Creality 3d print mill kickstarter

Creality launches its 3DPrintMill (CR-30) conveyor belt 3D printer on Kickstarter - technical specifications and pricing

0Shares

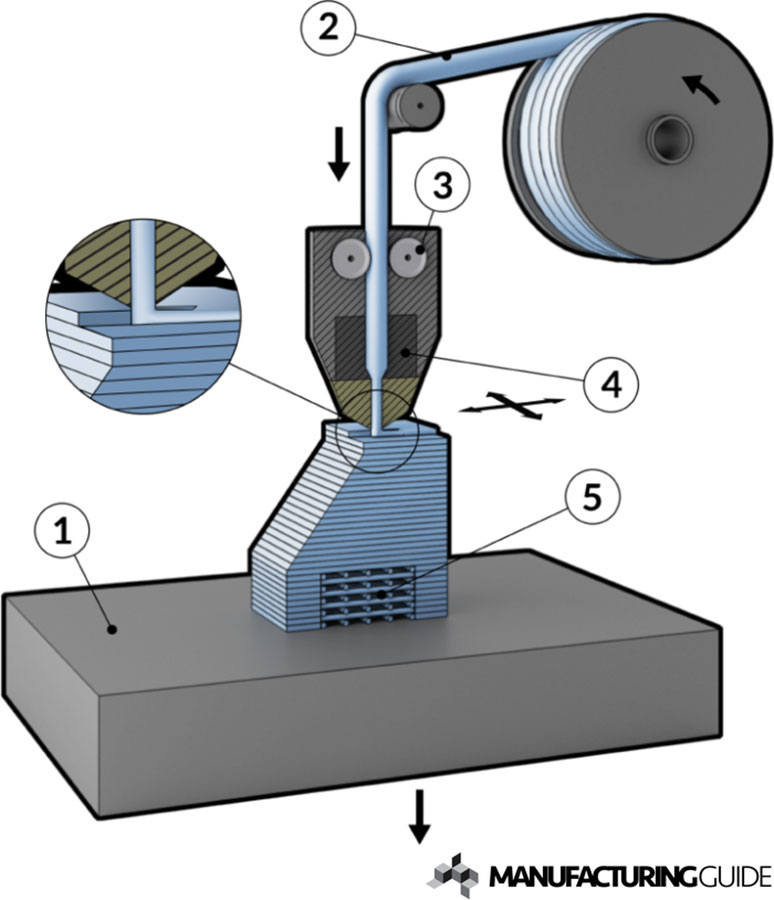

Chinese 3D printer manufacturer Creality has launched a Kickstarter campaign for its latest FDM system, the CR-30.

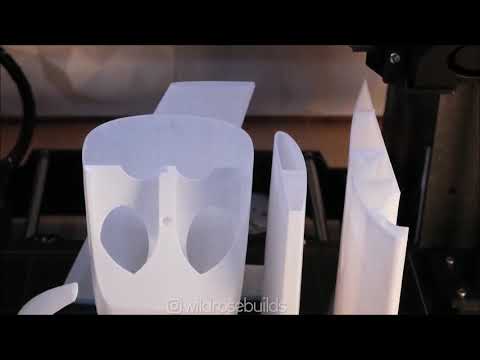

Also dubbed the 3DPrintMill, the conveyor belt-based machine was developed in collaboration with tech YouTuber Naomi Wu, and has already surpassed $1M in crowdfunding. Seeing as the CR-30 operates on a belt, it features a build volume of 200 x 170 x (theoretically) infinite millimeters. As such, it’s primarily aimed at designers, SMEs, and anyone else looking to replace their print farms with a hands-free continuous printing engine.

