3D printing quotation

Custom Online 3D Printing Service

CapabilitiesCustom Online 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Our 3D Printing ServicesMaterialsApplications and BenefitsSizes and TolerancesAbout 3D Printing3D Printing GuideXometry's Online 3D Printing Services: High-Quality Rapid Prototyping and Production Parts

Xometry offers an industry-leading 3D printing service online. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop-shop for accurate, precise, custom 3D printed parts at an affordable price. Upload your 3D CAD file to get an online quote and lead time within seconds. We print everything from single prototypes to thousands of production-grade parts.

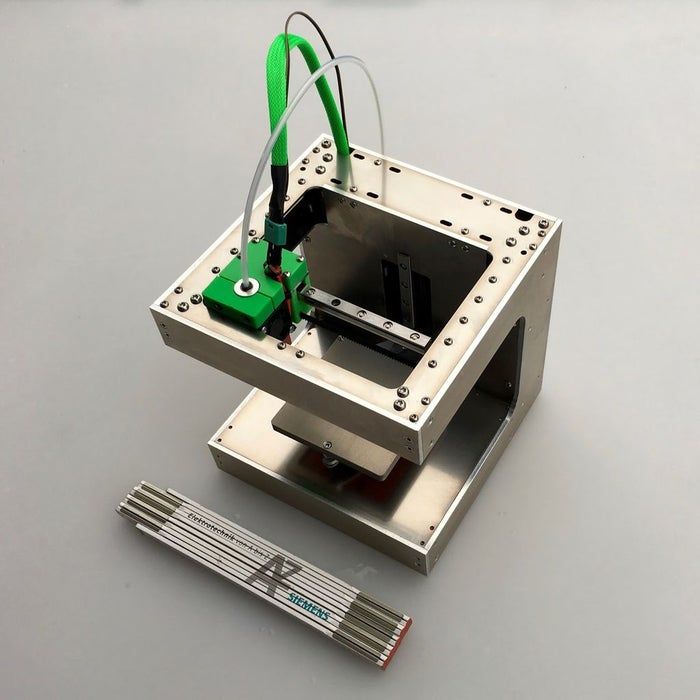

We use the latest additive manufacturing technology to build affordable functional parts in over 60 metals and plastics. Xometry offers eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more. For a great introduction to additive manufacturing, please visit our Complete Guide to 3D Printing.

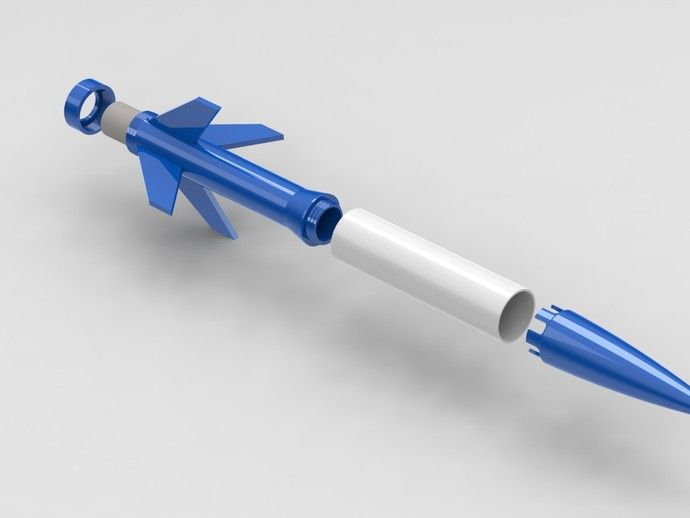

Use the 3D viewer above to preview Xometry’s part rendering features.

Thermoplastic 3D Printing

Selective Laser Sintering (SLS) 3D Printing Service

Upload your CAD file to get instant quotes on SLS parts. Parts ship in days. Free shipping on all US orders.

Selective Laser Sintering (SLS) 3D Printing Service

HP Multi Jet Fusion (MJF) 3D Printing Service

Guaranteed quality prototypes and production parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

HP Multi Jet Fusion (MJF) 3D Printing Service

Fused Deposition Modeling (FDM) 3D Printing Service

High Quality Large Format FDM 3D Printing Free Shipping on All US Orders

Fused Deposition Modeling (FDM) 3D Printing Service

Thermoset 3D Printing

Stereolithography (SLA) 3D Printing Service

High-Resolution Prototypes in Days Free Shipping on All US Orders

Stereolithography (SLA) 3D Printing Service

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

High-Performing Prototypes and Serialized Production Parts Free Shipping on All US Orders

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

PolyJet 3D Printing Service

Prototypes, color concept models, and simulated overmold parts in days Free shipping on all US orders

PolyJet 3D Printing Service

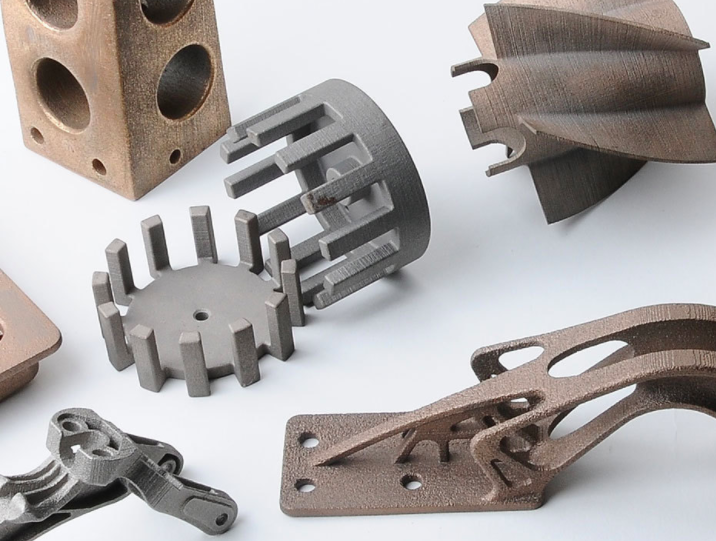

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Upload your CAD files to get an instant quote on metal prototypes and production parts. Free shipping on all US orders.

Free shipping on all US orders.

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Upload your CAD files to get an instant quote on parts. Free shipping on all US orders.

Metal Binder Jetting 3D Printing Service

Get flexible payment options for the parts your business needs.

The Best 3D Printing Material Selection

Durable Nylon

Nylon is one of the most versatile options for 3D printing with great feature detail and performance.

