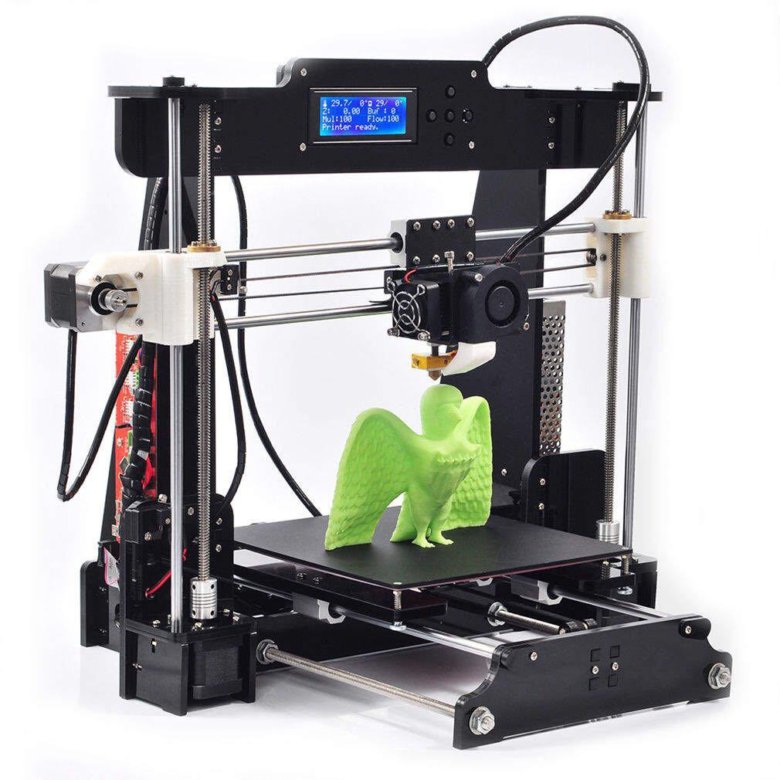

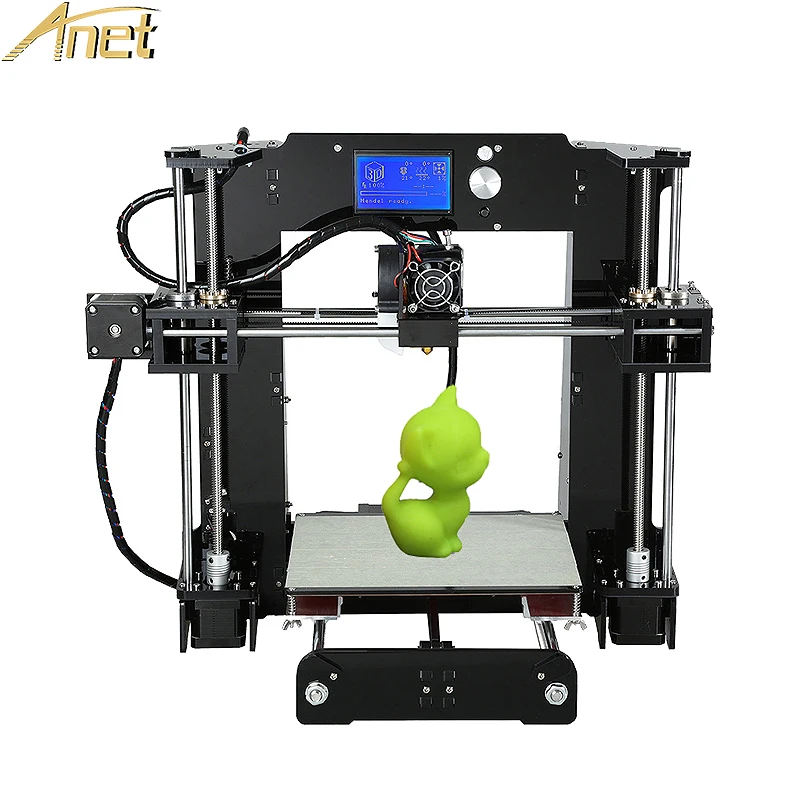

Cheap abs 3d printer

Best ABS 3D Printers 2022: Low-Cost & Premium

Fancy dabbling in ABS 3D printing but aren’t sure where to start? We’ve pulled together a comprehensive guide showcasing the very best ABS 3D printers under the sun. You’ll find budget picks, professional-grade workhorses, and everything in between, with a guarantee that each one is money well spent.

7 Best Throwing Axes and Hatchets +...

Please enable JavaScript

7 Best Throwing Axes and Hatchets + Buying Guide [2022 Tried & Tested]

Not every printer has what’s needed to craft quality prints, but, as is increasingly the case in the 3D printing space, there are quite a few options out there. It’s no longer a case of finding a lone suitable printer but picking the right one from a sea of potential candidates. We’ll help you sort the wheat from the chaff and hone in on the very best out there.

What Is ABS?

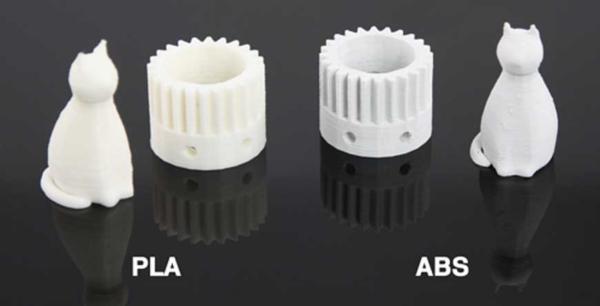

ABS filament, or acrylonitrile butadiene styrene, is, alongside PLA, it is one of the most popular filaments used in 3D printing. Makers favor ABS for its durability over PLA, which tends to be more brittle and less flexible. Due to its high melting point, ABS fares better in high-temperature environments and is prized among makers for its impact and chemical resistance.

This makes ABS a favorite in manufacturing, including injection molding, for applications as broad as plastic toys such as the ubiquitous Lego block to car dashboards by way of the plastic shell on countless home appliances.

ABS is notoriously difficult to tame and challenging to work with, though. The thermoplastic requires relatively high and stable temperatures to melt, unlike PLA, which becomes malleable at a comparatively lower temperature.

Other challenges surface as a consequence, notably ABS’ propensity for warping, a symptom of thermal contraction, something ABS is prone to due to its fast solidification properties. In other words, ABS shrinks when cooling. It’s vital to manage the speed at which the filament sheds temperature to avoid issues.

Best ABS 3D Printers 2022

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

FlashForge Adventurer 3 – Top Pick For Beginners and Casual Makers

- Price: Available on Flashforge Official store here / Check price on Amazon here

- Build volume: 150 x 150 x 150 mm

- Max extruder temperature: 240°C

The FlashForge Adventurer 3 taps liberally into the beginner-friendly playbook. This 3D printer for ABS abounds with features that take much of the initial sting out of 3D printing. As exemplified by a plain, uncomplicated touch screen and a removable flexible build platform, FlashForge Adventurer 3 removes many of the customary initial hurdles.

The simplicity extends to generally more hands-on aspects with assisted calibration, automatic filament loading, and an easy detachable nozzle assembly. And then, there’s pure convenience thanks to Wi-Fi connectivity and a serviceable built-in camera to monitor prints via the cloud.

With such a focus on ease-of-use, FlashForge could have side-stepped finicky ABS printing, but the FlashForge Adventurer 3 is well equipped to handle that capricious thermoplastic.

The printer features a fully enclosed chamber, which, when allied to an extruder capable of reaching 240°C in under a minute and a heated bed topping out at 100°C, you have everything required for ABS to flourish. While unremarkable, the print quality is consistent enough to generate perfectly adequate parts for decorative, or household use ends.

What the FlashForge Adventurer 3 isn’t is a machine for professionals or veteran printers. We could pinpoint the cramped 150 x 150 x 150 mm, the minimal slicer compatibility, or the filament chamber only accommodating FlashForge’s filament, but ultimately, this isn’t the target audience here.

If you’re a beginner or educator looking for a low-cost, ABS-capable printer that won’t bombard you with options or advanced features, the FlashForge Adventurer 3 is a compact, dependable machine.

Creality CR-200B

- Price: Available at Creality official store here / Amazon here

- Build volume: 200 x 200 x 200 mm

- Max extruder temperature: 260°C

You’ve likely heard of the Creality Ender and CR series. But, far less central to Creality’s marketing pushes is the Creality CR-200B. A sharp fully-enclosed printer designed from the ground up to be user-friendly, the Creality CR-200B targets makers eager to print using high-temperature filaments on a budget. It’s among the best ABS 3D printers for first-timers.

Despite being inexpensive, the Creality CR-200B sports a well-rounded feature set, tuned to handle ABS, in particular. The enclosed design joins forces with an extruder with a temperature cap of 260°C and a heated carborundum glass bed that can maintain 100°C. The Creality CR-200B provides just the right environment for ABS to print, and, more crucially, cool slowly to avoid warping and other issues.

Put to the test, the Creality CR-200B’s print quality screams predictability, although the results won’t compete with printers twice the price. For hobbyist’s projects, the prints are more than fit for purpose, whether you’re creating decorative pieces or basic functional parts to make life easier around the house.

The presence of a 4.3-inch touch screen, a smart filament runout sensor, an internal LED light, and fully assembled shipping make the Creality CR-200B effortless to fire up and use for beginners. If aesthetics are important, the Creality CR-200B’s contoured edges and clean black/white design are easy on the eye.

There’s no skirting around the fact the Creality CR-200B’s 200 x 200 x 200 mm build volume isn’t much to write home about, even by budget standards. Other than the limited potential for larger prints and manual bed leveling, we’d wager thrifty makers looking for a reliable ABS printer will have next to no complaints working and honing their skills with the Creality CR-200B.

Qidi Tech X-Plus

- Price: Check price on Amazon here

- Build volume: 270 x 200 x 200 mm

- Max extruder temperature: 300°C

The Qidi Tech X-Plus meets all those toasty temperature requirements for cooking up quality ABS, but with an interesting twist. Rather than a single extruder that can vary temperatures, Qidi Tech made the bold choice of including two interchangeable extruders. Elegant, but also practical.

Each one focuses on providing the best thermal environment possible using either high-temperature filaments such as ABS or your garden variety 3D printing staples like PLA and PETG. One of the two extruders hits temperatures up to 300°C, surging far higher than the baseline requirement for ABS. Nylon and PC also play nice with the Qidi Tech X-Plus.

The Qidi Tech X-Plus ABS-friendly chops extend further, positioning it as one of the best 3D printers for ABS printing. It houses a double-sided reversible heated bed, one side fine-tuned to accommodate ABS printing. Additionally, the Qidi Tech X-Plus has a fully enclosed chamber and air filtration system, ticking off yet another temperature requirement for printing ABS and dealing with toxic fumes in the process.

Additionally, the Qidi Tech X-Plus has a fully enclosed chamber and air filtration system, ticking off yet another temperature requirement for printing ABS and dealing with toxic fumes in the process.

You’d expect all these features to come with trade-offs. Fortunately, that isn’t the case here. The Qidi Tech X-Plus arrives with a touch screen, plenty of connectivity options, including Wi-Fi, and, best of all, effortless assisted bed leveling. Either beginners looking for a gentle way into ABS printing or even semi-professionals that prize efficiency will relish these.

The Qidi Tech X-Plus has a 270 x 200 x 200 mm build volume to cap things off. Not exactly small, nor big, the build volume is suitable for many applications, but if large prints form part of your plans, a heftier alternative is a better bet.

FlashForge Creator Pro 2

- Price: Available at Flashforge Official store here / Check price on Amazon here

- Build volume: 200 x 148 x 150 mm

- Max extruder temperature: 240°C

The FlashForge Creator Pro 2 ticks all the boxes for ABS printing. The printer has an enclosed chamber, a 240°C extruder, and a heated bed up to 120°C, but it stands out from the crowd thanks to an independent dual extruder setup.

The printer has an enclosed chamber, a 240°C extruder, and a heated bed up to 120°C, but it stands out from the crowd thanks to an independent dual extruder setup.

The IDEX, as it’s called, allows the printing of different material types simultaneously. These can work with different colors/filament types for mirrored, duplicate, or multi-color prints. Alternatively, it can complete independent prints simultaneously. Doing so opens up many ABS printing possibilities, not least for more complex projects with overhangs that require soluble support structures such as rafts and brims.

Better yet, FlashForge keeps the asking price relatively low for what is usually a technology reserved for far more expensive ABS 3D printers. IDEX and inexpensive aren’t usually synonymous, but they are in the case of the FlashForge Creator Pro 2.

Though the FlashForge Creator Pro 2 arrives fully assembled and boasts user-friendly features like a touch screen, bed leveling is manual. When considered alongside the IDEX system, seasoned makers or small businesses with technical expertise will find this printer a better fit than a beginner looking for an easy first step into 3D printing with ABS.

