3D printing newtown

chbMAKERS' Corner - C. H. Booth Library

Now open by appointment!

Phone (203) 426-4533, ext. 3, or email Darcy to book your time with our maker equipment. C. H. Booth Library cardholders of all ages may use the chbMAKERS’ Corner.

chbMAKERS’ Corner Hours (Hours may change due to programs and events.):

- Sunday – Monday: Closed

- Tuesday – Wednesday: 2:00 – 7:30 pm

- Thursday: 1:00 – 6:30 pm

- Friday – Saturday: 11:00 – 4:30 pm

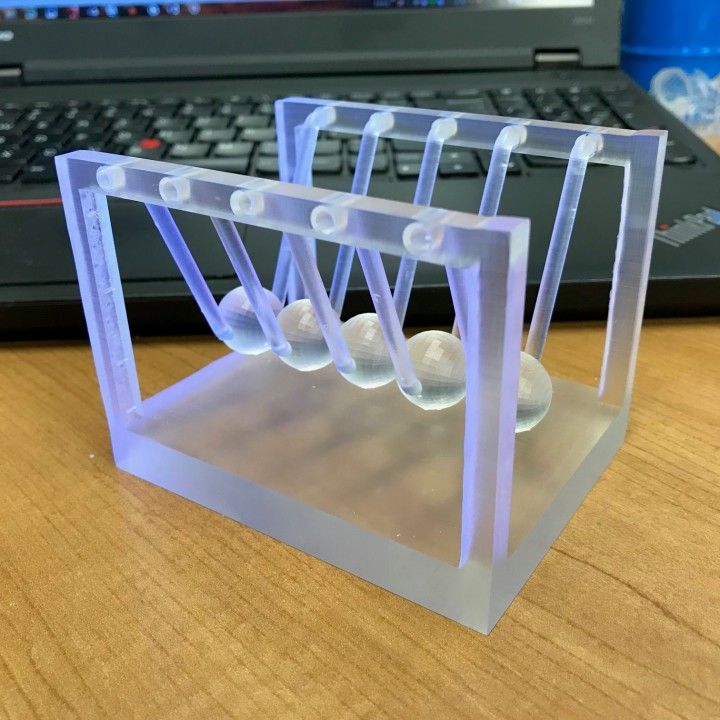

3D Printing

Use our 3D printer without even leaving home! Email us the 3D model in .stl file format. Once we’ve checked your print to make sure it will fit on one of our printers we’ll send you an email with our available filament colors for that printer and where you our in our print queue. Once our print is finished we’ll email you to let you know when it can be picked up.

This service is limited to C. H. Booth Library cardholders only. Prints must be completed in 6 hours. Your print may be resized to fit this time limit. If your design must be resized, library staff will let you know before printing.

Cost of printing: The first 2 hours are free. It is $2 per hour after.

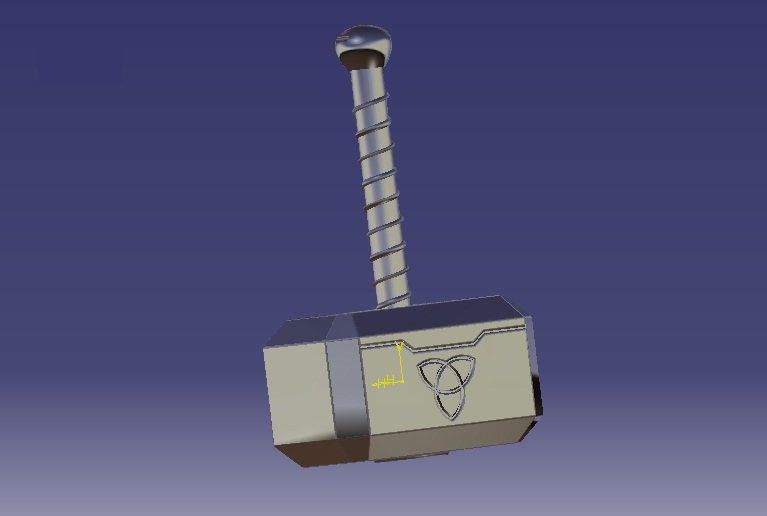

Find ready-to-print files at Thingiverse. You can find all sorts of fun things to print online, from keychains to household tools, decorations to replacement parts, and more!

Design your own 3D models at TinkerCAD. TinkerCAD is free and offers tutorials to get you started.

Note: Library staff are unable to assist with the designing of 3D models. The library is not responsible for the quality of your design.

What else can you do?

We’ve got something for everyone – so come get creative with us! Convert home movies to digital format. Customize a mug for a friend. Speak your mind by starting a podcast. You can do all of this and so much more in the chbMAKERS’ Corner.

Check out the Equipment Inventory for a full list of what’s available or download our brochure for more information about what we have to offer!

