3D printing ahmedabad

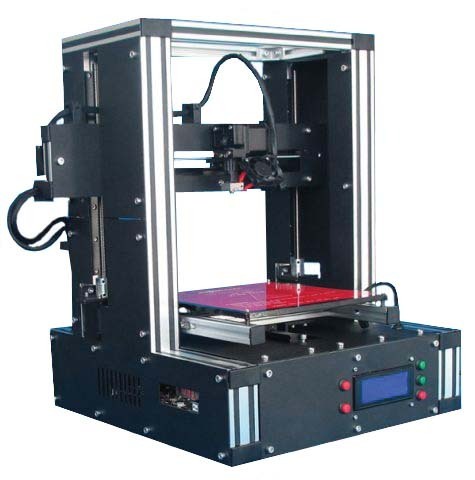

3D Printing Service in Ahmedabad

Is 3D printing just for rapid prototyping?

3D printing is an essential tool for accelerating the prototyping process. However, its applications stretch well beyond prototyping to other facets of the product lifecycle.

• Manufacturing – Design freedom and economically viable low-to-mid-volume production enable new possibilities for product design and operational improvement. Applied in combination, these two capabilities have the potential to transform decades-old supply chains and business models.

• Tooling – 3D printed tooling advantages include on-demand production, customization, digitization of designs and unrestrained design flexibility. This cuts out costly suppliers, compresses lead times, enables digital warehousing and accelerates manufacturing floor productivity.

• Sales and Retail – 3D printing gives retailers the ability to innovate, delivering highly customized, on-demand products and new experiences such as “co-designed” items developed in conjunction with the customers.

• Aftermarket Supply – Businesses that embrace 3D printing for spare and replacement parts can replace warehouses of spare parts with 3D printers or a contract 3D printing service bureau to produce parts on a just-in-time basis.

How does 3D printing impact product development and speed to market?

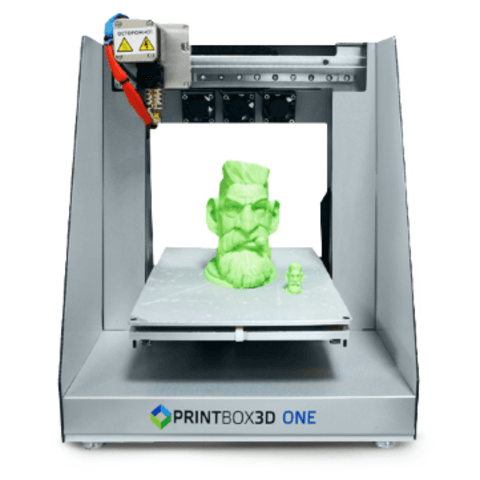

3D printing accelerates the process by reducing the time and cost associated with prototyping and refining the design. Many more 3D printed prototypes can be produced in the time needed to mold or machine them and for much less cost. Highly realistic prototypes printed on full-color multimaterial printers look like the final product, cultivating faster and better decisions.

What can designers do with 3D printing?

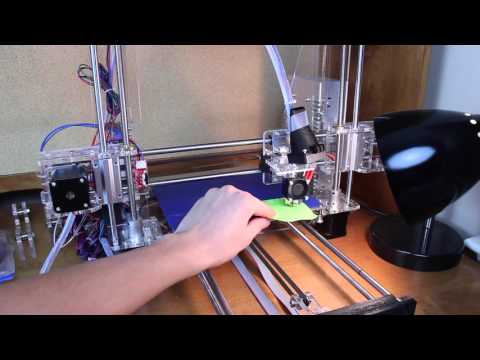

3D printing gives designers the capability to drastically shorten the design process compared to traditional methods of hand-modeling or outsourcing to model shops.

Keep the design process entirely in-house. With 3D printing, designers gain full control over the design process. Creating models in-house saves the time associated with outsourcing. More timeline flexibility empowers designers to try new ideas and iterate often, resulting in better products that stand out.

