in a certain way under a stream of water. The requirements for the compactness of the system and the accuracy of the angles for working with water, indicated by the client, greatly complicated the implementation of the project. Using traditional methods, the task would be impossible. However, with the help of 3D printing, we were able to embed the gripper in another part and create internal channels to bring water to the sample exactly as required. 3D printed parts may be less than 5% of the entire system, but when solving problems like this, they become almost the most important part of the project.” nine0003

Simplicity. Convenience. Creativity

What the team didn't expect was the ease of adoption of 3D printing and the variety of benefits. Labman uses the Materialize OnSite service, an online service that allows users to submit CAD files, receive a quote, and then receive a printed part within days. “This is the perfect solution for us,” says Tom Geil, Labman Design Engineer. “We just hand over the project with the exact specification and get the right part. nine0003

“This is the perfect solution for us,” says Tom Geil, Labman Design Engineer. “We just hand over the project with the exact specification and get the right part. nine0003

iQB Technologies accepts orders for 3D printing and 3D scanning. We will select the best solution for your project and promptly complete the order! Leave an online application:

Leave a request

Everything we create is up to the customer, and a lot of the work is focused on the design phase, whether it's determining the right twist angle for mixing powders or designing a gripping device that allows you to take samples for analysis without ruining them. nine0003

It takes a long time to test ideas and find the best solution. Before the advent of 3D printing, creating such parts, testing them, making changes to the design and re-manufacturing took a huge amount of time. Now we can quickly and cost-effectively print several versions of the prototype to find the optimal solution. And because we have found an easy way to use 3D printing by outsourcing, the journey from initial idea to testing has become much shorter, which is not only beneficial for us, but also for our customers. ” nine0003

” nine0003

The freedom of design that 3D printing offers attracted us - we knew we could create new shapes, combine parts into a single structure, and combine different methods and materials to reduce the overall weight

Sean Devereux, Labman Automation

Gradual introduction

Designing in Labman requires a detailed analysis of the customer's specification, which specifies the required functions of the system and the features of its operation, as well as goals (spraying the liquid in a certain way, controlling the air flow directed to the samples/materials). Only after that the team proceeds to constructive study to create the optimal solution. nine0003

“We quickly began to understand which of the requirements of the TOR can be easily implemented using a 3D printer. I'm not talking so much about being able to print, but about how useful it is for the common functionality that all of our customers require,” explains Tom. “For example, we often need wiring to take up as little space as possible, but at the same time be protected from water and possible interference. Previously, it was necessary to develop asymmetric braces, which required a lot of financial and time costs. With 3D printing, everything has changed.” nine0003

“For example, we often need wiring to take up as little space as possible, but at the same time be protected from water and possible interference. Previously, it was necessary to develop asymmetric braces, which required a lot of financial and time costs. With 3D printing, everything has changed.” nine0003

Also, the Labman team discovered the unprecedented flexibility that 3D printing offers when making changes to specifications. Tom continues: “Quite often, requirements change in the middle of a project—for example, when a client wants to add new features to the system, or if the properties of other components differ from previously predicted ones. In such cases, 3D printing helps a lot, making it easy to adapt to changes and get a new part that meets the new requirements.” nine0003

“We learn more with every new project or implementation. It's true - you try something new, learn something, share knowledge... and at the same time open up new horizons and implement new methods in your daily work. And these methods turned out to be so productive that we even began to develop branded components and devices for 3D printing that brought us fame, for example, mobile MDU dispensers, which we can easily produce in small batches.”

And these methods turned out to be so productive that we even began to develop branded components and devices for 3D printing that brought us fame, for example, mobile MDU dispensers, which we can easily produce in small batches.”

Looks Matter

For inventor Rob Hodgson, another important factor in the company's rapid adoption of 3D printing was customer response. “The quality of materials allows us to use printed components not only for prototyping and testing, but also for manufacturing equipment,” Rob shared.

“Materials such as alumide can be threaded into cage nuts and other complex metal parts that can be easily replaced when needed. Also, using 3D printing, we also improve the aesthetics of our systems. Many of the parts that we were able to create from aluminum or stainless steel did without ugly design decisions and intricate cable management. They look much better. nine0003

They look much better. nine0003

Don't forget that systems often cost millions of pounds - a major capital investment. First of all, they must perform their function, but for many of our serious customers, their appearance is also important. Recently, we have been working on a state-of-the-art robot for the University of Liverpool's Innovative Materials Plant, a unique facility that is available to large companies from all over the world. The solution we provided, which includes many bespoke and 3D printed components, serves as the face of the university and should look like it. For them it is a business card, and for us it is a demonstration of our products. This is another great advantage of 3D printing. nine0003

All of this, plus our partnership with Materialize, has helped us break new ground, quickly adopt new technologies, and make them work for the company.”

Reliable partnership as a basis for success

The ability to combine in-house design expertise with third-party manufacturing through Materialize's 3D services helped Labman quickly realize several key benefits.