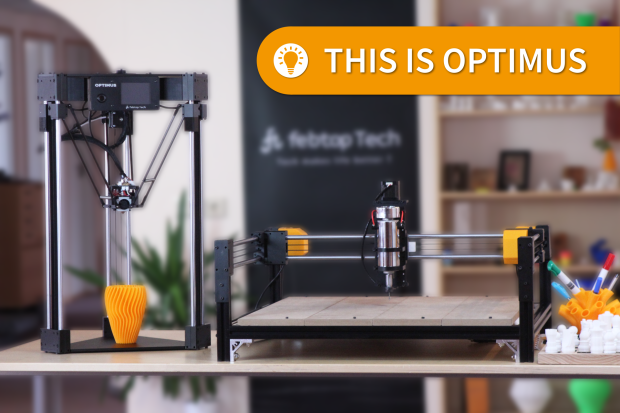

Combination cnc machine and 3d printer

The 5 Best 3 in 1 3D Printers 2022 (with Laser Engraving & CNC!)

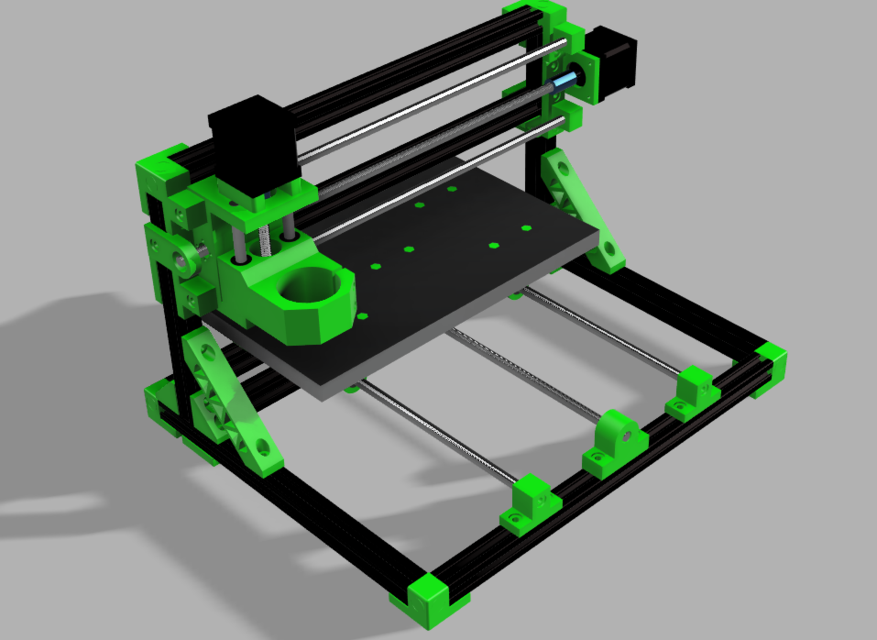

Ideally, we would all own one machine that could complete every manufacturing task required – a 3D laser printer that printed, laser cut, CNC carved, and more. While not quite there yet, 3 in 1 3D printers offer jack-of-all-trades versatility across 3D printing, CNC machining, and laser engraving – to various levels.

These printers, sometimes called multifunction 3D printers or AIO 3D printers, feature removable tool heads that can be switched out to change their function. If you want to create a prototype and want to carve a wood model first, use the CNC machine, and then switch back to the 3D printer extruder to create the final plastic prototype.

Top 3-in-1 Pick For 3D Printing, CNC & Laser Cutting

Snapmaker 2.0 Modular 3 in 1 3D Printer A350T/A250T

$1169 ($600 off!)

Switch the toolheads within minutes to 3D print, CNC cut, and laser cut and engrave in one machine. You can even buy the higher-power 10W laser attachment, a 4-axis rotary add-on for cutting or engraving round objects, and more!

Snapmaker here

We earn a commission if you make a purchase, at no additional cost to you.

Having tested dozens of 3D printers over the years, including our top pick, the Snapmaker 2.0, we’ve collated our findings into our top recommendations for 3-in-1 3D printers to help you make the best choice for you.

| Name and brand | Type of printer | Build volume (mm) | Price | Available at: |

|---|---|---|---|---|

| Snapmaker 2.0 | 3 in 1 3D printer | Varies by model | $1,199-$1,799 | Snapmaker here |

| Snapmaker Original | 3 in 1 3D printer | 125 x 125 x 125 | $450 | Snapmaker here |

| ZMorph Fab | 4 in 1 3D printer | 250 x 235 x 165 | $4,000 | Amazon here |

| Creality CP-01 | 3 in 1 3D printer | 200 x 200 x 200 | $819 | Amazon here |

| Ecubmaker TOYDIY | 4 in 1 3D printer | 180 x 180 x 180 | $549 | Amazon here |

| 5axismaker | CNC mill 3D printer | Varies by model | £5,500 / £6,800 | |

| Diabase H-Series | 3D printer CNC hybrid | Depends on number of axes | $9,750+ |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

How good are all in 1 3D printers?

Naturally, focusing on being good enough at everything means some quality is lost in some areas. Elites athletes could not compete at the top of the NBA, NFL, and NHL simultaneously – even Michael Jordan couldn’t crack baseball – and the same is true for less specialized all in 1 3D printers.

That doesn’t mean that the 3D printer and laser engraver hybrids we recommend don’t perform well. For hobbyist projects, 3D laser printers are great – but we do not recommend starting a full-service manufacturing company after buying a desktop 3D printer laser engraver CNC mill machine.

The criteria we used to judge the best 3 in 1 3D printers

In rating the 3 in 1 3D printers we recommend below, we compared:

- 3D printer quality: most of these 3 in one 3D printers are made by 3D printer companies and are mostly focused on additive manufacturing.

Therefore, the 3D printer’s quality is key.

Therefore, the 3D printer’s quality is key. - CNC mill power: some CNC machines cannot fully mill, but just engrave. More powerful CNC machines spin faster, can carve tougher materials, and work more accurately and for longer.

- Laser engraver power: as with the CNC machine, some all in 1 laser engraver 3D printers can only engrave, whereas others can cut through materials.

- How easy is it to change the tool heads: it’s all well and good having powerful tool heads that work perfectly, but if they’re too difficult or delicate to switch out, they may as well only have one function.

- Effectiveness of software: most of our recommendations feature specialized software that can slice models for 3D printing, and prepare CNC and laser projects. The best software is easy to use, yet effective and reliable across every function.

The Best All in 1 3D printers

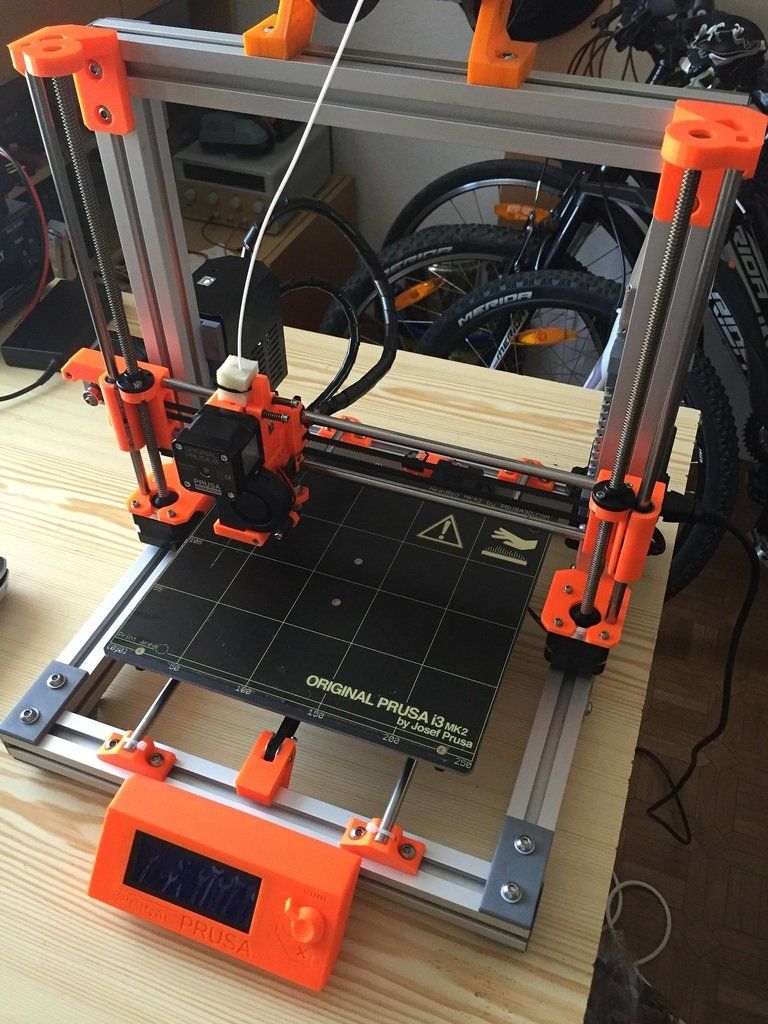

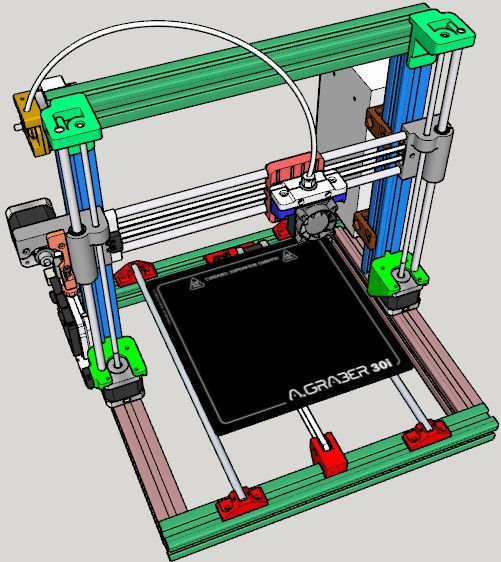

Snapmaker 2.0 – comes in 3 forms: A150, A250 & A350

- Price: $1,199 to $1,799 — Best price on Snapmaker Store here / Available on Amazon here

- Build volumes: A150 = 160 x 160 x 145 mm / A250 = 230 x 250 x 235 mm / A350 = 320 x 350 x 350 mm

- Type: 3D in 1 3D printer: 3D printing, CNC and laser engraving

The Snapmaker Original already made waves when it raised over $2. 2M on Kickstarter, but the Snapmaker 2.0 completely obliterated that by becoming the most funded technology project in the history of Kickstarter, raising an astonishing $7.85M. Thousands of elated fans who loved the Snapmaker Original came back to support the new version, and it has remained the most popular all in 1 3D printer since its full release.

2M on Kickstarter, but the Snapmaker 2.0 completely obliterated that by becoming the most funded technology project in the history of Kickstarter, raising an astonishing $7.85M. Thousands of elated fans who loved the Snapmaker Original came back to support the new version, and it has remained the most popular all in 1 3D printer since its full release.

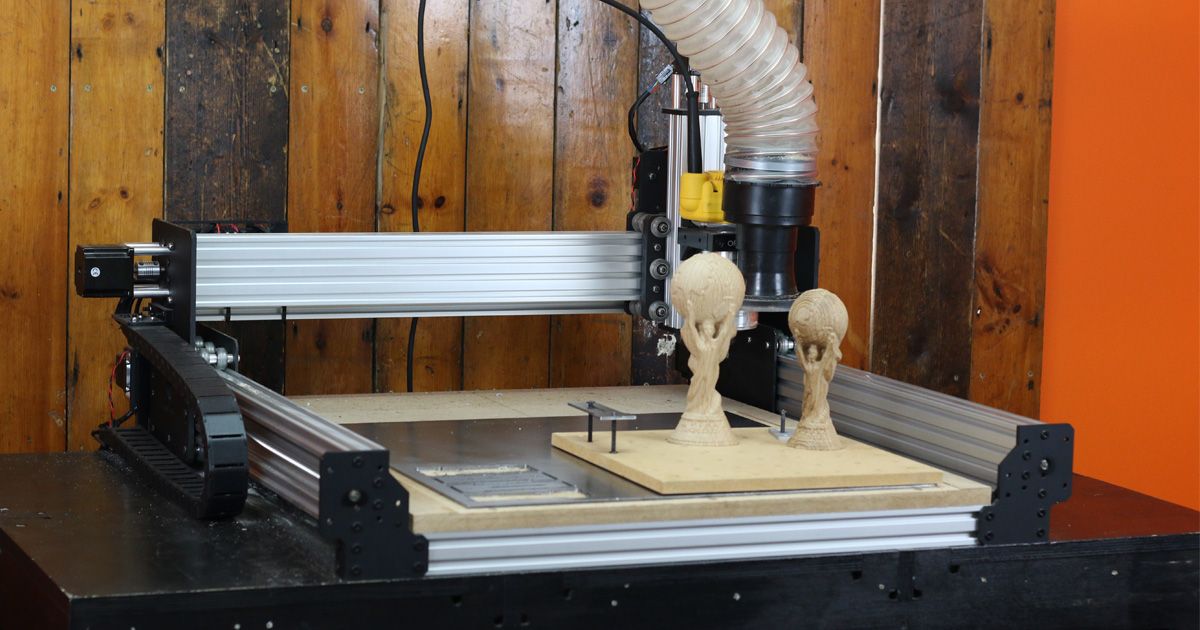

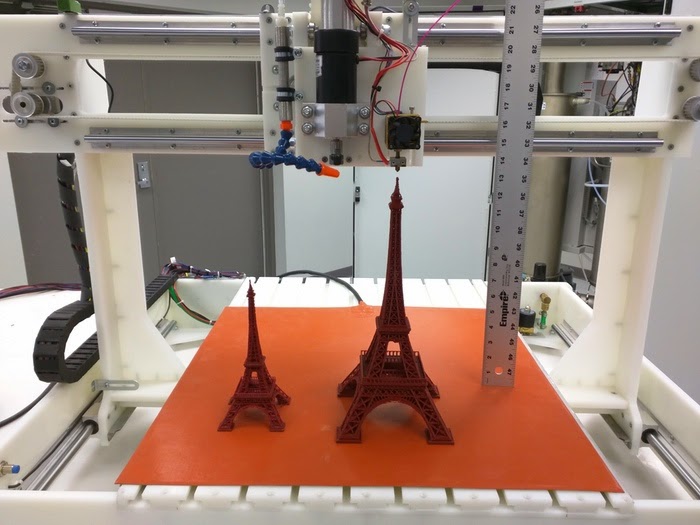

We have tested and reviewed the Snapmaker 2.0, and waxed lyrical about how great it was. It is undoubtedly the best 3-in-1 3D printer around, offering a fantastic 3D printing experience, as well as a great CNC carving and laser option. Arguably you could even call it a 4-in-1 3D printer, as you can also buy the 4-axis rotary module add-on which turns the laser and CNC toolheads into 360-degree, 4-axis versions. We carved cylindrical chess pieces, engraved cylinder gift boxes, and more with this add-on.Using the 4-axis rotary module to CNC carve a lion.

