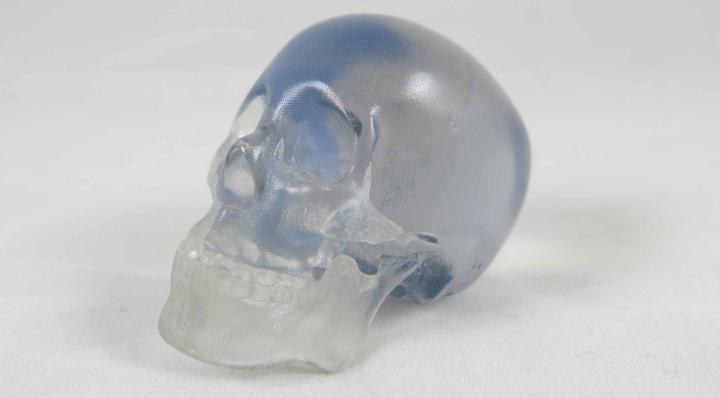

Clear resin for 3d printing

Guide to Transparent 3D Printing

Clear materials, such as glass or acrylic, have a wide variety of applications in consumer products, industrial uses, healthcare, and more. However, prototyping or producing low volumes of clear parts can be expensive and inefficient with traditional methods, which raises the question: can you 3D print transparent parts? The answer is yes, with the right technology and materials.

Stereolithography (SLA) 3D printing can create transparent objects that, with some post-processing, can be made optically clear. Formlabs' latest SLA 3D printers, the compact Form 3+ and the large format Form 3L, take clarity one step further by using a flexible resin tank that reduces peel forces, resulting in clearer parts with smooth surface finish.

There are multiple materials for producing translucent and transparent 3D printed parts:

- Clear Resin is a rigid material that polishes to near optical transparency, making it ideal for fluidics, moldmaking, optics, lighting, showcasing internal features, and any parts requiring translucency.

- BioMed Clear Resin is a rigid, transparent material for biocompatible applications requiring long-term skin or mucosal membrane contact.

- Elastic 50A Resin is a soft and stretchy material that is semi-translucent. It is ideal for prototyping parts normally produced with silicone.

- Flexible 80A Resin is a more stiff soft-touch material that is also semi-translucent. It is ideal for simulating the flexibility of rubber or TPU.

In this guide, we walk you through various finishing methods to create transparent 3D printed parts for a variety of applications, from optics to light pipes to fluidics. Methods range from quick solutions for adequate transparency, to niche techniques for creating optically clear parts.