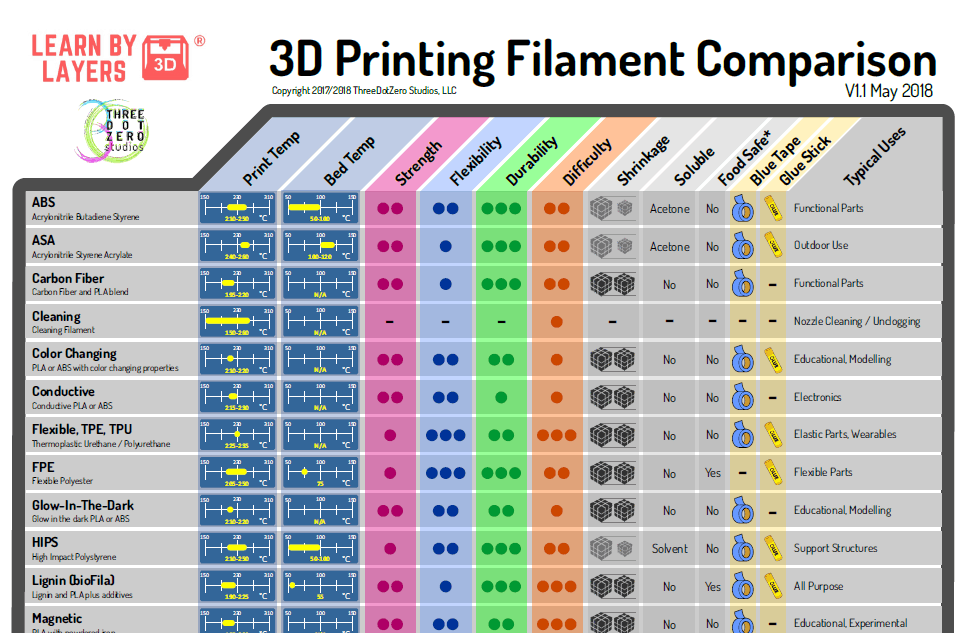

ABS and ASA

ABS and ASA 3D prints have a variety of colors and are a staple to 3D printed plastics.

ULTEM 9085 and ULTEM 1010

Tough, heat resistant, and durable ULTEM is engineered to withstand the most rigorous environments.

Elastomers and Rubber-like Materials

3D printed TPE and silicone-based elastomers give rubber parts without the need for tooling.

Metal 3D Prints

3D printed metal parts can achieve complex geometries without a sacrifice in performance.

Multi-Material Parts

PolyJet 3D can combine multiple properties in a single print for overmolds and other cosmetic features.

Materials for all Applications

Xometry has the widest variety of industrial 3D custom printing materials available for instant quoting.

New!

Flame Retardant Plastic 3D Printing

Xometry's 3D Print Service offers a variety of polymers that are flame retardant and qualify for UL-94 V-0 and FAR 25.853 60 second burn test. This includes FDM ULTEM 9085, FDM ULTEM 1010, and SLS Nylon 12, Flame Retardant. These polymers are perfect for aviation and aerospace applications. Learn more about 3D Printed Flame Retardant Plastics.

Ready to start making custom 3D printed parts?

Free shipping on all 3D printing orders!

Applications of 3D Printing

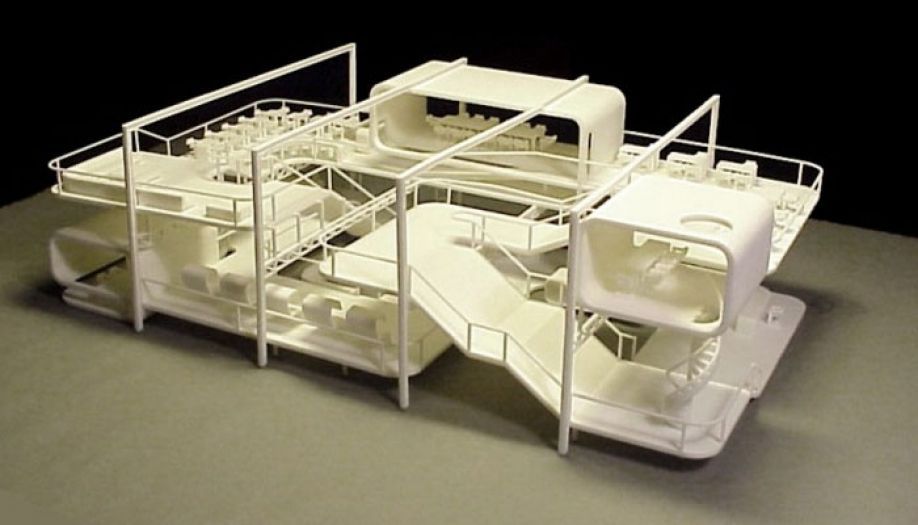

Concept Models

The speed and versatility of 3D Printing lets product developers create physical snapshots of their designs through the iterative process.