The 3D printer can print PLA, ABS and flexible filaments like TPU, and with WiFi connectivity as well as a USB port you can print remotely online, or offline using a USB. The portable and movable touchscreen used to operate the printer looks and acts like a smartphone, simplifying your workflow and making it easy to control and manage projects.

The portable and movable touchscreen used to operate the printer looks and acts like a smartphone, simplifying your workflow and making it easy to control and manage projects.

Moreover, the filament run out detector automatically pauses your print when you run out, giving you time to load more filament and resume without ruining your print, and if you buy the enclosure add-on you can more easily print ABS to prevent warping — and it’ll keep dust in from CNC, and the laser brightness out of your eyes.

A vase we 3D printed with the Snapmaker 2.0.As a laser engraver, you can create contrasting images on fabrics, leather, plywood and acrylic materials. The built-in camera lets you remotely monitor your design and ensure everything goes smoothly. It’s an effective low-cost 3D laser printer. We also tested it as a laser cutter, and managed to cut out and assemble a gift box from a thin sheet of soft wood 1.5mm thick.The Snapmaker 2.0 also works as a laser cutter as well as a 3D printer.

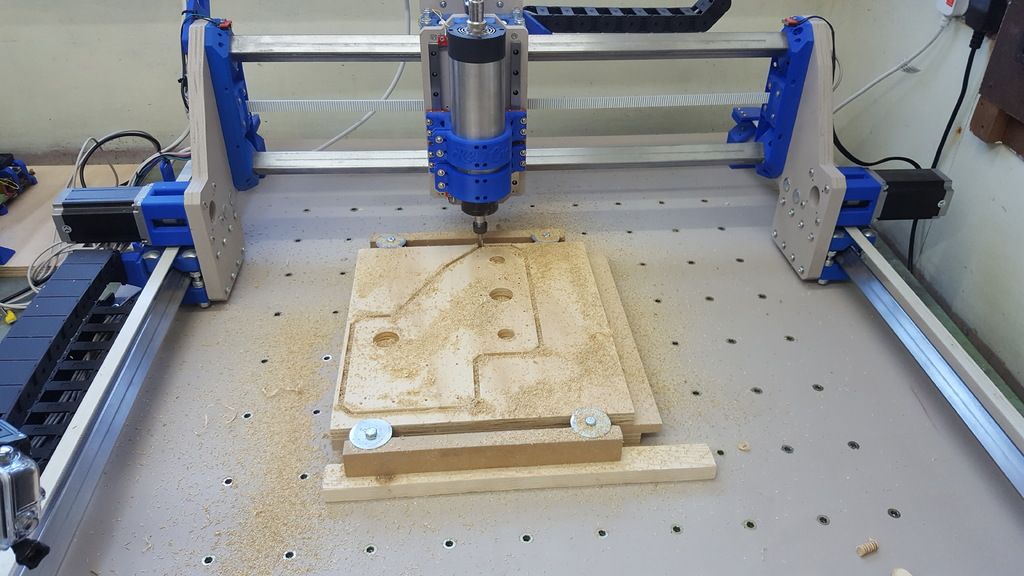

The CNC machine can carve designs on walnut, PCB woods, as well as carbon fiber sheets, acrylic and hardwood. A key upgrade on the 2.0 is the increased speed, meaning that larger projects can be created in record time.

Overall, we highly recommend the Snapmaker 2.0 models, of which we tested the largest version — the Snapmaker 2.0 A350. You can optionally buy the enclosure, 4-axis rotary module, and the new 10W powerful laser toolhead, but we did not try the 10W laser add-on.

For our CNC & laser review: we tested the Snapmaker 2.0 CNC and laser toolheadsThe finished lion CNC carved piece, from the Snapmaker 2.0 3-in-1 3D printer.

We recommend picking up the enclosure for safer and more consistent making, as well as spare bits for CNC. Snapmaker’s store has all these in one place, which you can visit here.

Top 3-in-1 Pick For 3D Printing, CNC & Laser Cutting

Snapmaker 2.0 Modular 3 in 1 3D Printer A350T/A250T

$1169 ($600 off!)

Switch the toolheads within minutes to 3D print, CNC cut, and laser cut and engrave in one machine. You can even buy the higher-power 10W laser attachment, a 4-axis rotary add-on for cutting or engraving round objects, and more!

You can even buy the higher-power 10W laser attachment, a 4-axis rotary add-on for cutting or engraving round objects, and more!

Snapmaker here

We earn a commission if you make a purchase, at no additional cost to you.

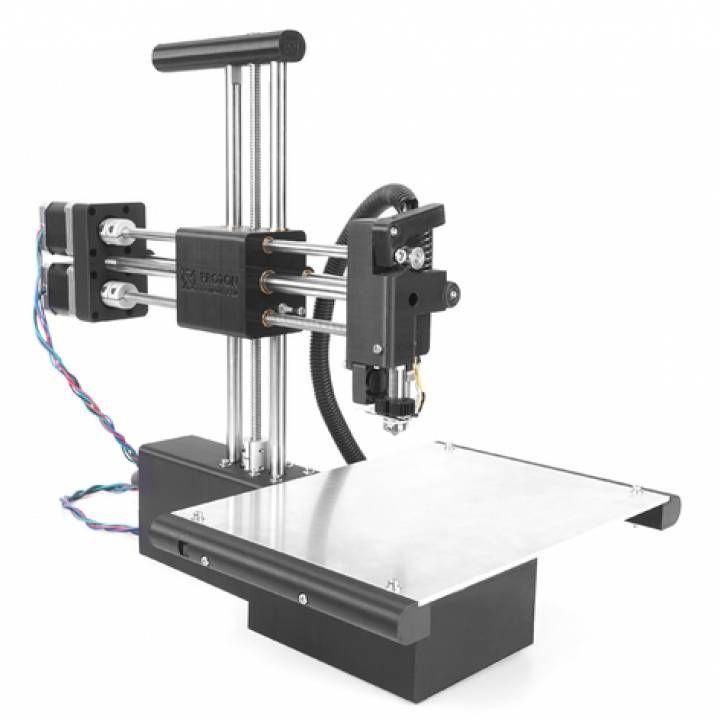

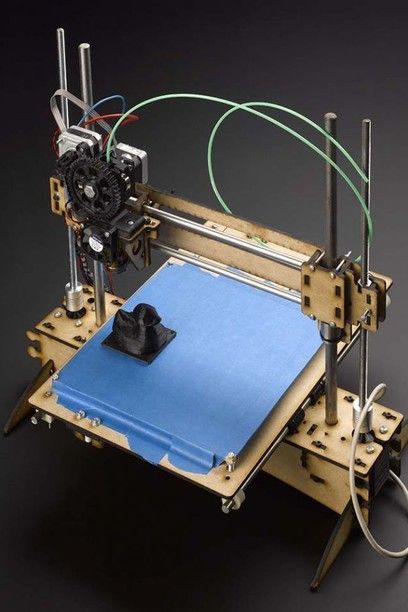

Snapmaker Original — good starter laser engraver 3D printer

- Price: $439 — Available on Snapmaker Official Site here / Available on Amazon here

- Build Volume: 125 x 125 x 125 mm

- Type: 3 in 1 3D printer: 3D printing, CNC and laser engraving

Snapmaker came out and made headlines when they raised an incredible $2.2M on Kickstarter for their first all in 1 3D printer, the Snapmaker Original. Functional as a small 3D printer as well as able to carve wood and engrave images on phone cases and other materials, the Snapmaker Original captured the hearts of many makers worldwide, becoming a roaring success.

- You can also buy an enclosure for the printer here.

The 3D printer’s heated bed can reach up to 80C, allowing for the printing ABS as well as PLA. It’s precise, with up to 50-micron layer resolutions. The heavy metal frame anchors the printer down and improves stability and durability, with the heavier frame less susceptible to vibrations that could affect print quality and surface finish.

The CNC carver can create intricate details in areas up to 90 x 90 x 50 mm, and the laser engraver works on areas up to 125 x 125 mm.

Snapmaker’s 3 in 1 software, Snapmaker Luban, can 3D print, CNC and laser engrave all in one platform and switch seamlessly between each tool head.

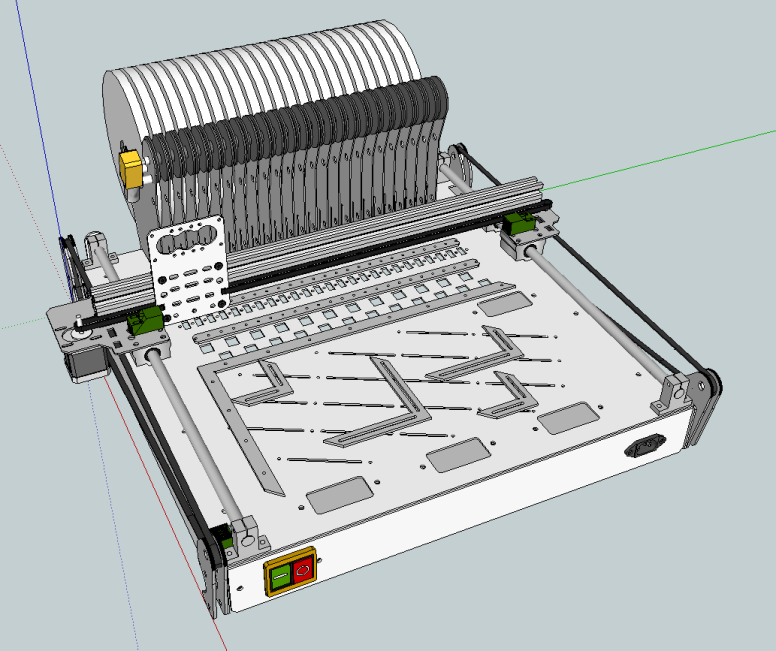

Snapmaker claim you can build the 3D printer in just 10 minutes, and that switching out tool heads to change the all-in-one 3D printer’s function is very simple. Highly rated by makers as one of the best 3 in 1 3D printers in its price range, the Snapmaker have since recently followed up the Original with the Snapmaker 2.0, with larger build volumes and a higher price tag. A selection of wood and other material parts carved using the Snapmaker Original’s CNC tool head. Source: snapmaker.com

A selection of wood and other material parts carved using the Snapmaker Original’s CNC tool head. Source: snapmaker.com

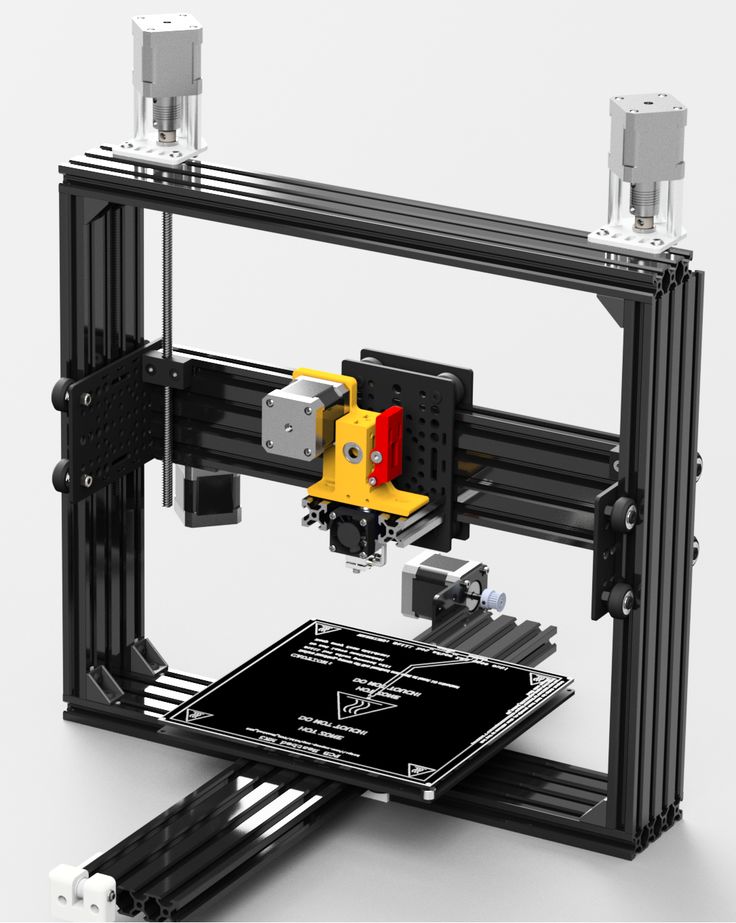

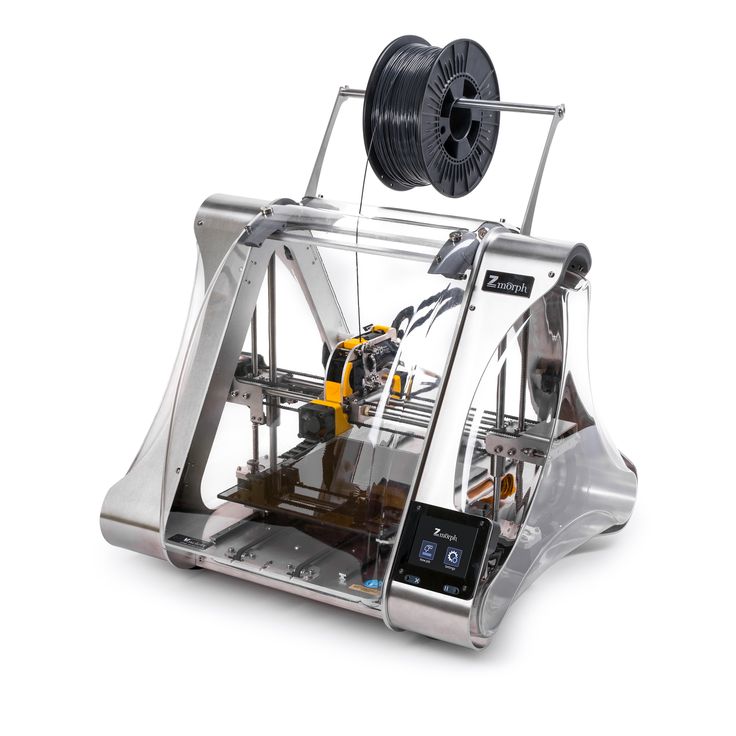

ZMorph Fab — 4 in 1 3D printer

- Price: $3,999 for the full set — Available on Matterhackers here / 3DPrima Europe here

- Build Volume: 250 x 235 x 165 mm

- Type: 4 in 1 3D printer: with CNC milling, laser cutting & engraving, and thick paste extruder

- Country based: Poland

Polish 3D printer company ZMorph make some of the most versatile all in 1 3D printers around, with the Fab able to 3D print, CNC machine, engrave and laser cut, and can even be switched into a food 3D printer using ZMorph’s thick paste extruder. This edible material option can print chocolate, as well as other similar materials like icing and cooking dough.