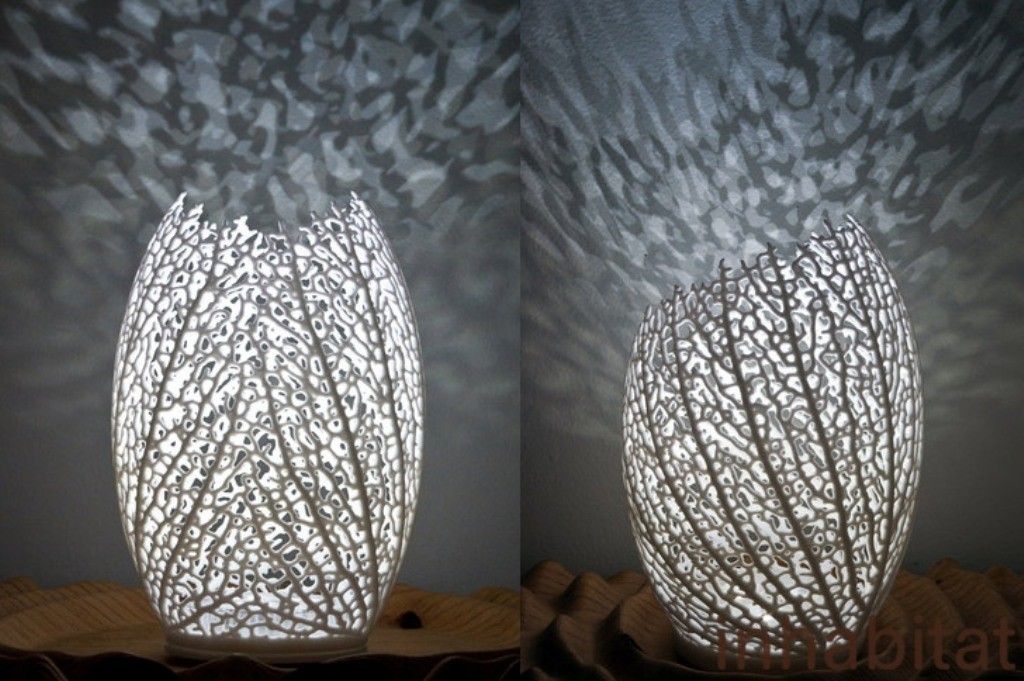

Clear and transparent 3D prints are ideal for creating clear prototype parts, showing internal cavities and details, housing LEDs, creating windows, or printing see though anatomical models and medical devices. Formlabs and our customers have used Clear Resin to create a completely optically clear lens for a fully 3D printed camera, tiles for a Fresnel lens installation in Times Square, light pipes, prisms, millifluidic devices, and more.

Formlabs applications engineer Amos Dudley designed and 3D printed a lens for a fully 3D printed camera.

Sample part

Curious to see how transparent 3D prints SLA 3D printing is capable of? We’ll ship a free clear 3D printed part to your office.

Request a Free Sample Part

Yes, but with caveats. Polymethylmethacrylate (PMMA), commonly known as acrylic, is a transparent thermoplastic that is commonly used as a more durable alternative to glass. While 3D printing acrylic is possible with fused deposition modeling (FDM) 3D printers, it's not really user-friendly as the material itself is toxic and prone to warping, while the 3D printed parts are only semi-translucent due to the lower resolution of FDM printers.

For a 3D printing acrylic-like fully transparent parts, we recommend printing on an SLA 3D printer with Clear Resin and then post-processing the 3D printed parts for full transparency using one of the methods mentioned in this article. Using an acrylic spray is one of the methods to ensure clarity.

Using an acrylic spray is one of the methods to ensure clarity.

We’ve tested several techniques for post-processing parts 3D printed in Clear Resin. In this post, we’ll cover manual sanding, clear coating, and resin dipping. Each finishing option requires varying levels of effort, depending on the degree of transparency and surface finish your part requires.

Applications: Manual sanding and polishing can be effective for simple shapes with few details, but are less suited to finishing complex models. It is very difficult to reach total optical transparency with this method.

You’ll have to sand to extremely fine grits to manually finish a transparent part, but with some effort, you can sand and polish parts to be as clear as a magnifying glass. It is, however, very challenging to completely eliminate all layer lines via manual finishing—you may notice micro-scratches when holding the part at a shallow angle to the light.

Instructions: Use a range of incremental sandpaper grits to smooth your surface, then polish the part with acrylic cleaner and a microfiber cloth.

At around 3000 grit, transparent 3D printed parts become glossy and very smooth to the touch. By 12000 grit, they are reflective. Try using a range of sandpaper and micromesh pads with grits from 400 to 12000, in increments of 200, slowly and carefully to clean the parts between grit levels and to eliminate scratches from the previous level before moving on to the next.

Our support site offers a simple visual step-by-step guide for manual sanding, including an optional finish with acrylic spray.

Tip: If you only need semi-transparency, simply use mineral oil to create an even finish and hide any light spots on your part.

We’ve tested a variety of methods of polishing clear 3D prints, from hand sanding and spray coating to resin dipping.

Applications: Spray coating is an easy, fast way to improve the clarity of parts without much reduction in detail. This method is effective for all kinds of models, as it's able to coat complex details that may be hard to reach with regular sanding and polishing.

Clear coating alone helps to conceal layer lines and protect parts from UV exposure, which can cause yellowing and unintended post-curing. If you’re looking for a smooth, glass-like surface finish, perform the manual sanding and polishing technique prior to coating; the more sanding that comes before clear coating, the better the clarity. This additional step is great for post-processing prototypes that look like fully transparent plastic, e.g., packaging, bottles, and microfluidics.