The Creality CR-30 3D printer. Photo via Creality.The 3DPrintMill / CR-30

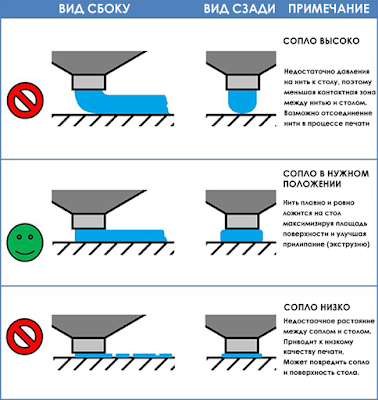

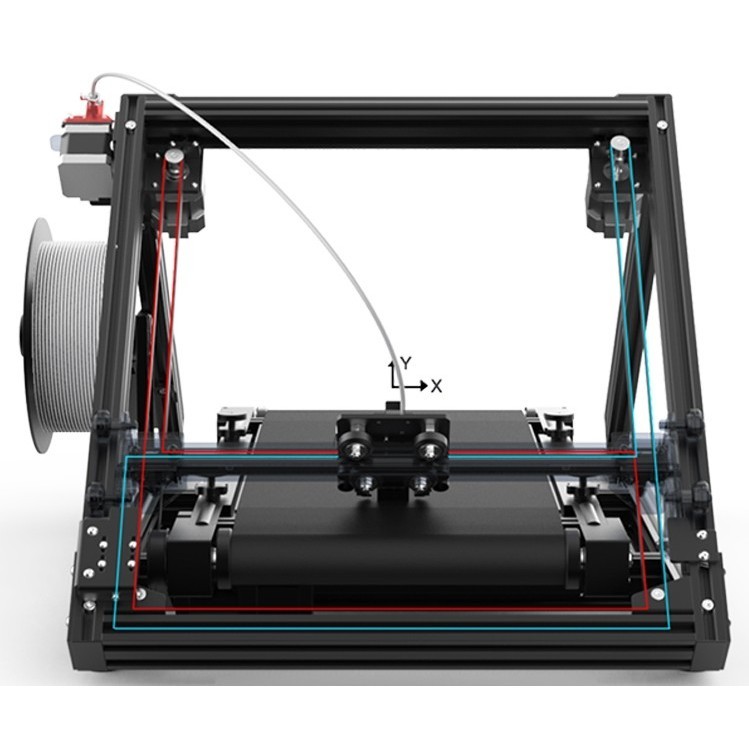

Creality’s latest machine comes packaged in four separate parts – the base, front, rear, and control panel. Using the allen keys and tools included with the printer, it should only take around half an hour to assemble the whole thing into a usable piece of kit. The all-metal frame weighs 16.5kg, and is designed to dampen any and all vibrations from the Core-XY motion gantry. The hotend sits at 45º and has a maximum temperature of 240ºC, with claims that it can print with materials such as TPU and PETG. The company has also stated that it plans to launch an optional direct drive extruder conversion kit in the near future.

The Z-axis conveyor belt is made of nylon, and is expected to last several years before needing a replacement. Extra belts can be purchased for $45 and swapped out in around ten minutes. Looking underneath the belt, there is a 220W aluminum print bed capable of a maximum temperature of 100ºC, which should provide ample adhesion for the polymer parts above. The bed assembly as a whole can be releveled using a series of top-mounted knobs lining the outer edges of the conveyor belt.

Internally, the CR-30 packs an “ultra-quiet” 32-bit motherboard. Connectivity options comprise a USB slot and SD card reader, and the machine even has a smart filament detector with print resume functionality. In situations where the power cuts off or the filament spool runs dry, the system will pause the print until it’s safe to resume from where it left off.

In situations where the power cuts off or the filament spool runs dry, the system will pause the print until it’s safe to resume from where it left off.

The CrealityBelt slicer

Naturally, Creality is also offering a brand new slicing software designed specifically for the CR-30. CrealityBelt can be used to slice a model of any length, but it can also slice multiple models in a line for a series build. Included in the program is a set of ready-made slicing profiles developed by slicer expert Tom Jackson (aka FilamentFrenzy), who is well-known in the open-source community.

To complement the slicer, Creality also enlisted Scott Lahteine, the maintainer of the Open Source Marlin project, to code the firmware for the CR-30. In true open-source fashion, the firmware is compliant with the GPL and is accessible to any users that may want to tinker around with it.

Hands-free batch 3D printing on the CR-30. GIF via Creality.

GIF via Creality.Technical specifications and pricing

Below are the technical specifications for the Creality 3DPrintMill / CR-30. Pledges for the machine begin at a discounted rate of $538. The Kickstarter campaign will continue to run until December 18, after which the system will retail at $999. Deliveries are expected to commence in May 2021.

| Build volume | 200 x 170 x infinite mm |

| Machine dimensions | 535 x 656 x 410 mm |

| Max. nozzle temperature | 240°C |

| Max. bed temperature | 100°C |

| Weight | 16.5 kg |

| Nozzle diameter | 0.4 mm |

| Layer thickness | 0.1 – 0.4 mm |

| File transfer | USB/SD |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Creality CR-30 3D printer. Photo via Creality.