With 3D printing, designers gain full control over the design process. Creating models in-house saves the time associated with outsourcing. More timeline flexibility empowers designers to try new ideas and iterate often, resulting in better products that stand out.

Prototype faster and smarter. Outsourcing is often too expensive and time-consuming to allow iteration of more detailed prototypes, especially models that incorporate CMF (color-material-finish). The speed and streamlined workflow of 3D printing gives designers the freedom to create dozens of detailed prototypes while reducing the time to arrive at the optimal design.

Create beautiful, highly detailed models. With full-color, multimaterial printing, designers can create prototypes that look, feel, and even function like the real thing in just a few hours. The ability to assess the color, texture, and ergonomics of a product means better feedback and faster approval from clients.

Is 3D printing a replacement for conventional manufacturing technology?

3D printing is not a wholesale replacement for existing manufacturing methods like molding and machining. Its benefit lies in supplementing these other technologies at points where they can’t compete. For example, 3D printing’s additive nature is able to make structures that aren’t possible with machining or molding. It also makes low- to mid-volume production economically viable because there’s no need for the tooling investment. Similarly, it’s much faster to get started, which is why GM turned to 3D printing to retool its production line to produce ventilators in the pandemic. In short, 3D printing is another tool in the toolbox, but one that offers key benefits over traditional manufacturing practices when used strategically.

Its benefit lies in supplementing these other technologies at points where they can’t compete. For example, 3D printing’s additive nature is able to make structures that aren’t possible with machining or molding. It also makes low- to mid-volume production economically viable because there’s no need for the tooling investment. Similarly, it’s much faster to get started, which is why GM turned to 3D printing to retool its production line to produce ventilators in the pandemic. In short, 3D printing is another tool in the toolbox, but one that offers key benefits over traditional manufacturing practices when used strategically.

What are the pros of using a service bureau?

Contracting with a service bureau to make your 3D printed parts is a good way to get introduced to the benefits of the technology. You gain the expertise and insight of a 3D printing specialist who can possibly guide you in optimizing the use of the technology for your specific purposes. Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

Which industries use it and how?

Additive manufacturing shows promise for the defense, energy, aerospace, medical and commercial sectors. Its alternative approach to machining, forging, molding and casting makes it a good choice for rapidly making highly customized parts. The technology also shows promise for creating parts on site, such as at forward-stationed military bases. Because of its potential, many companies are using the technology to get themselves into a position to use it. The growing field of companies using the technology includes makers of machine parts and novelty items.

How can THINK3D help me?

We’ve been in the business of helping customers solve problems for over 8 years with our 3D printing solutions. We can help you determine what technology is right for your application, whether a printer or a service bureau is more appropriate, as well as answer any questions you might have.

Are companies using Additive Manufacturing?

Yes, lots of different companies across a range of industries use additive manufacturing, including the medical industry, aerospace and more. Additive manufacturing is particularly useful for making complex or bespoke parts – whether for a new application or to replace an old part that may no longer be available.

How long does the 3DP process take?

The printing time takes in a few factors, including the size of the part and the settings used for printing. The quality of the finished part is also important when determining printing time as higher quality items take longer to produce. AM can take anything from a few minutes to several hours or days – speed, resolution and the volume of the material are all important factors here.

How do I find out if AM is right for me?

You probably know the answer to this one by now! It takes a discovery to analyze your current parts and determine whether or not there is an ROI for you at this point. If a basic ROI exists, then you will also profit from other AM benefits such as:

If a basic ROI exists, then you will also profit from other AM benefits such as:

- Freedom to design parts and sub-assemblies for the design, not for the manufacturing processes (DFM*)

- Have inventory on demand for both production and spare parts

- Eliminate costs of inventory and the time lag of supply chains

And!

- Gain the ability to quickly prototype with the same process with which you will manufacture — true rapid prototypes!

