Northeastern university 3d printer

Northeastern University Library Menu Categories Help & Services

Accessibility

Posted by Jeanine Rodriguez

Northeastern Library provides equal access and services to the Northeastern community. Building Accessibility Library locations in Boston (Snell Library) and Oakland (F.W. Olin Library)are wheelchair-accessible from the front entrance. Elevators, restrooms and water fountains are all accessible. In-Person Borrowing Help Proxy borrowing service allows you to choose another person as your “proxy” who can check… Read more »

Adds-ons & Plugins

Posted by Jeanine Rodriguez

Add-Ons & Plugins For expanded full-text access to library resources NU Login Bookmarklet The Login Bookmarklet lets you reload a web page through the Northeastern Library’s authentication server. If the article, website or database you’re viewing is one that the library subscribes to, and you’re not on the Northeastern wifi network, the bookmarklet will give… Read more »

Alumni

Posted by Jeanine Rodriguez

Welcome, Northeastern Alumni! In-Person Access Note: Due to ongoing construction, alumni access to Snell Library is temporarily suspended. Thank you for your patience, and we look forward to seeing you again soon. How to Get a Northeastern University (NU) Alumni Identification Card NU Alumni Husky ID cards allow you to enter Snell Library and check… Read more »

Ask A Librarian

Posted by Jeanine Rodriguez

Library help is available to all members of the Northeastern University community, including alumni and library users at Northeastern’s global campuses. We are happy to answer questions from members of the public. Please note that access to some of our facilities, collections, and services may be limited to Northeastern affiliates only. Connect with a Librarian… Read more »

We are happy to answer questions from members of the public. Please note that access to some of our facilities, collections, and services may be limited to Northeastern affiliates only. Connect with a Librarian… Read more »

Citations & Bibliographies

Posted by Jeanine Rodriguez

Creativity & Design

Posted by Jeanine Rodriguez

Digital Scholarship

Posted by Jeanine Rodriguez

What Is the Digital Scholarship Group? The Digital Scholarship Group (DSG) is part of Northeastern University Library’s digital scholarship services. DSG supports digital modes of research, publication, and collaboration at Northeastern. DSG staff provide expertise, infrastructure, and strategic guidance for researchers and projects, including: Digital humanities Digital archives and exhibit-building Support for digital tools and… Read more »

DSG supports digital modes of research, publication, and collaboration at Northeastern. DSG staff provide expertise, infrastructure, and strategic guidance for researchers and projects, including: Digital humanities Digital archives and exhibit-building Support for digital tools and… Read more »

Faculty & Staff

Posted by Jeanine Rodriguez

Teaching & Learning Contact your subject librarian about collections and services in your discipline. Put course readings on reserve for short-term loan. Reserves can be library-owned or personal copies of books, videos, or other resources. Get support for evaluating and selecting affordable course materials, including information on using the library’s e-journal and e-book content as… Read more »

Graduate Student

Posted by Jeanine Rodriguez

Explore Our Collections Search our catalog plus journal articles and more with Scholar OneSearch. Find e-journals. Access a complete A-Z list of Northeastern Library’s research databases. Find information about your borrowing privileges. Access your library account to renew borrowed items. Recommend a book or other material for purchase. Visit the unique digital and physical collections… Read more »

Find e-journals. Access a complete A-Z list of Northeastern Library’s research databases. Find information about your borrowing privileges. Access your library account to renew borrowed items. Recommend a book or other material for purchase. Visit the unique digital and physical collections… Read more »

Grant Writing

Posted by Jeanine Rodriguez

Grant-Funded Projects The library helps develop external funding proposals to support the university’s research mission. In particular, we can help with projects that involve the library’s collections and areas of research expertise. The library can support you in: Data management planning Digitization Guidance on digital research and publishing platforms Assistance with digital humanities project teams,… Read more »

With this New Technology, 3D Printing Comes to Life… Literally.