- We also have a ranking of the best food 3D printers.

- We also have a ranking of the best chocolate 3D printers.

ZMorph 3D printers are famed for their reliability and workhorse-like qualities, with the Fab no different. It’s a great 3D printer, with a high-quality heated bed that can comfortably 3D print ABS, HIPS, and other tougher filaments like Nylon. The printer can level itself automatically, and turn from a 3D printer to laser engraver or CNC router with ease.

It’s a great 3D printer, with a high-quality heated bed that can comfortably 3D print ABS, HIPS, and other tougher filaments like Nylon. The printer can level itself automatically, and turn from a 3D printer to laser engraver or CNC router with ease.

Additionally, with the dual head option, the ZMorph performs well as a dual extruder 3D printer, able to 3D print multiple colors, or soluble support materials such as HIPS and PVA, and even blend two colors together for multiple different shades in one part. The 3D laser printer CNC hybrid can be adjusted to print both 1.75mm and 3mm 3D printer filaments, and has a large enough build area to print even the largest of projects.

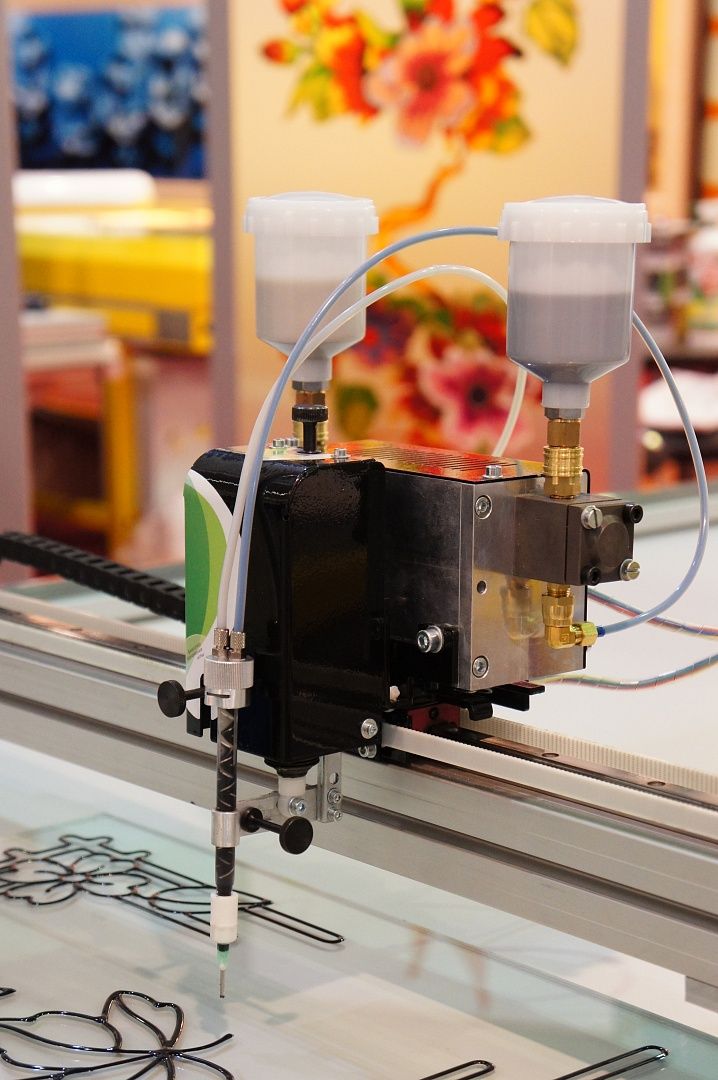

Using ZMorph’s CNC tool head, the ZMorph becomes a powerful CNC mill 3D printer that can mill and engrave almost any type of wood, as well as other materials like acrylic glass and EVA foam. The 300W power mills distances of up to 120mm/s, and ZMorph recommend a cutting depth of up to 0.5mm.

The Laser PRO tool head turns the Fab into a laser engraver 3D printer capable of burning and engraving plywood and many other types of wood, cardboard, leather, and acrylic glass using its powerful yet compact 2. 8W blue laser. Though the default speed is 15mm/s, the laser can work up to 120mm/s for faster engraving.

8W blue laser. Though the default speed is 15mm/s, the laser can work up to 120mm/s for faster engraving.

ZMorph’s Voxelizer 2 software acts as a 3D slicer for 3D printing parts, as well as offering CAD CAM software features for CNC and laser cutting models, all in one. Overall, it’s a fantastic and extremely versatile all in one 3D printer, and the closest available option to a full manufacturing suite machine.The ZMorph CNC tool head creating a design from wood. Source: ZMorph on Medium.

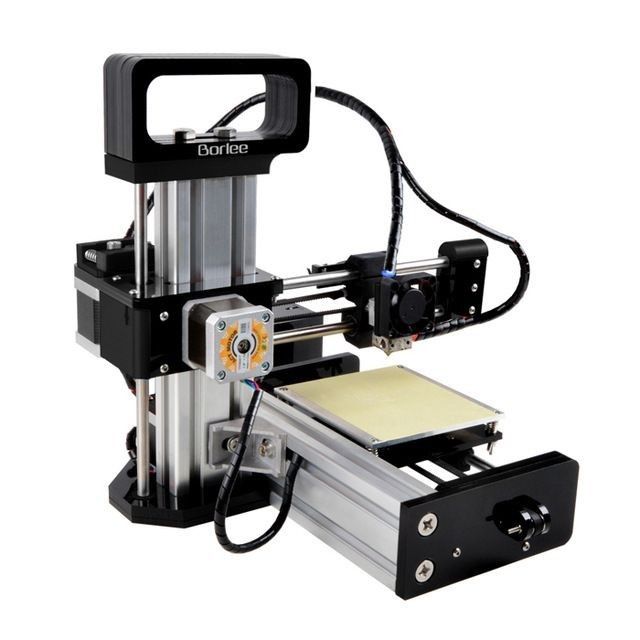

Creality CP-01

- Price: $819 — Available on Amazon here

- Build Volume: 200 x 200 x 200 mm

- Type: 3 in 1 3D printer: 3D printer, CNC & laser engraving

Creality make the current most popular affordable 3D printers in the world, including the Ender 3, Ender 5, and CR-10 ranges. The Creality CP-01 is their venture into the all-in-1 3D printer sector, offering CNC carving and laser engraving along with their 3D printer.

- We also have a ranking of the best cheap 3D printers.

As a 3D printer, it features a good 200 x 200 x 200 mm print volume, and comes with a heated bed that can reach up to 100C. These temperatures mean that ABS, HIPS and TPU 3D printing should be no problem, and in theory means you could even try printing filaments like Polycarbonate and carbon fiber.

The textured glass print bed should help with adhesion and reduce warping, and the direct drive extruder also makes flexible filament 3D printing easier in most cases.

As a laser engraver, the Creality CP-01 3-in-1 3D printer features 0.5W laser tool, which can engrave areas of up to 100 x 90 mm. The engraver can create contrasting greyscale art on paper, plastics, and wood.

As a CNC carver, the CP-01 features a 4800RPM spinning CNC spindle capable of carving plastics, wood and PCB. It can carve the same sized areas as the 3D printer, at 200 x 200 mm.

The CP-01 comes with Creality’s own Workshop 3D printer software, which supports engraving and CNC functions. For 3D printing, Creality’s standalone Creality Slicer works well.

For 3D printing, Creality’s standalone Creality Slicer works well.

Overall, it resembles the Snapmaker and appears to offer similar specs and functions, so we will have to see if the kings of cheap 3D printers can compete in the all in 1 3D printer sector.

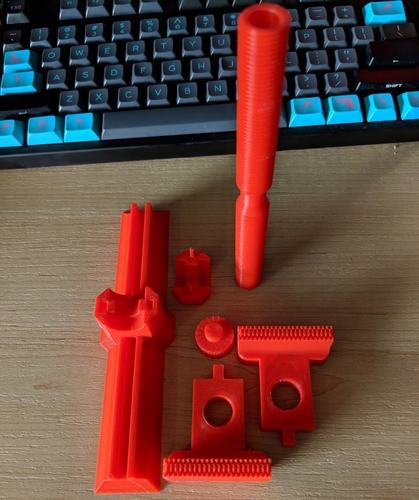

Each of the Creality CP-01’s tool heads for 3D printing, CNC cutting and laser engraving.5axismaker — Great CNC 3D printer

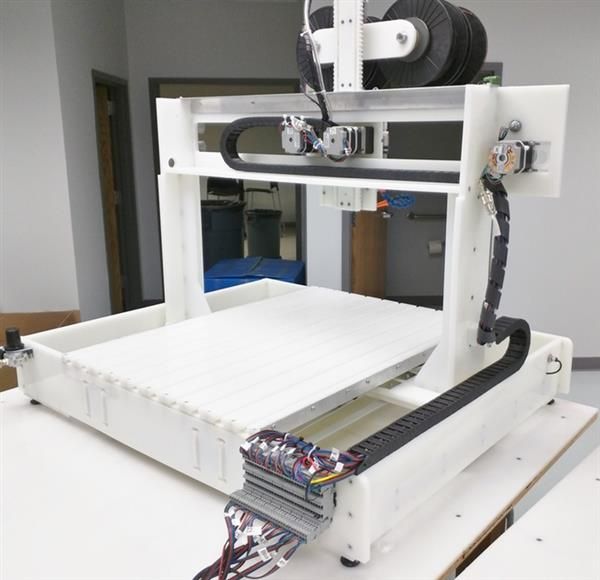

- Price: £5,500 / £6,800 depending on size

- Build volume: 5xm400 = 400 x 400 x 400mm / 5xm600 = 600 x 600 x 400mm

- Type: 2 in 1 3D printer with CNC milling

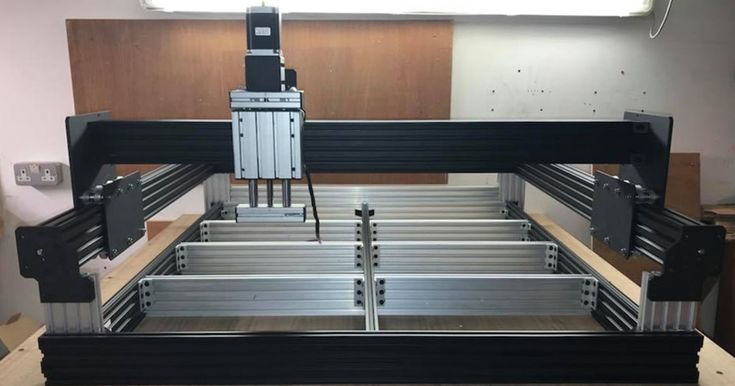

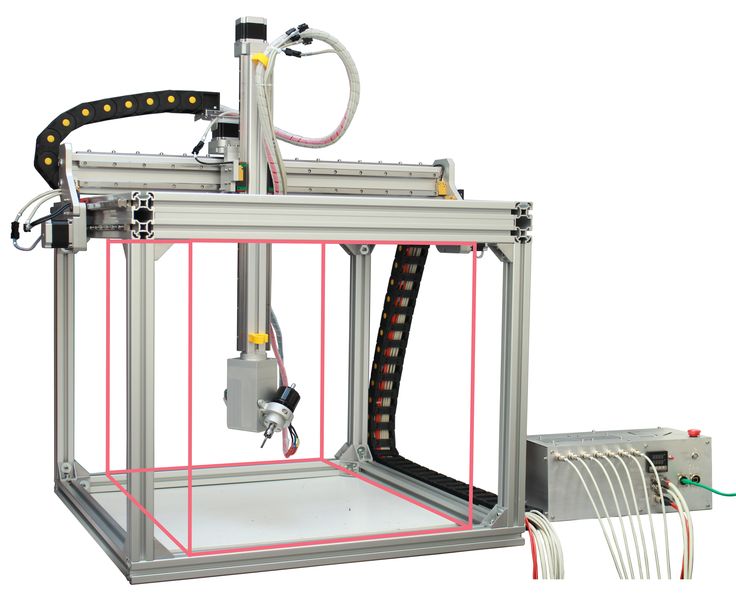

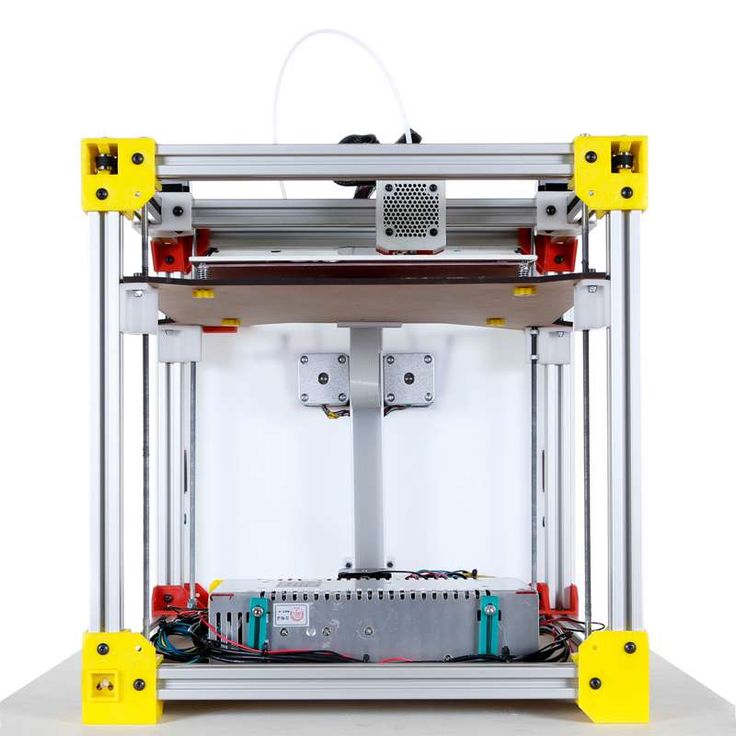

London-based 5axismaker have developed an excellent 3D printer CNC machine multi use 3D printer that comes in two main sizes to cover your manufacturing needs:

- 5axismaker 5xm400 model: 400 x 400 x 400 mm build volume

- 5axismaker 5xm600 model: 600 x 600 x 400 mm build volume

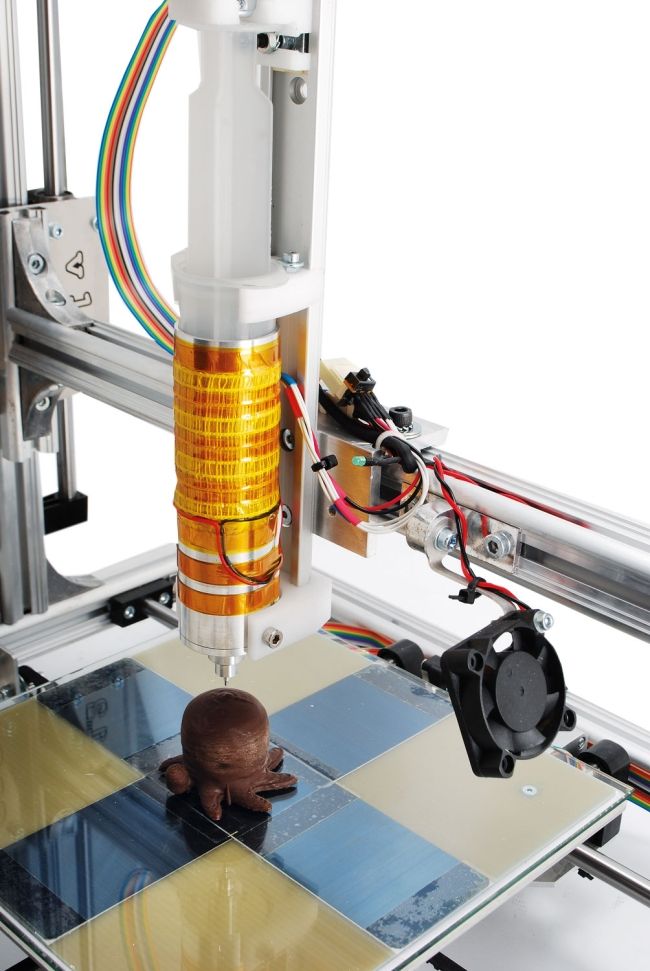

As a 3D printer, the 5axismaker comes with a default 0. 6mm nozzle — though you can switch out to a 0.4mm if you’re used to smaller nozzles, as well as sizes up to 1.2mm where speed is of the essence and you’re willing to sacrifice some precision. The 5axismaker can 3D print with PLA or ABS.

6mm nozzle — though you can switch out to a 0.4mm if you’re used to smaller nozzles, as well as sizes up to 1.2mm where speed is of the essence and you’re willing to sacrifice some precision. The 5axismaker can 3D print with PLA or ABS.

As a CNC machine, the 5axismaker offers fast 10,000-15,000 RPM spindle speeds on a powerful 500-1000W brushless motor capable of milling foam prototypes, hardwoods, carbon fiber, engineering plastics, machinable wax, and more. There is also a touchprobe option — but for this toolhead and any other custom tools, you’ll need to contact 5axismaker directly.

5axismaker have also developed their own in-house CAM software to support CNC milling and generate CNC codes, called 5xmonkey. The 5axismaker focuses particularly on CNC machining, choosing not to offer laser engraving with the 3D printer, but delivers well as a 2 in 1 3D printer.

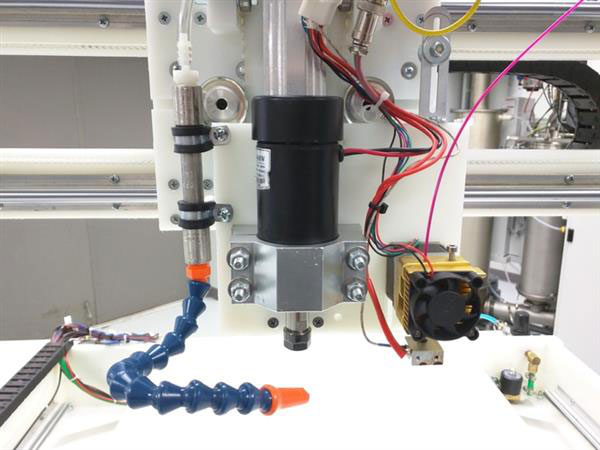

Diabase H-Series — powerful CNC mill 3D printer

- Price: starting at $9,750

- Build volume: depends on the number of axes

Another 2 in 1 3D printer focusing on 3D printing and CNC milling, Diabase offer three different options within the H-series:

- H5-400A Hybrid: doesn’t have the tool plate, 5- or 4-axis upgrade potential, but can still mill printed parts.

- H5-400A CNC Lite: offers 4- and 5-axis upgrading

- H5-400B CNC Full: offers 4-material printing, a 14-tool changer, and high-power spindle

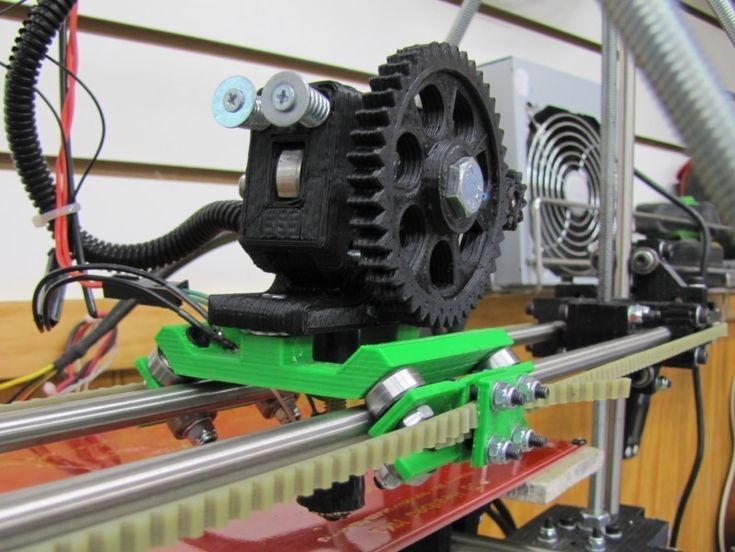

Diabase are already well known for their excellent 3D printer extruders focused on making flexible filament 3D printing as reliable as possible, previously thought to be difficult to print — especially on Bowden extruders.

They now offer a complete manufacturing solution, with their multifunction 3D printers able to print parts and them mill them seamlessly with each toolhead in a cohesive workflow.

The H-Series CNC mill 3D printer hybrid offers up to 5-axis CNC production along with 12,000 RPM speeds, for very intricate and complex part creation. As a 3D printer, it offers multi-material 3D printing, for example with TPU and PVA, with PVA’s solubility making it ideal for simply removing PVA supports later. The CNC mill part can mill soft metals up to 75 HRB strength — it really is a full-service solution. The Diabase H-Series’ rotary axes offer fantastic part complexity and intricate geometry options for manufacturing.

The Diabase H-Series’ rotary axes offer fantastic part complexity and intricate geometry options for manufacturing.

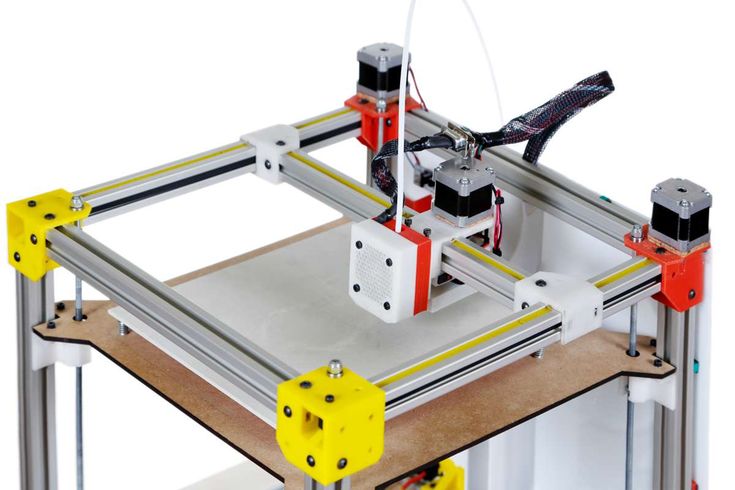

Ecubmaker TOYDIY — 4 in 1 3D printer

- Price: $549 — Available on Amazon here

- Build Volume: 180 x 180 x 180 mm

- Type: 4 in 1 3D printer: FDM, dual color, CNC engraving and laser engraving

- Country based: China

Though it calls itself a 4 in 1 3D printer, this claim involves splitting the 3D printing part into standard FDM 3D printing, and dual color 3D printing, which both fall under 3D printing. In reality, the Ecubmaker TOYDIY is a 3 in 1 3D printer, but with four easily changeable tool heads for 3D printing, CNC engraving or laser engraving.

For 3D printing, the extruder can reach temperatures of up to 240C, with a heated bed that can reach up to 50C. Therefore, printing higher temperature filaments like ABS and HIPS is not possible, and you’re restricted to using the Ecubmaker TOYDIY as a strictly PLA 3D printer. (Testing has occurred for using the dual extruder to print PVA as a support, though the company do not recommend this). Therefore, if using the dual extruder 3D printing option, you can only print two different colors of PLA, rather than soluble material supports.

(Testing has occurred for using the dual extruder to print PVA as a support, though the company do not recommend this). Therefore, if using the dual extruder 3D printing option, you can only print two different colors of PLA, rather than soluble material supports.

For a 3D laser printer that isn’t specialized in any one dimension, it’s surprisingly accurate – with layer thicknesses of up to 0.05 mm. The bendable, 3-layer build plate also makes removing finished prints easy and helps reduce warping, though PLA rarely warps badly anyway.

As a laser engraver 3D printer, the TOYDIY features a 1500MW purple laser which can engrave wood, plastic, leather, cardboard, and several other materials. However, this is strictly a laser engraver, and cannot cut materials.

The CNC tool head features a 385DC motor, and spins at between 8,000 and 10,000 RPM. The CNC printer can engrave and carve wood, plastics, acrylic and most non-metallic materials, but cannot be used with transparent materials like glass. Ecubmaker also stress that the CNC tool head should not be used for longer than 3 hours at once.

Ecubmaker also stress that the CNC tool head should not be used for longer than 3 hours at once.

The TOYDIY comes with Ecubmaker’s Ecubware 4 in 1 3D slicer software for every application type. The 3D laser printer comes with an SD card containing tutorials for the 3D printer, engraver and CNC carver to help you get started, and if you encounter any serious problems, you can return it within its warranty.Though only offering a small build volume, the TOYDIY is a great entry level multifunctional 3D printer.