Ntech Engineering Solutions - 3D Printing Company in Ahmedabad, Gujarat, India

Ntech Engineering Solutions

GET EXPERT COUNSELLING

3D PRINTING

Our 3D printing solutions unlocks the door of possibility to consolidate the chain of supply and allow companies to produce lower to mid volumes of parts .

3D LASER SCANNING

Our team of renowned experts of 3D designers produce custom deliverables ranging from point cloud data 3D models, 2D drawings, dimension inspection and RE.

3D PRODUCT DESIGN

By designing your product from the scratch, we can help you get the best ROI from our advanced manufacturing services and ensure that you have the optimum solution to meet the unique requirements.

VACCUM CASTING

From small switchgear parts to large bumpers of automobiles we ensure you to deliver exactly the same product you have desired, NTech has prototyped them all in the last few years.

Get Quote

Estimated quote after discussion.

Model Preparation

Send us the part for scanning.

Tech Resources

We scan the part & arrange resources

3D Printing

The part is printed as per the requirement

Packaging

Data delivery and return of part.

Pricing

Meeting Deadlines

Expertise

CONSISTENCY

Standard Pricing

Strict quality control

Professional customer service

Standard Pricing

Strict quality control

Professional customer service

Your satisfaction is our promise

The client sets out with one aim in mind, but this gradually evolves & expands or might change altogether during the 3D design process.

INSIGHT

Gathering apprehension is a foundation path for understanding the hierarchy of need with clients. we understand where the organisation is and where it need to.

we understand where the organisation is and where it need to.

CLARITY

Once we get to know the objective of our client we develop an integrated strategy and structural design.

ENABLEMENT

Through the agile methodology we start delivering our service with a clear execution process to ensure that resources are manage appropriately.

Ntech Solutions did a good job in 3D printing my order. They followed up every-time with me for my insightful comments regarding my 3D model. and suggested all necessary improvements and corrected my mistakes because of lack of printing experience.

Jay Patel

They have got a vast knowledge on creating Product Designs, Rapid prototyping systems and also their handling. They were already full with a lot of orders but they managed time and provided us the necessities on time.

Purvesh Simojiya

Excellent very organized, efficient, professional and it was great communicating back & forth. In the end produced a great product in a reasonable price.