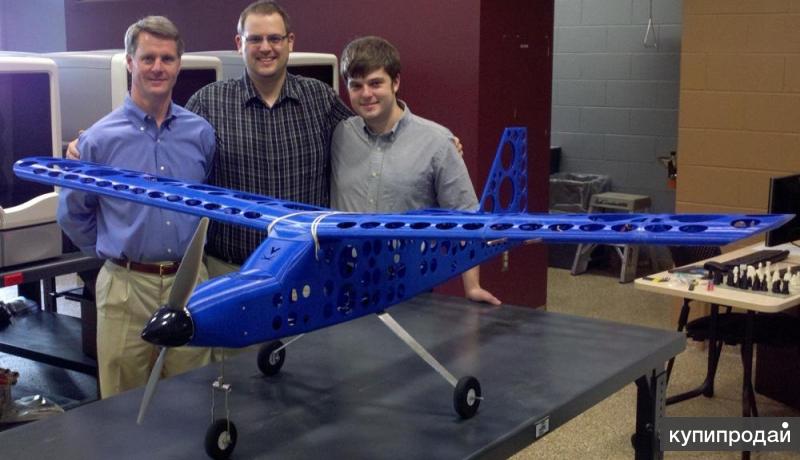

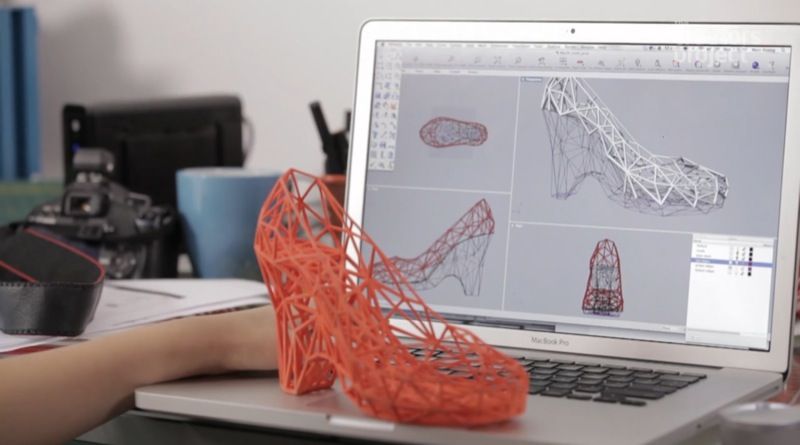

Rapid Prototyping

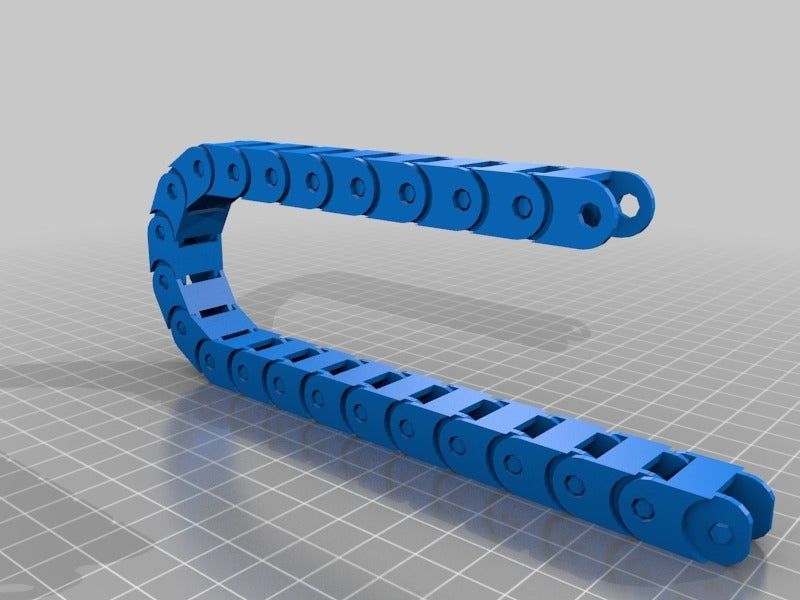

3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

Direct Digital Manufacturing

The high accuracy and consistency of 3D printing makes it an ideal way to build production quantities of discrete or customized parts.

Advantages of 3D Printing

Rapid Turnaround

Parts can typically be shipped in as little as 1 day, allowing for faster design iterations and speed to market.

Durability

3D printing can offer great impact strength, medium flexibility, and high resistance to environmental factors.

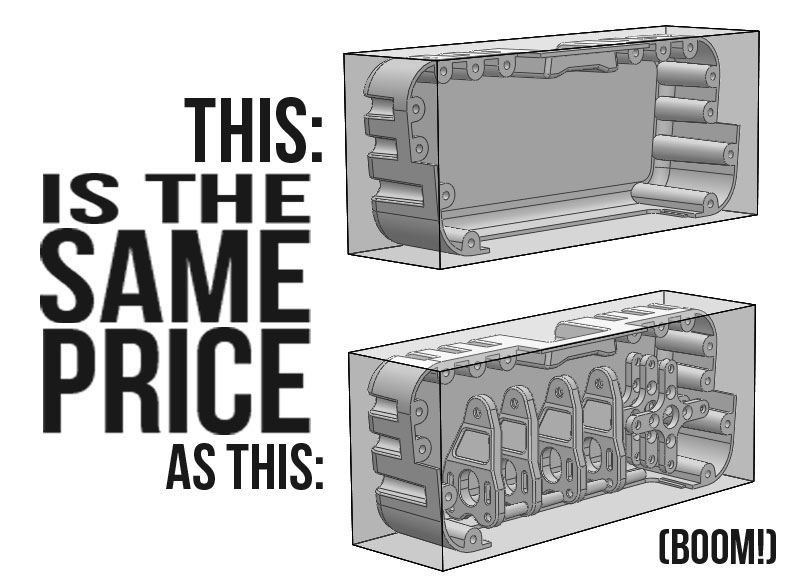

Complex Geometry

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

Precision

3D printing can achieve precise parts and feature details.

Part Production

3D printing with Xometry helps you produce end-use parts on-demand, increasing throughput.

Scalability

With 3D printing, you can make a single part or component as easily as dozens of production pieces.

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

Description Part Size | Tolerance Notes Xometry can accommodate 3D printing up to 24" x 36" x 36" without the need to split and bond parts. |

Description Minimum Feature Size | Tolerance Notes 0.030" - 0.060" is typical. |

Description Minimum Wall Thickness | Tolerance Notes 0.020" - 0.060" is typical. |

Description Clearance Between Features | Tolerance Notes At least 0.030" |

General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

What is 3D Printing?

What is 3D Printing?

3D printing is an additive manufacturing process where materials are joined together to make objects from 3D model data (CAD). Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Instant Quote Demo

See how fast and simple it is to get a quote for 3D printing using the Xometry Instant Quoting Engine®.

Why Choose Xometry for 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485 and AS9100D certified.

Become an additive expert with our Complete Guide to 3D Printing

3D Printing Services Available at Xometry

Bronze 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Bronze 3D Printing Service

Color 3D Printing Service by Xometry

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Color 3D Printing Service by Xometry

Large Scale 3D Printing Service on Xometry

Get instant online quotes on large scale 3D printed parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Large Scale 3D Printing Service on Xometry

Rubber 3D Printing Service on Xometry

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Rubber 3D Printing Service on Xometry

3D Printing Services Near You

AlabamaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Instant 3D Printing Quotes - Use This Online Quote Tool

Work with Fathom on your next 3D printing project. Our speed, commitment to quality and award-winning expertise are the reasons why companies from all industries trust Fathom with their low- to high-volume jobs. Some of Fathom’s clients include 9 of the Top 10 Fortune 500 companies (excluding service companies).

Our speed, commitment to quality and award-winning expertise are the reasons why companies from all industries trust Fathom with their low- to high-volume jobs. Some of Fathom’s clients include 9 of the Top 10 Fortune 500 companies (excluding service companies).