- 8mm & Super 8 Reel Converter

- Art and Craft Supplies

- Artograph Lightpad 12×17

- Book Scanner

- Bookbinding Machine

- Button Makers (1”, 2.

25”, 3”)

25”, 3”) - Canon Pro 300 Printer

- Circuit Cubes

- Clip Studio Paint Pro

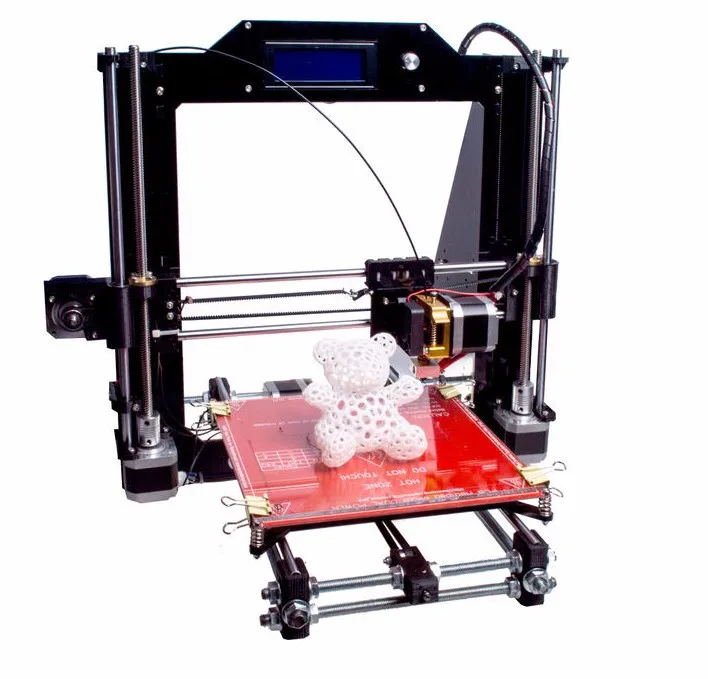

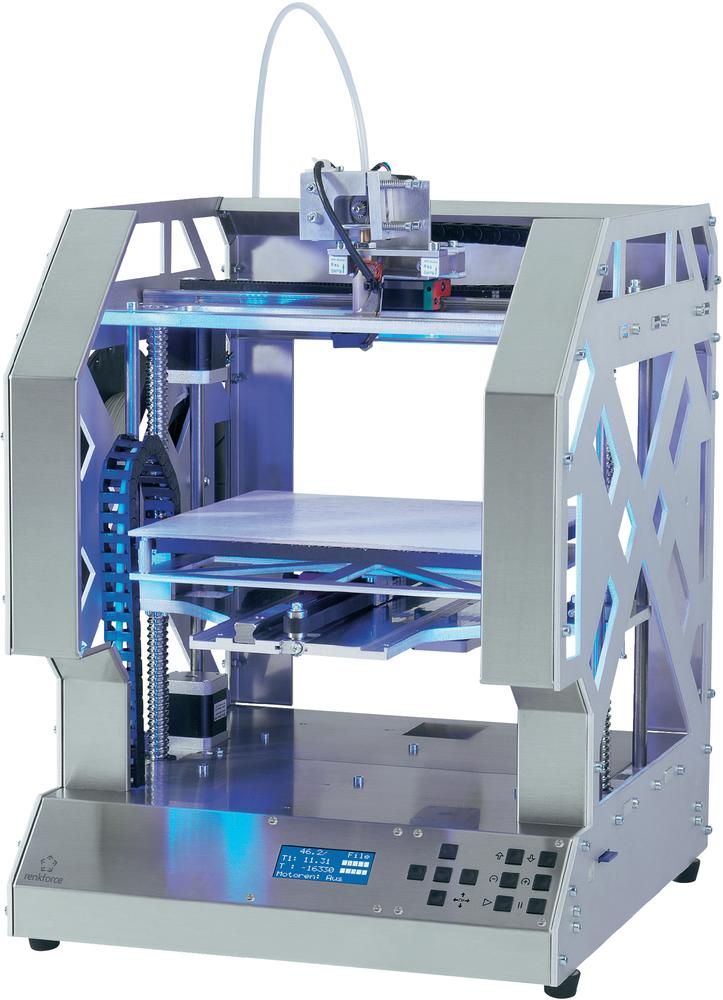

- Creality CR-10S Pro V2 3D Printer

- Cricut EasyPress 2

- Cricut Explore Air 2

- Cricut Mug Press

- Embroidery Machine

- Epson Expression 11000XL Large Format Scanner

- Green Screen

- Laminator

- iMac

- LittleBits

- LP to CD/MP3 Conversion Station

- Lulzbot Mini 2 3D Printer

- Makey-Makey

- Mat Cutter – 40″

- Mat Cutter – Oval

- Perler Beads

- Podcast Microphones

- Sewing Machines

- Snap Circuits

- Spheros

- VHS to DVD/MP4 conversion

- Video Camera and Tripod

Questions? Want to learn more?