Krunal Patel

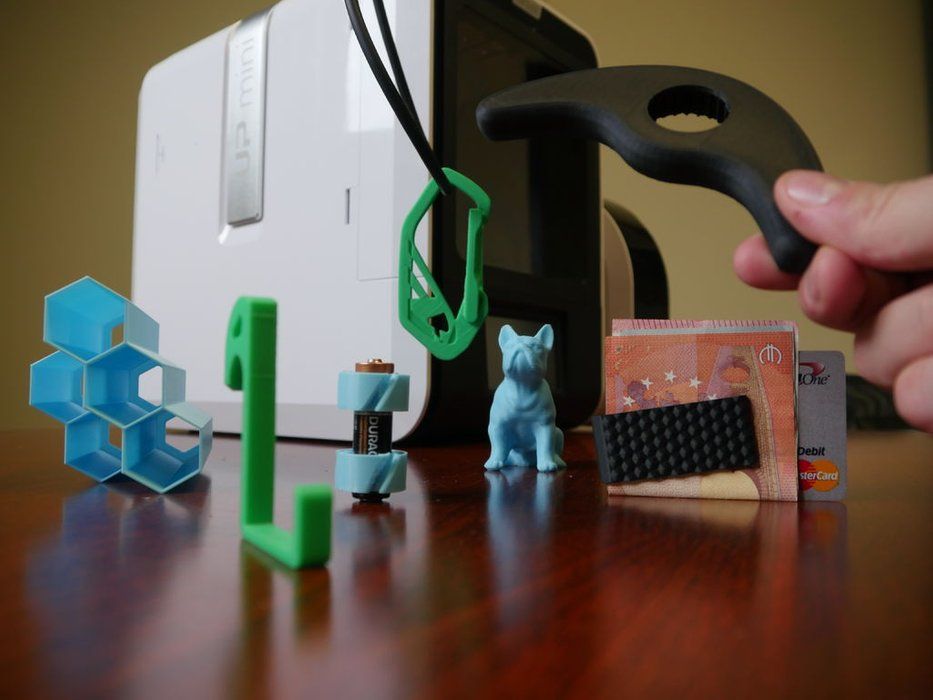

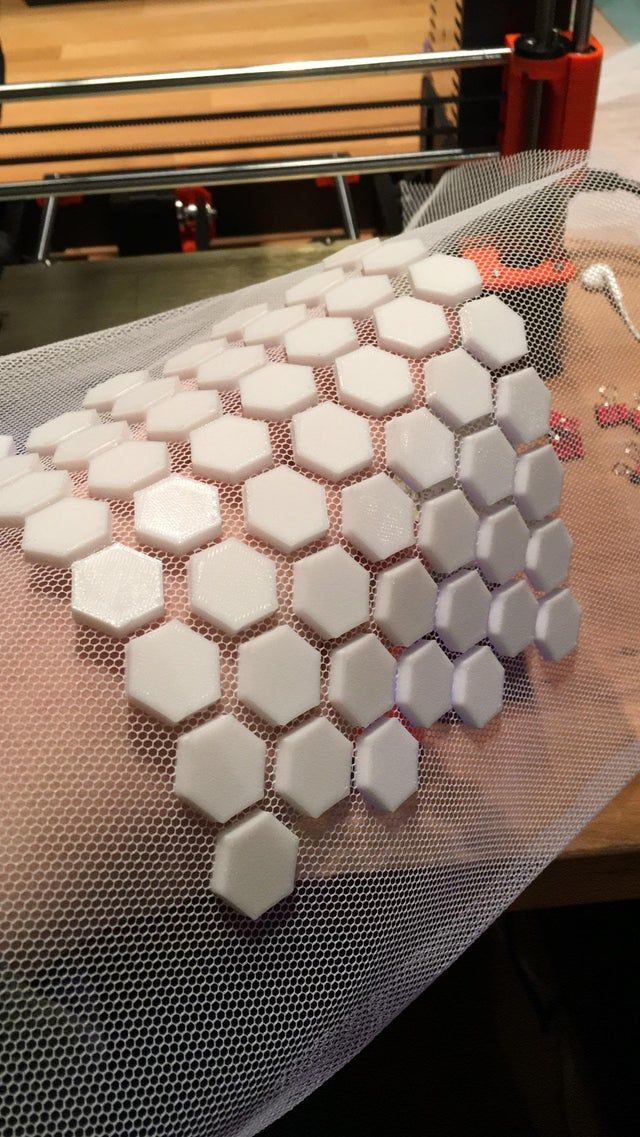

What is infill in 3D printing?

In 3D printing, infill refers to the structure printed inside the object. The size, shape, pattern, and percentage depends heavily on the design requirements. Higher infill percentage translates to physically stronger 3D printed samples.

Can different infills be chosen for my objects?

Yes, you can opt for different infills for your object. This can be manipulated through different levels in the software. Lower infill percentage can help you to save filament and print time.

How much time does it take to 3D print any object?

The time taken to print any object depends upon the size of the object and settings set for an object. A small object with less dimensions and infills can be printed in less than an hour. Objects with higher dimensions will take several hours to print.

A small object with less dimensions and infills can be printed in less than an hour. Objects with higher dimensions will take several hours to print.