Read more: the best dual extruder 3D printers

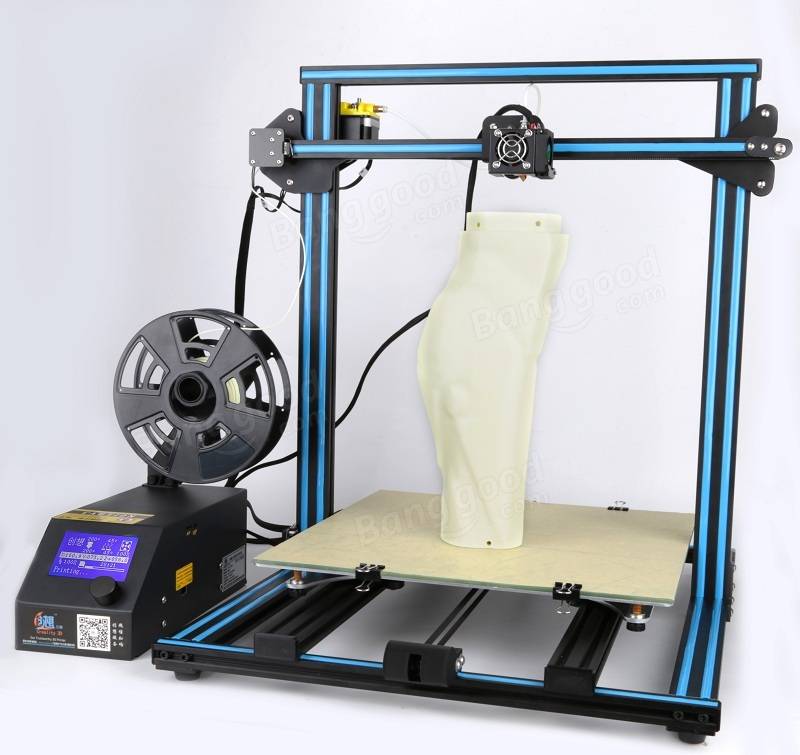

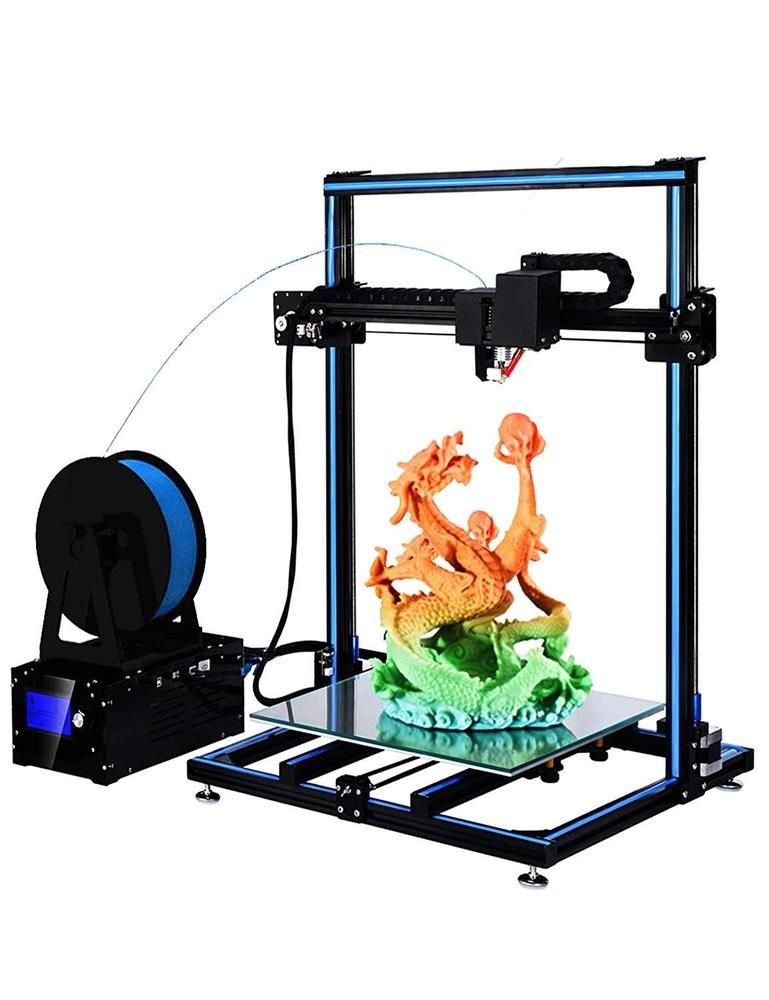

Creality CR-5 Pro

- Price: $1,199 — Available at Creality official store here

- Build volume: 300 x 224 x 380 mm

- Max extruder temperature: 300°C

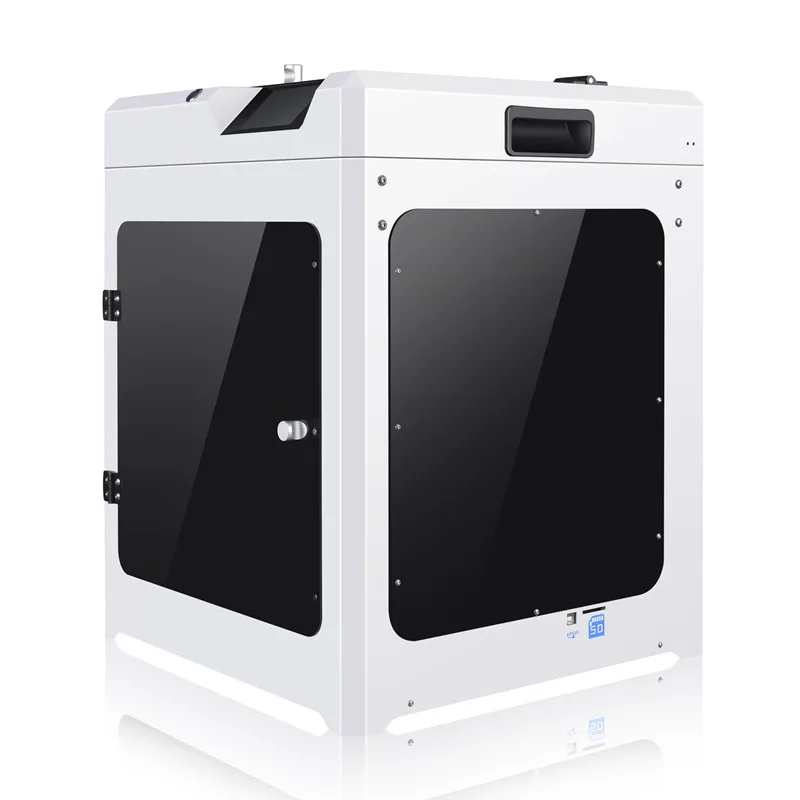

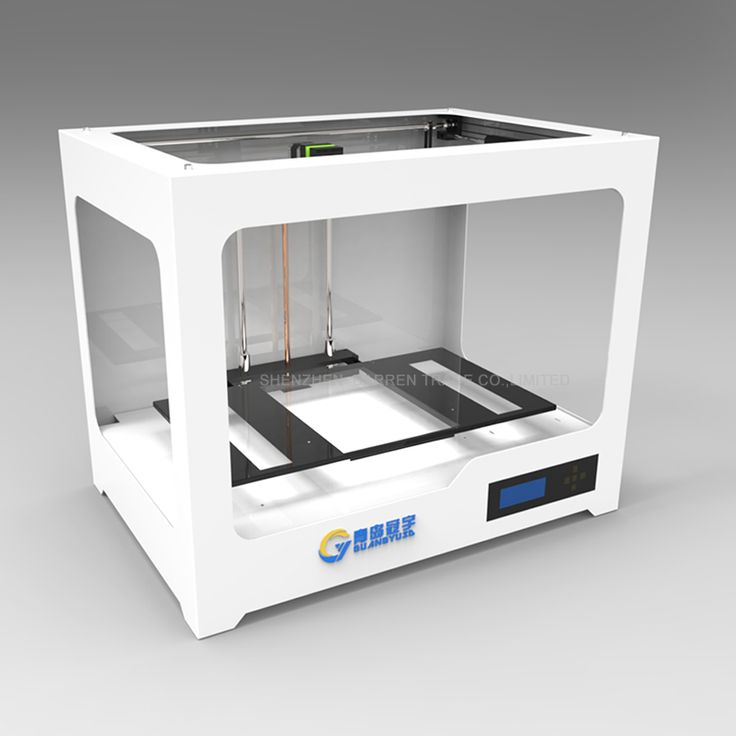

Striking in appearance with a distinct white shell and more than a passing resemblance to the stellar Ultimaker S5, the Creality CR-5 Pro asks you to dig deep into those coffers but justifies every penny.

A precision Bowden extruder melts ABS to an ideal 250°C while a 100°C heated bed ensures a warm landing pad. Additionally, the chamber is enclosed, trapping in all the heat ABS depends on.

Standard stuff for an ABS-ready printer, you could say. But the Creality CR-5 Pro goes the extra mile. It has an Ultrabase-like carborundum glass plate, a roomy 300 x 225 x 380 mm build volume, and print quality with a level of smoothness and accuracy you won’t find on budget ABS 3D printers.

It isn’t easy to define the Creality CR-5 Pro as an industry-grade or a consumer-level printer as it seems to straddle both categories. But, therein lies the printer versatility. The Creality CR-5 Pro can serve hobbyists with the cash to spare just as well as a small business looking for a productivity-geared ABS printer.

Read more: the best enclosed 3D printers

Dremel 3D45 – Best ABS 3D Printer For Schools

- Price: $1,999 — Available on Matterhackers here / Available on Dynamism here

- Build volume: 254 x 152 x 170 mm

- Max extruder temperature: 280°C

The Dremel 3D45 is all about simplifying and streamlining ABS printing by bringing it under a user-friendly ecosystem that takes care of everything from the outset. For schools and educators that rank safety, ease of use, and performance on the same level of importance, the Dremel 3D45 is among the best options currently available.

The Dremel 3D45 spec sheet reads like a list of ideal ABS printing requirements: an enclosure, a 280°C all-metal extruder, and a 100°C heated bed. Using Dremel’s own ABS filament dials in optimum settings automatically and guarantees excellent prints every time. Safety and easy printing also pop up throughout the machine with carbon filters, see-through panels, a touch screen interface, and semi-automatic bed leveling.

The ecosystem theme here might be too restrictive and tight to swallow for lone makers who favor options and possibilities. There’s very little left to chance, which by extension stunts what the Dremel 3D45 can do beyond a narrow, hand-held, printing experience.

Read more: the best 3D printers for schools and education

Ultimaker S3

- Price: $4,000 — Available on Dynamism Webstore here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

- Max extruder temperature: 280°C

Last but not least, the Ultimaker S3 struts onto our list of the best ABS 3D printers. Deemed a more cost-friendly counterpart to the Dutch manufacturer’s $6000 Ultimaker S5, the Ultimaker S3 surges up the ranks as a versatile professional 3D printer suited to prototyping to batch-print manufacturing.

Deemed a more cost-friendly counterpart to the Dutch manufacturer’s $6000 Ultimaker S5, the Ultimaker S3 surges up the ranks as a versatile professional 3D printer suited to prototyping to batch-print manufacturing.

What makes the machine such a competent ABS printing pick is the combination of 280°C extruders, 140°C heated bed, and sleek enclosure design. The resulting print quality is among the best of any printer on our list, defined by excellent finish, distinct, precise edging, and fine detail. Should you want to work with other filament types, the Ultimaker S3 handles PLA to PVA, CPE, and nylon equally well, too.

The Ultimaker S3 also houses a dual extrusion system, meaning you can juggle two filament types or colors in a single print. The printer also ships with swappable print cores, each with properties suited to a particular filament type.

It’s worth touching on other features, too. For the price, you’ll land all the most coveted ease-of-use bits and bobs, including automatic bed leveling, Wi-Fi connectivity, a touchscreen interface, filament sensor, and more besides.

Buyer’s Guide – What To Consider When Buying An ABS 3D Printer

Enclosed Chamber

An enclosed chamber is a must-have and non-negotiable feature when shopping around for an ABS 3D printer. The reasoning behind this comes down to temperature control. ABS shrinks or contracts when it cools.

If ABS’ temperature drops too quickly, this can cause unwanted warping and curling. You’ll want to avoid this with an enclosure that ensures a steady temperature, allowing ABS to cool at a slower, more controlled rate, canceling out the likelihood of problems.

Extruder/Nozzle Temperature

ABS melts anywhere from 220°C to 230°C. Look for printers sporting an extruder and nozzle capable of temperatures from 220°C to 250°C as standard, if not higher, if you plan to work with more heat-sensitive materials such as nylon.