If you liked this article, you may also be interested in:

- Our guide to the best 3D pens

- Our guide to the best 3D scanners

- The complete dual extruder 3D printer buyer’s guide

- Our ranking of the best FDM 3D printers

The 5 Best 3-in-1 3D Printers for Complete Fabrication – Clever Creations

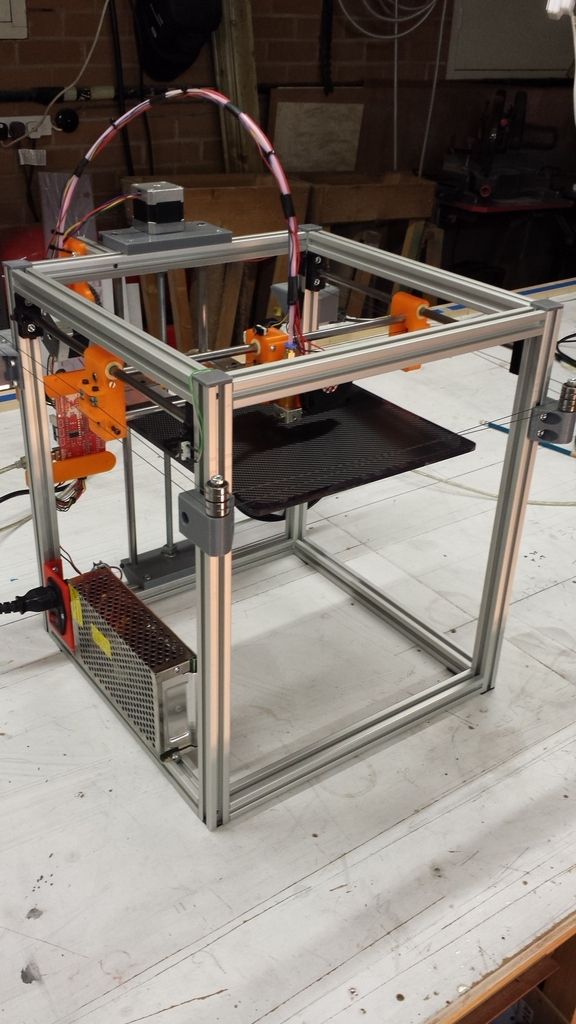

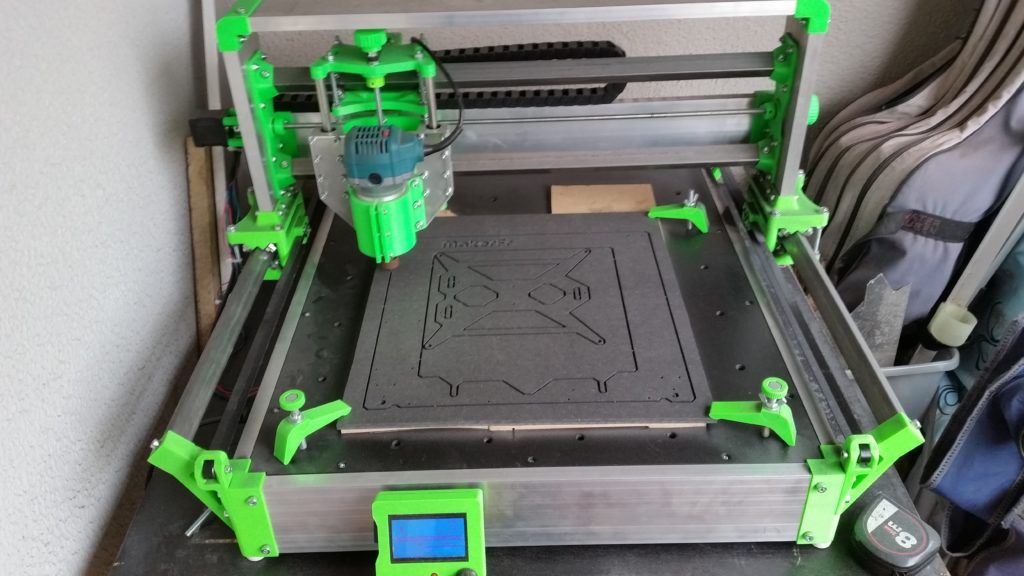

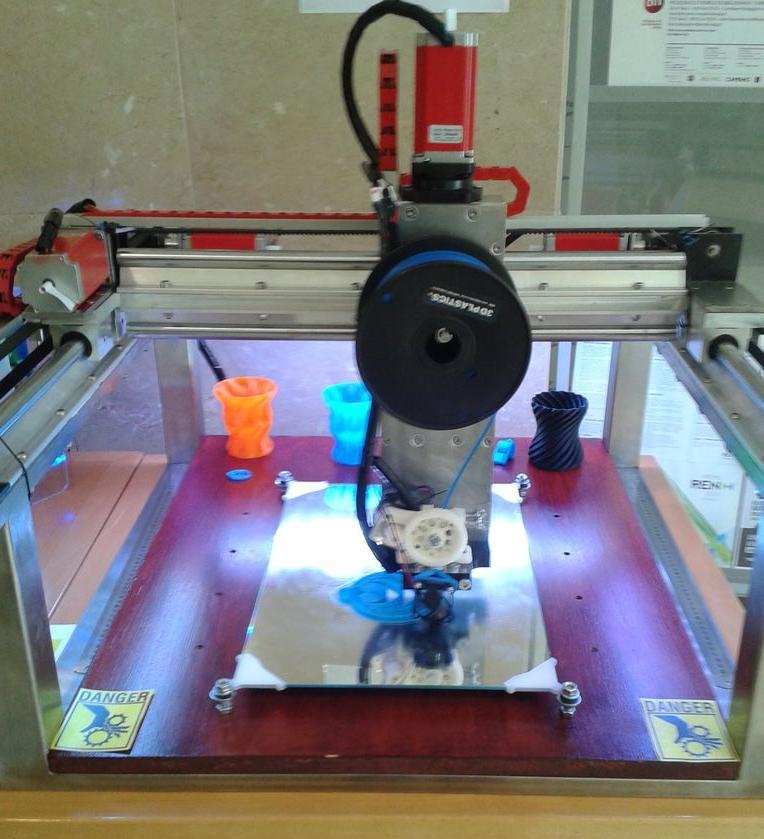

3-in-1 3D printers are very much in demand due to their unique value proposition. You can 3D print using a print head, carve using a CNC bit, and engrave your models using a laser, all on a single machine. This versatility opens up several avenues for DIY makers, hobbyists, and creators who can enjoy these processes without having to purchase multiple machines.

This versatility opens up several avenues for DIY makers, hobbyists, and creators who can enjoy these processes without having to purchase multiple machines.

The Snapmaker 2.0 popularized this category of multi-purpose machines. With its excellent features and solid build quality, it became the go-to 3-in-1 3D printer for many enthusiasts. But it’s not the only one in the market.

In this article, we’ve gathered a list of 3D printer / laser cutter / CNC router combo machines that are available today. We’ll go over each one’s key features and applications, and highlight the areas where they excel. By the end, you’ll know which is the best 3-in-1 3D printer that perfectly aligns with your needs.

| 3-in-1 3D Printer | Summary | Build Volume | Enclosure | Price (~) | Best Offer |

|---|---|---|---|---|---|

| Snapmaker 2.0 A350T | Best overall | 320 x 350 x 330 mm | Optional | $1599 | Snapmaker |

| Snapmaker Artisan | Best high-end | 400 x 400 x 400 mm | Enclosed | $2799 | Snapmaker |

| EcubMaker TOYDIY | Best on a budget | 180 x 180 x 180 mm | None | $699 | Amazon |

| ZMorph Fab | Best 3D printer & CNC mill | 235 x 250 x 165 mm | Enclosed | $2199 | MatterHackers |

| Creality CP-01 | Best Creality 3-in-1 3D printer | 200 x 200 x 200 mm | None | $602 | Creality |

Why Buy a 3-in-1 3D Printer?

3D printing is only a single facet of the rapid prototyping process. You can also use CNC milling and laser engraving and cutting to create prototypes and end-use components. So, what’s the advantage of having all these technologies in a single machine?

You can also use CNC milling and laser engraving and cutting to create prototypes and end-use components. So, what’s the advantage of having all these technologies in a single machine?

Desktop Space Savings

3-in-1 3D printers use your desktop space more effectively by combining all three functions in a single machine. You don’t need to buy separate machines for each process, so you save a lot of space on your workbench or 3D printer table.

Cost Savings

An all-in-one 3D printer can be more cost-efficient than purchasing three separate machines. Not only do you save on the machine’s cost, but you also eliminate the need for hosting three devices. For example, you won’t need multiple enclosures, air filters, power outlets, and so on.

Having the option to use one of the manufacturing methods, for example, CNC cutting, only once in a while can also justify the purchase of a 3-in-1 machine. In that situation, buying a separate CNC router might not be worth it.

These savings can benefit budget users, small shops, and educational institutions that do not have the space or the money to buy different devices for each process.

Ease of Use

The best 3-in-1 3D printers are designed to be easy to use. You don’t need vast technical knowledge, and the features in these machines are straightforward to configure in the accompanying software.

In addition, switching between the various machining modes is usually quick and effortless. So you can quickly get started even if you’re unfamiliar with CNC milling and laser engraving.

It should be said that not all 3-in-1 3D printers are equally easy to use, and some require more experience to operate. A lot of it depends on the software that comes with the machine, which we’ll cover in more detail later.

The Best 3D Printer / Laser Cutter / CNC Milling Combo Machines in 2022

Snapmaker 2.0 A350T

Best overall

Check Price

AmazonSnapmakerMatterHackersAliExpress

The Snapmaker 2. 0 reigns in the hobbyist level 3-in-1 3D printers category with its sleek industrial design and ease of use. The Snapmaker 2.0 features a fully modular design, and its simple plug-n-play tool heads (modules) make it easy for you to switch between its various modes.

0 reigns in the hobbyist level 3-in-1 3D printers category with its sleek industrial design and ease of use. The Snapmaker 2.0 features a fully modular design, and its simple plug-n-play tool heads (modules) make it easy for you to switch between its various modes.

It has three separate tool heads, one each for 3D printing, CNC milling, and laser engraving. In terms of 3D printing features, you get a direct extrusion setup with a hot end that reaches up to 275 °C. This allows you to use a wide variety of 3D printing filaments, including PLA, PETG, ABS, and other materials.

Its heated bed with an automatic bed leveling system helps you achieve reliable and consistent 3D prints. The Snapmaker 2.0 also uses an intuitive color touchscreen for its controls, which makes it easy to navigate the printer’s menus and settings.

Its laser engraver module has an inbuilt camera that autofocuses the laser on the workpiece. The 1.6W laser engraver can precisely engrave dots up to 0. 2 mm and works well on paper, leather, wood, and corrugated fiberboards.

2 mm and works well on paper, leather, wood, and corrugated fiberboards.

For CNC machining, the Snapmaker 2.0 comes with an ER11 collet which supports 0.5 – 6.5 mm drill bits and has a maximum spindle speed of 12,000 RPM. It’s sufficient for milling woods, acrylics, and other plastics.

There’s no option for the stock Snapmaker 2.0 with metals. For that, the laser tool head and CNC router functionality are not powerful enough. There is a 10 Watt laser module accessory available, however, that is more powerful and can engrave metals.

The Snapmaker 2.0 also comes with an optional fully enclosed build chamber that keeps the laser cutting fumes and CNC router swarf contained. It’s a pricy addition to the setup, but it does what it’s supposed to do.

On the software side, the Snapmaker 2.0 uses Snapmaker’s Luban software to tie the machine together. You can use it to prepare your files for all three different processes, without the need for any third-party software.

Considering its features, modularity, and range of accessories, the Snapmaker 2.0 is a well-rounded 3-in-1 3D printer suited for hobbyists and professionals alike. It is a great addition to any hobbyist workspace, DIY maker space, or prototyping lab that can fully utilize its multi-purpose capabilities.

Recommended:

Snapmaker 2.0 A350T Review: A Capable 3-in-1 3D Printer

Standout Features

- Complete, well-rounded machine

- Built-in camera for laser engraver

- Solid construction

- Materials included

Technical Details | |

|---|---|

| 3D printing build volume | 320 x 350 x 330 mm |

| Laser engraving area | 320 x 350 mm |

| CNC carving area | 320 x 350 x 275 mm |

| Max nozzle temperature | 275 °C |

| Laser power | 1600 mW |

| CNC spindle speed | 6,000 - 12,000 RPM |

| Supported materials | PLA, ABS, PETG, TPU, Wood, leather, plastic, fabric, paper |

| Connectivity | Wi-Fi, USB cable, USB flash drive |

| Supported OS | Windows, macOS, Linux |

What We Like

- Large touchscreen with easy-to-use UI

- All-in-one Snapmaker Luban software

- Plenty of add-ons and accessories

Could Be Better

- No enclosure included

- Time-intensive to switch beds

Find Snapmaker 2. 0 A350T at

0 A350T at

AmazonSnapmakerMatterHackersAliExpress

Snapmaker Artisan

Best high-end

Check Price

Snapmaker

The Snapmaker Artisan is the latest and the best 3-in-1 3D printer from the Snapmaker team. It improves vastly upon the Snapmaker 2.0 and comes with an excellent set of features to deliver the best prototyping experience for its users.

Its giant build volume of 400 x 400 x 400 mm is enough to classify it as a large 3D printer and lets you 3D print a full-face helmet in a single piece with ease.

It also features a dual-extrusion 3D printer tool head with easily swappable nozzles and hot ends. This improvement over the Snapmaker 2.0 gives you the ability to 3D print with multiple colors and materials at once, as well as use soluble supports for complex geometries.

The maximum hot end temperature of the Artisan is also bumped up to 300 °C, giving you access to a slightly wider range of 3D printing filaments.

The laser engraver features a 10W high-power laser by default, which lets you engrave at faster speeds and on more materials. Its 0.2 mm precision remains unaltered, and you can still engrave fine details without losing quality.

Its 0.2 mm precision remains unaltered, and you can still engrave fine details without losing quality.

Additionally, there’s a 200W CNC mill with a maximum spindle speed of 18,000 RPM, giving you a feed rate of 3000 mm/min. Whether it is sufficient to machine metals is something that remains to be seen, but it is a definite improvement over the Snapmaker 2.0.

To aid user experience, the Artisan now comes with a 7-inch touchscreen that is housed in the same space as the rest of the machine’s electronics. This design gives it a cleaner look and lets you easily separate the electronics from the device’s hardware.

The Snapmaker Artisan 3D printer is yet to be released worldwide and is only available for pre-order. With its quality features and demanding price tag, it is a 3-in-1 3D printer that is more aligned for enthusiast DIYers, as well as users with professional and industrial use cases.