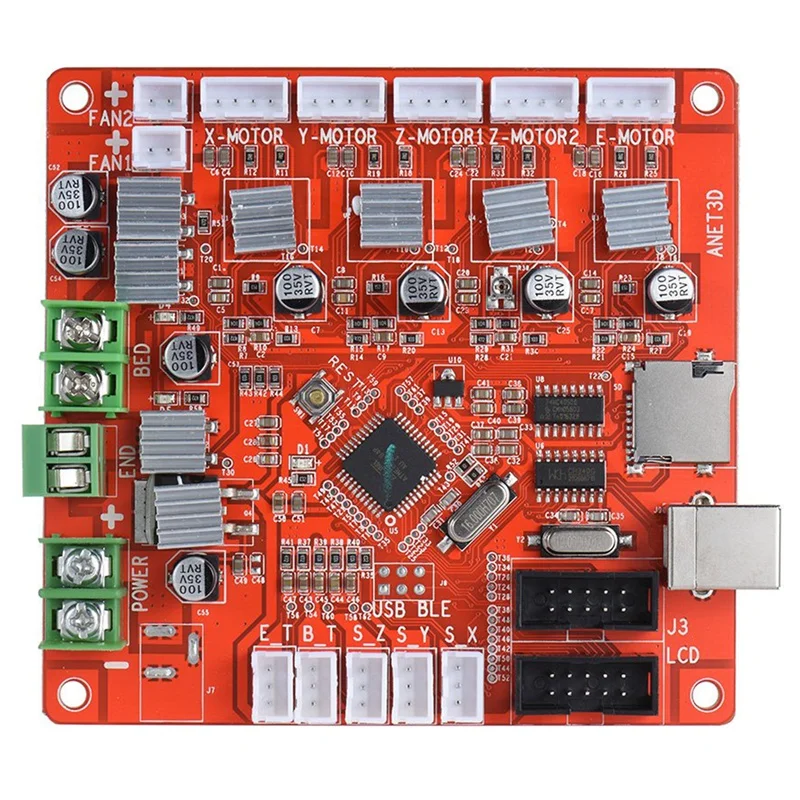

How Does 3D Printing Work?

Here a digital 3D image created on a computer then analyzed & which is divided into layers, as if sliced horizontally or vertically.

Then each slice is produced in succession on the 3D printer, gradually produce a whole object. There are many such alternative processes that can produce an object in this way also.

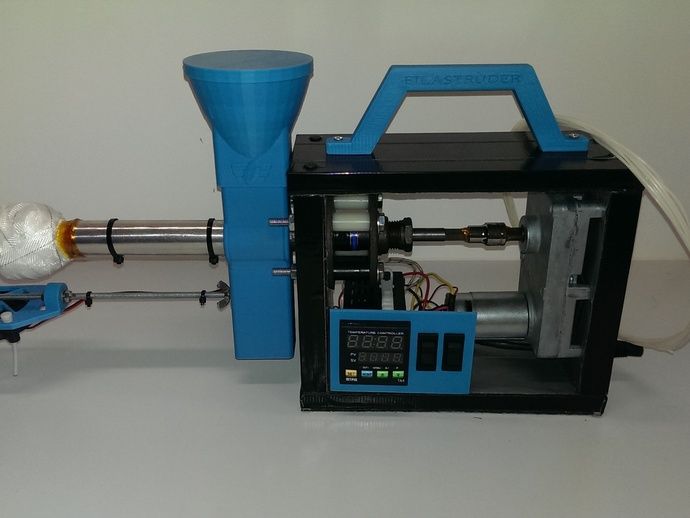

Which Materials Can Be 3D Printed?

ABS is made from petroleum & it is considered to be strong. We use certain experimental materials like mixing wood, metal or nylon particles into PLA plastic. We have certain new 3D printers offer higher temperature build chambers, here where more high-temp materials such as PEEK, ULTEM, PAEK can be used