Instructions: There are several options for clear coating 3D prints, from inexpensive sprays to products that require a dedicated room and tools.

- General purpose clear coat spray paints: There is a wide variety of high quality and affordable sprays. We recommend using a 2K clear coat.

- Automotive sprays: High-solids acrylic urethane clearcoats offer very high gloss and are designed for air-dry and baking conditions, but require a spray gun and dedicated space for spraying, as well as a base coat.

For spray coating, start with a clean, dry part already washed in isopropyl alcohol (IPA). Do not post-cure the part ahead of spraying, as this can cause yellowing. Let the part air dry. Once it’s completely dry, apply two to three spray coats in a dust-free environment.

Tip: For a fee, auto body shops may do the coating for you with a spray like Lesonal Universal Clear. In most cases, these shops will use a light solvent, like naptha to clean and prepare the part’s surface prior to painting.

For an installation in Times Square, Window to the Heart, the Formlabs and Aranda/Lasch teams worked with an auto body shop to spray coat each tile in Lesonal Universal Clear.

Applications: This method is best for when you need very transparent parts, and only works on flat or near-flat surfaces, such as a lens or a window into the interior of a part.

Resin dipping results in parts that are extremely smooth, with clear and sharp surface reflections.

This technique can be used to create an even smoother finish for parts printed in other SLA materials, although it can reduce detail.

Instructions: Apply Clear Resin to the part with drops from a syringe, or by dipping the part as as desired. The viscous resin will fill layers and scratches on the part, forming a completely smooth surface.

The layer of resin should be as thin as possible, while still eliminating layer lines. Pull off any bubbles with a syringe. Completely post-cure the part using the appropriate settings, then repeat the process for the other side, both dipping and post-curing.

Three stages of resin-dipped lenses, with the final lens on the left.

Note: The dipping process alters focal length slightly for lenses. For our 3D printed camera lens, Formlabs applications engineer Amos Dudley designed and printed a lens testing device.

With the Form 3+ SLA 3D printer, you can create clear and fully transparent 3D prints affordably and with minimal post-processing.

Download our white paper for a detailed overview of SLA ecosystems and the step-by-step 3D printing workflow.

Curious to see the quality and clarity firsthand? Request a free transparent 3D printed sample part.

Request a Sample Printed in Clear Resin

How To 3D Print Transparent Resin Parts

Getting transparent 3D printed parts can be quite challenging, but the team of engineers at Liqcreate have developed a process that anyone can do at home.

Updated on November 14, 2022

by

Liqreate Engineers

Getting transparent 3D printed parts can be quite challenging. Clear and transparent 3D prints are ideal for creating clear prototype parts, showing internal cavities and details. Applications like LED housings, prototyping lens parts and microfluidic devices are a few examples of application 3D-printed with clear resin.

Resin 3D-printing is one of the only 3D-printing technologies that can create high resolution transparent plastic parts. One of the challenges in resin 3D-printing is to produce perfect transparent parts that will not yellow over time. Often, first-time-users are surprised by the transparency of parts fresh from the printer, as seen in the Coca-Cola bottle in the image below on the left side. After washing and drying, the transparency is lost and the part has a “frost” finish (middle bottle). A post-processing step is necessary to create long-lasting transparent plastic parts.

One of the challenges in resin 3D-printing is to produce perfect transparent parts that will not yellow over time. Often, first-time-users are surprised by the transparency of parts fresh from the printer, as seen in the Coca-Cola bottle in the image below on the left side. After washing and drying, the transparency is lost and the part has a “frost” finish (middle bottle). A post-processing step is necessary to create long-lasting transparent plastic parts.

Figure 1: Parts 3D-printed with Liqcreate Clear Impact resin, on the left part fresh from the printer, middle after washing and drying, on the right after coating.