Neel Joshi, associate professor of chemistry and chemical biology, and Avinash Manjula-Basavanna, a postdoctoral researcher, work on programmable microbial ink for 3D printing of living materials, in the Mugar Life Sciences building. Photo by Matthew Modoono/Northeastern University

News @ Northeastern Homepage

With this new technology, 3D printing comes to life … literally.

0%

Up Next

If humans are to live on Mars or the moon one day, we’ll need to be able to construct buildings to live, sleep, eat, and work in space. The way to do that, space agencies have said, is to 3D-print habitats or their components. But hauling enough of the Earth-derived materials used for most 3D printing from our planet to another celestial body isn’t a feasible option.

Biology could solve that problem, says Neel Joshi, associate professor of chemistry and chemical biology at Northeastern. And Joshi’s team may have devised just the technology for the job: a 3D-printable material that is alive.

And Joshi’s team may have devised just the technology for the job: a 3D-printable material that is alive.

“Like a tree has cells embedded within it and it goes from a seed to a tree by assimilating resources from its surroundings in order to enact these structure-building programs, what we want to do is a similar thing, but where we provide those programs in the form of DNA that we write and genetic engineering,” Joshi says.

The researchers have figured out how to program the bacterium Escherichia coli, also known as E. coli, to produce an entirely biological ink which can be used to 3D-print solid structures. That microbial ink, which is described in a paper published Tuesday in the journal Nature Communications, has yet to be tested on a cosmic scale, but the scientists have used the gelatinous material to print small shapes, such as a circle, a square, and a cone. They have also successfully programmed it to build materials with specified attributes with other applications that could be useful in medicine.

Neel Joshi, associate professor of chemistry and chemical biology, works on programmable microbial ink for 3D printing of living materials, in the Mugar Life Sciences building. Photos by Matthew Modoono/Northeastern University

“We want to use living cells, microbes, as factories to make useful materials,” says Avinash Manjula-Basavanna, a postdoctoral fellow in Joshi’s laboratory and co-lead author on the new paper. The idea, he says, is to harness the properties that are unique to the materials that make up living things for a spectrum of purposes, ranging from therapeutic to industrial.

“Think about it as a platform for building many different things, not just bricks for building buildings or construction,” Joshi says. He explains the work by comparing it to the way a polymer chemist considers how to devise plastic materials that can serve distinct purposes. Some plastics are hard and retain their shape, while others are stretchy and soft.

“Biology is able to do similar things,” Joshi says. “Think about the difference between hair, which is flexible, and horns on a deer or a rhino or something. They’re made of similar materials, but they have very different functions. Biology has figured out how to tune those mechanical properties using a limited set of building blocks.”

“Think about the difference between hair, which is flexible, and horns on a deer or a rhino or something. They’re made of similar materials, but they have very different functions. Biology has figured out how to tune those mechanical properties using a limited set of building blocks.”

The particular natural building block the scientists are taking advantage of is a protein produced by the bacterium E. coli. The material, called Curli fibers, is produced by the bacterial cells as they attach to a surface and to one another to form a community. The same properties that make the Curli fibers a sort of glue for the bacteria also make it an attractive material for microbial engineers like Joshi and his colleagues.

The researchers 3D-printed small shapes using the microbial ink that they developed from the bacterium Escherichia coli, also known as E. coli. Image courtesy of Duraj-Thatte et al., Nature Communications

To make the microbial link, the scientists started by culturing genetically engineered E. coli in a flask. They fed the bacteria nutrients so that they would multiply, and as they divided they would produce the desired polymers, the Curli fibers. Then, the researchers filtered out the gelatinous polymers and fed that material into a 3D printing apparatus as the microbial ink.

coli in a flask. They fed the bacteria nutrients so that they would multiply, and as they divided they would produce the desired polymers, the Curli fibers. Then, the researchers filtered out the gelatinous polymers and fed that material into a 3D printing apparatus as the microbial ink.