Tags 3DPrintMill CR-30 Creality Kickstarter naomi wu Scott Lahteine Tom Jackson

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Creality's CR-30 Launch Succeeds, But Fails To Reach Open Source Milestone « Fabbaloo

By Kerry Stevenson on December 18th, 2020 in printer

Tags: 3dprintmill, belt, creality, kickstarter, open source

The Creality 3D-30 belt 3D printer [Source: Naomi Wu]Creality’s second Kickstarter campaign ended earlier today and there’s good news and bad news.

The campaign was unusual as Creality is by no means a startup company, the typical user of a Kickstarter campaign. In fact, Creality is one of the largest producers of 3D printers worldwide, making apparently tens of thousands of machines each month.

Why do a Kickstarter? Creality experimented with one earlier this year when they launched the CR-6 SE. It was perhaps a different way for the Asian company to gain some coverage and exposure in the West, which is often quite challenging for companies in China. The strategy worked, as the launch brought in over 10,000 orders and well over US$4M.

With that success in mind, the company chose to use Kickstarter again to launch another 3D printer, and one that is quite unusual. The CR-30, a.k.a. 3DPrintMill, is a belt 3D printer. It’s capable of 3D printing very long objects or printing continuously without the need for human intervention, print after print.

I believe this form of 3D printing could eventually become quite popular, but at this time it’s a very strange concept for many existing 3D printer operators.

CR-30 Kickstarter

Did the 3DPrintMill Kickstarter succeed?

Sort of.

The company set a rather modest goal of around US$12,000, and that level was easily passed within the first few minutes of the campaign opening. Over the next weeks, the campaign collected well over 2,000 orders for the belt 3D printer, raising near US$1.4M.

It would seem to be a success, as early reviews of the unusual device are mostly quite positive. I’m hoping to test one myself in the future in our lab. It’s likely CR-30 sales will continue to grow well after the campaign ends as an increasing number of 3D printer operators gain an understanding of belt 3D printing.

But there’s one element that didn’t quite make it.

Naomi W with the Creality 3D-30 belt 3D printer [Source: Naomi Wu]Creality Promoter Naomi Wu arm-twisted Creality management into a highly unusual commitment: if the Kickstarter were to hit US$5M, they would open source the CR-30 design.

The US$5M target likely did not seem unreasonable, given the success and funding level obtained on the previous CR-6 SE launch. However, the sales fell far short of that goal. Why? It’s likely a combination of several factors, including a higher price than the inexpensive CR-6 SE, Internet trolling and misunderstandings of the belt 3D printing concept.

However, the sales fell far short of that goal. Why? It’s likely a combination of several factors, including a higher price than the inexpensive CR-6 SE, Internet trolling and misunderstandings of the belt 3D printing concept.

As a result, it appears Creality will not be open sourcing the CR-30 belt 3D printer design.

Belt 3D Printing Futures

That’s a blow to the belt 3D printing concept, as a proven open source design would have led to many innovative belt 3D printer designs. It could have kicked forward the concept far more rapidly.

However, it seems that Creality ran into the same problem that so many other 3D printer companies do: users don’t yet understand what to do with the technology. Stratasys spent years explaining to the aerospace industry how to make 3D printable panels, and others worked with engine manufacturers to get their heads around metal 3D printing. It seems that same type of effort must be done for belt 3D printing.

Fortunately, there are now a few belt 3D printer options available on the market, including Creality’s, and their presence will slowly expose the concept to others.

I believe that eventually belt 3D printing will be much more popular than it is today. It’s just that it will now take a bit longer.

By Kerry Stevenson

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Naomi Wu Interview on Creality 3DPrintMill 3D Printer

Supermaker Naomi Wu answered our questions about the upcoming Creality 3D Printer thirty.

Shenzhen-based Naomi is well known in the 3D printing community for her efforts to promote the achievements of manufacturers as well as creating some interesting designs. One of them, the T-beam impact-resistant TTGO case, was our project of the week a few months ago. nine0007

nine0007

The project she is currently working on is the upcoming Creality CR-30 or 3DPrintMill 3D Printer. This unusual 3D printer prints at an angle on a moving conveyor belt to enable continuous 3D printing or the production of objects larger than the size of the 3D printer itself. In this video, Naomi introduces the device:

We asked a few questions to learn more about the project and what we can expect when it is released. nine0007

Fabbaloo : Can you tell us how this project started and how you got involved? What is your relationship with Creality and White Knight/NAK 3D?