Contact YA Librarian Darcy Sowers via email: [email protected] or telephone: (203) 426-4533, ext. 3.

3D Printing Service Near You

43 3D Printing Services are currently ready to take your order and deliver custom parts to Newtown, New South Wales, Australia. Through our platform, you can order 3D printed prototypes, replacement parts and many other custom projects without any minimal size or quantity requirements. If you have an idea of what technology, material or application suits your order, use filters to narrow down the search. You can also explore vendors’ portfolios with printed examples and customer ratings for a full perspective on their experience with different types of parts.

Through our platform, you can order 3D printed prototypes, replacement parts and many other custom projects without any minimal size or quantity requirements. If you have an idea of what technology, material or application suits your order, use filters to narrow down the search. You can also explore vendors’ portfolios with printed examples and customer ratings for a full perspective on their experience with different types of parts.

Sort byDistanceLowest PriceBest Rating

Category

Location

International

Technology

AnyAnyfdmslamjfdup

Product Application

AnyAnyPrototypeHD PrototypeJewelryDentalMulti-colorMetalMiniatures

MaterialSelect allUnselect all

(taulman) PCTPE3D Color-inkjet PLA8K Resin304 Stainless Steel316L Steel PlasticA2 Tool SteelABSABS+ABS-CFABS-ESD7 (Static dissipative)ABS-M30ABS-RABS-like ResinABSiASAASA-CFAccura ClearVueAccura e-StoneAgilusAlumideAluminaAlumina ZirconiaAluminium AlSi10MgAluminium Alloy AlSi12Aluminium NitrideAluminum PLAAmphora HT5300Antero 800NA (PEKK)Antero 840CN03 (PEKK-ESD)Anti-Microbial PLA (Purement)Bio-based TPUBio-compatible (MED610)BioMed-ResinBiocompatible ABS (ABS-M30i)Biocompatible PC (PC-ISO)BlueCast CR3ABlueCast LSBlueCast OriginalBlueCast X-FiligreeBlueCast X-OneBlueCast X5BlueCast X10Brass PLABrick PLABronze PLACF-TPUCPE (co-polyester)CPE+Carbon FiberCastForm PSCastable ResinCastable Wax 40 ResinCeramic FilamentCeramic ResinChameleon PLA (Thermochromic)ClearBiomedResinCobalt-Chrome (CoCr)Color-Blending PLAColorFabb XT CF20 (PET-G)Color KitColorfabb HTConductive PLACopperCopper PLACordieriteCrystalFlex (SBR)Cyanate Ester (CE)D2 Tool SteelDURABIODental LT ResinDental Non-Castable ResinDental SG ResinDigital ABSDraft ResinDuraForm EXDuraForm FlexDuraForm GFDuraForm HSTDuraForm PA PlasticDuraForm® ProX™ PA PlasticDurable (PP-like) ResinDurusE-GumEPU 40 (polyurethane elastomer)ESD-Safe PCESD-Safe PETGESD-Safe PLAESD-Safe PVDFESD-safe PEKKElastic Resin (Soft and flexible)Elixir PLA (Extra Shiny)FLEX (Elastic TPE)FPU 50 (Flexible Polyurethane)FR-ABS (Flame Retardant)FabProElasticFabProFlexibleFabPro JewelCastFabProProtoFabProToughFiberglassFlexfill 98A TPUFlexible ResinFoaming PLAFormfutura ApolloXFormfutura FlexiFilFormfutura TitanXFull-color plastic (VisiJet C4 Spectrum)Full-color sandstone (VisiJet PXL)Fused SilicaGlass-reinforced NylonGlass-reinforced ResinGreen-TECGreen-TEC Pro CarbonGreen-TecProGrey Pro Resinh23 Tool SteelHD GlassHIPSHPLA-CFHP PA-12HSHT FiberglassHTPET+Heat Treatable PLA (HTPLA)High Reactive ResinHigh Temp