Microbes have been used to make the ink for 3D printing before, but, Joshi and Manjula-Basavanna say, what sets this microbial ink apart is that it is not blended with anything else. Their gel is entirely biological.

One of the perks of a truly living material is that it is, in fact, alive, Manjula-Basavanna says. And that means that it can do what living things can do, such as heal itself, the way skin does. In the right conditions, the cells in the microbial gel could simply make more of itself.

It’s not necessarily always growing, Joshi says. For example, if the cells were left alive in the small cone that the team made from the microbial gel, “if you were to take that whole cone and dunk it into some glucose solution, the cells would eat that glucose and they would make more of that fiber and grow the cone into something bigger,” he says. “There is the option to leverage the fact that there are living cells there. But you can also just kill the cells and use it as an inert material.”

“There is the option to leverage the fact that there are living cells there. But you can also just kill the cells and use it as an inert material.”

While the initial gel is made entirely from genetically engineered E. coli, the researchers also tried mixing the ink with other genetically engineered microbes with the goal of using the 3D-printed materials for specific purposes. That’s how they made a material that could deliver an anticancer drug, which it released when it encountered a specific chemical stimulus. In another experiment, they also programmed another material to trap the toxic chemical Bisphenol A (BPA) when it encountered BPA in the environment.

“You could think about taking a bottle cap and printing our material on the inside of it so that if there was BPA around, it would be sucked up by that and not be in your drink,” Joshi says.

This study was simply a proof-of-concept endeavor, but Joshi sees this microbial ink as opening a door to all kinds of possibilities for building things with biology.

“If there is a way to manufacture in a more sustainable manner, it’s going to involve using living cells,” he says. “This is advancing more towards that type of paradigm of building things with living cells.”

For media inquiries, please contact Marirose Sartoretto at [email protected] or 617-373-5718.

- Topics

- Science & Technology bacteria biofilm biomanufacturing biomaterials chemical biology chemistry College of Science E. coli engineered living materials microbes Neel Joshi research

- Credits

- Written by Eva Botkin-Kowacki.

NEFU created a 3D scanner to work at low temperatures

https://ria.ru/20201009/scanner-1579072790.html

NEFU created a 3D scanner to work at low temperatures

NEFU created a 3D scanner for work at low temperatures - RIA Novosti, 09. 10.2020

10.2020

NEFU created a 3D scanner for work at low temperatures ... RIA Novosti, 09.10.2020

2020-10-09T17: 11

2020-10-09T17: 11

2020-10-09T17: 11

Science

Yakutsk

North-Eastern Federal University

/HTML /HTML /HTML /HTML /HTML head/meta[@name='og:title']/@content

/html/head/meta[@name='og:description']/@content

https://cdnn21.img.ria.ru /images/39514/72/395147255_0:35:1025:611_1920x0_80_0_0_3bdb9b7e3ce40466c0f15bb9490fb583.jpg