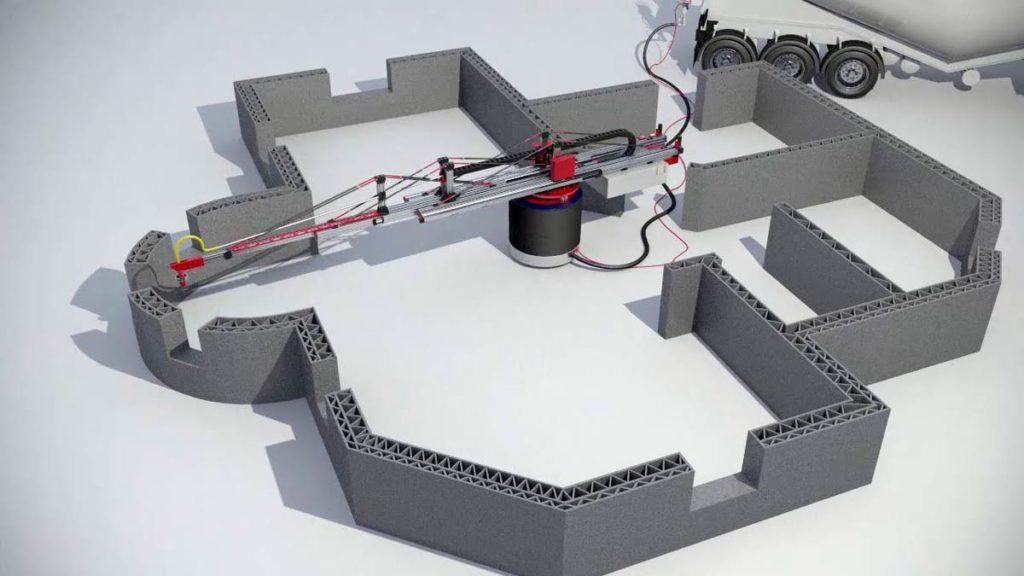

How Big An Object Can I 3D Print?

arge projects typically take a long time to complete, often hours or days. Actually it depends on the specific 3D printer you are using. Each one has a max build volume. Typical max size for desktop 3D printers: 150/300 mm P.S. (per side)

Actually it depends on the specific 3D printer you are using. Each one has a max build volume. Typical max size for desktop 3D printers: 150/300 mm P.S. (per side)

4D printing? Overcoming additive manufacturing with smart materials

4D printing? Breaking Additive Manufacturing with Smart Materials

While we're still trying to understand the possibilities and limitations of 3D printing and additive manufacturing, a new term has been added to our vocabulary. 4D printing is nothing but a digital manufacturing technology, 3D printing, which includes a new dimension: temporal. This means that the printed material, when it is ready, will be able to autonomously modify, transform or move due to its internal properties that respond to environmental stimuli.

This concept was popularized by researcher Skylar Tibbits, who coordinates the Massachusetts Institute of Technology (MIT) self-assembly lab in collaboration with Stratasys and Autodesk. The technology is still fairly new, but it is expected to be used in many areas, from construction, infrastructure, automotive and aeronautics, and even healthcare, in combination with bioprinting.

The technology is still fairly new, but it is expected to be used in many areas, from construction, infrastructure, automotive and aeronautics, and even healthcare, in combination with bioprinting.

4D printing is directly dependent on the materials used to create the object. So-called smart materials, as researcher Anna Ploszajski shows in this lecture, are solids that have a property—shape, size, or color—that change in response to external stimuli such as heat, light, moisture, pressure, or magnetism. simple due to its inherent material properties. In Anna's words: “Today's three-dimensional material world is made up of passive, inanimate materials such as brick, steel, and glass. The 4D structures are composed of active, animated, so-called "smart" materials that move autonomously—swell, contract or bend in response to a stimulus—in combination with passive materials. This allows them to move and change shape without the use of robotics, electronics or motors. ”

”

She gives the example of a pine cone as a natural intellectual material. It works through two layers of stiff fibers that run in different directions, allowing the cone to be opened or closed so that the seeds are released only when the time is favorable for germination in the soil (hot and dry). In high humidity, the bud stays closed, protecting the seeds. This is one example of how the desire to understand and replicate the complex natural processes of adaptability, resilience, and efficiency is what motivates material engineers. It is also the driving force behind biomimicry, in which 4D printing can materialize many of the ideas that the technology has yet to materialize.