Naomi Wu : “I learned about Infinite-Z printers around 2016 when Bill Steele showed off his designs. I immediately saw the potential, but at that moment both the creation and the purchase were beyond my means. In 2018, I arranged for Bill to meet the founders of Creality here in Shenzhen to develop a custom infinite Z-axis 3D printer for them. It was a friendly and productive meeting, but the Creality bosses had not yet seen the market for tape printers. Bill, fortunately, was very kind and we kept in touch. In the end, the founders of Creality agreed to dedicate some internal resources and development time to a project under my control. In 2019Carl Braun aka Nax3D made his White Knight and I talked to him but since he was selling kits I decided as a matter of courtesy not to use his open source design and instead continue to develop an independent design, though of course based on his ideas. We kept in touch and when I finally had something pretty close to going to market, Carl agreed to act as a paid consultant and really took it to the next level.

It was a friendly and productive meeting, but the Creality bosses had not yet seen the market for tape printers. Bill, fortunately, was very kind and we kept in touch. In the end, the founders of Creality agreed to dedicate some internal resources and development time to a project under my control. In 2019Carl Braun aka Nax3D made his White Knight and I talked to him but since he was selling kits I decided as a matter of courtesy not to use his open source design and instead continue to develop an independent design, though of course based on his ideas. We kept in touch and when I finally had something pretty close to going to market, Carl agreed to act as a paid consultant and really took it to the next level.

For those of us who have been here for a while, the way previous open source 3D printer projects were brought to market in China... among other things, it was just disrespectful to the people who created these projects: by companies that took credit for "reinventing" the standard Prusa and Replicator clones. Yes, you can copy, but there is a correct way to do it. It was bad and I never liked it and you have to bite your tongue when the community complains about it because they are right. I waited for years to prove that it was unwise and not good to do so, that it was short-sighted. So far with 3DPrintMill that has been true and I owe a lot to Carl and Bill for letting me show some people here that if you do it right, play by the rules, the community will support you.” nine0007

Yes, you can copy, but there is a correct way to do it. It was bad and I never liked it and you have to bite your tongue when the community complains about it because they are right. I waited for years to prove that it was unwise and not good to do so, that it was short-sighted. So far with 3DPrintMill that has been true and I owe a lot to Carl and Bill for letting me show some people here that if you do it right, play by the rules, the community will support you.” nine0007

Fabbaloo : Is this a CR-30 or a 3DPrintMill? Or are they different things?

Naomi Wu : “Creality model number is CR-30, product name is 3DPrintMill. It's really meant for small-scale production, so I needed a name that would resemble it: sawmill, rolling mill, etc. But at the same time, it's a treadmill game because of the belt."

Fabbaloo : I first used a belt driven 3D printer in 2010 with MakerBot's "Automated Build Platform". Although the device was a little unstable, the ability to 3D print a continuous stream of objects seemed very powerful. Today, I still see skepticism about the tape concept from many people. Why do you think there was no interest in this concept? What do people not understand?

Although the device was a little unstable, the ability to 3D print a continuous stream of objects seemed very powerful. Today, I still see skepticism about the tape concept from many people. Why do you think there was no interest in this concept? What do people not understand?

Naomi Wu : “Lack of interest is news to me, my inbox is full of requests for pre-samples. From most of my discussions, I've always been worried about the ABP patent, which is now owned by Stratasys. Infinite-Z doesn't break that, but people are still worried about objections from such a big player and don't want to take the risk.

The interest was huge, and frankly, a little skepticism is great. I'm not trying to sell it to people who don't need it and convince them they need it. There won't be a single bearded hipster video on Kickstarter with a MacBook and ukulele music in the background. That's not who it's aimed at. People who need 3DPrintMill know exactly why they need it as soon as they see how it works. It's like a Bridgeport milling machine or a high-end gaming computer. People who look at them and ask "What is this for?" probably shouldn't buy them. nine0007

It's like a Bridgeport milling machine or a high-end gaming computer. People who look at them and ask "What is this for?" probably shouldn't buy them. nine0007

This is not for little figures, not the best first printer for kids. I was really targeting people or companies that print long objects such as cosplay and prop makers, sign makers, molding restorers and other long decorative items, but mostly those who need to make 10-1000 items - small scale production, Etsy and eBay stores, local machine shops as a cheaper alternative to CNC to offer to customers, people printing PPE and daily necessities, all that sort of thing. nine0007

It has the potential to be fantastic for education when we can line up the prints, this means little hands can get their part after they fall into the bin without touching the hot parts to tear them off heated base. But 3DPrintMill is not intended to replace traditional FDM 3D printers, and a little reality check is a good thing. If you're a pocket-saving teenager, for God's sake, buy an Ender-3 as your first $200 printer, not this thing. " nine0007

" nine0007

Fabbaloo : The main problem with the MakerBot ABP was the tape itself, which after repeated heating could warp, becoming an uneven surface for subsequent prints. How has belt technology changed? How durable can a belt be over the long term? Will it be consumable?