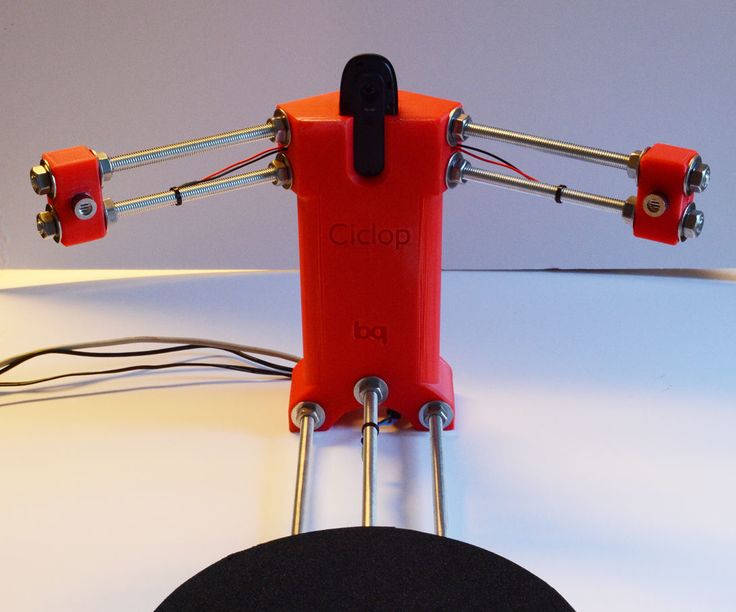

YAKUTSK, Oct 9 – RIA Novosti. International Center of the North-Eastern Federal University Future Skills: NEFU has developed an industrial 3D scanner for working at low temperatures, and is also preparing to implement a project to create a construction 3D printer, director of the center Roman Gogolev told RIA Novosti. According to Gogolev, a 3D scanner is part of a suit with augmented reality and GPS stuffing, which is designed to work at low temperatures. "We are working on creating full-fledged digital twins for further system modeling based on these twins. An industrial non-contact 3D scanner creates digital twins that have high detail and information content. According to the project, the scanner can work at minus 20, if we implement it completely, then it reaches minus 25. So far, the materials do not allow us to "go down" lower, but we can experiment. In fact, the prototype has now worked at a temperature of minus 15," Gogolev said. According to the director of the center, field trials were and on metal supports of gas pipelines, metal supports of buildings. In addition, the device allows you to create digital twins of static non-solid objects. "First of all, the scanner is designed to create metal structures, pipes. But it can scan other things - bones, teeth, parts, engines, even art objects. The only negative is that we still use hybrid technology. In the future, if possible, we will be able to scan glare objects," the source said. According to the developers, the cost of a serial product is from 10,000 to 17,000 euros per unit. The plans are to offer the development to corporations and engineering firms.

An industrial non-contact 3D scanner creates digital twins that have high detail and information content. According to the project, the scanner can work at minus 20, if we implement it completely, then it reaches minus 25. So far, the materials do not allow us to "go down" lower, but we can experiment. In fact, the prototype has now worked at a temperature of minus 15," Gogolev said. According to the director of the center, field trials were and on metal supports of gas pipelines, metal supports of buildings. In addition, the device allows you to create digital twins of static non-solid objects. "First of all, the scanner is designed to create metal structures, pipes. But it can scan other things - bones, teeth, parts, engines, even art objects. The only negative is that we still use hybrid technology. In the future, if possible, we will be able to scan glare objects," the source said. According to the developers, the cost of a serial product is from 10,000 to 17,000 euros per unit. The plans are to offer the development to corporations and engineering firms. "There is already a proposal to buy out all the data of the project. There are already customers for 3D scanning itself and for digital twins. And as soon as we register the scanner itself, customers will definitely be on it. We are more focused on the foreign market. In extreme cases, we will put it on we will transfer the crowdfunding platform to a group of students as a technology startup. While we are actively refining, we would like to make a higher quality product," said the head. Future Skills: NEFU is preparing to implement another innovative project. "We are waiting for high-precision equipment to appear in the Center to make a construction 3D printer. We already have the project ready, it remains to be implemented. We would like to assemble it here in Yakutsk. This is our second major project that can be monetized, and it , perhaps, will become a new milestone in the history of high-tech production in Yakutia," Gogolev added. nine0003

"There is already a proposal to buy out all the data of the project. There are already customers for 3D scanning itself and for digital twins. And as soon as we register the scanner itself, customers will definitely be on it. We are more focused on the foreign market. In extreme cases, we will put it on we will transfer the crowdfunding platform to a group of students as a technology startup. While we are actively refining, we would like to make a higher quality product," said the head. Future Skills: NEFU is preparing to implement another innovative project. "We are waiting for high-precision equipment to appear in the Center to make a construction 3D printer. We already have the project ready, it remains to be implemented. We would like to assemble it here in Yakutsk. This is our second major project that can be monetized, and it , perhaps, will become a new milestone in the history of high-tech production in Yakutia," Gogolev added. nine0003