Heated Bed

Be sure to pick out a 3D printer with a heated bed and one ideally capable of temperature up to 120°C. However, 100°C works well enough with ABS. A heated bed ensures ABS is deposited on a suitably hot platform to avoid warping and other issues.

A heated bed ensures ABS is deposited on a suitably hot platform to avoid warping and other issues.

Budget

The best 3D printers for ABS printing are available at various price points. Features set them apart. You’ll find everything needed to print using ABS confidently on budget options. However, they will often lack quality-of-life features such as auto-bed leveling, Wi-Fi connectivity, and the like.

There’s also a direct correlation between price and the final quality of the prints. Pay more, and the results are generally of better overall quality.

If you’re starting 3D printing, we recommend opting for an inexpensive option to test the waters, with the option to level up to a pricier model as you become more confident.

Fans

While fans are great tools for less heat-sensitive materials like PLA, they can be detrimental to ABS printing. Introducing fans that remove heat from the chamber can complicate keeping the right thermal environment for ABS to shine. We recommend 3D printers with the option to turn fans off.

We recommend 3D printers with the option to turn fans off.

Key 3D Printer Features Needed to Print With ABS

While more demanding compared to relatively docile and predictable PLA, ABS can thrive in the right conditions.

Enclosed Chamber

First and foremost, a stable thermal environment. A 3D printer with an enclosed chamber provides such an environment, bottling heat inside the build area and blocking out warp-inducing cool air from souring the printing process.

High-Temp Nozzle

Alongside, due to ABS’ temperature sensitivity, it requires an extruder with a nozzle capable of reaching temperatures ranging from around 220°C to 250°C depending on specific filament manufacturer recommendations. Similarly, ABS fares best with a heated bed capable of maintaining a temperature around 100°C to 110°C.

Print Surface & Adhesive

Beyond specification-related requirements, you can take more granular steps to print with ABS successfully. Among them is working with a clean print surface, using an adhesive to help that all-important first layer latch onto the build plate, and switching off cooling fans if a printer has them.

Ventilation for ABS Toxic Fumes

Finally, working with ABS, you’ll invariably have to contend with wafts of pungent, foul-smelling, toxic fumes. Sufficient ventilation in the workspace helps dissipate these fumes, so be sure to crack open a window. Better yet, 3D printers housing air filters, ideally HEPA variants, help keep fumes in check, ridding them of their most harmful properties.

ABS 3D Printer Upgrades — These Will Help You Print Better Parts

Most ABS plastic 3D printers ship with everything you need to get started, but there are always ways to improve the process and level up your printer. Here are three of the most common upgrade paths available to you.

All-Metal Hotend

One cost-effective upgrade that can prolong the longevity of your 3D printer is switching from a PTFE-lined hot end to an all-metal hot end or Capricorn tubing. PTFE lining is prone to wear and tear at temperatures approaching 250°C. Installing an all-metal variant is an excellent way to cut down on future maintenance.

Read more: the complete 3D printer nozzle buyer’s guide

BLTouch Sensor

Bed leveling is hands down the most frustrating part of 3D printing and is often the cause of countless printing issues and complications. If your printer doesn’t have automatic bed leveling or, at least, assisted bed leveling, then drafting in a BLTouch Sensor to help is a wise upgrade.

Read more: auto-leveling 3D printing

PEI Sheets

Not so much a hardware upgrade, as a handy tip, using PEI sheets can make all the difference when printing with ABS. PEI, or Polyetherimide, sheets remove the need for hair spray, glue, tape, and whatnot to ensure a firm and accurate first layer, all while being relatively inexpensive. Convenient because they are easy to install and require no preparation work, PEI sheets simplify the often hit-and-miss nature of 3D print adhesion.

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

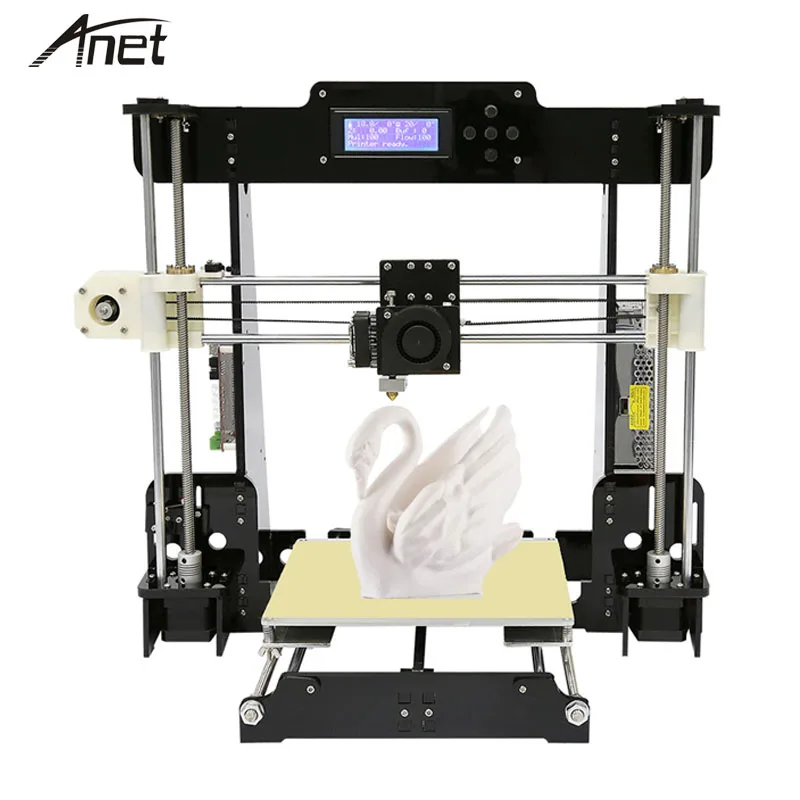

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

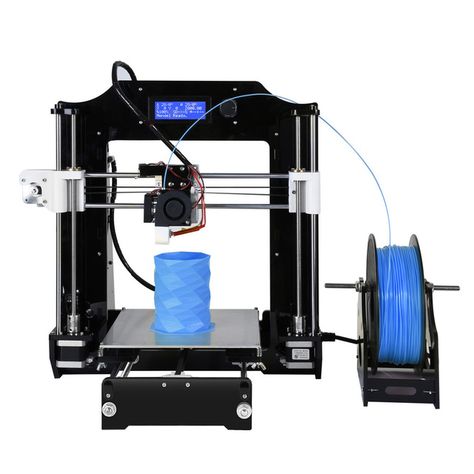

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $429. 99 99 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

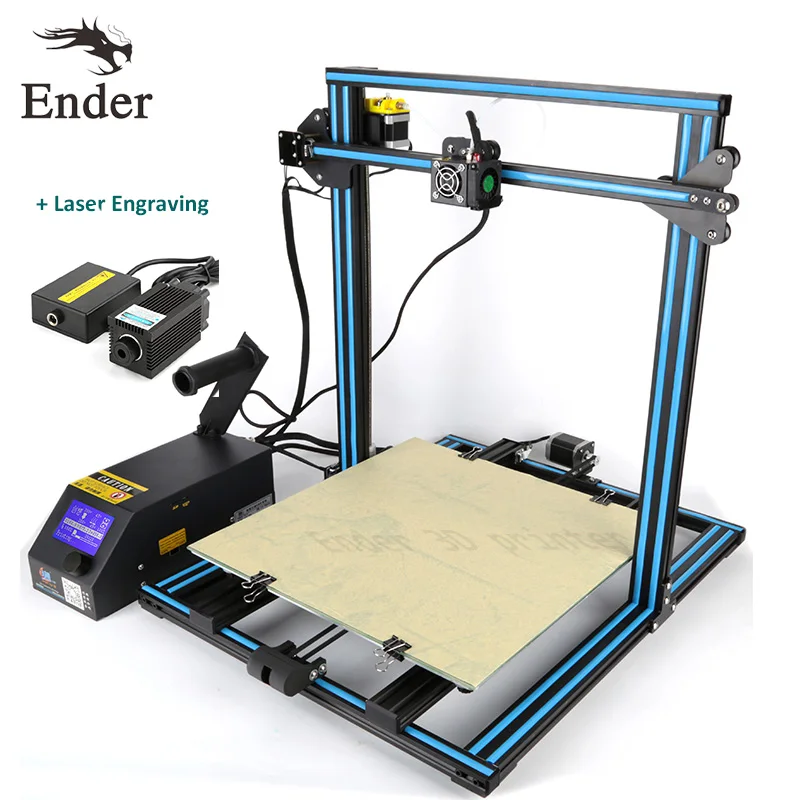

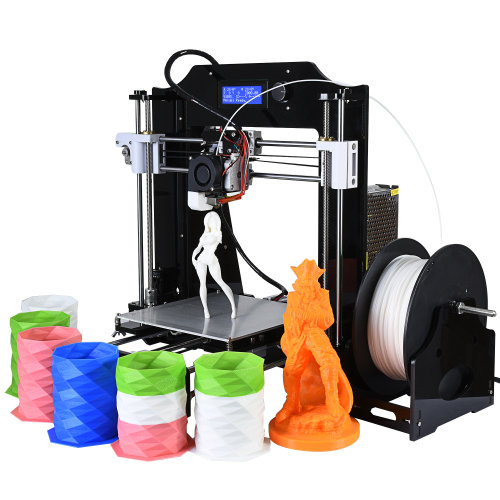

Top 20 Inexpensive 3D Printers ($199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. This is amazing.

Today, you can easily find a cheap 3D printer for under $200. This is amazing.

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts.

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the price range from $ 200 to $ 1000

| 3D PRICE | Material Material | Working space (mm) | Price | 459 |

|---|---|---|---|

| Flashforge Finder | PLA | 140 x 140 x 140 | 499 |

XYZPRINING DA vinci jr. 1.0 Pro 1.0 Pro | PLA | 150 x 150 x 150 | 499 |

| XYZprinting da Vinci Jr. Mix 2.0 | PLA | 150 x 150 x 150 | 599 |

| Printrbot Simple | |||

| Dremel Idea Builder | PLA | 230 x 150 x 140 | 899 |

| Printrbot Simple Pro | PLA | 200 x 150 x 200 | 999 |

| Prusa i3 MK2 | PLA, ABS, exotic | 250 x 210 x 20022 | |

In the article we are considering unfinished, but high -quality 3D printers from AM etc.

If you want to buy them, even if you live in large cities such as Kyiv, Moscow, St. Petersburg, Minsk, it may turn out that these models will not be in the online stores of your city, or they may be with a decent mark-up relative to the cost that indicated in the article.

Since most of them are European / American, it is possible that they will not be in stores at all.

Therefore, before making a choice, I recommend looking directly at eBay, Amazon, Aliexpress, etc. - many sellers on these planforms deliver to the CIS countries within 1-4 weeks on average.

It is especially worth monitoring these platforms during the discount period - Black Friday or Chinese New Year (Aliexpress or Gearbest) - prices on such days can be 2 or more times lower than usual and it is worth waiting for a few weeks.

Monoprice MP Select Mini ($199)

Probably the best 3D printer on our list. Why? Because the Monoprice MP Select Mini is an impressive development with a thoughtful, compact design at a very low price. This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB.

The heated bed and wide temperature range of the extruder are especially pleasing, because for such a small price you get the opportunity to print in different materials: from ABS B to PLA or exotic materials like conductive PLA plastic, wood, metal-based composites and PVA.

For those who are worried about the lack of a guarantee - for such a price it is possible without it. This model is upgradeable. For example, you can install a new nozzle, change the table and add WiFi connectivity.

Small working space - 120 x 120 x 120 mm. Over time, this will definitely not be enough for you.

Specifications of cheap 3D printer Monoprice MP Select Mini

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: SD card, USB.

Back to the list of 3D printers

M3D Micro Retail ($249)

The M3D Micro 3D printer hit the market thanks to Kickstarter. This model was presented with an incredible price of $349.

This model was presented with an incredible price of $349.

The working space of the M3D Micro is 109 x 113 x 166 mm. There are several body color options. The company has implemented "Micro Motion Technology" - a set of innovative solutions - thanks to which you get excellent quality 3D printing at a small price.

Today, this inexpensive 3D printer already costs even less than the price announced on Kickstarter. You can buy it for $249 with a 12 month warranty. By the way, it is already possible to pre-order the next "pro" version.

Specifications of cheap 3D printer M3D Micro Retail

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 116 x 109 x 113 mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- XY accuracy: 15 microns;

- Open Source: no;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to 3D printer list

XYZprinting da Vinci Mini ($289)

Da Vinci Mini is a successful attempt to make the 3D printer user-friendly. This model has only one button and 5 multi-colored indicators that reflect the current status of 3D printing. In addition, this affordable 3D printer is WiFi capable so you can control it over a network in your home, office or lab.