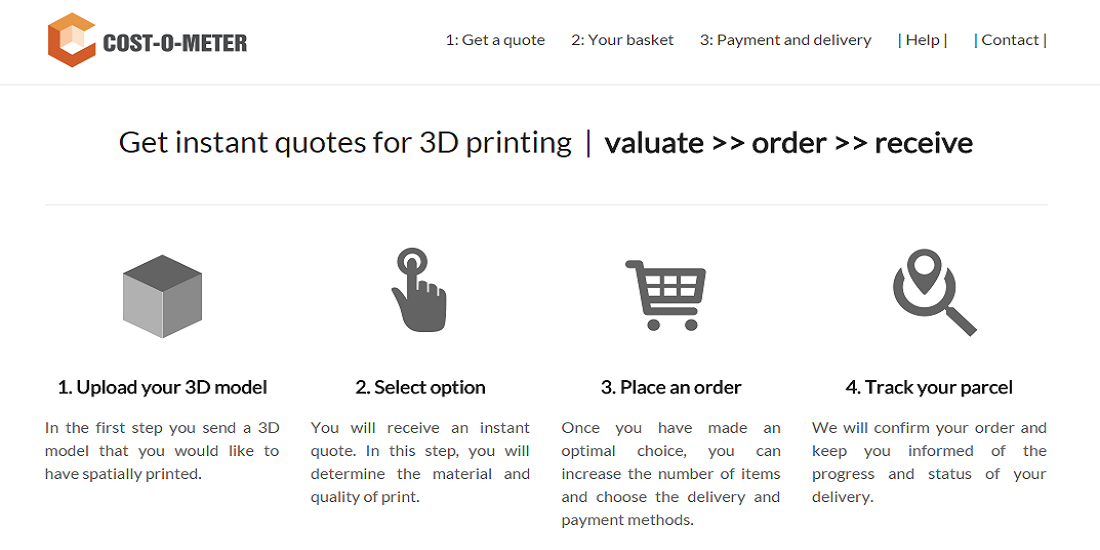

Just upload your file to our SmartQuote® tool and receive an online quote in seconds.

If you have questions on how to drive cost-saving manufacturing options, improved functionality and part speed, talk to a Fathom expert today. Our engineer team specializes in rapid manufacturing for even the most complex projects.

Additive Manufacturing Services Quotes Made EasyFor an instant online quote, add your file, volume desired, and part details. See below.

Looking for 3D Printing Prices?- Receive a free 3D printing quote by using our Price Quote Tool.

- You can build cost models for your next project by using our cost calculator.

The cost of a 3D printing project depends on the complexity of the design, materials used and volume desired. The minimum cost is $150 per order.

The cost of a 3D printing project depends on the complexity of the design, materials used and volume desired. The minimum cost is $150 per order.

- Once you have entered the details of your project and have customized the technology and materials, your custom quote will appear on your screen within seconds.

- Parts are dependent on complexity, quantity and technology

- Same-Day //

- PolyJet

- Next-Day //

- PolyJet, SLA & FDM

- Two-Days //

- PolyJet, SLA, FDM, MJF & SLS

- Three-Days //

- DMLS

- Same-Day //

3D Printing Quote Considerations by Technology

You can reduce the cost of your project by selecting the best technology and process. Fathom’s experts will review your quote to ensure you are staying on budget while utilizing the optimal production plan. See our technologies below. //

See our technologies below. //

FDM 3D Printing Quotes

Fuse Deposition Modeling is used to build concept models, functional prototypes and end-use parts.

Get an FDM Quote Now

- What is FDM?

- Often referred to as Fused Filament Fabrication (FFF), FDM uses a continuous filament of engineer-grade thermoplastic material. FDM facilitates quicker lead times and the ability to build functional prototypes using engineering grade plastics with strong thermal and chemical resistances. FDM is also an ideal technology when high strength-to-weight ratios are desired.

- FDM Material Considerations

- TPU (Thermoplastic Polyurethane Elastomer)

- High Elongation

- Toughness & Abrasion Resistance

- Wide Application Variety (e.g. flexible hoses, tubes, air ducts & vibration dampeners)

- Antero™ 800NA (Polyetherketoneketone)

- High Heat Resistance

- High Chemical Resistance

- Low Outgassing & High Dimensional Stability

- High Strength, Toughness & Wear-Resistance

- ULTEM™ 1010 Resin (Polyetherimide)

- Food Safety & Bio-Compatibility Certification

- Highest Heat Resistance, Chemical Resistance & Tensile Strength

- High Strength & Thermal Stability

- ULTEM 9085 Resin (Polyetherimide)

- Flame, Smoke, Toxicity-Certified Thermoplastic

- High Heat & Chemical Resistance

- High Flexural Strength

- Ideal for Commercial Transportation Applications (e.

g. airplanes, buses, trains & boats)

g. airplanes, buses, trains & boats)

- FDM Nylon 12™ (Polyamide 12)

- Excellent for Repetitive Snap Fits, Press Fit Inserts & Fatigue-Resistance Applications

- Free of Powders – Simple, Clean Process

- FDM Nylon 12CF™ (Polyamide 12CF)

- Carbon-Filled Thermoplastic with Excellent Structural Characteristics

- Highest Flexural Strength

- High Strength-to-Weight Ratio

- PC (Polycarbonate)

- Most Widely Used Industrial Thermoplastic

- Superior Mechanical Properties & Heat Resistance

- Accurate, Durable & Stable for Strong Parts, Patterns for Metal Bending & Composite Work

- Strong for Demanding Prototyping Use

- PC-ISO™ (Polycarbonate – ISO 10993 USP Class VI Bio-Compatible)

- Bio-Compatible (ISO 10993 USP Class VI)1 Material

- Sterilizable Using Gamma Radiation or Ethylene Oxide (EtO) Sterilization Methods

- Strong Uses for Applications Requiring Higher Strength & Sterilization

- PC-ABS (Polycarbonate – Acrylonitrile Butadiene Styrene)

- High Dimensional Stability

- High Impact Resistance

- Versatile Material with Good Heat Resistance

- ASA (Acrylonitrile Styrene Acrylate)

- UV-Stable Parts

- Best Aesthetics of any FDM Material

- Ideal for Production Parts for Outdoor Infrastructure & Automotive Parts

- ABS-ESD7™ (Acrylonitrile Butadiene Styrene)

- Static-Dissipative with Target Surface Resistance of 104 ohms (typical range 105 – 103 ohms)2

- Assembly Tools for Electronic & Static-Sensitive Products

- Widely Used for Functional Prototypes of Cases, Enclosures & Packaging

- ABS-M30™ (Acrylonitrile Butadiene Styrene)

- Versatile Material Good for Form, Fit & Functional Applications

- Familiar Production Material for Accurate Prototyping

- TPU (Thermoplastic Polyurethane Elastomer)