https://ria.ru/20201008/molekula-578861081. html

html

Yakutsk

RIA Novosti

1

5

4.7

9000

Internet-.ru

4955 -6601

FSUE MIA "Russia Today"

https: //xn---c1acbl2abdlkab1og.xn--p1ai/Awards/

2020

RIA Novosti

5

9000 4.7 9000 9000 9000 90007 495 645-6601

FSUE MIA Rossiya Segodnya

https://xn--c1acbl2abdlkab1og.xn--p1ai/awards/

ABOUT/COPYRIGHT.HTML

https: //xn---c1acbl2abdlkab1og.xn--p1ai/

RIA Novosti

1

5

4.7

9000

4

49000 645-6601

FSUE MIA Rossiya Segodnya

https://xn--c1acbl2abdlkab1og.xn--p1ai/awards/

1920

1080

true

1920

1440

true

https://cdnn21.img.ria.ru/images/39514/72/395147255_81:0:942:646_1920x0_80_0_0_e1a501

1e00f8e1c948d70822fe5.jpg

1920

1920

True

RIA Novosti

1

5

4. 7

7

9000 9000

7 495 645-6601

FSUE MIA "Russia today"

9 9000 9,0000002 https: //xn---c1acbl2abdlkab1og.xn--p1ai/Awards/RIA Novosti

1

5

4.7

96 9000

7 495 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 646 64 64 64 64 64 64 646 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64 64AP

Federal State Unitary Enterprise MIA "Russia Today"

https://xn--c1acbl2abdlkab1og.xn--p1ai/awards/

Technology, Yakutsk, North-Eastern Federal University

Science, Technology, Yakutsk, North-Eastern Federal University

YAKUTSK, 9October - RIA Novosti. International Center of the North-Eastern Federal University Future Skills: NEFU has developed an industrial 3D scanner for working at low temperatures, and is also preparing to implement a project to create a construction 3D printer, director of the center Roman Gogolev told RIA Novosti.

As Gogolev noted, the 3D scanner is part of a suit with augmented reality and GPS stuffing, which is designed to work at low temperatures.

"We are working on creating full-fledged digital twins for further system modeling based on the same twins. An industrial non-contact 3D scanner creates digital twins that are highly detailed and informative. According to the project, the scanner can work at minus 20, if we implement it completely, then it reaches minus 25. So far, the materials do not allow you to "go down" lower, but you can experiment. In fact, the prototype has now worked at a temperature of minus 15," Gogolev said. nine0003

According to the director of the center, field tests were carried out on metal supports of gas pipelines, metal supports of buildings. In addition, the device allows you to create digital twins of static non-solid objects. "First of all, the scanner is designed to create metal structures, pipes. But it can scan other things - bones, teeth, parts, engines, even art objects. The only negative is that we still use hybrid technology. In the future, if possible, we will be able to scan glare objects," the source said. nine0003

The only negative is that we still use hybrid technology. In the future, if possible, we will be able to scan glare objects," the source said. nine0003

October 8, 2020, 16:09Science

Siberian scientists have created a diagnostic molecule

According to the calculations of the developers, the cost of a serial product is from 10 thousand to 17 thousand euros per unit. The plans are to offer the development to corporations and engineering firms. "There is already a proposal to buy out all the data of the project. There are already customers for 3D scanning itself and for digital twins. And as soon as we register the scanner itself, customers will definitely be on it. We are more focused on the foreign market. In extreme cases, we will put it on crowdfunding platform, we will transfer it to a group of students as a technology startup. While we are actively refining, we would like to make a higher quality product," the head said. nine0003