Unfortunately, you can only use the manufacturer's own 3D materials. On average, they cost 20% more than usual. However, the company also argues that the materials used (PLA) will be 100% non-toxic.

Specifications of cheap 3D printer XYZprinting da Vinci Mini

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

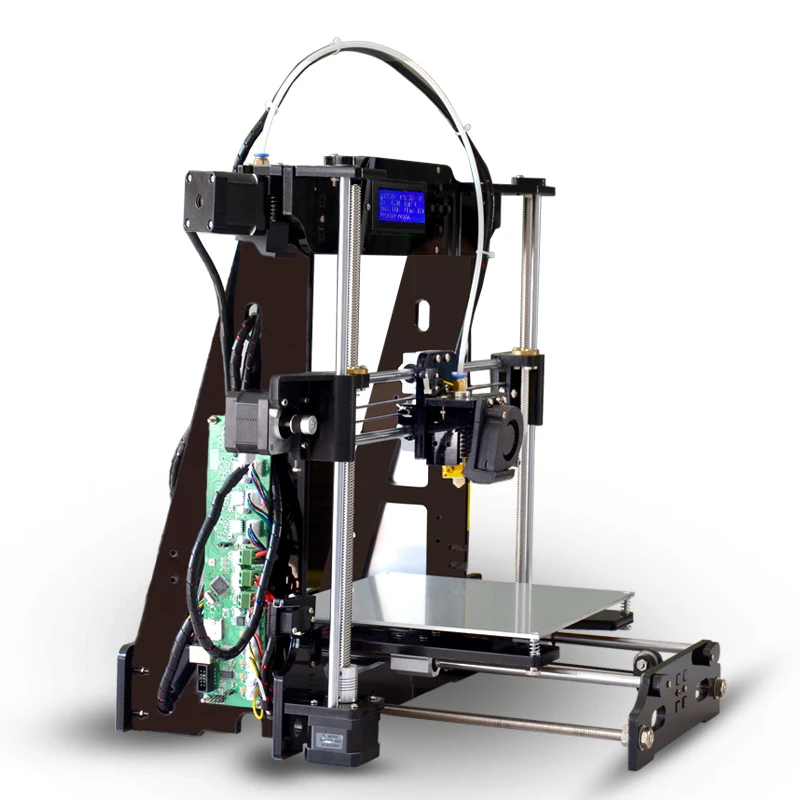

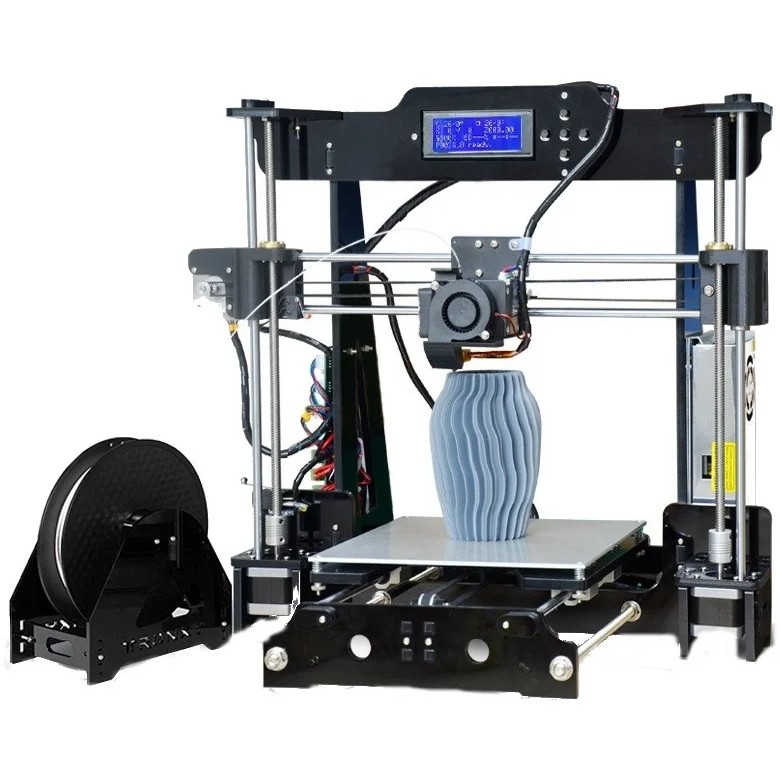

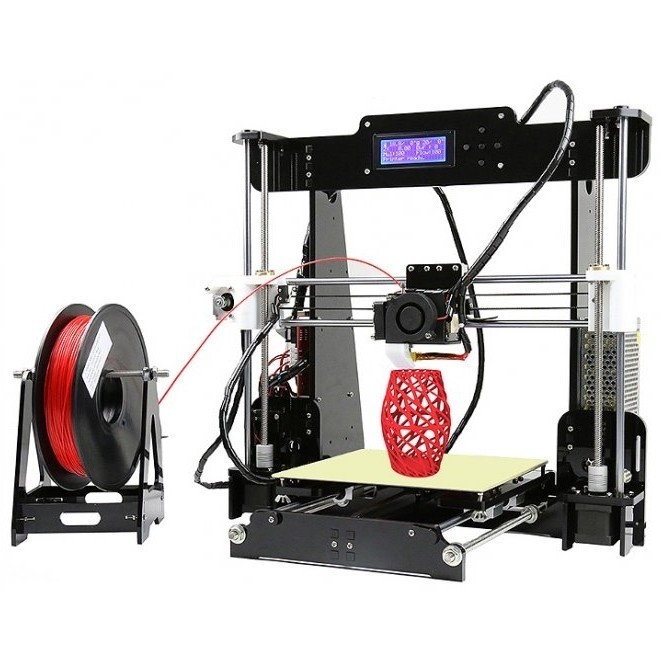

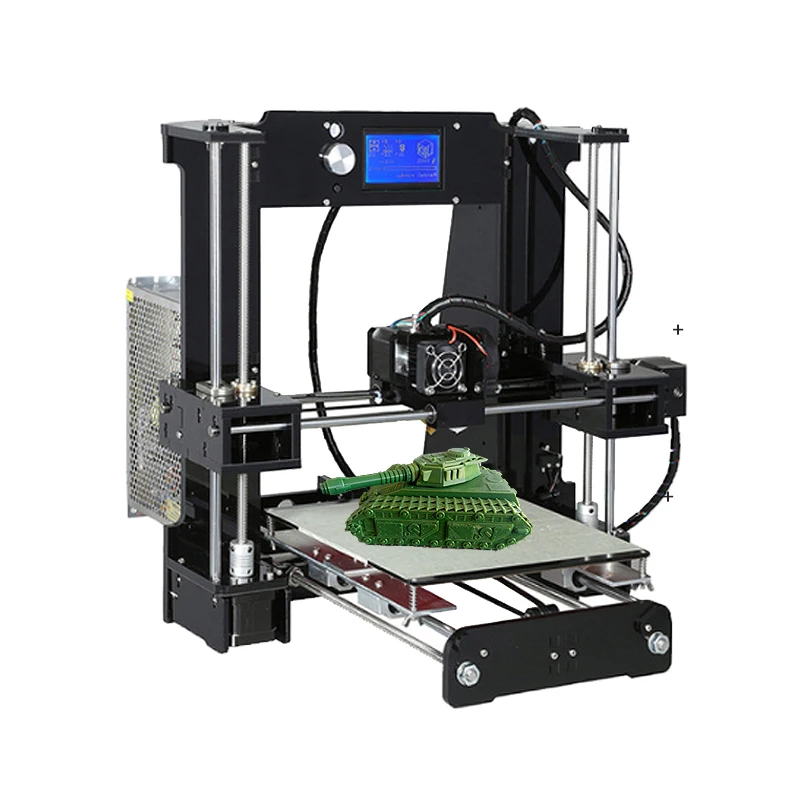

Monoprice Maker Select V2($299)

The next cheap 3D printer with a good reputation is the Monoprice Maker Select V2.

This model is an analogue of the Wanhao Duplicator i3, which, in turn, borrowed the design from the Prusa i3. But this does not affect the quality, as the Monoprice Maker Select V2 is easy to use and gives excellent 3D printing results.

Monoprice Maker Select V2 design feature is that the power supply and control panel are placed outside the 3D printer. The working space of this model is 200 x 200 x 180 mm. And this is really a good indicator for the money.

Specifications of cheap 3D printer Monoprice Maker Select V2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

New Matter MOD-t ($299)

New Matter is a young startup that offers a 3D printer MOD-t - An interesting design with a minimalistic design. This cheap 3D printer is WiFi enabled so you can manage print settings and print from your computer, tablet or smartphone. The working space is 150 x 150 x 125 mm. Thanks to the case, the noise during its operation is reduced. But the most interesting and attractive thing about MOD-t is the price. Only $299. In general, this is an interesting, high-quality model.

Specifications of cheap 3D printer New Matter MOD-t

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 100 x 125 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB, WiFi.

Back to the list of 3D printers

Printrbot Play ($399)

The Printbot Play is a very popular budget 3D printer that is often used in education. This inexpensive, reliable model, which is almost entirely made of metal.

The working space is 100 x 100 x 130 mm. Printbot Play has an extruder manufactured by the company itself - Alu Extruder v2. The body is made of powder coated steel and aluminium. SD slot provided.

You can upgrade the basic design of the Printrbot Play with a heated stand or increase the Y-axis stroke.

Back to 3D Printer List

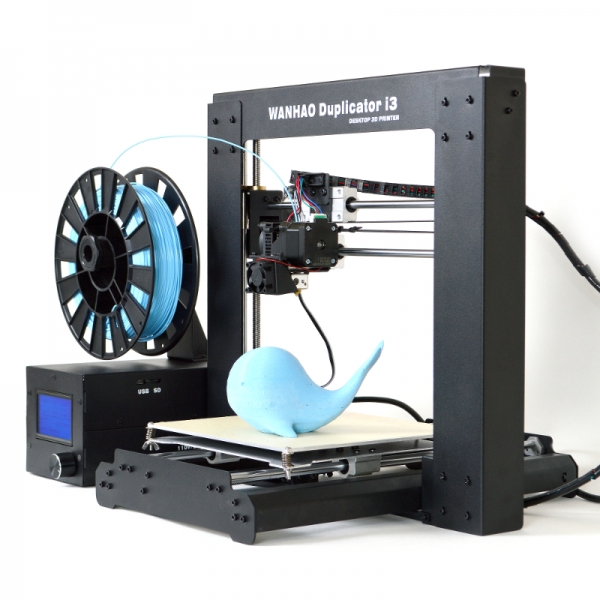

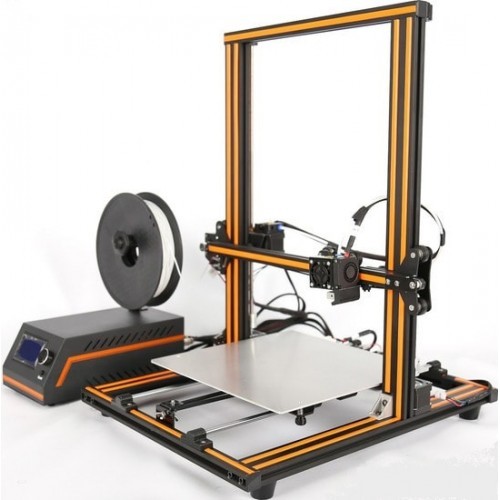

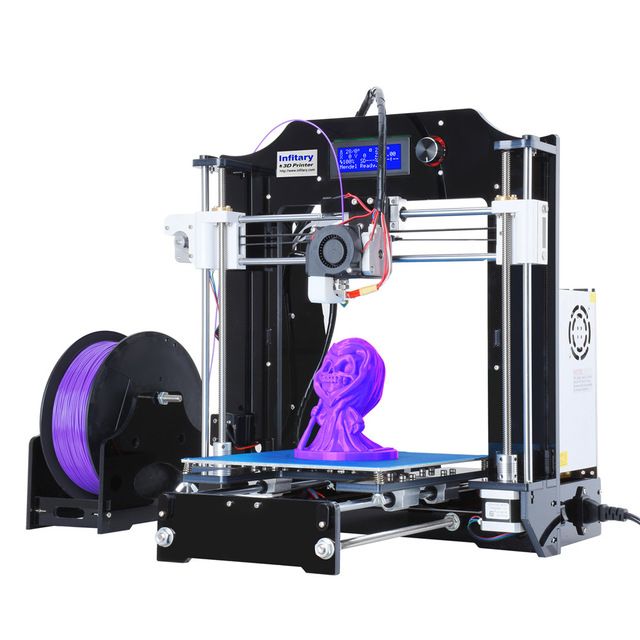

Wanhao Duplicator i3 Plus ($459)

The Wanhao Duplicator i3 Plus is an upgraded version of the popular Wanhao Duplicator i3 (which in turn is based on the Prusa i3).