Standout Features

- 300 °C dual extrusion 3D printing

- 10W laser module

- Large work area

- Industrial grade built quality

Technical Details | |

|---|---|

| 3D printing build volume | 400 x 400 x 400 mm (Single nozzle) 350 x 400 x 400 mm (Dual Nozzle) |

| Laser engraving area | 400 x 400 mm |

| CNC carving area | 400 x 400 mm |

| Max nozzle temperature | 300 °C |

| Laser power | 10W |

| CNC spindle speed | 18,000 RPM |

| Supported materials | PLA, ABS, ASA, PETG, PVA, HIPS, Nylon, Carbon Fiber sheets, Hardwood (Beech, Walnut), Softwood, HDF, MDF, Plywood, Basswood, Paulownia, Pinewood, etc. |

| Connectivity | Wi-Fi, USB cable, USB flash drive |

| Supported OS | Windows, macOS, Linux |

What We Like

- Included laser proof enclosure

- Big 7-inch touchscreen with simple UI

- Multi-material 3D printing

- Dual-side 3D printing surfaces

Could Be Better

- Only available as preorder

- Takes up a lot of space

Find Snapmaker Artisan at

Snapmaker

EcubMaker TOYDIY

Best on a budget

Check Price

Amazon

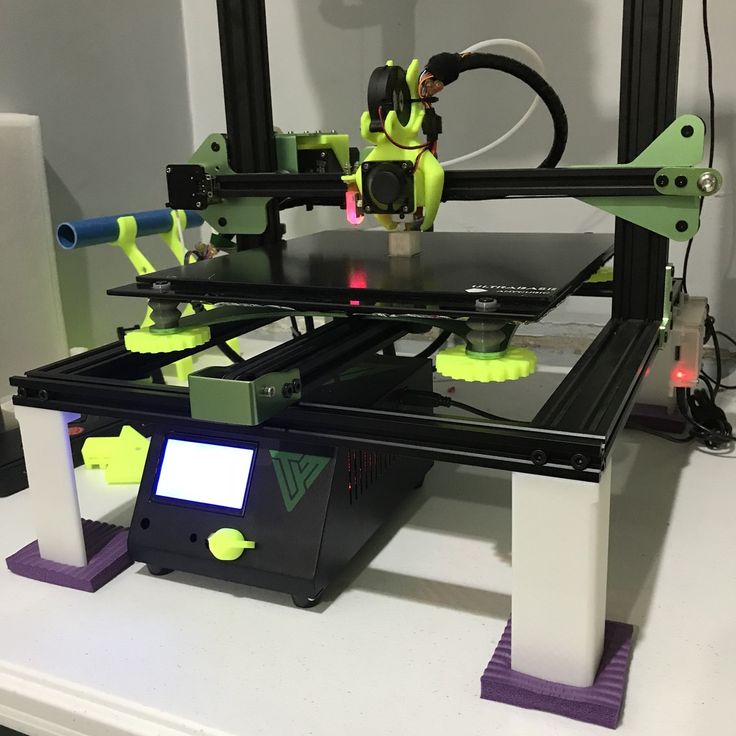

As a more tiny and compact machine, the EcubMaker 4-in-1 3D printer has no rival in its category. And while it resembles the Original Snapmaker, the EcubMaker stands out with its excellent build quality, rugged design, and a small LED light at the top.

The 3D printer comes fully assembled right out of the box, and you get four separate modules with the machine. The extra fourth module is a Y-style hot end for multi-color 3D printing with the EcubMaker. A pretty cool addition that’s not found on any other machines on this list.

The extra fourth module is a Y-style hot end for multi-color 3D printing with the EcubMaker. A pretty cool addition that’s not found on any other machines on this list.

To help you save time, the tool heads on the EcubMaker are easy to switch and are held in place with a single screw. This is a convenient solution for quickly switching between 3D printing, CNC milling, and laser engraving.

The EcubMaker TOYDIY 4-in-1 3D printer also has a flexible magnetic bed. Simply remove and bend it after 3D printing, and the model will pop right off.

You also receive a basic CNC engraving base plate and holding clamps along with several necessary tools you’d need to carry out CNC machining on the EcubMaker.

The knob-control LCD screen controller, lack of an enclosure, and a small working area are some of its notable downsides. But all of its features at a budget price more than compensate for this.

The EcubMaker 3D printer is a well-built machine suitable for first-time users, beginners, and professionals who need a budget machine for their rapid prototyping needs. It also makes a great learning tool for students in schools and colleges.

It also makes a great learning tool for students in schools and colleges.

Standout Features

- Flexible magnetic printing bed

- Industrial linear guide rails

- Fully-assembled package

Technical Details | |

|---|---|

| 3D printing build volume | 180 x 180 x 180 mm |

| Laser engraving area | 180 x 180 mm |

| CNC carving area | 180 x 180 mm |

| Max nozzle temperature | 220 °C |

| Laser power | 1.5W |

| CNC spindle speed | 14,500 RPM |

| Supported materials | PLA, Wood, Plastic, Acrylic, PCB, Plexiglass |

| Connectivity | SD card |

| Supported OS | Windows |

What We Like

- Automatic bed leveling

- Compact form factor

- Dual-color 3D printing

- LED light for illumination

Could Be Better

- Tiny work area

- Limited material support for 3D printing

- No enclosure

Find EcubMaker TOYDIY at

Amazon

ZMorph Fab

Best 3D printer & CNC mill

Check Price

MatterHackers

As a premium all-in-one machine, the ZMorph Fab barely has any other competitors in this category. It’s a complete machine designed for the entire rapid prototyping workflow.

It’s a complete machine designed for the entire rapid prototyping workflow.

At first glance, its fully-enclosed design and aluminum panels all over give you an accurate representation of its industrial build quality. The ZMorph Fab is built like a tank and uses high-quality components to ensure structural rigidity and stability while milling the most challenging materials.

It’s designed for complete autonomy, and all its features are centered around ease of use. Its automatic bed leveling, auto-tool detection, and calibration make it a true plug-and-play machine.

A closed-loop stepper motor system ensures high repeatability and reduces the chances of any missed steps. Compared to open-loop systems, this results in much smoother and more precise motion, especially when milling at high speeds.

ZMorph comes with its Voxelizer software and features a standardized CAM workflow, easy tool change, and path visualization while doubling up as a slicer for 3D printing. A HEPA-carbon air filter is built into the machine, preventing 3D printer fumes, laser smoke, and CNC debris from escaping your work area.

A HEPA-carbon air filter is built into the machine, preventing 3D printer fumes, laser smoke, and CNC debris from escaping your work area.

Out of the box, the machine functions as a single extrusion 3D printer and a CNC machine. However, ZMorph has multiple tool heads which let you carry out laser engraving and dual extrusion/multi-material 3D printing on the machine.

Its steep price might seem high for many users. But, considering its range of features and the high quality it delivers, the ZMorph Fab can be an excellent choice for professional prototyping purposes.

Standout Features

- Dual extrusion 3D printing

- Smart tool heads

- Fully-enclosed design

- Silent stepper drivers

Technical Details | |

|---|---|

| 3D printing build volume | 235 x 250 x 165 mm |

| Laser engraving area | 235 x 250 mm |

| CNC carving area | 235 x 250 x 85 mm |

| Max nozzle temperature | 250 °C |

| Laser power | 2. 8W 8W |

| CNC spindle speed | N/A |

| Supported materials | PLA, ABS, PET, Nylon, PVA, HIPS, BS, Nylon, HDPE, PTFE, PC, PP, POM, PMMA. |

| Connectivity | USB, Ethernet, SD card |

| Supported OS | Windows, macOS, Linux |

What We Like

- Robust build quality

- Included air-filter

- Easy-to-use Voxelizer software

- Excellent print quality

- Upgradeable modular tool heads

Could Be Better

- Laser tool head is aftermarket accessory

- Motion driveways are exposed to dust in the enclosure

- High price

Find ZMorph Fab at

MatterHackers

Creality CP-01

Best Creality 3-in-1 3D printer

Check Price

Creality

Creality’s well-known for its budget-oriented 3D printers, and the CP-01 is no exception. It is positioned as a budget alternative to the expensive Snapmaker 2.0 and is ideal for beginners on a budget looking for their first 3-in-1 3D printer.

It is positioned as a budget alternative to the expensive Snapmaker 2.0 and is ideal for beginners on a budget looking for their first 3-in-1 3D printer.

The CP-01 comes in a medium form factor, featuring a modest 200 x 200 mm work area in all three modes. You receive three interchangeable modules, one for each function. You can easily swap them with the help of four screws to switch between the various manufacturing modes.

As a 3D printer, the CP-01 supports materials up to 280 °C and has a heated and textured glass print bed. The printer supports basic materials such as PLA, ABS, PETG, and PVA; however, you can feel the lack of an automatic bed leveling system in the printer.

For the laser engraving module, the CP-01 has a sub-0.5W laser , which is adequate for engraving on paper, cardboard, and plastic. Because its power is super limited, you can’t laser engrave on much else, let alone do any laser cutting.

Lastly, as a CNC machine, there’s a tungsten alloy CNC cutter in the box that you can use with the CNC tool head with a maximum spindle speed of 4800 RPM. Again, it’s not the most powerful, but it is able to take on light materials, like soft woods and plastics.

Again, it’s not the most powerful, but it is able to take on light materials, like soft woods and plastics.

One of the biggest limitations is that there is no single software to prepare files for 3D printing, CNC milling, or laser cutting. As a result, you will have to use multiple programs. Not only is this more difficult to learn, but it can also be a hassle during operation.

You will also find that the open lead screws and belt drives will accumulate dust and debris over time. If you don’t put additional time into keeping them clean, this can lead to issues with your 3D prints, engravings, and milling projects.

For approximately $600, however, the CP-01 is a decent 3-in-1 3D printer from Creality that can serve as a budget prototyping machine for a variety of small projects.

Standout Features

- Modular design and assembly

- Full aluminum frame

- High-power stepper motors

Technical Details | |

|---|---|

| 3D printing build volume | 200 x 200 x 200 mm |

| Laser engraving area | 200 x 200 mm |

| CNC carving area | 200 x 200 mm |

| Max nozzle temperature | 280 °C |

| Laser power | Less than 0. 5W 5W |

| CNC spindle speed | 4,800 RPM |

| Supported materials | PLA, ABS, TPU, wood, plastic, paper, PCB |

| Connectivity | USB cable and MicroSD card |

| Supported OS | Windows, macOS, Linux |

What We Like

- Affordable

- Quick-swappable modules

- Easy-to-use UI

- Fast assembly

Could Be Better

- No all-in-one software

- Extremely slow laser cutter

- Underpowered CNC milling cutter

Find Creality CP-01 at

Creality

What to Look for When Buying a 3-in-1 3D PrinterCompromisesNo machine on the list is a perfect 3-in-1 3D printer, and each has some drawbacks. It’s crucial to consider the compromises that you’re willing to make when buying an all-in-one 3D printer.

For example, the lead screws on the Snapmaker 2. 0 are great for machining, as they provide a lot of torque. However, this comes at the cost of slower speeds, which is not ideal for 3D printing.

0 are great for machining, as they provide a lot of torque. However, this comes at the cost of slower speeds, which is not ideal for 3D printing.

Similarly, the Creality CP-01 is available at a lower cost than any other 3D printer but lacks good software and has an inferior build quality. On the other hand, the EcubMaker 3D printer comes with many features at a low price point. But it has a tiny work area, limiting you from working on large projects.

The two top 3-in-1 3D printers on the list, the Snapmaker Artisan and the ZMorph Fab, have some of the best functions for a multi-purpose machine. But, their high price and large form factor make them an impractical solution for those who need a budget 3-in-1 3D printer for small projects.

It is important to look at the various parameters of these machines and choose the most important ones for your needs. Doing so will ensure you get the best 3-in-1 3D printer within your budget and the one that best matches your needs.

Material CompatibilityMaterial compatibility is crucial in determining the applications for which you can use 3-in-1 3D printers. The more materials you can work with, the more options you have to solve your engineering problems and fully express your creativity.

The more materials you can work with, the more options you have to solve your engineering problems and fully express your creativity.

For 3D printing, the three most popular materials are PLA, ABS, and PETG. All the 3D printers mentioned in this list are capable of printing these materials without any hiccups. The Snapmaker Artisan 3D printer, however, takes the lead with its high-temperature hot end (300 °C), letting you print with more advanced engineering plastics.

For CNC milling and laser engraving purposes, you must consider the power of the spindle or laser. Basic materials such as paper, wood, MDF, plexiglass, and leather can usually be worked with on basic machines. But if you want to work with metals or other tougher materials, you’ll need to make sure that the machine has enough power and is rigid enough (in the case of CNC cutting).

Laser Type and PowerA semiconductor laser engraver is the most suitable type of laser for a 3-in-1 3D printer. They’re compact, portable, easy to operate, and compatible with various materials. With lasers, the higher the laser power, the better its cutting and engraving performance. A high-power laser will also have faster working speeds and reduce your work times significantly.

They’re compact, portable, easy to operate, and compatible with various materials. With lasers, the higher the laser power, the better its cutting and engraving performance. A high-power laser will also have faster working speeds and reduce your work times significantly.

Creality’s CP-01 uses the lowest powered laser engraver with a power rating of 0.5W. This will limit your engraving and cutting capabilities, and you’ll need to laser engrave at extremely slow speeds to get good-quality results.

With the Snapmaker 2.0 A350T and EcubMaker, you get a 1.6W laser that is adequate for most basic purposes and delivers an acceptable working speed. The ZMorph’s 2.8W laser engraver, too, is powerful for laser engraving but might fall short for high-depth laser cuts.

The Snapmaker Artisan 3D printer with its 10W laser is the best laser engraving machine in the list and delivers high engraving speeds of up to 6000 mm/min. Snapmaker claims this speed is almost 8 times that of a 1. 6W laser engraver, letting you create terrific workpieces instantly.

6W laser engraver, letting you create terrific workpieces instantly.

Snapmaker 2.0 A350T does allow you to upgrade to a 10W laser engraver without buying a separate machine altogether. This choice makes the most sense if you’re on a budget and still need a high-power laser engraver in your 3-in-1 device.

It is often also possible to tinker with your machine and install a third-party laser module with a higher power rating. This might void your warranty, however, and could be dangerous if not done correctly.

Software CompatibilityRunning multiple processes on a single machine is a challenging task. A good piece of software will help you to achieve a smooth workflow by bundling up all the different functions in a single place.