There are a wide range of clear resins available for 3D-printing. Not every resin is suitable for long lasting transparent parts. For instance epoxy resins, often used in large 355nm laser 3D-printers are notorious for their discoloration over time. Next to epoxides, acrylates and urethanes are used in LCD, DLP, desktop laser based and MSLA 3D-printers. Depending on the quality of the resin, some are better for clear, non-yellowing parts. There are a few factors that are important when it comes to transparent parts:

Depending on the quality of the resin, some are better for clear, non-yellowing parts. There are a few factors that are important when it comes to transparent parts:

- Resin formulation and quality

- Post-processing

- Post-curing

Resin formulation and type of 3D-printer

The basics of good transparent and low/non-yellowing parts is the resin itself. Low quality raw materials and impurities in the resin can cause extra yellowing over time. Next to selecting high quality raw materials, the resin technology and additives are important as well. In this article we are using Liqcreate Clear Impact developed for impact application prototypes and designed to prevent extra yellowing overtime.

Post-curing clear parts

Post-curing is an important step in resin 3D-printing. During printing, the resin does not fully cure and is often soft and bendable. With a proper post-cure, its final properties are achieved. Often a good dose of UV (365, 385 or 405nm) at a slightly increased temperature is required for near 100% conversion. To get the least yellowing for clear parts during post-processing and after, it is important to post-cure at room temperature, preferably in three steps of 5 minutes. At elevated temperatures, side products can cause extra yellowing.

Often a good dose of UV (365, 385 or 405nm) at a slightly increased temperature is required for near 100% conversion. To get the least yellowing for clear parts during post-processing and after, it is important to post-cure at room temperature, preferably in three steps of 5 minutes. At elevated temperatures, side products can cause extra yellowing.

Post-processing clear parts

After printing, clear parts often look amazing. They are 100% transparent, which change when the parts are washed. After washing in IPA or Ethanol, the parts slowly turn into a frost finish once the solvent is drying. To get back to a transparent finish, some post-processing steps are required.

There are a few possibilities to post-process clear parts to get a transparent surface finish. The mostly used techniques are:

- Sanding and polishing

- Resin dipping

- Nitrogen UV-curing

- Spray coating

Sanding and polishing

Manual sanding and polishing is an effective and affordable method for parts with simple shapes. Often solid parts like lenses, microfluidic devices or solid parts like prisms can be effectively turned into transparent parts. Start with a rough sandpaper grid and work towards a very smooth grid. Sand and polish all the layer lines and defects away and eventually with the finest grid, parts turn transparent. The final finish should be polished with a microfiber and special cleaner. A polishing wheel can make this job easier, as long as the parts are not too complex and difficult to reach by hand or wheel.

Often solid parts like lenses, microfluidic devices or solid parts like prisms can be effectively turned into transparent parts. Start with a rough sandpaper grid and work towards a very smooth grid. Sand and polish all the layer lines and defects away and eventually with the finest grid, parts turn transparent. The final finish should be polished with a microfiber and special cleaner. A polishing wheel can make this job easier, as long as the parts are not too complex and difficult to reach by hand or wheel.

Figure 2: Glass protection cover

Resin dipping

Resin dipping was first proposed by Formlabs in their article on post-processing of clear parts. It works by dipping the part in 3D-printing resin and then post-cure it. After a few layers the parts turn transparent. It should be noted that 3D-printing resin is perhaps not the best type of resin to use as a coating. The viscosity and sticky surface finish will not be ideal for daily used parts and the details are partly faded away by the layer of the resin.

Nitrogen curing

Taking the best part of resin dipping and making it even better, you end-up with nitrogen curing your parts. When your parts are printed, don’t wash them and let most of the resin drip off the part. This way a thin resin coating is left on the part. Adding a bit of heat can make the resin layer thinner to preserve more details. When the layer is thin enough, cure the part in an UV-chamber with nitrogen. This will eliminate all the oxygen and give a non-sticky and transparent part.

Spray coating

Easiest of all is to wash your parts with IPA/ethanol, dry and UV-cure them, followed by a spray coating. If the part is simple, a sanding step can be executed before coating. This will increase the translucency and erases the pixel and printing layers. Use an acrylic spray and spray multiple layers to get good surface finish. The Coca Cola can in the picture above on the right side is made this way, without sanding. For an easy, affordable and fast process, this method is advised. The transparency can be boosted with adding more coating layers on top. After a few layers parts can look like the 3D-printed protective glass below.