Naomi Wu : “I think the first impression was that special belts were needed. I think the reality is that it took a larger belt ecosystem to find the right belt. When Charles Pax created ABP, he had at best what McMaster-Carr had to work with. And whatever relatively small assortment of conveyor belts they had, nothing worked, not in paper, Kapton, or other materials he tried to make his own out of. The straps they tried warped from the print or fell apart, so it was decided that more exotic straps were needed. nine0007

The fact is that problems such as twisting, stretching, heat resistance are actually not all that unusual in a production environment. Here in Shenzhen, we have had no problem ordering dozens of different belts from local suppliers, designed in different materials to solve exactly these problems. So while I'd like to tell you that the belt is Creality's "secret sauce" or some ridiculous startup crap, it really isn't. There are well-established, proven materials that do exactly what we need really well and do it industrially for thousands of hours in much more severe conditions. Exactly how many hours remains to be seen, but far more than either Carl or I managed to put in even if we were typing 24/7 for weeks at a time.” nine0007

Here in Shenzhen, we have had no problem ordering dozens of different belts from local suppliers, designed in different materials to solve exactly these problems. So while I'd like to tell you that the belt is Creality's "secret sauce" or some ridiculous startup crap, it really isn't. There are well-established, proven materials that do exactly what we need really well and do it industrially for thousands of hours in much more severe conditions. Exactly how many hours remains to be seen, but far more than either Carl or I managed to put in even if we were typing 24/7 for weeks at a time.” nine0007

Fabbaloo : Obviously modified versions of the current cutting software must be used to prepare a 3D print job for 3D tape printers, and this has been known to work. But how do you think tape printer slicing software will evolve? For example, do we want to randomize the location of a repeating print on the tape to avoid wear, or do we want to automatically generate serial numbers to keep track of the prints that go into the collection container? What other slicing features on a tape printer do you see in the future? nine0007

Naomi Wu : “Well, BlackBelt3D has been a huge contributor to the development of BlackBelt Cura and deserves a lot of credit for that. Bill Steele has a post processor to convert the standard GCODE to infinite Z, but it's nowhere near as perfect. Bringing software and firmware up to an acceptable standard in China is difficult, but now I have the opportunity to hire foreign consultants in Creality, such as Carl Brown and Scott Lachtein - now the lead developer of Marlin. It worked well for them, so I think they will expand it. Therefore, I am confident that software improvements will be done properly, even if we cannot do it ourselves. What features will be added - it will be community feedback."

Bill Steele has a post processor to convert the standard GCODE to infinite Z, but it's nowhere near as perfect. Bringing software and firmware up to an acceptable standard in China is difficult, but now I have the opportunity to hire foreign consultants in Creality, such as Carl Brown and Scott Lachtein - now the lead developer of Marlin. It worked well for them, so I think they will expand it. Therefore, I am confident that software improvements will be done properly, even if we cannot do it ourselves. What features will be added - it will be community feedback."

Fabbaloo : What was the most difficult technical challenge when creating 3DPrintMill? What advice would you give to others intending to develop a belt 3D printer?

Naomi Wu : “I think Carl, Nak3D, really solved the biggest problem when he proved that there is not a single insurmountable problem that stands in the way of inexpensive infinite Z printers. Of course, belts are the source of the problem but his steel belt works great. 3DPrintMill is not a revolution, it's just an iterative thing. I did not try to invent something completely new - we are not very good at it. I did what they knew in the Chinese factory, and a big team of engineers could do really well: make it cheaper, more reliable, and start mass production. The plan is for 3DPrintMill to be open source, if you want to make a belt printer these design files are a great place to start and I'm really looking forward to seeing what people come up with." nine0007

Of course, belts are the source of the problem but his steel belt works great. 3DPrintMill is not a revolution, it's just an iterative thing. I did not try to invent something completely new - we are not very good at it. I did what they knew in the Chinese factory, and a big team of engineers could do really well: make it cheaper, more reliable, and start mass production. The plan is for 3DPrintMill to be open source, if you want to make a belt printer these design files are a great place to start and I'm really looking forward to seeing what people come up with." nine0007

Fabbaloo : Complex 3D printing is much easier if you can use a soluble support material, but it requires the ability to use multiple materials. Do you think it is possible to implement multi-material capabilities on the 3DPrintMill or future versions of the 3D printer? What is the best way to do this?