For example, Snapmaker’s Luban combines all the functions you’d need for 3D printing, CNC carving, and laser engraving in a single place. You can switch between different modes, access various features, and prepare your files for machining, all within a single software.

Similarly, the Zmorph Fab comes with its Voxelizer software, and the EcubMaker has its Ecubware. Both are designed as companion software for their machines and complement their hardware very well.

But, Creality’s CP-01 3D printer is an exception and comes with no single software. You’ll need different software for each process, making it challenging to prepare the files.

Therefore, you’d be better off with a Snapmaker 2.0 A350T or the EcubMaker 3-in-1 3D printer. These machines have well-designed software that goes along with them and will give you a better overall experience.

Accessories and Add-onsAccessories and add-on modules extend your printer’s capabilities and let you fine-tune the machine as per your needs. Especially with a CNC machine and laser engraver functionalities, aftermarket accessories will help you with specific applications on your 3-in-1 3D printer.

The Snapmaker 2.0 comes with a host of accessories and add-ons such as the rotary module, 10W laser tool, power modules, linear rails, and air filters. In the box, too, you get a bunch of accessories and tools that enhance the user experience with the machine. This compatibility ensures that you can fully customize the printer to your workflow, and get the best value.

In the box, too, you get a bunch of accessories and tools that enhance the user experience with the machine. This compatibility ensures that you can fully customize the printer to your workflow, and get the best value.

Likewise, the ZMorph Fab has up to five different tool heads that you can purchase as aftermarket accessories. These let you use multi-material 3D printing and laser engraving on the printer.

Ease of SwitchingAnother crucial yet overlooked factor to consider while buying a 3-in-1 3D printer is the ease of switching into different modes. An easy-to-switch mechanism that takes less time to shift between modes will deliver a smooth workflow experience.

To ensure a seamless 3-in-1 experience, all the machines in this list have some degree of modular design. You get separate, easy-to-switch modules and components for each process.

With the Snapmaker 2.0 A350T, Creality’s CP-01, and the EcubMaker, you get small, interchangeable tool heads. These are held onto the machine via a slide-n-screw mechanism. Switching the tool heads and preparing the machine for the following process usually takes a few minutes.

These are held onto the machine via a slide-n-screw mechanism. Switching the tool heads and preparing the machine for the following process usually takes a few minutes.

The machining beds can be more difficult to swap out. Since they need to withstand high forces for CNC machining and need to be mounted as flat as possible, they are sometimes fastened with a lot of bolts. Removing these to swap out the bed can take some time.

Enclosure Options3D printing, CNC milling, and laser engraving emit harmful fumes, dust, and dirt during machining. While an enclosure is not strictly necessary, it helps to separate the working area from the surroundings. It also helps to keep all the waste material within a contained area.

Especially if you’re planning to use it as a CNC machine, an enclosed chamber will keep all the swarf inside and reduce your cleaning efforts. Likewise, when you burn materials using a laser cutter, an enclosure gives you the option to funnel off any smoke with a fan and exhaust hose.

For 3D printing, an enclosure can be useful for keeping the print temperature consistent. This is especially important when you’re printing with ABS filament, which has a higher chance of warping if the temperature fluctuates.

For this reason, you can find many aftermarket 3D printer enclosures, as well as enclosed 3D printers. When buying a 3-in-1 3D printer, however, you’ll have to check whether you want an enclosure and whether it comes included or separately.

The ZMorph Fab 3D printer considers all of this and comes in a neatly enclosed chamber with an air filter. The enclosure does not take up additional space on your desktop and is built around the frame of the printer itself. The Snapmaker Artisan, too, comes with an enclosure; however, it occupies significantly more desktop space than the Zmorph.

With the Snapmaker 2.0, you can purchase a separate enclosure. As for the other 3-in-1 3D printers on the list, you’d have to either create a DIY enclosure or use some makeshift solution for enclosing the machines.

You can convert a 3D printer into a laser engraver or cutter by installing a laser engraving module on the print head carriage. The ones sold by 3D printer manufacturers as add-ons are often only powerful enough for laser engraving. For laser cutting, you will need a high-powered laser module that can output 2 Watts or more.

Also, keep in mind that the design of a 3D printer is not ideal for laser cutting. The build volume is often too small, and the print bed needs to be protected from the laser beam.

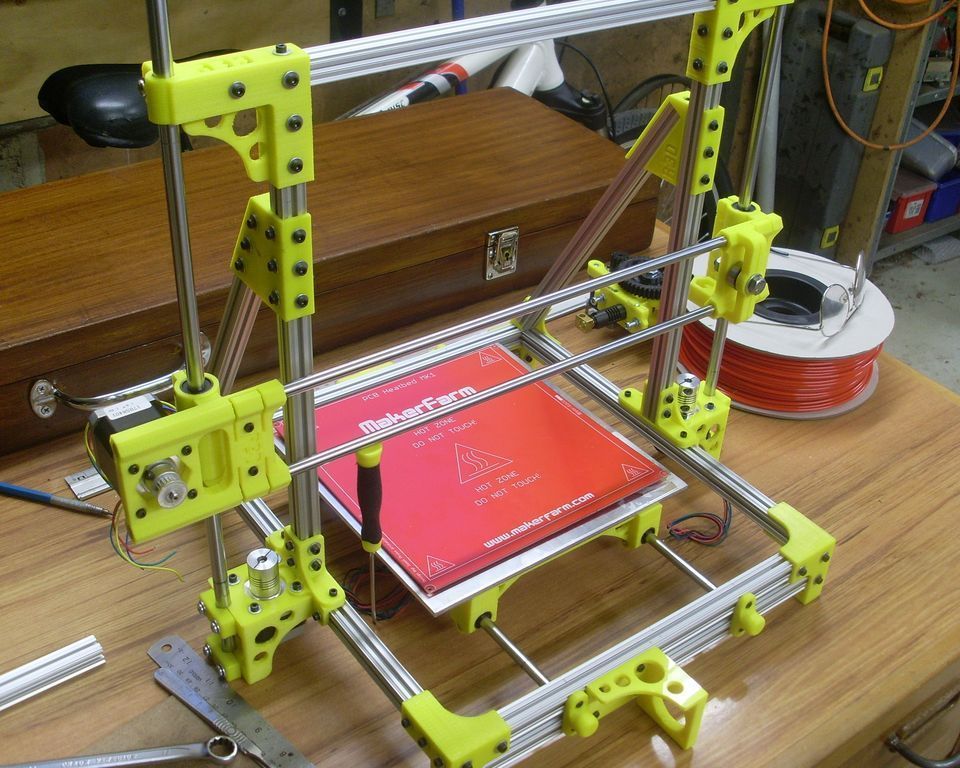

Since 3D printers, CNC machines, and laser engravers all work on the same principle, namely computer-controlled machining, it’s theoretically possible to convert a 3D printer into any of these machines. However, it is often more practical and economical to buy a machine that’s specifically designed for the task you want to do.

With enough effort, however, you can even turn a 3D printer into a hot wire cutter,

What does a 3-in-1 3D printer do?A 3-in-1 3D printer is a combination of 3D printer / laser engraver / CNC cutter. As such, you can use it for 3D printing, CNC carving or CNC machining, and laser engraving. You won’t be able to do this all at once, but you can switch between the three functions by changing the tool head and/or the machining bed.

As such, you can use it for 3D printing, CNC carving or CNC machining, and laser engraving. You won’t be able to do this all at once, but you can switch between the three functions by changing the tool head and/or the machining bed.

There are decent 3-in-1 3D printers out there, like the Snapmaker. The reality, however, is that any 3D printer / laser engraver / CNC cutter machine comes with a number of compromises. If you want the best results for each type of manufacturing, you are always best off getting three separate machines.

Can a 3D printer be used as a CNC?You could use a 3D printer as a CNC milling machine if you replace the print head with a CNC cutter. The design of 3D printers does not lend itself to CNC machining, however, so you won’t get great results.

The belt-driven axes of a 3D printer are not capable of dealing with the forces generated by the CNC mill, and the print bed is also not designed to withstand CNC machining forces.

Conclusion

3-in-1 3D printers are excellent for hobbyists, shops, and industries with limited working space. You get the benefits of all the machining processes in a single package, often at a much lower price. That said, you need to consider the software, accessories, and material compatibility before you make the decision.

The Snapmaker 2.0 is our pick for the best overall 3-in-1 3D printer you can buy. It has a great track record, comes with an excellent set of features, and features several add-on accessories. At its current price, it gives you the best value 3D printer / laser engraver / CNC milling machine combination there is right now.

Alternatively, the ZMorph Fab and the EcubMaker are two other great 3-in-1 3D printers. The ZMorph is the best in the high-end category and suited for professional applications. In contrast, the EcubMaker is the best budget all-in-one 3D printer. Both machines have a solid build quality and rich features for their price and will give you a superb machining experience.

What are your thoughts on an all-in-one 3D printer? Do you think it’s better to get a multi-purpose machine or use separate devices for each process? Let us know in the comments below.