SLA 3D Printing Quotes

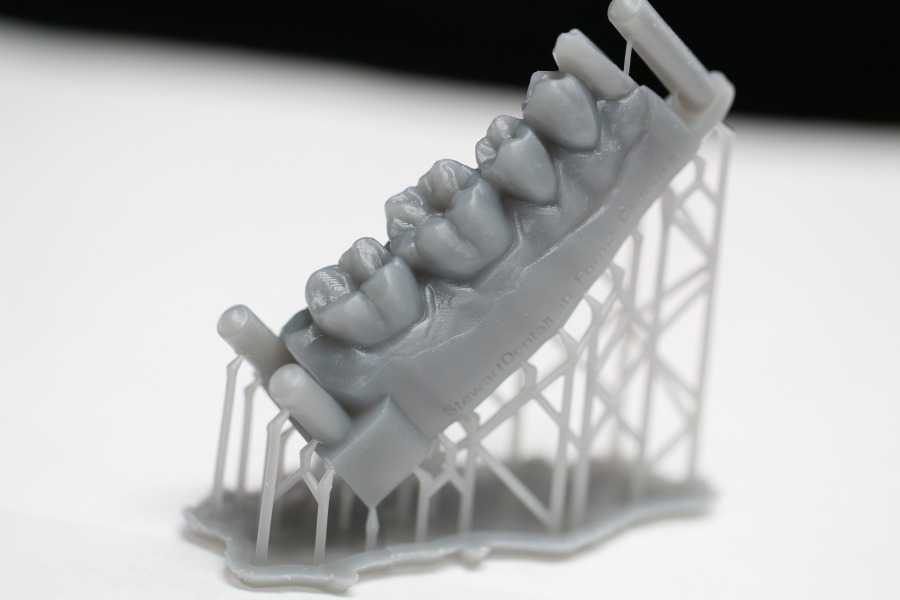

Stereolithography (SLA) is used for high-resolution finishes specifically with medium to large-sized parts.

Get an SLA Quote Now

- What is SLA?

- Stereolithography (SLA) is also known as SL, stereolithography apparatus, optical fabrication, photo-solidification, or resin printing. SLA is used to build prototypes and production parts in layers. A laser traces the part’s cross-section pattern along the surface of liquid resin. Light is used to cure the photosensitive polymers, solidifying the pattern and adhering it to the layer below. Stereolithography is used for smooth surface finishes with high detail, similar to injection molded parts.

- SLA Material Considerations

- Accura 25

- Often Used for Aesthetic Models, Complex Geometries & High-Quality Finishes

- Highly Cost-Effective for Medium- to Large-Sized Parts

- Exceptionally Tough & Durable

- Great for Snap Fits, Assemblies & Master Patterns for Casting

- One of the Most Versatile Technologies for Post Processing

- Accura ClearVue

- Often Used for Aesthetic Models, Complex Geometries & High-Quality Finishes

- Highly Cost-Effective for Medium- to Large-Sized Parts

- One of the Most Versatile Technologies for Post Processing

- Can be Polished for Near Optical Clarity

- Accura 25

PolyJet 3D Printing Quotes

PolyJet manufacturing is capable of smooth surfaces, thin walls and complex geometries, with accuracy as high as 0. 1mm.

1mm.

Get a PolyJet Quote Now

- What is Poly Jet?

- PolyJet can be used with a wide range of materials with properties ranging from rubber to rigid, transparent to opaque. During PolyJet printing, the material is distributed in layers onto a build platform and then cured by a flash of UV light. Multiple materials can be used in a single build to achieve a combination of colors and characteristics (e.g., parts made of both rigid and flexible materials).

SLS 3D Printing Quotes

SLS is a popular powder-based additive technology used to create models, prototypes and end-use parts in durable, engineering-grade thermoplastics.

Get an SLS Quote Now

- What is SLS?

- Selective Laser Sintering (SLS) is an additive manufacturing process. During SLS, a blade spreads a thin layer across the build volume. A laser is used to sinter cross-sections of the part which fuses the powder together, gradually building a solid structure layer by layer.

SLS is similar to selective laser melting (SLM) wherein the materially is melted, not sintered.

SLS is similar to selective laser melting (SLM) wherein the materially is melted, not sintered.

- Selective Laser Sintering (SLS) is an additive manufacturing process. During SLS, a blade spreads a thin layer across the build volume. A laser is used to sinter cross-sections of the part which fuses the powder together, gradually building a solid structure layer by layer.

- SLS Material Considerations

- Nylon PA2200 (White)

- Nearly Isotropic

- Parts Built Without Supports, Allowing for Complex Geometries

- Durable Production Quality Thermoplastic

- PA 12 Glass Bead

- High Rigidity

- Resistant To Wear & Tear

- Thermally Resilient

- PA 11

- High Impact Resistance & Elongation At Break

- Higher Temperature Resistance Than PA 12

- Does Not Splinter Under Load

- PA 11 Fire Retardant

- High Ductility Combined With Strength

- Flame-Retardant Properties Are Similar To ULTEMTM Filament

- Carbon-Filled Nylon 11

- High Strength Combined With Increased Impact Resistance & Elongation At Break

- Electrostatically Dissipative

- Nylon PA2200 (White)

MJF 3D Printing Quotes

Multi Jet Fusion is quickly becoming a popular choice for 3D printing prototypes and production parts.

Get an MJF Quote Now

- What is MJF?

- Multi Jet Fusion (MJF) is capable of 3D printing parts with high detail, as well as suitable for applications that require durability (e.g. snap fits). During the MJF process, thin layers of powder are distributed repeatedly to build a solid structure. It is common for designers and engineers to choose this technology for short production.

DMLS 3D Printing Quotes

DMLS allows you to create precision metal prototypes and low-volume metal production parts that would otherwise be impractical or cost-prohibitive to produce.

Get a DMLS Quote Now

- What is DMLS?

- Direct Metal Laser Sintering (DMLS) is a rapid 3D printing technique using a high-power laser to melt and fuse metallic powders together into a solid three-dimensional part made of metal. DMLS parts have excellent mechanical properties, exceptional surface quality and high detail resolution.

Using DMLS technology allows for cavities and undercuts not possible using conventional machining processes.

Using DMLS technology allows for cavities and undercuts not possible using conventional machining processes.

- Direct Metal Laser Sintering (DMLS) is a rapid 3D printing technique using a high-power laser to melt and fuse metallic powders together into a solid three-dimensional part made of metal. DMLS parts have excellent mechanical properties, exceptional surface quality and high detail resolution.