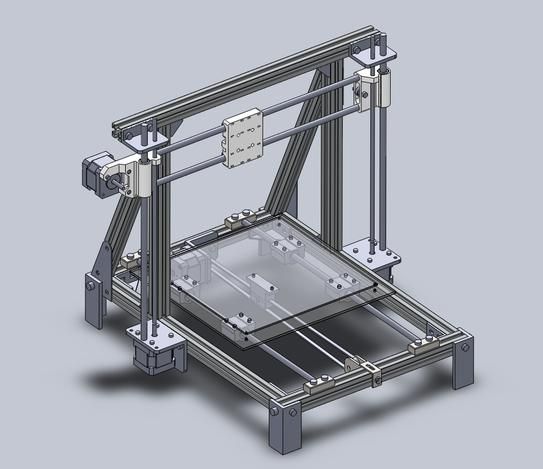

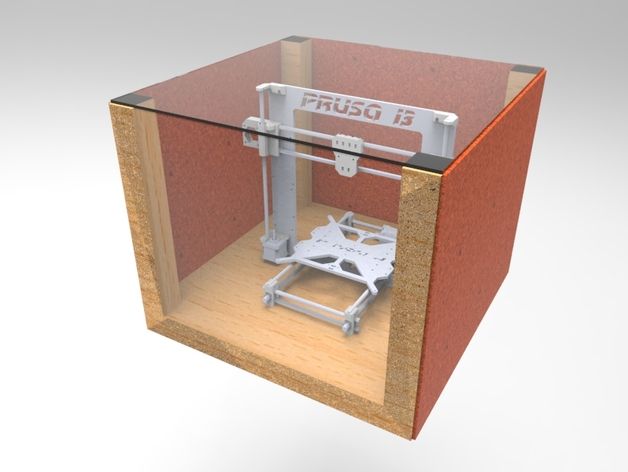

Future Skills: NEFU is gearing up for another innovative project. "We are waiting for high-precision equipment to appear in the Center to make a construction 3D printer. We already have the project ready, it remains to be implemented. We would like to assemble it here in Yakutsk. This is our second major project that can be monetized, and it , perhaps, will become a new milestone in the history of high-tech production in Yakutia," Gogolev added.

"We are waiting for high-precision equipment to appear in the Center to make a construction 3D printer. We already have the project ready, it remains to be implemented. We would like to assemble it here in Yakutsk. This is our second major project that can be monetized, and it , perhaps, will become a new milestone in the history of high-tech production in Yakutia," Gogolev added.

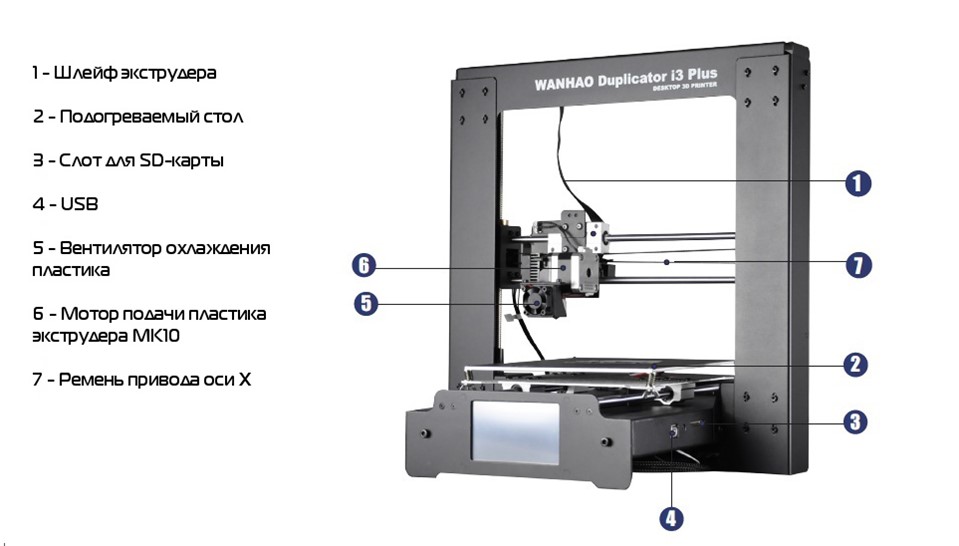

Educational-scientific-experimental laboratory "Center for three-dimensional modeling and virtual reality"

Tasks facing the laboratory

"Augmented reality in education" . The task is to develop new, relevant educational products and standards (training courses, manuals and laboratory workshops, electronic resources) based on augmented reality technology. Development of educational complexes for school education.