The transparency can be boosted with adding more coating layers on top. After a few layers parts can look like the 3D-printed protective glass below.

Figure 3: Sprayed glass protection cover

Team Liqcreate wish you happy printing!

Article Tags

- 3D Printing

- Firmware

- 3D Design

- MatterControl

- Press Releases

- Small Business

- Automotive

- E3D

- Jewelry Making

- Engineering

- Entertainment Industry

- MatterControl Touch

- ESD Materials

- NylonX

- BCN3D

- Open Source

- Crafty Pen

- Digital Fabrication Anatomy

- How To

- Hardware and Upgrades

- Tips and Tricks

- Weekend Builds

- Top Ten

- Education

- Tech Breakdown

- Women in 3D Printing

- Project Ideas

- Advanced Materials

- Reference

- Pulse Dual Extrusion

- Product Spotlight

- Aerospace

- Jobs

- Military & Government

- Multi-Tool Machines

- Getting Started

- Healthcare

- How To Succeed With Any 3D Printing Material

- Creality3D

- Architecture

- 3D Printer Reviews

- Hacker of the Month

Related Products

View all related productsFunToDo Nano Clear - perfectly transparent photopolymer

Consumables

ZOBU 3D ARTEL Anycubic Photon Wanhao Duplicator 7 (D7)

In our assortment replenishment - Photopolymer FunToDo Nano Clear, transparent (1 kg)

Nano Clear - an ideally transparent photopolymer for DLP / LCD printing with minimal shrinkage. Prints with resolution up to 2 microns (0.002 mm). There are many applications where high precision transparent resin is required: microfluidics (microfluidics), micro illumination, microscopic filters, etc. This is a unique transparent resin that has no stray light! Nano Clear resin can be dyed. To obtain the desired shade of color, purchase a complete set of pigments (4 pieces of 20 ml) and mix in any proportion. nine0003

Prints with resolution up to 2 microns (0.002 mm). There are many applications where high precision transparent resin is required: microfluidics (microfluidics), micro illumination, microscopic filters, etc. This is a unique transparent resin that has no stray light! Nano Clear resin can be dyed. To obtain the desired shade of color, purchase a complete set of pigments (4 pieces of 20 ml) and mix in any proportion. nine0003

NanoClear resin model, after polymerization, is close in feel and properties to molded plastic product. Nano Clear polymer has a Shore D hardness of 85. Viscosity 80 mPas.

Advantages of FunToDo resin:

- Reasonable price and high accuracy. Layer thickness from 10 µm

- For super fast printing. Cure time 0.5 s for 0.02 mm layer with 240W lamp power

- Wide illumination range 225-415nm Resin suitable for most DLP/LED and SLA printers

- Ultra-low shrinkage. What you see on the screen is what you get! Object shrinkage only 0.

5%

5% - Safety. FunToDo resins are low odor

FunToDo's resin is one of the best resins on the professional 3D printing market. This photopolymer differs from competitors in uniform saturated color, as well as high speed 3D printing. The resin is compatible with almost all DLP/LED and SLA 3D printers on the market:

Anycubic Photon is one of the best selling photopolymer printers

Anycubic Photon S - a novelty with modernized mechanics and a diode matrix, which has a directional illumination

3D Artel Zobu (bestseller!) - the most budgetary, but very reliable and fast 3D printer, with an autonomous control unit and control in Russian

3D Artel Zobu 3.0 - minimal stray light and the most accurate printing thanks to a matrix with a focusing lens

Wanhao D7 - a universal photopolymer printer model from the leader, Wanhao Wanhao D7 Plus - Offline 3D Printer with Commercial Slicer in Russian Wanhao Duplicator 8 is the largest printable area of a low cost printer

The combination of an affordable price, as well as a short exposure time, allows you to significantly save your money, reduce the cost of 3D printing and lead time.