- DMLS Material Considerations

- Stainless Steel (Ph2)

- High Hardness & Strength

- Good for Prototype & Production Parts

- Stainless Steel (GP1)

- High Toughness & Ductility

- Good for Engineering Applications

- Cobalt Chrome (MP1)

- High Temperature Resistance

- Good for Turbines & Engine Parts

- Maraging Steel (MS1)

- Easily Machinable & Excellent Polishability

- Good for Injection Molding Tooling & Conformal Cooling

- Aluminum AlSi10Mg

- Low Weight & Good Thermal Properties

- Good for Automotive & Racing

- Nickel Alloy IN718

- Heat & Corrosion Resistant

- Good for Turbines, Rockets & Aerospace

- Stainless Steel (316L)

- Corrosion & Pitting Resistant

- Good for Surgical Tools, Food & Chemical Plants

- Titanium Ti-64 *

- Light Weight, High Strength, Corrosion Resistance

- Good for Aerospace, Motorsport Racing

- Titanium Ti-64 ELI *

- Corrosion Resistance, Biocompatibility

- Good for Medical, Biomedical, Implants

- Stainless Steel (Ph2)

Why Engineers & Designers Use Fathom for 3D Printing & Additive Manufacturing Quotes

- Instant Quoting – Fathom provides instant quotes with our SmartQuote instant quoting tool.

- Advanced Techniques – Fathom is a leader in advanced rapid manufacturing, introducing engineers to innovative processes they did not know were possible.

- Engineering Expertise – Fathom’s team of engineers is ready to give you a fast quote. Let our experts help you evolve your rapid manufacturing process. Contact an engineer today.

- Quality & Reliability – Fathom delivers high-quality work with a quick turnaround, ensuring our clients meet critical deadlines. It is the reason that Fathom is used by 9 of the Top 10 Fortune 500 Companies, 8 of the Top 10 Fortune 500 Industrial Companies and 7 of the Top 10 Fortune 500 Aerospace & Defense Companies (excluding service companies).

- Example (A) Accelerated Lead-Time—While the cost per part is close in this example, the critical requirement was getting parts in days, not weeks.

Fathom recommends taking an AM approach as a bridge-to-production solution or to avoid tooling. By using 3D printing, parts can also be built as needed.

Fathom recommends taking an AM approach as a bridge-to-production solution or to avoid tooling. By using 3D printing, parts can also be built as needed. - Quantity Required / / 3,500

- AM Part Cost / / $3.52 ea (Lead-Time of 5 Days)

- IM Part Cost / / $3.60 ea (Lead-Time of 35-40 Days, Prototype Tool)

- Break-Even Point / / 3,740 Parts

- Material Used & Weight / / PA12 (4.6 g)

- Part Dimensions / / 25 mm × 23 mm × 25 mm

- Injection Molding with Amortized Tool Price

- Example (B) Limited Production Run—The tooling cost of this part is high because of a complex parting line and challenging features. When a lower volume of parts is required, Fathom recommends taking an AM approach to reduce on cost and manufacturing time.

- Quantity Required / / 1,500

- AM Part Cost / / $8.

18 ea (Lead-Time of 6 Days)

18 ea (Lead-Time of 6 Days) - IM Part Cost / / $12.46 ea (Lead-Time of 40-56 Days)

- Break-Even Point / / 1,829 Parts

- Material Used & Weight / / Glass-Filled PA12 (14.2 g)

- Part Dimensions / / 83 mm × 15 mm × 109.24 mm

- Injection Molding with Amortized Tool Price

- Read More Additive Manufacturing vs. Injection Molding Break-Even Examples

Over 530 machines power Fathom’s manufacturing facilities, including mills, lathes, presses, press brakes, turret punches, and additive systems. Fathom utilizes 12+ high-precision machines for 3D printing.

Fathom’s manufacturing technologies are not limited to 3D printing and include hybridized services leveraging 3D printing of all kinds. Ready for Metal 3D printing as part of a complex job? Fathom can do it.

A recent case study is listed below where Fathom delivered 20,000 parts in 27 days using 55+ tools, including multiple 3D printing services:

Case Study //

Real Customers.

Real Results.

Real Results.A customer came to Fathom with a complex project that spanned the technologies and processes of rapid production—and needed it done fast. Fathom delivered.

20,000 Parts // Within 27 Days

15,000

55+ Tools to Injection

Mold 15,000 Parts

First Article in 2 Weeks

3,000

3,000+ 3D

Printed Parts

2,000

2,000+ Metal

Fabricated Parts

Hybridized Services Used //

3D Printing / Additive Manufacturing—PolyJet, SLS, MJF.

DFM Analysis + CAD Mods.

CNC Machining. Laser Cutting.

Stamping. Die Cutting. Post-Opp Drilling.

24-hour Turnaround Urethane Casting.

Injection + Compression Molding.

Model Finishing. Insert Assembly.

Advanced Project Management.

Fathom’s Locations for 3D Printing ServicesTwo US-based Fathom locations offer 3D printing, offering nationwide coverage to the entire United States. Manufacturing and prototyping services include CNC machining, 3D printing, injection molding, CNC machining, etc. Fathom has provided over 200,000 quotes to the top US companies and is ready to quote you today.

Fathom has provided over 200,000 quotes to the top US companies and is ready to quote you today.

Locations include:

HEADQUARTERS

1050 Walnut Ridge Drive

Hartland, WI 53029

ISO 9001:2015

AS9100:2016

ITAR

CALIFORNIA

620 3rd Street

Oakland, CA 94607

ISO 9001:2015 Design Certified

NIST 800-171 Compliant

ITAR

Q: Does Fathom offer 3D printing?

A: Yes, Fathom offers 3D printing services.

Q: What is 3D printing?

A: 3D printing is sometimes referred to as additive layer manufacturing or additive manufacturing. During 3D printing, components are made in layers. A CAD drawing serves as instructions, telling the machine exactly where to lay the material.

Q: Is Fathom ISO certified?

A: Fathom’s certifications include ISO 9001:2015, ISO 9001:2015 Design, and ISO 13485:2016. For site specific certifications please visit: https://fathommfg. com/fathom-manufacturing-certifications

com/fathom-manufacturing-certifications

Q: Is Fathom ITAR certified?

A: Yes, Fathom is ITAR certified. For site specific certifications please visit: https://fathommfg.com/fathom-manufacturing-certifications

Q: Is Fathom AS9100:2016 certified?

A: Yes, Fathom is AS9100:2016 certified. For site specific certifications please visit: https://fathommfg.com/fathom-manufacturing-certifications

Q: Is Fathom NIST 800-171 certified?