The main features of this cheap 3D printer are a large working space of 200 x 200 x 180 mm, a steel frame, electronics integrated into the design itself (previously it was taken out separately), a slot for a full-size SD card and a touchscreen display for control.

Wanhao Duplicator i3 Plus Cheap 3D Printer Specifications

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Flashforge Finder ($499)

FlashForge Finder is one of the newest 3D printers on our list. This affordable 3D printer offers an average working space of 140 x 140 x 140mm.

This Finder features a transparent sidewall design so you can view the 3D printing process from any angle. A color display is installed, it is possible to transfer data via WiFi network. The printer comes with some supplies and a USB flash drive, so you can start 3D printing almost immediately.

Specifications of cheap 3D printer FlashForge Finder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 140 x 140 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- XY accuracy: 11 microns;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

XYZprinting da Vinci Jr. 1.0 Pro ($499)

What's so special about the da Vinci Jr. 1.0 pro? This is a new model from XYZPrinting, which includes many advanced features, such as support for printing materials from other manufacturers and increased speed of 3D printing.

Also features an auto-calibration mechanism, a closed chamber with a unique cooling system, and a 0.3mm nozzle option for high-quality printing of fine model details. All in all, this is a great 3D printer with a lot of useful features and at a low price.

Specifications for cheap 3D printer da Vinci Jr. 1.0 Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to 3D printer list

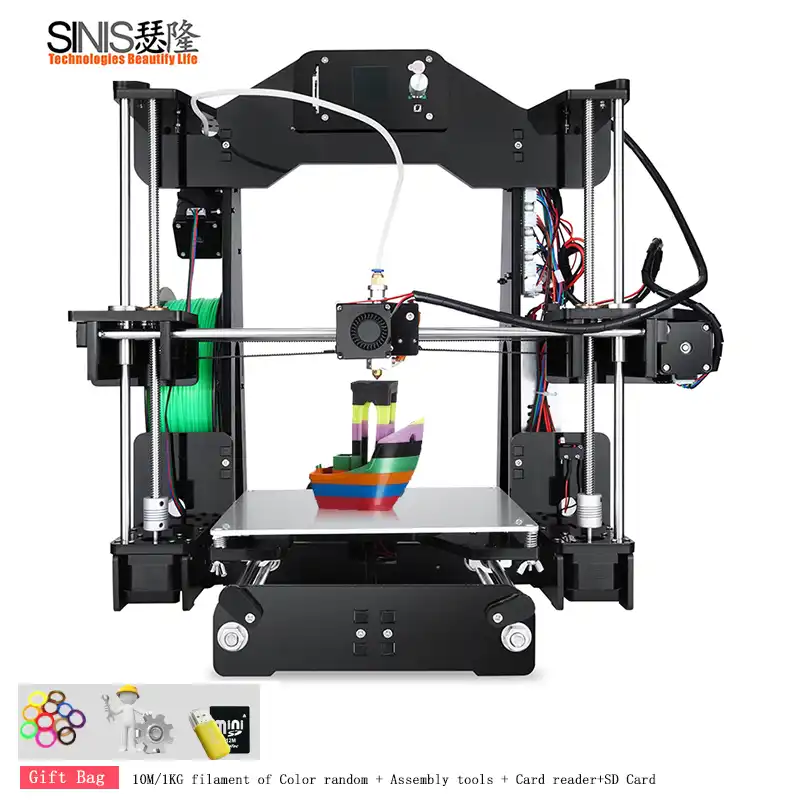

XYZprinting da Vinci Jr. Mix 2.0 ($599)

XYZprinting provides a wide range of low cost 3D printers. And paying attention to each model is quite difficult, although many of them are very interesting.

XYZprinting da Vinci Jr. Mix 2.0 stands out because it can print with two different materials and mix them to create multi-colored models. This dual-color 3D printing technology is rare in this price range ($500 to $1,000), so if you're interested in experimenting with multicolor printing, XYZprinting da Vinci Jr. Mix 2.0 is a great choice.

However, there is a drawback. This 3D printer is not compatible with materials from other manufacturers, so you will have to buy special materials from XYZprinting (as we mentioned above, they cost 20% more, but are not toxic).

Specifications of cheap 3D printer XYZprinting da Vinci Jr.

Mix 2.0

Mix 2.0 - Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 200 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card, WiFi.

Back to 3D printer list

Printrbot Simple ($599)

Printrbot Simple is the flagship of the Printbot empire. This model has a great open design with a solid aluminum frame and a working space of 150 x 150 x 150mm. This inexpensive 3D printer comes fully assembled at a very good price. As you need and want to experiment, you can add a heated table and expand the workspace in the horizontal plane.

Specifications of cheap 3D printer Printrbot Simple

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 80 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to the list of 3D printers

UP mini 2 ($599)

The UP mini 2 is a low cost 3D printer that packs in impressive design and functionality. For starters, it has a touch screen panel and the ability to connect via WiFi.

But the most interesting is further. Implemented power failure protection system. 3D printing will continue after the emergency stop. Built-in HEPA air filtration system. Automatic detection of the height of the extruder nozzle. A separate, closed container for the material, thanks to which it does not deteriorate under the influence of moisture from the environment.

Great 3D printer for a small price. The only thing that upsets me a little is the small working space - 120 x 120 x 120 mm.

Specifications of cheap UP mini 2 3D printer

- Printer type: FDM;

- 3D printing materials: PLA, ABS;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 150 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D Printer List

Monoprice Maker Select Ultimate ($699)

The Monoprice Maker Select Ultimate is an extraordinary beast that combines elements from two leaders in the world of 3D printing - Zortax and Ultimaker. The Monoprice Maker has an aluminum perforated printing table, which was offered in the Zortax M200 (thanks to this table, the grip of the base of the model with the table is much better), and the software part is almost identical to Ultimaker 2 (very user-friendly interface and functionality).

This model uses a "Bowden extruder", i.e. the feed units and nozzle are separated, unlike the direct feed. This improves reliability and reduces the likelihood of 3D printing errors (although, most likely, it was necessary to sacrifice printing speed, as the weight of the printing unit increases). Given the cost, this is a good model, the analogues of which are much more expensive.

Specifications of cheap UP mini 2 3D printer

- Printer type: FDM;

- 3D printing materials: PLA, ABS, exotic;

- Working space: 200 x 200 x 175 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Robo C2 ($799)

The Robo C2 is a small 3D printer with tons of connectivity options. Using a specialized application, you can monitor the status of 3D printing from your smartphone or tablet. It can be connected to a Chromebook. Thanks to the built-in slicing program, you do not need to install additional printing software.

Probably the most impressive is the integration with Amazon Alexa. Users can stop, cancel and check the status of 3D printing in real time using voice commands.

What does this inexpensive 3D printer offer? Working space 127 x 127 x 150 mm. The 3D printing speed is 300 mm/s and the resolution is 20 microns. There is a built-in 3.5'' color touch screen, a system for monitoring the amount of remaining material for printing, automatic calibration and a removable self-aligning print platform. The only drawback is that the table is not heated, so you have to use PLA plastic.

Specifications of cheap 3D printer Robo C2

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 127 x 127 x 150 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to the list of 3D printers

Wanhao Duplicator 4S ($829)

The Duplicator 4S has 2 extruders. It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

One of the features of this model is a high-precision material feed wheel, which ensures the same filament feed speed. The Duplicator 4S is equipped with a 0.4mm precision nozzle.

Specifications of cheap 3D printer Duplicator 4S

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40 mm/s;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 0.4 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Polar 3D Printer ($899)

Polar 3D belongs to a separate category of 3D printers in this top, since this model implements the polar coordinate system. This causes the table to rotate and the print head to move up, down, right, and left.

Thanks to the polar coordinate system, this 3D printer is powered by two stepper motors, so it consumes less power. In addition, it turned out to realize a larger size of the working area: 203 (table diameter) x 152 (Z coordinate) mm.

Nominal price $899, but there are special discounts for educational institutions. The discounted price is only $599.

Specifications of cheap 3D printer Polar 3D

- Printer type: FDM;

- Materials for 3D printing: PLA;

- Working space: 203 (table diameter) x 152 (Z-coordinate) mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 400 microns;

- Number of extruders: 1;

- 3D printing speed: 40 mm/s;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB, WiFi, SD card.

Back to 3D printer list

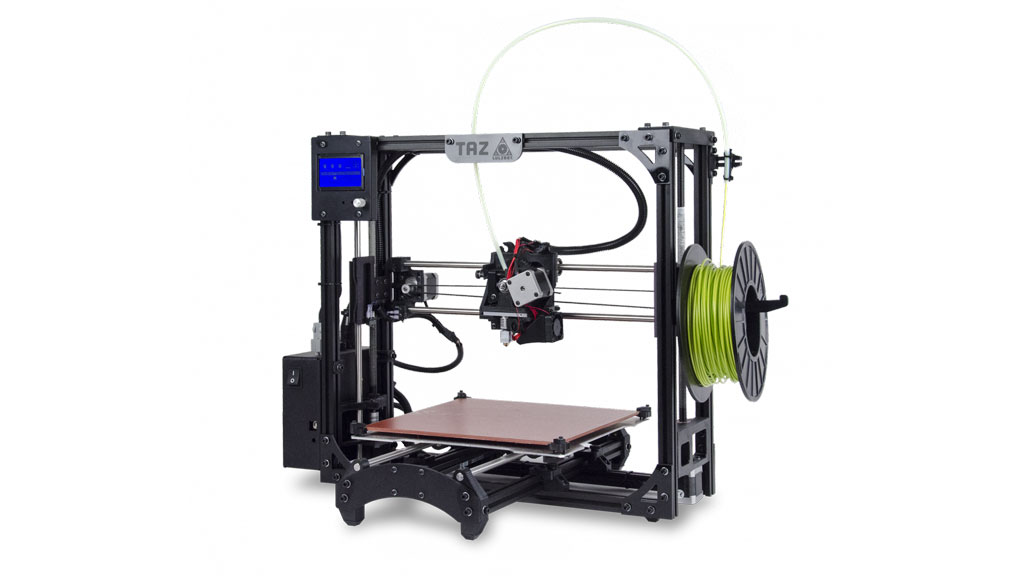

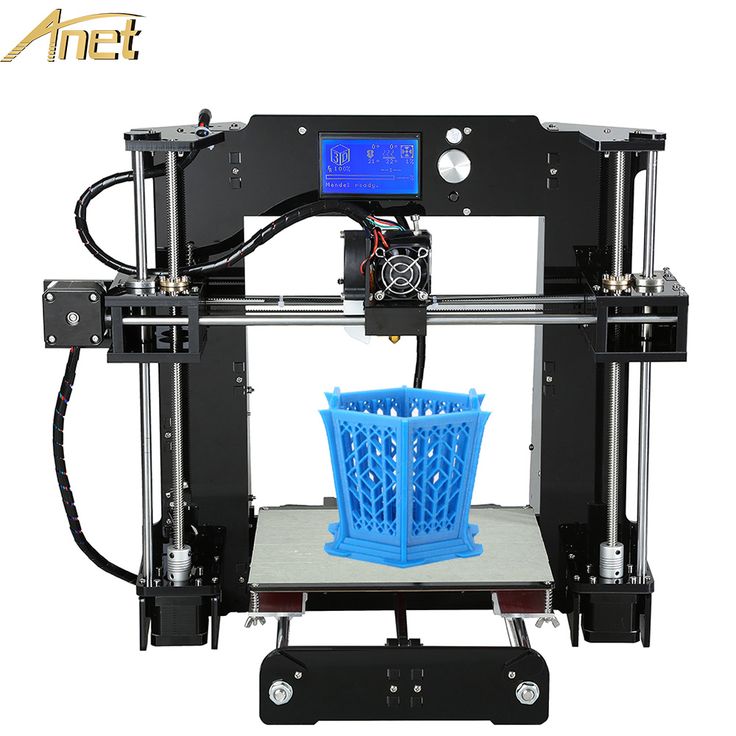

FlashForge Creator Pro ($899)

You've probably heard of this 3D printer. FlashForge Creator Pro is very similar to Makerbot Replicator 2X. This inexpensive 3D printer has 2 extruders, it has a steel closed case.

Other features include a table sizing system, and a guide screw that makes the guide system more stable and durable. The design is nothing special, but this model has earned positive reviews from the 3D community due to its reliability, versatility and ease of use.