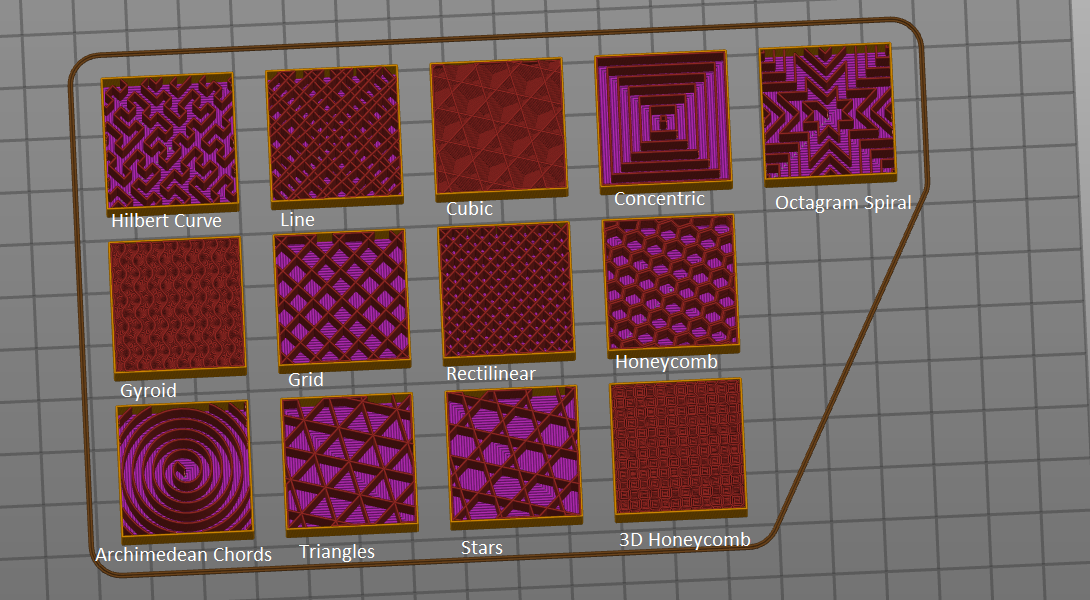

"Digital production and 3D technologies" . The task is to create educational resources on 3D modeling and printing, digital production for natural sciences and engineering disciplines. nine0003