A: Yes, Fathom’s certifications include NIST 800-171. For site specific certifications please visit: https://fathommfg.com/fathom-manufacturing-certifications

Q: What is the difference between additive manufacturing and 3D printing?

A: There is no difference between 3D printing and additive manufacturing. Both additive manufacturing and 3D printing refer to manufacturing processes during which parts are made by adding material.

Q: How much does your 3D printing service cost?

A: The cost of 3D printing depends on the material selected, the volume of parts ordered, the complexity of the part’s design, the cost of labor and more. For an accurate quote, submit your project details through Fathom’s SmartQuote application.

For an accurate quote, submit your project details through Fathom’s SmartQuote application.

Q: What material is used in 3D printing?

A: While plastic is the most popular material used in 3D printing, a wide range of materials may also be utilized including metal and carbon fibers.

Q: What are the benefits of 3D printing?

A: 3D printing offers numerous advantages. Freedom of design, customization, cost efficiency and on-demand capabilities are just a few of the benefits of 3D printing.

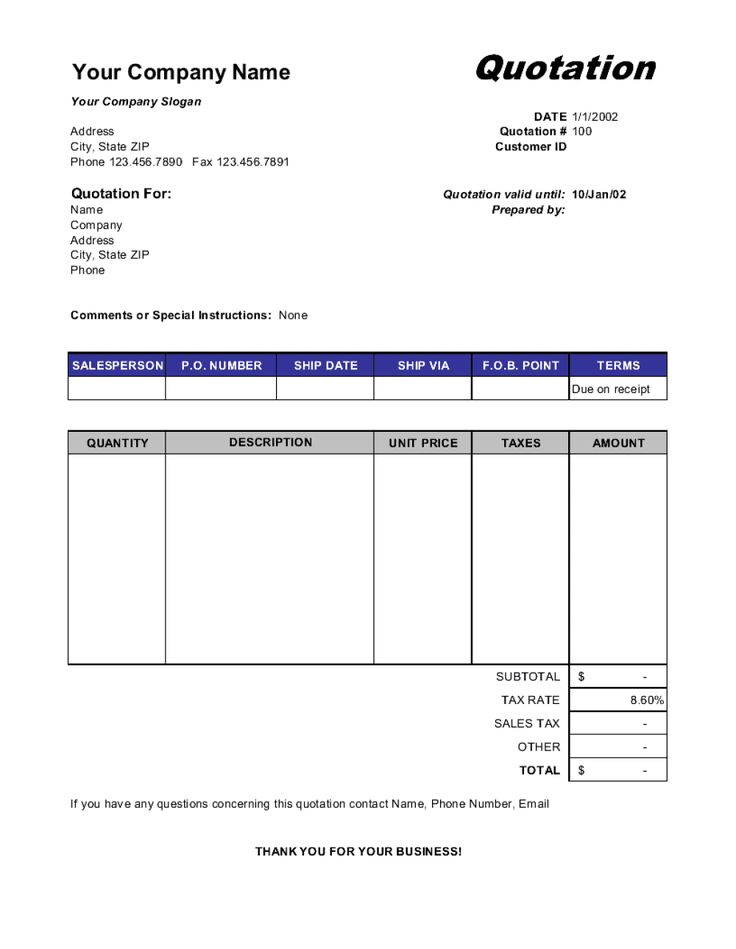

Commercial 3D Printing Accounting Program Suggestions

This has been asked and written many times about how to calculate the cost of commercial printing. Most, as I understand it, count either simply on a calculator or make a tablet in Excel to calculate the cost.

I decided to try to kill all birds with one stone - to write a program for commercial 3D printing that could satisfy the needs of, if not absolutely all, then at least the vast majority of printers :) The reason was this article - https://3dtoday. ru/blogs/krom-berg/reestr-pechati-s-raschetom and comments on it. nine0003

ru/blogs/krom-berg/reestr-pechati-s-raschetom and comments on it. nine0003

Estimated features of the program:

1. Calculation of the cost of printing (details below).

2. Accounting for residual materials.

3. History of printouts.

4. Purchase history of materials.

5. Reports for the selected period (purchases, costs, income).

Now more detailed explanations of the items.

1. Calculation of the cost of printing

As I see the implementation of a fairly universal calculation of the cost of printing. The current idea of the calculation method is as follows: the basic print accounting unit is the so-called "Job". Quest includes:

a) "Equipment" - such as a printer or dryer or anything else that is used at work. Name, capacity, cost of electricity, depreciation cost (with indication of the unit of measure), cost of preparation for printing (meaning only the preparation of the printer itself), the minimum cost of printing on this printer.

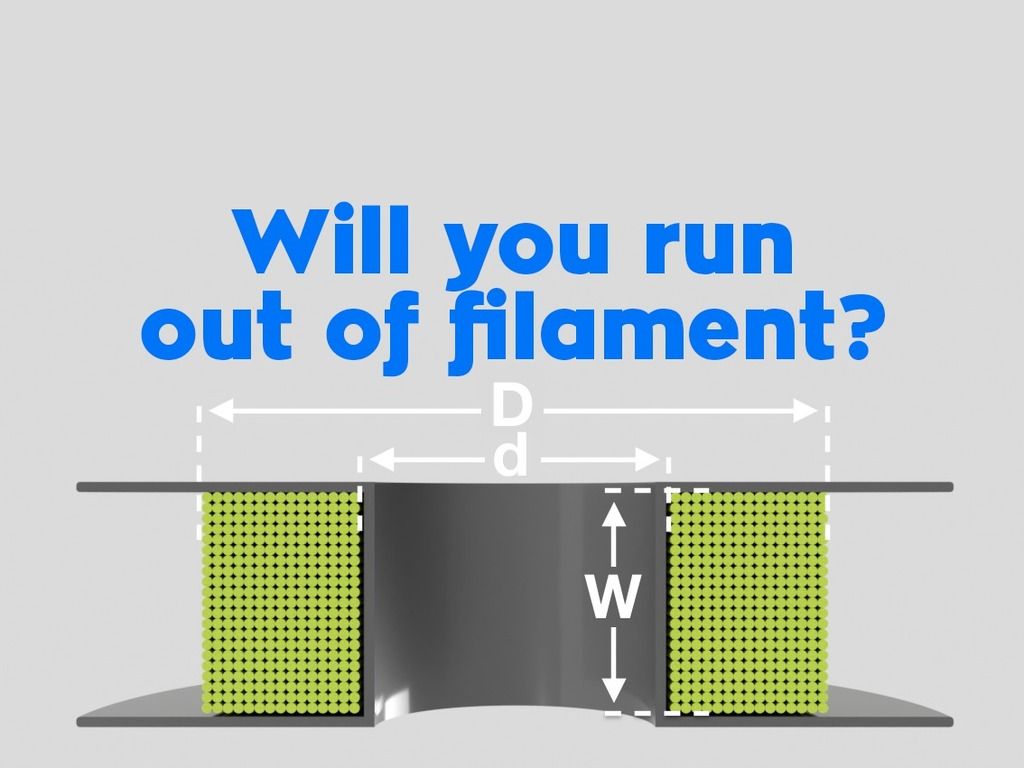

b) "Materials" - filament, photopolymer, post-processing chemicals, etc. For each material, its quantity is indicated.