The main goal of 4D printing is to program the material, making it react according to the parameters of the environment. But what can it be used for? In this talk, Skylar Tibbits shows some ongoing experiments in which objects, when heated or stimulated, bend in some way and take on other three-dimensional volumes. The researcher also mentions various other possibilities for 4D printing, such as in the field of infrastructure: for example, a drainage pipe that can contract or expand with the flow of water; or a sewer system that can transport waste through contractions and relaxations, similar to peristaltic bowel movements, that can traverse slopes of terrain.

Future applications can be seen in the construction and manufacturing or advanced materials industries, where parts can self-transform from raw materials to finished built-in structures without human intervention. This is truly a radical shift in our understanding of structures that have remained static and rigid up to this point (aerospace, automotive, construction, etc.) and will soon become dynamic, adaptable and customizable to work on demand. . 4D printing, enhanced by multi-material technology, could potentially revolutionize our ability to control and precisely program materials, from ideation to shape-shifting printing.

(Skylar Tibbits | Self Assembly Lab, MIT)

Serious research is already underway in the field of 4D printing of polymeric materials for tissue and organ regeneration or even bone reconstruction. The possibilities are endless and experiments can go much further. Imagine all that smart materials and 4D printing can bring to building envelopes by adapting to climate and responding to a wide variety of stimuli. Even though the technology is still in its infancy and concentrated in a few technology labs around the world, it looks like it has a promising future. When we seek to understand and imitate nature rather than master it, the results are often impressive. If history shows that it's not the strongest that survives, but the one that adapts best to change, 4D printing with smart materials seems to be worth considering.

.

Lathe Shri Ambica Industries Computer-aided lathe, lathe, business, metal, ahmedabad png

About this PNG

- Image size

- 1000x600px

- File size

- 543.09KB

- MIME type

- Image/png

resize PNG

width(px)

height(px)

License

Non-Commercial Use, DMCA Contact Us

- Metal lathe Lathe, Business, people, business, tool Shop png 500x500px 187.43KB

- Metal lathe Machine Turning Computer numerical control, machining parts, machine Shop, machining Parts, augers png 667x415px 292.76KB

- Metal lathe Spindle Electroerosive machining Milling, others, miscellaneous, machining, machining png 945x604px 638.36KB

- Augers Tool Computer numerical control Drill, others, miscellaneous, angle, text png 1200x1200px 16.99KB

- Metal lathe Leadscrew, others, quality, metal, lathe png 1200x1200px 962.55KB

- Metal lathe Milling machine Cylindrical grinder, lathe, forklift, industry, lathe png 1000x642px 565.

54KB

54KB - Car Computer Icons Auto Part, car, car, transport, streamline png 512x512px 17.4KB

- Computer numerical control Arizona Business CNC lathe, engineering, screw, business png 561x645px 351.13KB

- Chain Brass Manufacturing Hoist, service, technic, steel png 646x1902px 1.14MB

- Metal lathe Cylindrical grinder Machine Augers, others, metal, metal Lathe, machine png 1200x705px 735.78KB

- Machine tool Computer numerical control machine-Drehmaschine Machining CNC lathe, industry, cnc Machine Tool, augers png 800x600px 473.46KB

- Milling machine Computer CNC Machine tool Lathe, sale design, miscellaneous, angle, machine png 717x902px 694.81KB

- Machine tool Milling Grinding machine Cutting tool, machine border, miscellaneous, angle, machine Tool png 500x930px 384.72KB

- Nut bolt Bolt Motorcycle Flange Screw, Loose buckle nuts, nuts, steel, auto Part png 1099x1039px 1MB

- Crown, crown, gold, sticker, crown png 600x600px 193.72KB

- Metal lathe Metalworking Machining, cnc, quality, metal, lathe png 1024x1024px 218.37KB

- Fastener Nut Bolt Stainless steel, thread fastener, screw, steel, metal png 640x480px 269.