nine0003

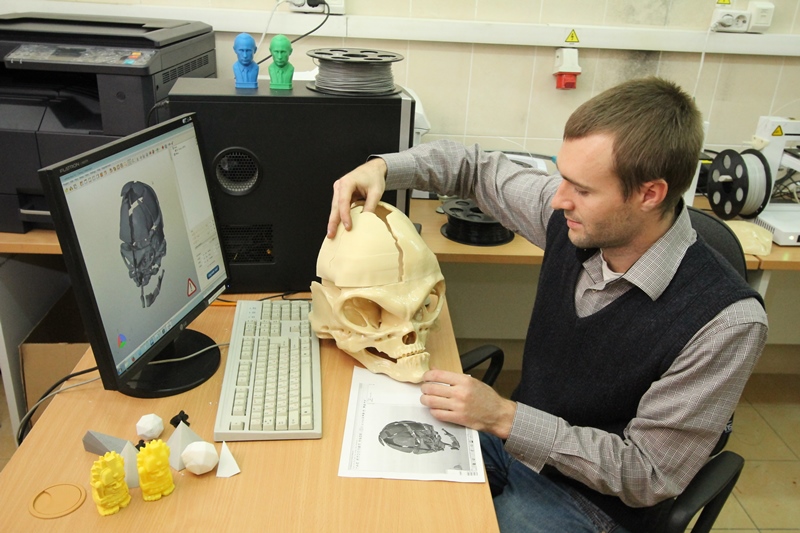

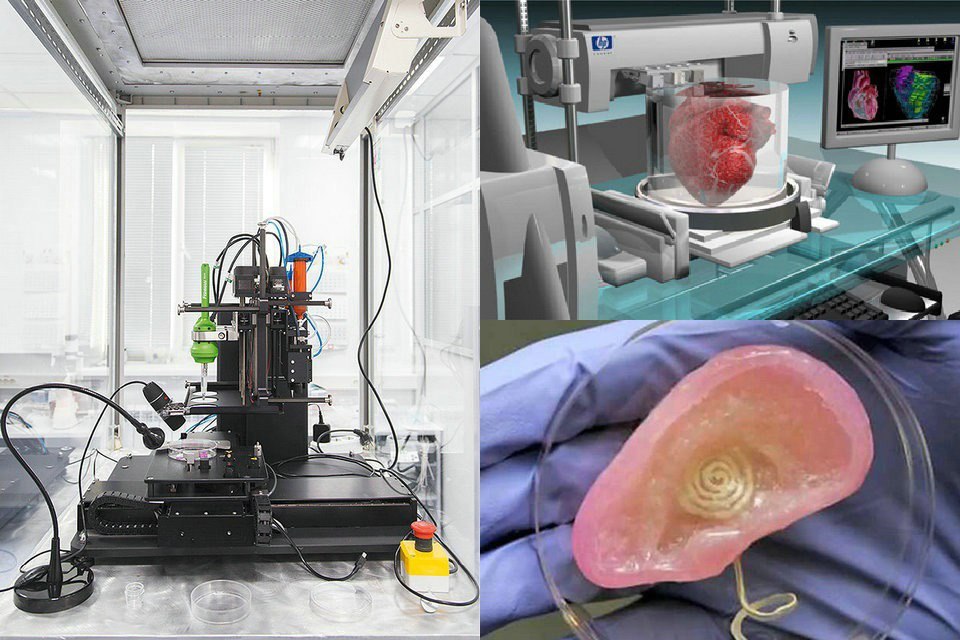

"3D technologies in medicine and paleontology" . The task of implementing research and development work in the field of medicine, paleontology

"Scanning and 3D printing technologies in medicine" . Carrying out scientific and research work to create high-precision 3D models of human organs and body parts based on scanning and tomography for the tasks of surgery, orthopedics, dentistry, rehabilitation, and education. 3D printing of models and equipment.

Topographic anatomical 3D+ human atlas . Creation of an interactive teaching aid based on augmented reality technologies. Section "3D+ topographic anatomy and major surgical interventions in the head area".

"Mammoth fauna 3D+". Creation of high-precision digital copies of skeleton bones of mammoths, woolly rhinos, cave lions and other paleontological objects in order to create a database for scientific research, dissemination of scientific knowledge and creation of interactive expositions of the NEFU Mammoth Museum. nine0003

nine0003

The operation of the scanning probe microscope (SPM) NanoEducator is based on the dependence of the interaction between the probe in the form of a sharp tungsten needle and the surface of the sample under study on the probe-sample distance. The interaction can be current (due to the tunnel current) or power.

SPM NanoEducator allows implementing various methods of measuring tunneling and "semi-contact" atomic force microscopy and can be used not only for educational purposes, but also for scientific purposes in research in the field of physics and technology of micro- and nanostructures, materials science, catalysis, physics and chemistry polymers, tribology, cytology, etc. Its distinctive features are:

- ease of use,

- use of a video camera for visual control of the probe status,

- inexpensive and repeatedly recoverable probe,

- connection of the electronic unit to a PC via USB port,

- multitasking, providing the ability to use a computer simultaneously with device operation.