Specifications of cheap 3D printer FlashForge Creator Pro

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40-100 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to 3D Printer List

Dremel Idea Builder ($899)

The Idea Builder is plug and play. This 3D printer is designed by Dremel. It has a color touch screen display. Sufficiently large working space - 230 x 150 x 140 mm. Unfortunately, the table is not heated. On the other hand, since only PLA plastics can be used, this model is great for classrooms and teaching labs.

Specifications of cheap 3D printer Dremel Idea Builder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 230 x 150 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Printrbot Simple Pro ($999)

The Printrbot Simple Pro is a major upgrade from the original Simple. Same open design, no body. Like its predecessor, the Printrbot Simple Pro is compact and portable. All-metal construction for excellent vibration damping and shock resistance.

The main differences are the built-in color touch screen, the ability to connect via WiFi and the free cloud service (optional), which greatly improves the 3D printing process. The Simple Pro is equipped with a 32-bit processor, which ensures smooth and fast movements. And at the same time, this model is included in our top 20 cheap 3D printers, since its cost is $999.

Specifications of cheap 3D printer Printrbot Simple Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 200 x 150 x 200 mm;

- Minimum layer height: 50 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

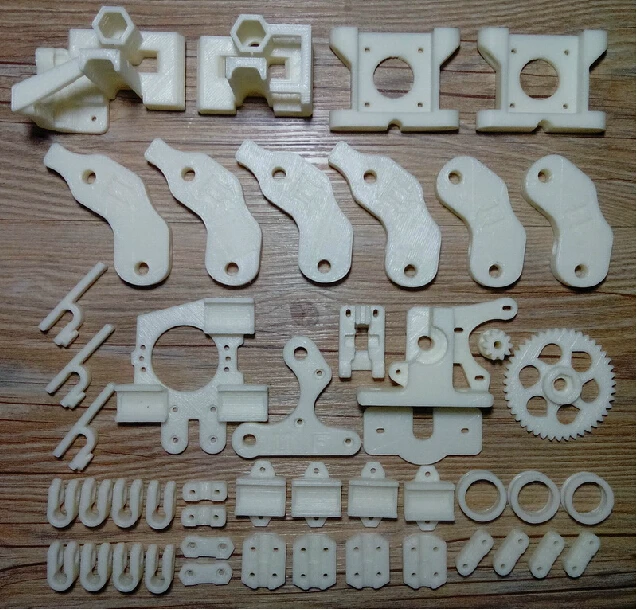

Prusa i3 Mk2 ($999)

This is one of the best 3D printers you can buy in this price range. All nodes are open-source licensed and part of the Rep-Rap project, so there are many copies around ... but all replicas are worse than the original.

The Prusa i3 Mk2 is equipped with a heated table that has technology to compensate for temperature differences in the center and corners. There is an automatic calibration system. And of course, amazing documentation. This is an extremely versatile 3D printer that you will 100% appreciate when you start printing with unusual materials such as PLA, PET, HIPS, Flex PP or Ninjaflex, etc.

The Prusa i3 Mk2 is a 3D printer that is constantly being developed and supported by the manufacturer. Its developer Josef Prusa regularly adds new features, software and design improvements (for example, the ability to color 3D print). If you look for quality competitors in the 3D printing market, then the cost of their equipment will be in the region of $2000 - $3000.

If you look for quality competitors in the 3D printing market, then the cost of their equipment will be in the region of $2000 - $3000.

The only drawback is that if you decide to buy a Prusa i3 Mk2, you will have to wait about 2 months, as the company cannot keep up with the high demand.

Specifications of cheap 3D printer Prusa i3 Mk2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 250 x 210 x 200 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 50 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: SD card.

13 notes about 3D printing, after 3 years of owning a 3D printer / Habr

This article will be, first of all, of interest both to those who have directly dealt with 3D printing, that is, who owns a 3D printer, but also to those who are just about to join the ranks of 3D printers and are thinking about buying their own printer.

In the framework of this article, I want to present my observations, as a direct owner of a 3D printer, for more than 3 years.

Despite the fact that 3D printers have been known for a long time and, in my memory, have become widely used, judging by the information on various resources, starting around 2010 (I may be wrong, these are my subjective observations), for a long time I ignored this sphere, it’s hard to say why…

I probably considered it some kind of “childish pampering”, another hype topic for which there is simply not enough time…

The turning point happened when one of the wheels on my travel suitcase wore out . You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons.

And it’s like “lightning flashed in the middle of the day: 3D printer!” It is with his help that I can fix this problem! Looking ahead, I’ll say that I didn’t succeed in fixing the suitcase in this way, so I had to use a different approach . ..

..

As a result, I “upped” it - installing wheels from unnecessary roller skates. Thanks to this “up”, the suitcase has become a real all-terrain vehicle and, even being very loaded, it rides easily - pushed forward even with “one finger”. And even in the snow, 5-6 cm thick. A tank, not a suitcase turned out! By the way - I took spinning wheeled "units" in Leroy. Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

But this thought itself became a kind of trigger that allowed me to finally join the world of printers and buy my first 3D printer.