Naomi Wu : “Multiple printheads is definitely the next step. It won't be a big deal, but definitely something for the 'professional' version of the printer once this one is released and we get more feedback from users." nine0007

It won't be a big deal, but definitely something for the 'professional' version of the printer once this one is released and we get more feedback from users." nine0007

Fabbaloo : While I'm sure 3DPrintMill will be of interest to hobbyists, what features will 3DPrintMill and its software bring to the attention of small manufacturers? What will make the device attractive for business?

Naomi Wu : “Automatic printing. The old knock off base trick is cute, but it's time consuming in the real world to set up because each shape of the piece fits the base slightly differently, so it's not a standard practice written into firmware or software slicing. Tray robots work, but they cost as much as the annual salary of two employees. Tape printers - you just put a basket in front of it and the parts pile up. The real key feature we need to implement there is the ability to have one GCODE file of an object on the map and choose in the machine interface how many copies you want. At the moment this is still done in the slicer and is not optimal.” nine0007

At the moment this is still done in the slicer and is not optimal.” nine0007

Fabbaloo : I'm sure you can't be specific, but can you give us a hint when we might see this amazing device available for purchase?

Naomi Wu : “Aiming for November.”

Top 3D Shop home nine0007 Blog December 29, 2022 23 FlashForge Focus 8.9 3D printer review Read the review of the FlashForge Focus 8.9 photopolymer 3D printer, a portable 4K 3D printer for digital dentistry, about its specifications, features and capabilities. Read more December 29, 2022 18 Review of the Creatbot Peek 300 3D printer Read the review of the Creatbot Peek 300 3D printer, an industrial machine for 3D printing with refractory engineering superplastics. Read more December 29, 2022 26 Review of 3D printers TotalZ AnyForm LPRO Read the review of 3D printers TotalZ AnyForm LPRO series - about the features of the series, the characteristics of the devices produced within its framework and their capabilities. Read more December 26, 2022 40 Formlabs Fuse 1+ 30W 30W 3D Printer Review Read about the new Formlabs Fuse 1+ 3D SLS 3D printer, its features, specifications and capabilities. Read more December 26, 2022 53 Overview of Raise3D Pro3 and Pro3 Plus 3D printers Read about the Raise3D Pro3 and Pro3 Plus FFF 3D printers, their configuration, design, capabilities and features. Read more December 20, 2022 75 Overview: 3D printing with pellets and its applications Read about direct 3D printing with pellets - plastic granules, the advantages of such printing, the equipment and materials used, its areas of application, pros and cons. Read more December 02, 2022 394 Review: Flashforge Guider 3 3D Printer Read about the Flashforge Guider 3 3D printer, its design, features, packaging and state-of-the-art solutions for high-quality 3D printing. Read more December 02, 2022 600 Review: Flashforge Guider 3 Plus 3D Printer Read about the Flashforge Guider 3 Plus 3D printer, its features, design, package and know-how. Read more December 02, 2022 642 Review of the Flashforge Creator 4 3D printer Read the review of the Flashforge Creator 4 professional 3D printer - about its device, specifications, package and features. Read more December 02, 2022 398 Review: Flashforge Waxjet 400 and 410 Wax 3D Printers Read about the Flashforge Waxjet 400 and Flashforge Waxjet 410 wax 3D printers, high performance industrial wax printers for metal casting, for industry, jewelry and medicine. Read more December 02, 2022 97 Review: Flashforge Filament Drying Station Read about the Flashforge Filament Drying Station, which improves the quality and stability of 3D printing, its features and characteristics. Read more November 21, 2022 444 3D printing of car parts: everything you need to know Read about examples of how 3D printers are used in 3D printing of car parts Read more November 21, 2022 140 WASP 3D Printer Application Case Review Read about WASP 3D printer application cases in industry, design and engineering. nine0007 Read more November 17, 2022 222 Shining 3D 3D scanners are registered in the register of measuring instruments of the Russian Federation Top 3D Group, the official distributor of Shining 3D industrial 3D scanners, notifies all its customers that Shining 3D laser mask 3D scanners are approved by the Federal Agency for Technical Regulation and Metrology as Measuring instruments of the Russian Federation.

nine0007

nine0007  nine0007

nine0007  nine0007

nine0007