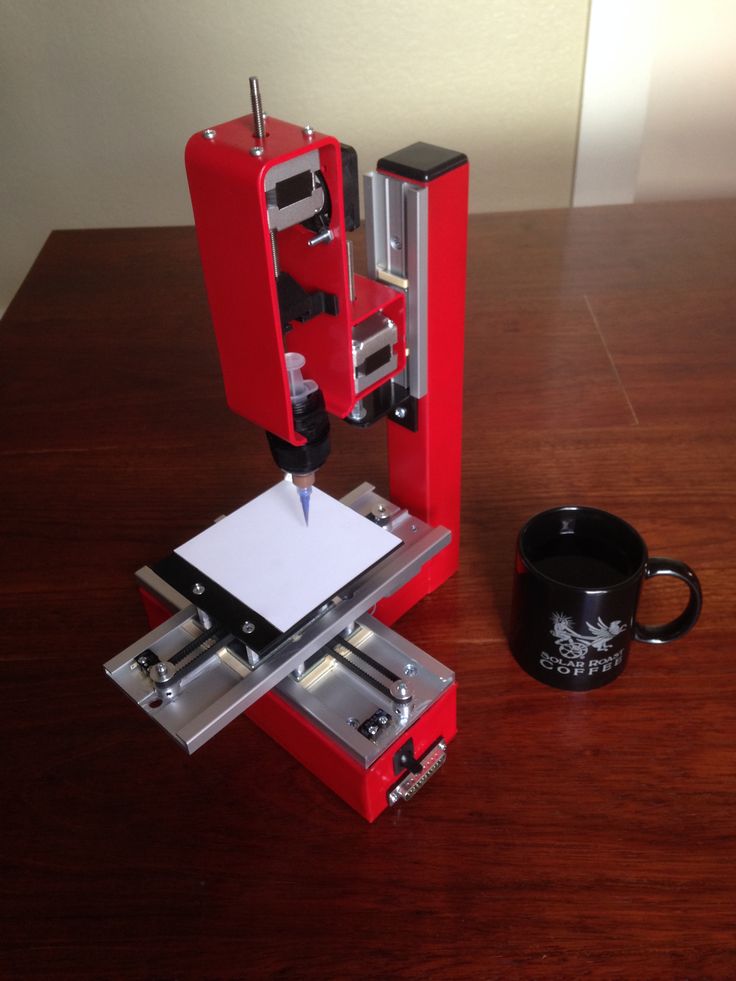

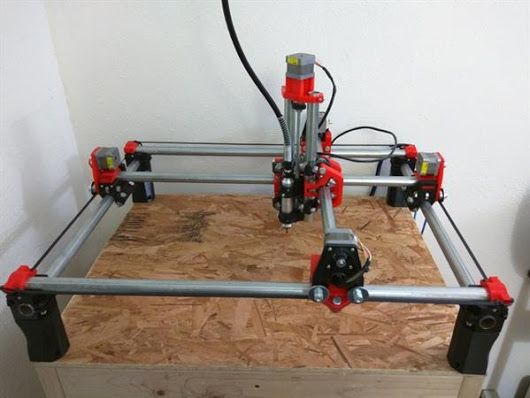

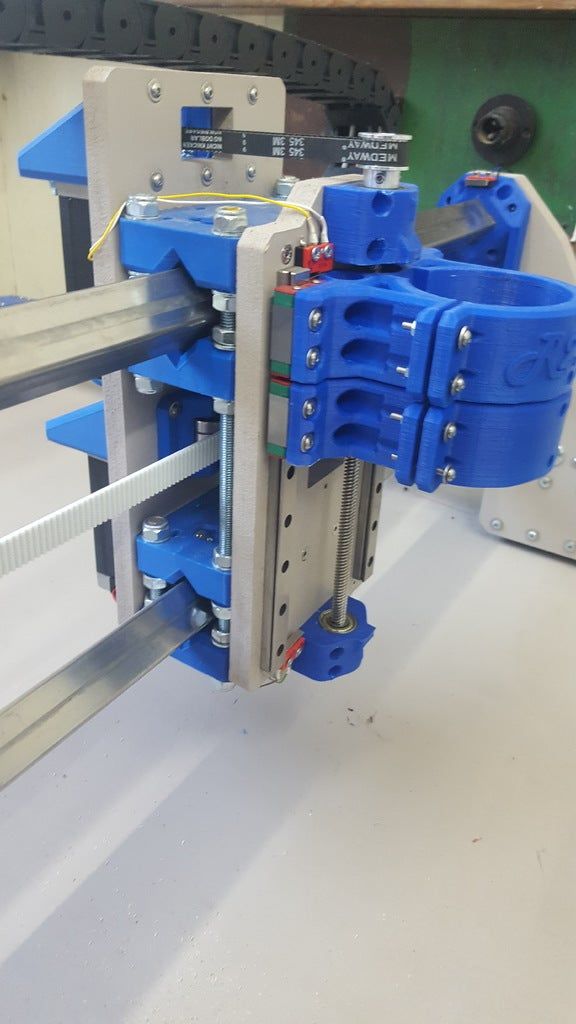

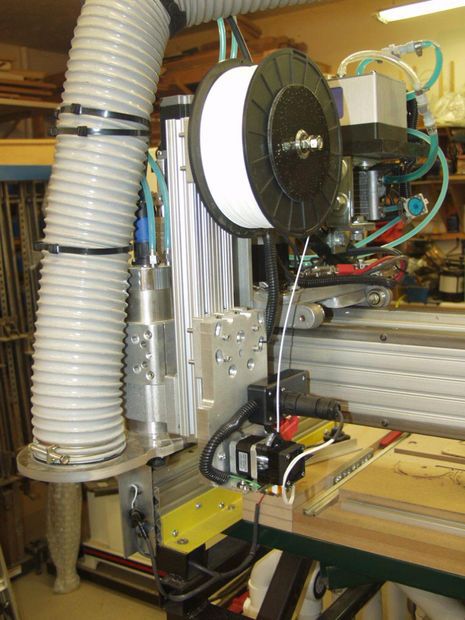

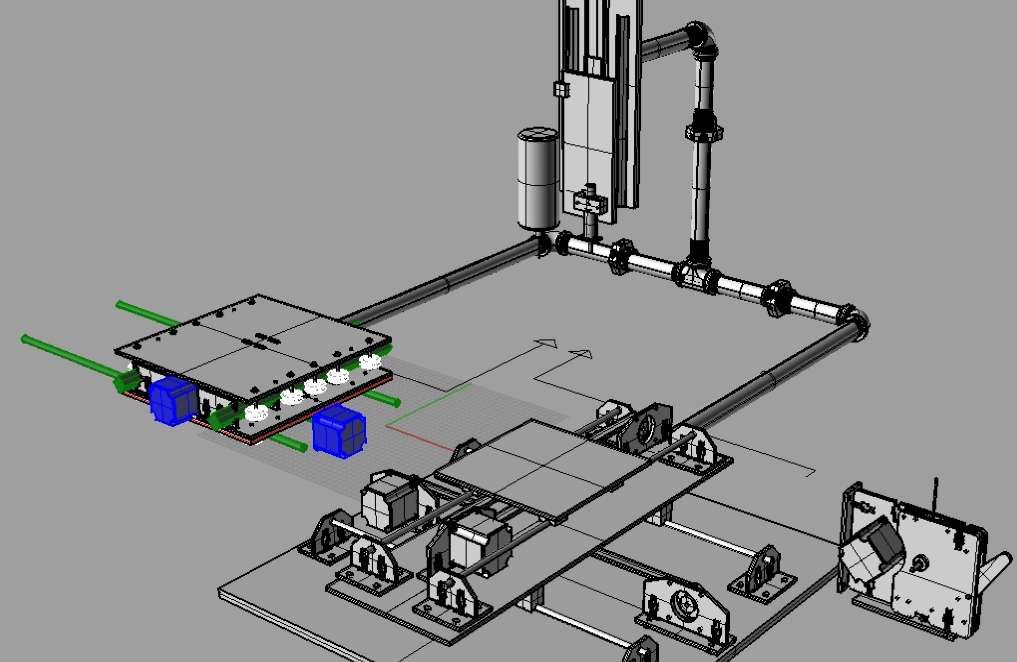

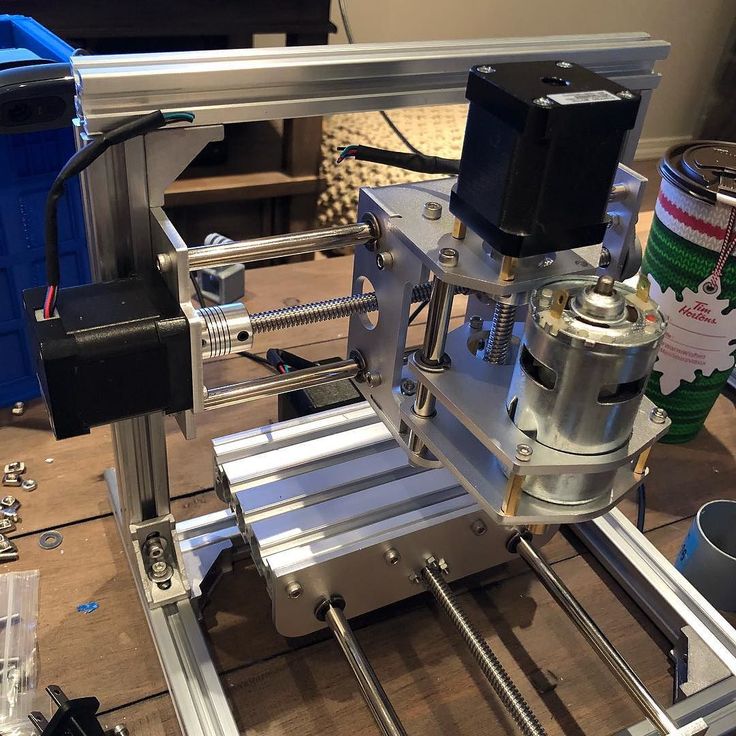

How to convert a CNC machine into a 3D printer?

Before you start converting the CNC machine into a 3D printer, you first need to stock up on the necessary tools and materials. This is the most important and preparatory stage, where you can buy cheap used devices at a lower price. When planning to turn a CNC machine into a 3D printer, anyone can significantly expand the functionality of the equipment. In order to manage the transformed machine-printer in the future, it is recommended to use the Mach4 program. To print in 3D, you need to create a file in STL resolution. It is supported by most 3D printers. If you need to convert the file format, then you can use one of the following programs: Soildworks, google Sketchup and other programs.

To print in 3D format on a desktop CNC machine, it is recommended to use a 3D printer extruder. The temperature sensor must first be replaced with a 3K thermocouple.

The temperature sensor must first be replaced with a 3K thermocouple.

What to do

There is a myth that it is almost impossible to convert a CNC machine into a 3D printer without professional technical knowledge. However, if you use the ready-made instructions, select the necessary materials and tools, then everyone will be able to cope with the task.

To obtain a proper result, the following procedure is recommended:

• Remove the spindle holder. In the holes that have become free, it is necessary to fix the adapter-corner. It is necessary in order to install and fix the print head of the 3D printer;

• To fix the filament spool for 3D printing, you need to assemble a stand made of aluminum profile. It is a resistant metal that is tolerated by almost any mechanical impact;

• on an existing CNC machine, you need to fix a special stand with a spool and thread for 3D printing;

• install additional software;

• download the Mach4 program from the official website of the developer. It is worth noting that the program does not require heavy-duty hardware for normal operation. The package contains Skeinforge software, which enables the normal conversion of 3d files to G-code;

It is worth noting that the program does not require heavy-duty hardware for normal operation. The package contains Skeinforge software, which enables the normal conversion of 3d files to G-code;

• In addition, you need to install the Russian-language interface. In this case, management becomes much easier;

• Mach4mill must be selected to run the Mach4 program. After the download comes to an end, you need to go to the menu and find "Wizards" select "Pick Wizard";

• double click on the button and select "Open STL File"print addon"";

• click on the file and find Open in English. It is necessary to wait until the program completes the creation of the 3D file, then the settings with printing in 3D format should open;

• Next, you need to return to the Mach4 window, you must click on the Post Gcode to Mach4 button. The resulting code is easy to save.

After you manage to bring the print head to the starting print location, you need to erase or reset the coordinates of the tools.

Printing is started by simultaneously holding the combination ALT + R.

What materials can I buy

To make your own 3D printer, you can alternatively purchase the following devices and materials:

• Arduino Mega 2560. This is the main element that will be responsible for the future control of the printer in 3D format. Can be purchased from the Chinese store Aliexpress;

• if you plan to buy the brain offered above, then Mosfet transistors with any other powerful devices are best suited;

• foil fiberglass;

• M6 threaded stud in the amount of 3 pcs. Each is one meter long;

• guides for X, Y, Z axes. In order not to spend extra money, it is enough to use old printers. However, most often there are differences in diameters. Therefore, the bushings will have to be made independently.

You can also borrow stepper motors from an ordinary dot matrix printer. It is necessary to prepare at least 5 pcs. To make a CNC printer, it is not necessary to spend a lot of money to purchase important technical items.

You can choose from our catalog

Wedding Rings 1623

More info

Quick view

Add to favorites

Wedding Rings 952

More info

Quick view

Add to favorites

Wedding Rings 323

More info

Quick view

Add to favorites

Wedding Rings 269

More info

Quick view

Add to favorites

Wedding Rings 1228

More info

Quick view

Add to favorites

Wedding Rings 1430

More info

Quick view

Add to favorites

Wedding Rings 85

More info

Quick view

Add to favorites

Wedding Rings 135

More info

Quick view

Add to favorites

Wedding Rings 715

More info

Quick view

Add to favorites

Wedding Rings 379

More info

Quick view

Add to favorites

Wedding Rings 912

More info

Quick view

Add to favorites

Wedding Rings 1516

More info

Quick view

Add to favorites

3D printing or CNC machining

Accelerate product development, reduce costs with a digital manufacturing platform.

Get an instant quote

Upload to production in 5 min.

CNC milling technology has been around since the 1950s and is essentially the opposite of 3D printing. In the case of 3D printing, the computer controls the printer's print head, which "adds" material in three dimensions, with CNC machining, the milling tool is controlled, which removes material. The key difference between the two technologies lies in the way the given geometry is formed.

Designing 3D models for CNC machines and 3D printers is often carried out on the same software, but already at the next stage of preparing the output data, completely different transformation methods are used. So, for CNC processing, a solid model is used, formed by three-dimensional elements - bodies, and for 3D printing, a surface model - consisting of polygons or a shell.

While 3D printing may seem like an evolving and underdeveloped technology, new printers continue to appear in factories as alternatives to CNC machines. Many companies, getting acquainted with 3D printing, are faced with the complexity of the new technology, but continue to look for ways and areas to apply it in their business.

Many companies, getting acquainted with 3D printing, are faced with the complexity of the new technology, but continue to look for ways and areas to apply it in their business.

Miscellaneous

CNC milling machines and 3D printers have different technological capabilities and limitations that allow them to solve different problems.

CNC milling machine allows you to efficiently produce large, heavy and high-precision products in large runs, which can be used for the production of commercial and industrial equipment, machines, engines. CNC technology also allows the production of small batches of products, but usually with a higher unit cost.

The flexibility of 3D printing makes it possible to quickly switch between different products. However, since the unit cost of a product is always the same, regardless of quantity, 3D printing is not economically viable for large print runs.

The adaptability of 3D printing makes it useful for creating unique, personalized designs, such as custom trauma or dental implants.

Technology selection

When choosing between CNC and 3D printing, there are a few simple guidelines that can be applied to your decision making process.

Choose 3D printing if:

• traditional methods do not allow the production of a part, for example, for very complex geometries

• production time is critical, printed parts can be produced within 24 hours

• low cost for small runs, number of identical parts (less than 10)

• materials that are difficult to process, but it is possible to print, such as alloys of certain metals

CNC machining:

• offers high accuracy and uniformity of mechanical properties throughout the volume of the product (isotropy, as opposed to anisotropic properties in printed products), but usually comes at a higher cost, especially for small volumes

• stability of time costs and the result with a proven technological process

In this case, the key factor is the total number of products - circulation. And if mass production of items (hundreds or more) is required, then neither CNC nor 3D printing can be a cost-effective option. Traditional molding techniques such as investment casting or injection molding will be the best choice.

And if mass production of items (hundreds or more) is required, then neither CNC nor 3D printing can be a cost-effective option. Traditional molding techniques such as investment casting or injection molding will be the best choice.

Materials

CNC machining is mainly applied to the processing of metals and modeling plastics:

• Plastics: ABS, nylon, polycarbonate, PEEK

• Metals: aluminium, stainless steel, titanium, brass

3D printing predominantly works with plastics and, to a lesser extent, with metals:

• Plastics: nylon, PLA, ABS, ULTEM, ASA, TPU

• Metals: titanium, stainless steel, cobalt-chromium alloys

Product geometry complexity

CNC

There are a number of constraints to consider when designing CNC parts, including tool access and tolerances. A feature of CNC machining is the internal corners of the product, which always have a radius due to the shape of the cutting tool, but the outer surfaces can have sharp edges. Also, most non-standard geometries require rotation of the part to access different sides. Rearranging the workpiece increases the processing time, non-standard fixtures and additional fasteners may also be required, which together affect the final cost of the product. Read design guidelines for CNC machining.

Also, most non-standard geometries require rotation of the part to access different sides. Rearranging the workpiece increases the processing time, non-standard fixtures and additional fasteners may also be required, which together affect the final cost of the product. Read design guidelines for CNC machining.

3D print

The ability to create very complex geometries is one of the key benefits of 3D printing. The technology has fewer restrictions, but it should take into account the possible wall thickness of the part, overall dimensions, as well as the need to build support for most types of printing.

Manufacturing process

CNC

The main difference between the CNC machining process is that after the CAD file is received for production, the technologist or engineer works out the choice of tool, processing speed, tool path and changing the position of the part. All these factors greatly influence the quality of the final part and the working time. That is, the preparation process is time-consuming, and the production itself in most cases requires the presence of an operator.

That is, the preparation process is time-consuming, and the production itself in most cases requires the presence of an operator.

3D printing

In 3D printing, the printer operator prepares the orientation of the model in the printer and adds support, and then sends the file to the printer, where it is printed without additional involvement of a specialist.

Post-processing

Also, parts both after machining and 3D printing can be applied a number of post-processing methods that improve the functionality and appearance of the product:

• blasting

• heat treatment

• anodizing

• painting, powder coating

• grinding and polishing

For printed products, post-processing can be additionally carried out on CNC machines to improve the accuracy and quality of the surface, parts are made with a built-in allowance, after which the material is removed mechanically.

Terminals

To a certain extent, CNC and 3D printing technologies overlap in their capabilities, but each of them has its own strengths and weaknesses that make them suitable for solving specific problems.

/cdn0.vox-cdn.com/uploads/chorus_asset/file/8170811/passivdom_autonomous_house_designboom_03_16_2017_818_001_818x544.jpg)