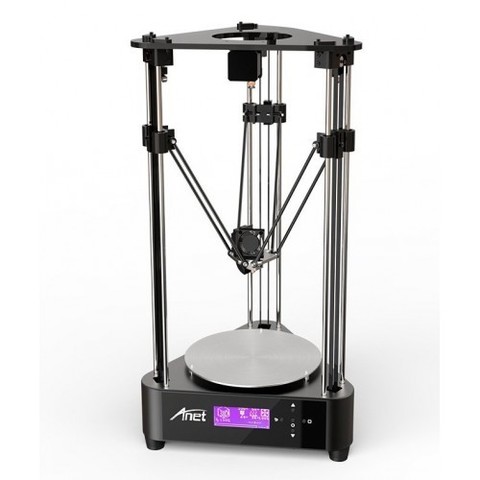

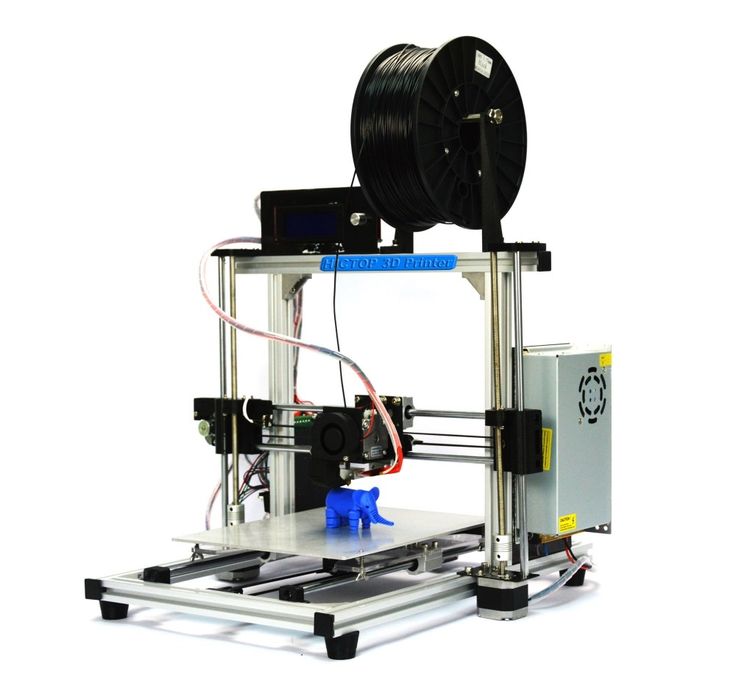

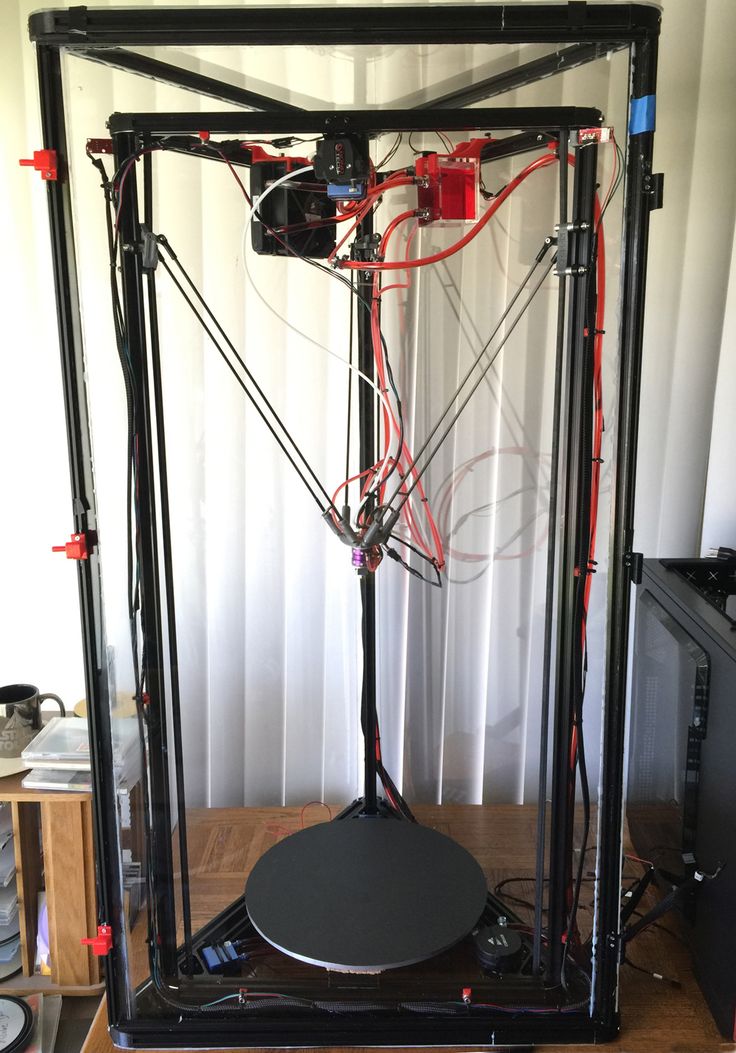

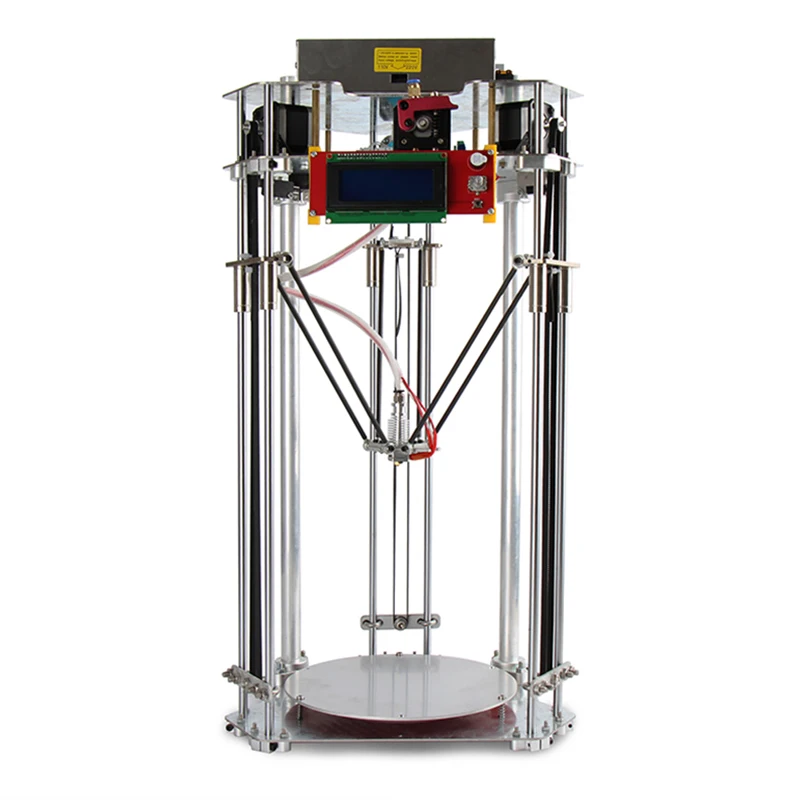

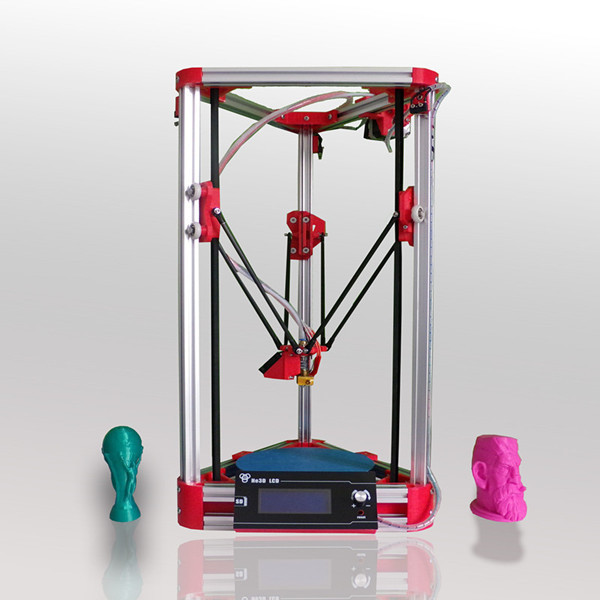

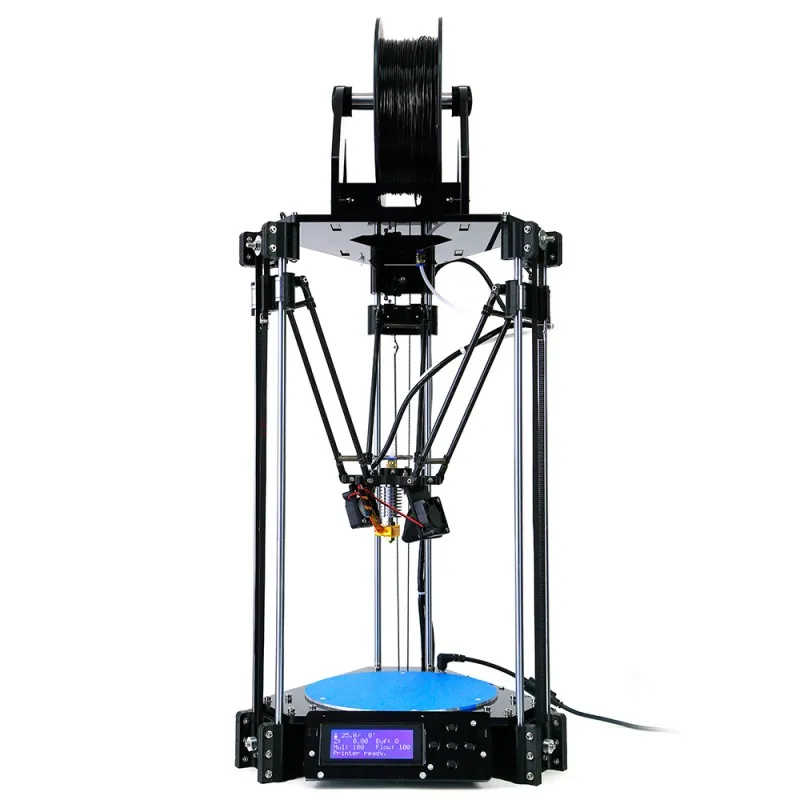

Like many, before buying it, I studied various forums and sites for a long time, delving into all the subtleties. And for some reason, I immediately liked the type of printer called the delta printer. Probably because during operation it looks like some kind of "alien device".

If at your leisure you like to sit “looking into the carpet”, then with the advent of such a printer you will have a much more interesting activity, even, one might say, hypnotizing :-))

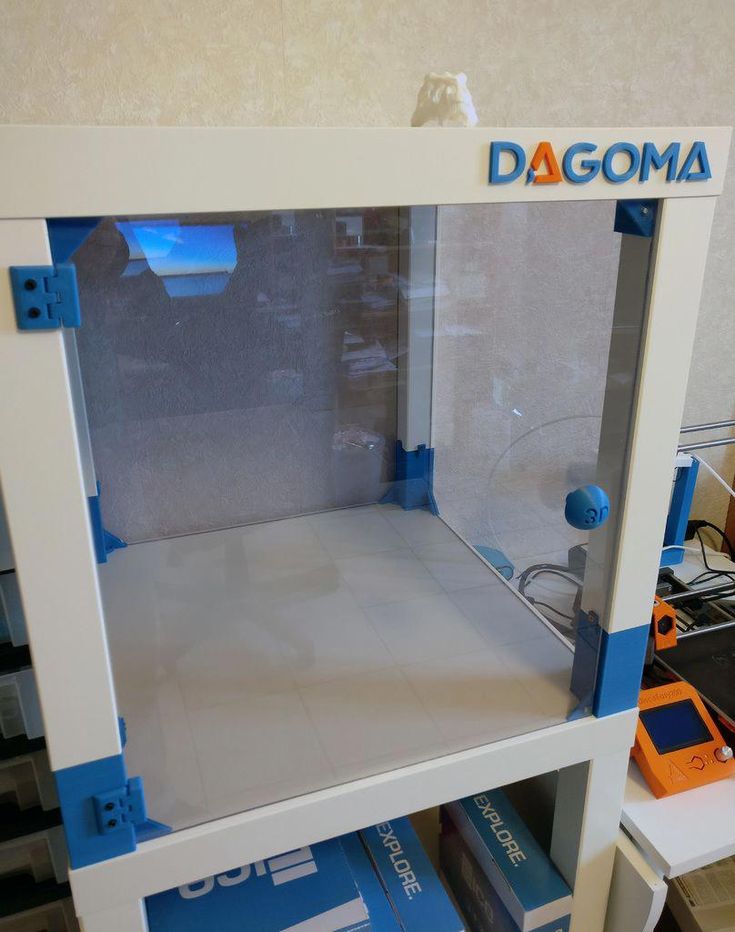

And this, in fact, is my delta (if anyone is interested), which went through, let's say, the "ultimate up": all the electronics are placed upstairs, on a self-made welded frame, covered with polyethylene and a magnetic door is made. The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

Well, yes, I won’t argue for a long time, let’s start reviewing the main facts that I have accumulated as a result of owning this car ... The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc.

▍ NOTE 1. Delta is good, but...

Here I should give a number of my observations regarding the delta printer:

- It contains a completely finished frame of the future box, which makes it easy to form a heat chamber. I understand that many printers are made in the form factor of a “certain box” (but this point cannot be ignored), which greatly facilitates the process of wrapping this box with heat-insulating material.

In my case, as such a material, I used a plastic film.

In my case, as such a material, I used a plastic film. - Already thanks to its design, delta allows you to work at much higher speeds than XY printers. By the way, it is on the delta principle that many modern high-speed industrial robots are built to sort various parts directly on the conveyor belt:

However, this plus does not allow to fully realize the occurrence of parasitic vibrations, even despite their suppressors:

Thus, accurate printing is possible, only at speeds (at least that was the case for me), no more than 60 mm per second. A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

▍ NOTE 2. "Size doesn't matter..." :-)

When I got the printer, I was impressed by the possibility of huge printouts, a la the handguards of some futuristic rifles, huge body parts, etc.

However, if you try to analyze the results of your many years of practice, it turns out that in most cases, rather small objects were printed that easily fit in the palm of your hand, a maximum of two palms. Despite such a seemingly small size, the printing of these details took a significant amount of time. Of course, this very much depends on which nozzle you print with. But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

Therefore, to be honest, the need for a printer that allows you to print "Venus de Milo in life size" is not obvious.

Of course, you can object to me that “I’m going to buy a printer, I’ll get used to it a bit and I’ll get started!!!”

Here you need to take into account one simple point: there are no universal things. And in order to understand how much 3D printing in general and your printer, in particular, you will need to solve your problems, and how much it will be able to solve such problems, you just need to first try the 3D printing method personally and then a lot will become clear to you .

Therefore, for a beginner, I recommend taking a small printer that allows you to print extremely small items that fit in the palm of two. With such a device, you will definitely never lose, as it will always be needed. In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

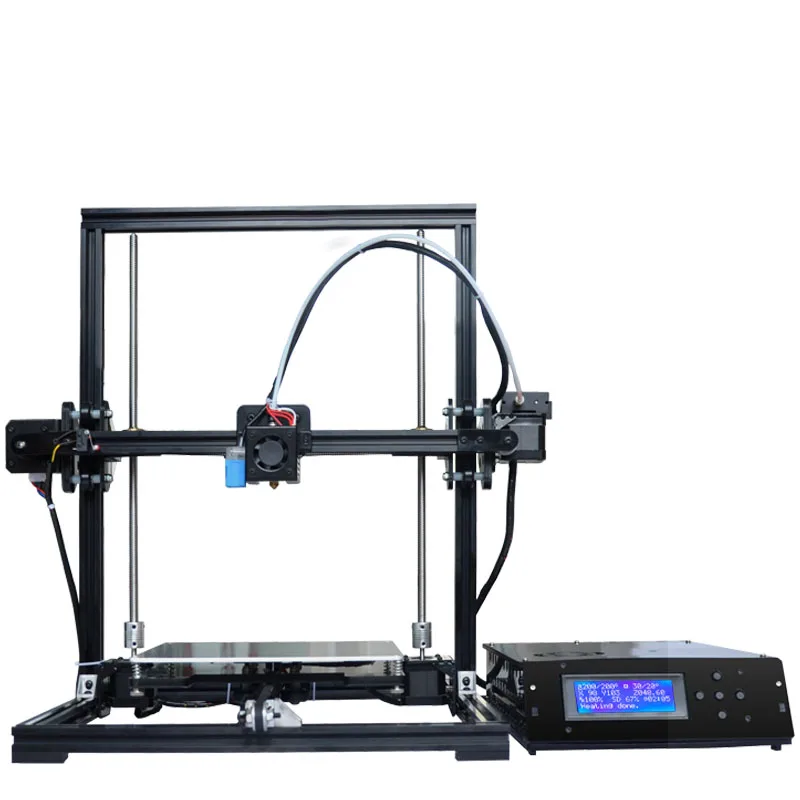

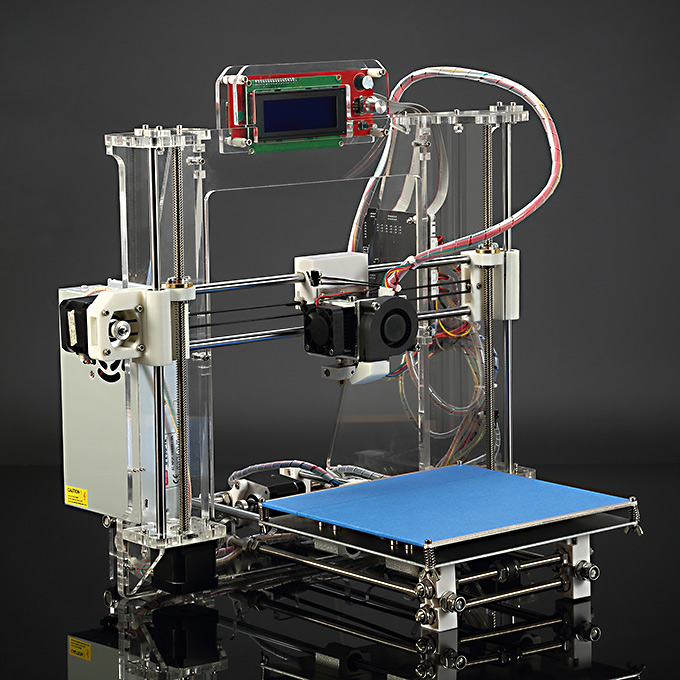

▍ NOTE 3. "What type of printer to get."

Based on the foregoing, I do not recommend taking a delta printer and this can be said right away.

Not because it is bad, in fact, it prints quite accurately, its main problem (in my opinion) is the inability to print rectangular flat, fairly large case components, as well as the inability to fully realize high-speed work, since the quality drops critically. Here it turns out to be a rather offensive situation - the printer can work quickly, but this cannot be done, since the quality will be “nothing”.