c) "Work" - design, preparation, post-processing, etc. nine0003

d) "Coefficient" - discounts, extra charges for complexity, etc. If the remaining amounts are added to the total cost, then "Coefficient" is a multiplier. It can be applied to any or all of the "Equipment", to any or all of the "Materials", to any or all of the "Work".

One "Task" can contain any number of "Equipment", "Materials", "Works" and "Coefficients". Each of these items is taken from directories along with the parameters: name, unit of measurement, cost of one unit. Each has a quantity. In each, you can change the cost if in this "Task" it should not be the same as in the reference book. nine0003

As an example, the contents of one simple "Task" will look like this:

- minimum cost 150 rubles - total 432.32 rubles

- 2) PLA filament green - manufacturer GREG3D - cost 1 kg 650 rubles - quantity 0.

156 kg - total 101.4 rubles

156 kg - total 101.4 rubles - 3) Work - Preparing the model for printing - cost per hour 400 rubles - quantity 0.5 hours - only 200 rubles

- 4) Work - Removal of supports - cost of an hour 300 rubles - quantity 0.25 hours - total 75 rubles

- Total cost of printing - 808.72 rubles

For each of the items there is a guide, from where they are added to the "Task". The directories contain all the main parameters - the name, unit of measure, unit cost, etc. In principle, all this could be entered in the "Assignment" without reference books, but it is more convenient with them, it seems to me :)

2. Accounting for leftover materials. nine0022

I'll tell you right away - this is not an accounting or warehouse program, there will be no strict accounting here. The remainder for each material is simply stored in the directory along with the rest of its parameters. When performing the next "Task", the corresponding amount of material participating in it is subtracted from the balance in the directory. And at "Purchase" - it is added (and at the same time the price changes). At any time, you can simply edit the amount of the balance in the directory without unnecessary movements. That is, this opportunity is only for indicative information, insofar as. nine0003

And at "Purchase" - it is added (and at the same time the price changes). At any time, you can simply edit the amount of the balance in the directory without unnecessary movements. That is, this opportunity is only for indicative information, insofar as. nine0003

3. History of printouts.

Well, just a list of completed or ongoing "Tasks". Each can be opened to view information - what is included in the "Task", at what price, etc. Each "Task" in the list can have the status "Current" or "Completed". You can filter by this status.

4. Purchase history of materials.

Also just a shopping list. When buying something, the user makes a "Purchase", which indicates the seller and what, how much and how much was bought. At the same time, the quantity of the corresponding material increases and its purchase price changes. The list of these purchases is preserved. Just for history, not affecting anything other than reports. nine0003

5. Reports for the selected period (purchases, costs, income).

Simple summary reports for the period selected by the user, without analytics and other bells and whistles :)

The program is written in C#. Installation does not require - unpack the archive and you can run. System requirements are minimal - the presence of .NET Framework 4.5. No additional programs (office, server, etc.) are required. All information is stored in a separate SQL database file, this file can be copied, transferred to another computer, placed on a network drive, etc. nine0003

While I'm doing work with directories, the main part of the program has not started yet. And while it has not been started, I want to ask and consult: who thinks about all this and are there any suggestions on the possible functionality of the program? :))

Or is it just an unnecessary fuming and no one needs such a program? :)

3D Printing and Quality 3D Printing Services - Quote

3D printing is the result of the advent of additive manufacturing technology. When creating a three-dimensional object, several layers of a specialized material are successively applied. For this, 3D printers were developed. Compared to other production tools, the printer is the most affordable and easy to manage. nine0003

When creating a three-dimensional object, several layers of a specialized material are successively applied. For this, 3D printers were developed. Compared to other production tools, the printer is the most affordable and easy to manage. nine0003

Request 3D Printing

Recently, 3D printing technology has become very popular. Some of those who have used a 3D printer think that it can only print the simplest miniature models. In reality, things are completely different. There is a huge range of work that can be done using 3D printers:

- 3D printing plays a very important role in the work of architects and designers. Thanks to this technology, various projects of all degrees of complexity are created (motorways, residential and office buildings, facilities for sports events, warehouse complexes, etc.). 3D allows you to visualize all ideas and visualize them with all even the most insignificant and small details. For a stronger impact on the management, in addition to the project layout, you can add several additional elements (cars, aircraft, construction equipment, ships, human figures, etc.

). nine0040

). nine0040 - Very well, 3D printing technology helps enterprises to create parts and mechanisms. With the help of 3D printing service, you can recreate an exact copy of any part sample. This copy will have the same properties as the original. This allows specialists to find existing shortcomings in the mechanism, correct them and evaluate performance.

- Thanks to the use of a 3D printer, it became possible to avoid defects in mass production of parts. To do this, simply order its 3D model and evaluate the quality of the finished product. It is also possible to recreate the housing for electrical appliances. The size and complexity of such cases can be completely different. nine0040

- But the 3D printer is used not only in manufacturing to create models of architectural designs and prototype parts, but also to make gifts. The execution of the order will take place as soon as possible and without much difficulty. After some time, you will have a unique souvenir in your hands, which is a miniature model of the selected object.

Benefits of 3D printing technology

The popularity of 3D printing is growing exponentially. And this is not surprising, because it has a number of positive qualities:

Saving a lot of time

Designers and architects now spend significantly less time creating layouts for their projects.

Sleepless nights are a thing of the past

It takes no more than 2 days from the date of order to create miniature models of any complexity.

Versatility

With the help of a 3D printer, orders of any complexity can be processed, even taking into account all the features of the prototype.

Individual approach to each client

In the process of creating a 3D model, all the wishes of the client are taken into account. This allows you to make exact copies that meet all requests.

Reliability

Only high-quality materials with good strength are used to create 3D models. That is why all finished copies are durable.