64KB

64KB - CNC milling machine CNC milling machine Industrial Engineering, angle, text, rectangle png 1200x1200px 10.49KB

- Milling machine Lathe Drilling machine, cutting machine, miscellaneous, company, machine png 888x1280px 952.62KB

- CNC machine CNC milling machine, cnc, steel, wood, cnc Machine png 850x495px 103.7KB

- Supply chain Risk management Business, chains, technic, steel, business png 756x510px 201.6KB

- Machine tool CNC milling machine Computer numerical control, milling machine, service, engraving, milling Machine png 800x533px 333.

51KB

51KB - Car Timing belt Spare part, engine, service, vehicle, transport png 2000x1318px 1.1MB

- Angle grinder Makita Grinding machine Tool Die grinder, cut-off machine, angle, grinder, random Orbital Sander png 1487x800px 1.37MB

- Computer numerical control Computer Icons CNC milling machine Machine Milling, others, angle, text, logo png 540x540px 5.81KB

- gray industrial gears illustration, Mechanical engineering Gear Mechanical system, industry, miscellaneous, mechanical Engineering, industry png 1000x1000px 433.59KB

- CNC router Computer numerical control CNC router Milling machine, wood, business, wood, cnc Machine png 865x689px 621.

6KB

6KB - Door handle Lock Window, stainless steel door, angle, furniture, toilet png 500x500px 52.68KB

- multiple gears, Used car Spare part Automobile, car parts, recycling, car, car Repair Shop png 1382x922px 961.28KB

- Piping & fitting Plumbing pipework Chlorinated polyvinyl chloride, others, steel, metal, plumbing png 600x500px 314.77KB

- Key frame Antique Photosearch, key, vintage Clothing, material, metal png 2443x2793px 2.65MB

- Metal lathe Toolroom Spindle, lathe, metal, tool, lathe png 1000x527px 419.24KB

- Skeleton key Lock, key, auto Part, metal, objects png 1150x1375px 616.36KB

- CNC lathe Machine tool manufacturing Turret lathe, automatic lathe, business, industry, metal png 602x439px 310.81KB

- Car Kia Motors Kia Sportage Spare part Auto mechanic, auto parts, angle, car, vehicle png 700x394px 272.32KB

- Metal lathe Milling machine 3D printing, wood, computer, wood, metal png 800x800px 398.8KB

- Augers drills Tool Machine Computer Icons, others, logo, drill, drill png 512x512px 3.76KB

- Metal lathe Manufacturing Machine Computer numerical control, lathe, india, business, lathe png 907x605px 282.

18KB

18KB - Metal lathe Computer numerical control Machine tool, cnc machine, metal, industry, lathe png 1280x822px 680.56KB

- Machine tool Laser cutting Manufacturing, cnc, industry, cnc, lathe png 864x939px 813.68KB

- Milling machine Computer numerical control Industry, mill, industry, mill, machine png 1641x1500px 1.09MB

- Gear, metal gear, miscellaneous, angle, metal png 1000x658px 871.25KB

- Car alternator Starter Truck Ignition system, car, truck, car, transport png 600x600px 405.7KB

- Machine tool Lathe Milling lathe, others, cnc, manufacturing, lathe png 630x472px 151.86KB

- CNC lathe Yamazaki Mazak Corporation CNC lathe, industry, machine Shop, cnc Machine png 800x600px 371.6KB

- gray and brass gear, Car Manual transmission Gearbox Automatic transmission, auto parts, driving, automobile Repair Shop, transport png 1280x800px 803.2KB

- Yamazaki Mazak Corporation Screw-cutting lathe, cnc machine, industry, cnc Lathe, lathe png 800x600px 591.88KB

- Toyota Land Cruiser Prado Car Toyota Hilux Engine, car, transport, auto Part, metal png 1500x1706px 2.06MB

- Learn more