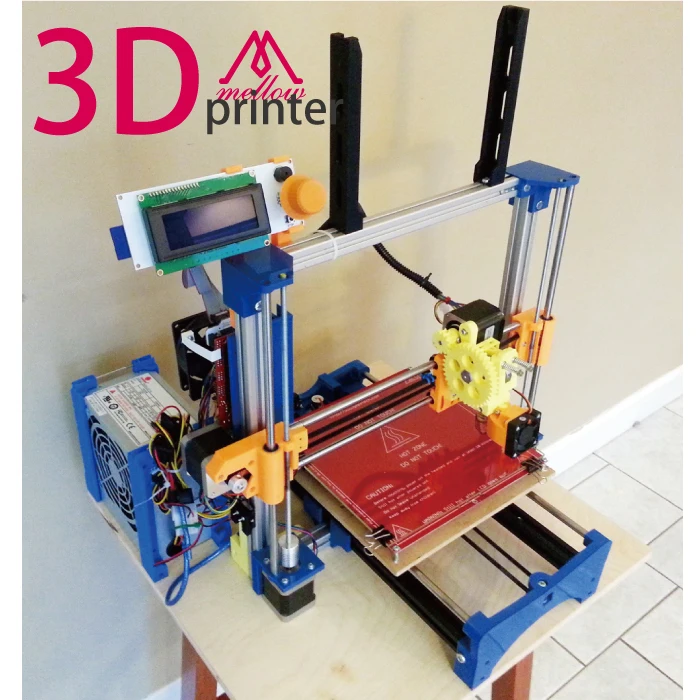

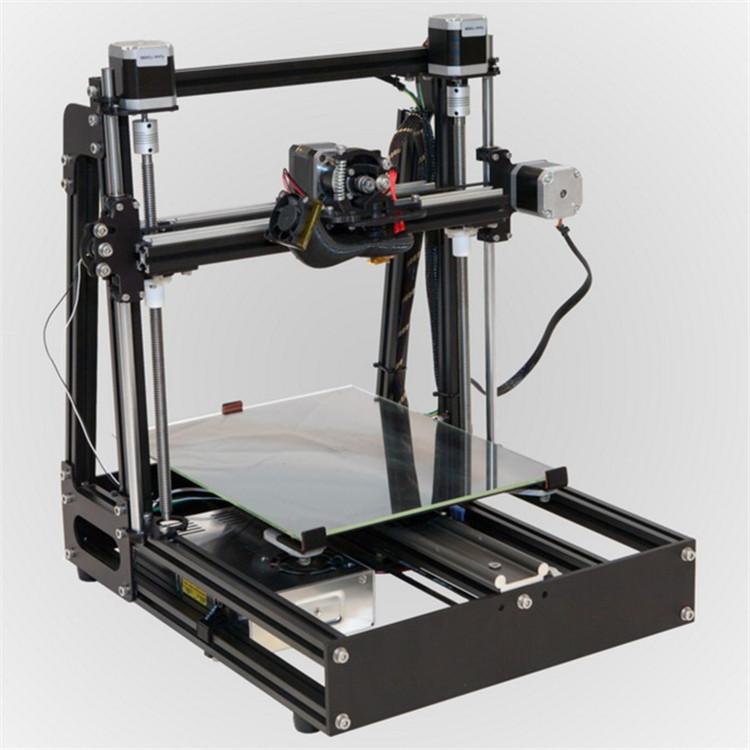

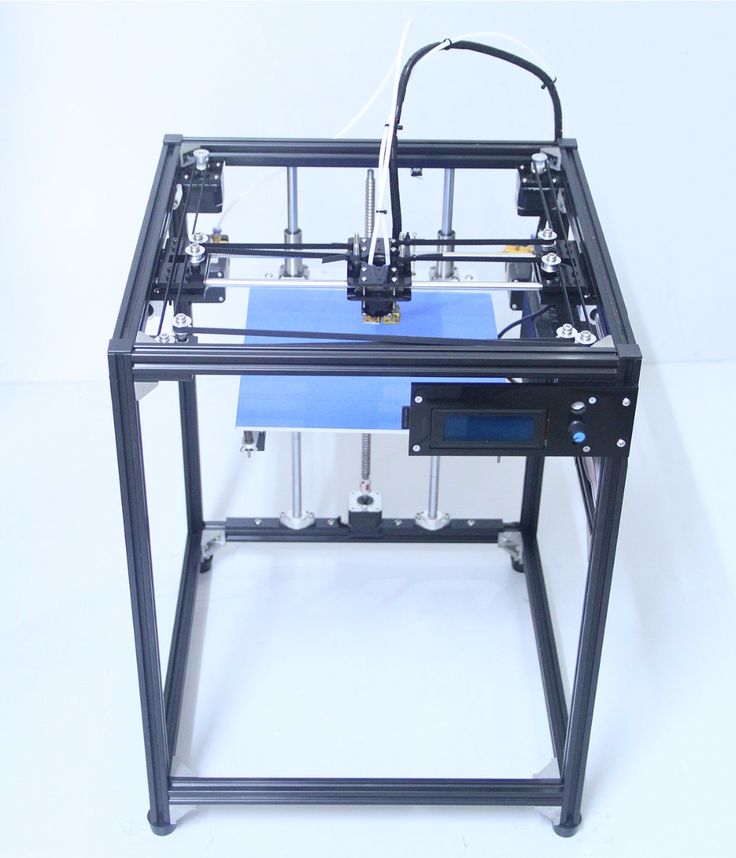

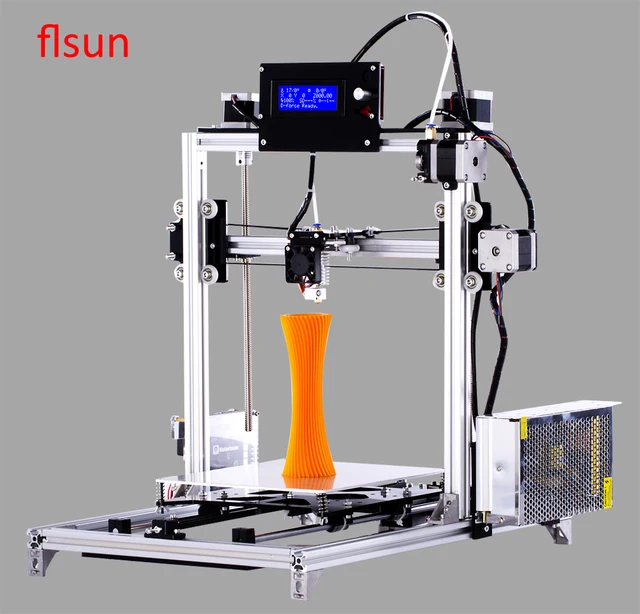

And then what kind to take? Depending on the budget and capabilities, I recommend taking any cube printer, for example, the same Core XY (the head moves, and the table goes down as the model “grows”, from top to bottom):

Image source: thingiverse.com

Such a printer allows you to easily print fairly large flat parts of cases, has good speed and accuracy. In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

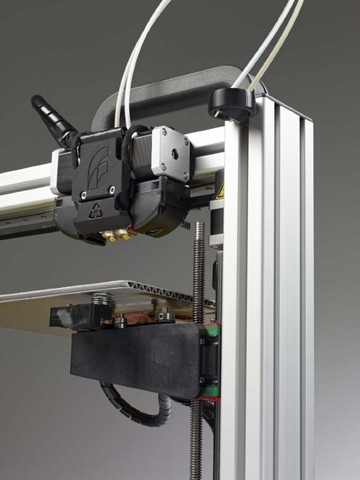

However, the advantages of this printer will not be fully revealed if it has a direct extruder. On the one hand, it will allow printing with rubber-like materials, on the other -

large inertia and head weight. And these are parasitic vibrations, wear of the fur. parts, etc. (like everything in life, “we treat one thing and cripple another” :-))

At the initial stages, this may not be necessary, but in the future it may be necessary to print, for example, tires for your homemade car. And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so.

"Crutches" of course. But even so.

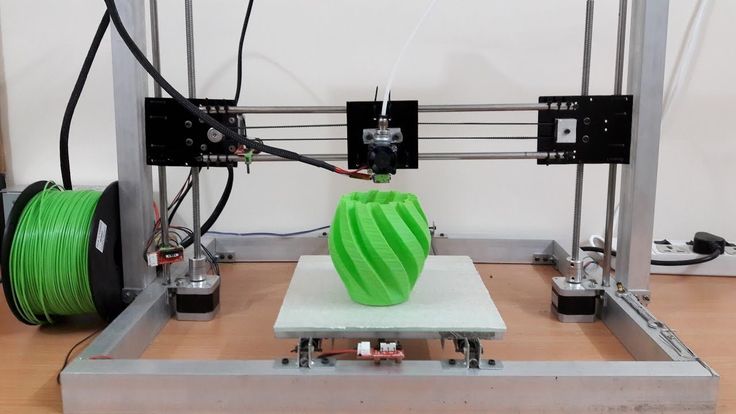

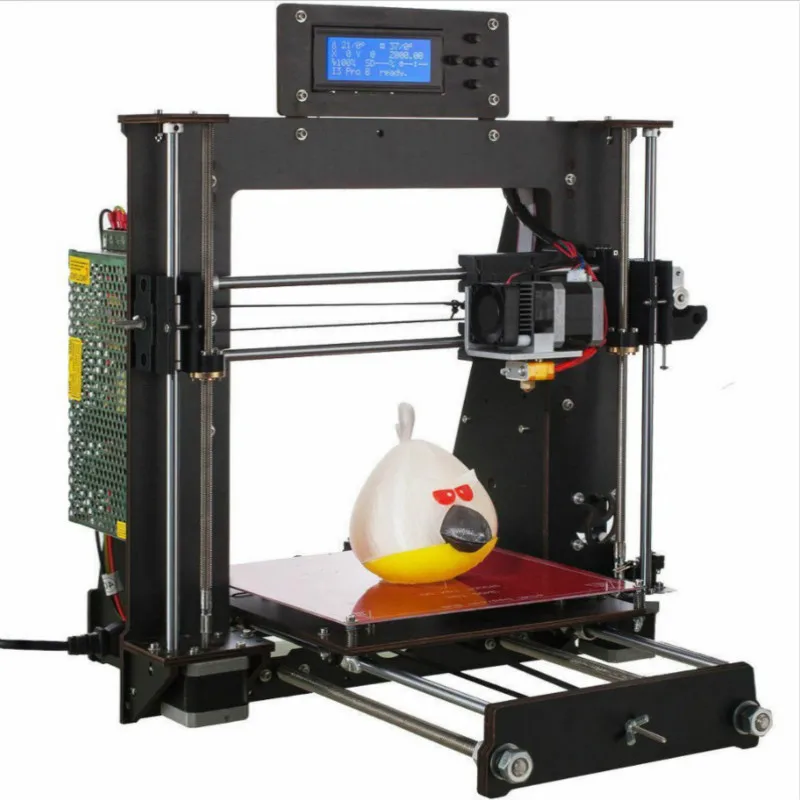

By the way, there are printers of a cheaper type, the so-called "drygostol", printing by moving the table and head:

They are inexpensive, moderately accurate, but they require a sufficiently high-quality gluing of the printed model to the table, because the table moves, and the model can come off when the table is jerked sharply. When printing large models, this can be a problem.

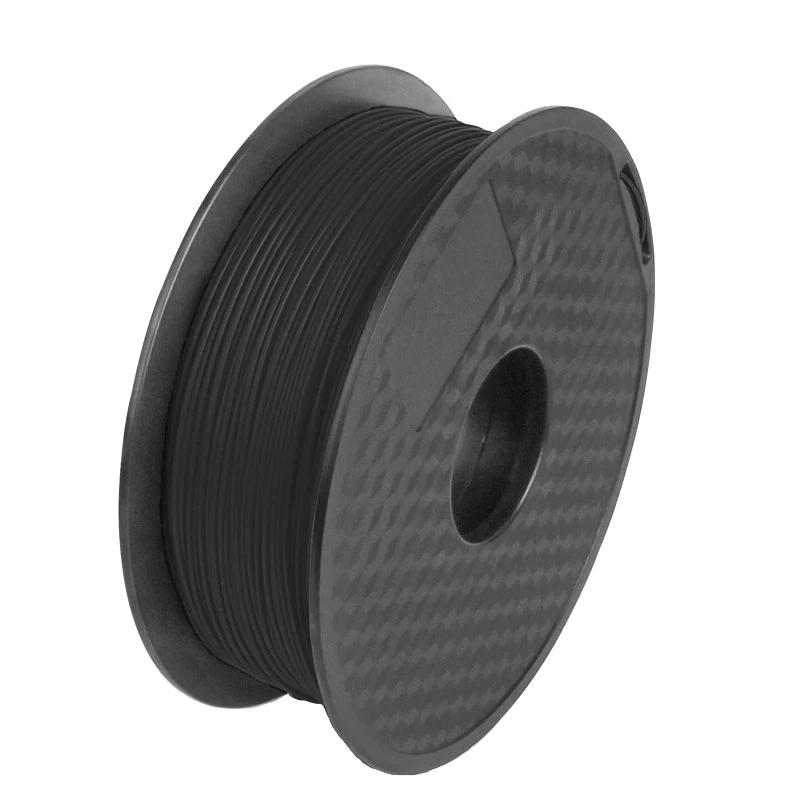

▍ NOTE 4. What to print with?

It's only a matter of taste and purpose. That is, if your printout will only stand on a shelf and should differ in some kind of aesthetic appearance, these are some requirements, if the printout is an engineering part that will be operated under conditions of increased mechanical load, these are different requirements. That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties.

For engineering parts, for example, I only use ABS. It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

I just wanted to say here that thanks to the low price and the practical experiments that I conducted with ABS plastic, I realized that it is completely meets all my requirements.

However, the fact that ABS plastic releases carcinogenic substances when heated is quite annoying and forces you to take measures to prevent poisoning. For this, my printer prints completely closed and on an open balcony. After printing, the printer chamber opens, and it remains open in this form until it is completely ventilated and cools down.

▍ NOTE 5. "ABS is difficult to type on, it separates, peels off the table, and in general..."