A cure time of 0.5 seconds for a 0.02 mm layer is easily achieved on standard DLP printers with lamp power around 240W. Photopolymers operate in a very wide range of wavelengths, from very short wavelengths of 225nm to the visible light limit of 415nm. Thanks to a good combination of reagents, almost any light source can be used to initiate the polymerization process. FunToDo photopolymers have ultra-low shrinkage! Today's standard of 3.5% is considered low shrinkage, but we have limited shrinkage to 0.5%. What you see on your computer screen is what you get. A shrinkage of 3.5% seems small, but if you take a 10cm (100mm) object, 3.5% becomes 3.5mm! This is a huge difference compared to the 0.5mm on Phantoudu polymer. FunToDo resins have a low odor and hardly irritate the skin. nine0003

Other FunToDo resins available in our shop:

FUN TO DO STANDARD BLEND 1000Fun To Do Snow White (Funtodo SW)Fun To Do Industrial Blend ResinFun To Do Dentifix-3DFun To Do Castable Blend (Funtodo CB) )Photopolymer FunToDo Deep Black

Subscribe to the author

Subscribe

Don't want

3

Choosing a liquid photopolymer for a 3D printer.

Classification of materials for SLA/DLP 3D printing. nine0001

Classification of materials for SLA/DLP 3D printing. nine0001 Contents:

- Introduction

- SLA Overview

- SLA standard resins

- Standard photopolymer resin - Standard

- Clear photopolymer resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility) nine0029 Dental Long Term Biocompatible Resin (Class IIa biocompatible)

- Class I biocompatibility vs Class IIa biocompatibility

- Castable SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail, and a smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0003

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0003

SLA 3D printing resin overview

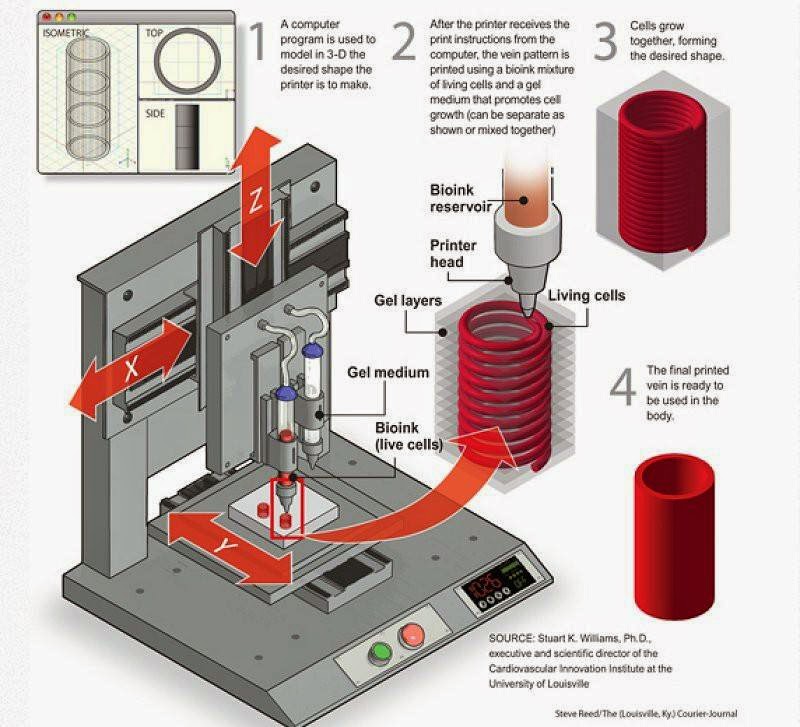

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0003

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0003

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0003

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0003

nine0003

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0003

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0003

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0003

nine0003

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0003

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0003

nine0003

durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough ( tough ) resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0003

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o o C, but has poor toughness and is even more brittle than standard resin.

ceramic ceramic reinforce resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0003

nine0003

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0003

Comparative chart of material properties of various technical resins. Image credit: Formlabs.

Dental and medical SLA resins

Photopolymer resin for medical devices - Custom Medical Appliances (1st Promoster Class 1) 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Class 1 biocompatible resins can be used to make medical equipment such as surgical guides.

Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room. nine0003

Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room. nine0003 Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible) 0020

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0003

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0003

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0003

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.