ResinHigh Temperature (RGD525)HydroxyapatiteIglidur I150Impact PLAInconel 625 Ni625Inconel 718Innofil Pro1Jewelry Wax (Solidscape 3Z Model)Kevlar-reinforced nylon LaserForm A6LaserForm Ni718LaserForm™ Ti Gr. 1²LaserForm™ Ti Gr. 5²LaserForm™ Ti Gr. 23²Liqcreate Clear ImpactLiqcreate Composite-XLiqcreate Flexible-XLiqcreate Strong-XLiqcreate Tough-XMagnetic Iron PLAMaraging SteelMarble PETGMarble PLAMatte Fiber HTPLAMatte PLANanoceramic ResinNonOilenNylonNylon-CFNylon 6/69Nylon GF30OnyxOnyx ESDOnyx FROnyx FR-APA-12 with Glass BeadsPA-CFPA11 NylonPA12 NylonPA 2200PA Cast NylonPC-ABSPC-ABS with Carbon FiberPC-ASAPC-CFPC-PBTPCTGPEEKPEEK-CFPEI-CFPEKKPETPET-CFPETG PETG (Recycled)PETG-CFPETG MattePETT (T-glass)PLAPLA+PLA++PLA-CFPLA-RecycledPLA/PHAPLA 3D870 (APLA)PLA FlexPLA NX-2PLATECPOM (Delrin)PP-CFPPSF/PPSU (Heat and chemical resistant)PRO HSPRO HTPSUPVAPVDF (PolyvinylideneFluoride)PaperPolyCastPolyMax PLAPolySmooth™ (PVB)PolyamidePolycarbonate (PC)PolyphenyleneSulfidePolypropele-GF-30PolypropylenePrecise PLAPrintaMent PURE (matt)Raptor PLAResinRigid 10K ResinRigid 4000 ResinRigid Polyurethane (RPU)Rigid opaque ResinRigurRiziumSTRubber-like (TPU)Rubber-like ResinSBSST-130Silicon NitrideSilicone ResinSilicoreSomos 201Somos EvoLVe 128Somos NeXtSomos WaterShed XC 11122Stainless Steel 17-4 PHStainless Steel 316LStainless Steel 420 Bronze InfusedStandard acrylic ResinSteel PETGStoneFil PLAStrong ResinTPCTPE SEBS 95ATPU 60DTPU 70DTPU 95ATPU Shore 45-56 ATPU Shore 79ATPU powderTR250 ResinTango (Rubber-like material)Titanium (Ti6Al4V)Titanium Ti64Tough3000Tough PLATough ResinTranslucent RigidTricalcium PhosphateTungsten Fill PLAULTEM(PEI) 1010 CGULTEM(PEI) 9085 CGUV Color Сhanging PLAUltem (PEI) 1010Ultem (PEI) 9085Urethane Methacrylate (UMA)VeroVisiJet CE-BKVisiJet CE ElastomericVisiJet CR-CLVisiJet CR-WTVisiJet FTX CastVisiJet FTX resinVisiJet M2 ElastomericVisiJet M2 RigidVisiJet M3VisiJet M3 DentcastVisiJet M5VisiJet SL ClearVisiJet SL e-StoneVisiJet® EX200VisiJet® HR200VisiJet® SR200Visijet CE-NTVisijet CF-BKWaterClear ResinWax-like ResinWax Filament (MoldLay)Wood PLAZ-ABSZ-ASA ProZ-ESDZ-GLASSZ-HIPSZ-PCABSZ-PETGZ-PLAZ-PLA ProZ-ULTRATZirconia 3YZirconia 8YZortrax Basic ResinZortrax Resin PRObronzeFill - PLA/PHA + fine bronze colorFabb-XT (Amphora AM1800)copperFill - PLA/PHA + fine copper corkFill - PLA/PHA + fine cork fibrecoPLAiglidur I180nGen-CFnGen Amphora AM3300 (PET-G)nGen FLEXwoodFill - PLA/PHA + fine pinewood zp130 Powder

1²LaserForm™ Ti Gr. 5²LaserForm™ Ti Gr. 23²Liqcreate Clear ImpactLiqcreate Composite-XLiqcreate Flexible-XLiqcreate Strong-XLiqcreate Tough-XMagnetic Iron PLAMaraging SteelMarble PETGMarble PLAMatte Fiber HTPLAMatte PLANanoceramic ResinNonOilenNylonNylon-CFNylon 6/69Nylon GF30OnyxOnyx ESDOnyx FROnyx FR-APA-12 with Glass BeadsPA-CFPA11 NylonPA12 NylonPA 2200PA Cast NylonPC-ABSPC-ABS with Carbon FiberPC-ASAPC-CFPC-PBTPCTGPEEKPEEK-CFPEI-CFPEKKPETPET-CFPETG PETG (Recycled)PETG-CFPETG MattePETT (T-glass)PLAPLA+PLA++PLA-CFPLA-RecycledPLA/PHAPLA 3D870 (APLA)PLA FlexPLA NX-2PLATECPOM (Delrin)PP-CFPPSF/PPSU (Heat and chemical resistant)PRO HSPRO HTPSUPVAPVDF (PolyvinylideneFluoride)PaperPolyCastPolyMax PLAPolySmooth™ (PVB)PolyamidePolycarbonate (PC)PolyphenyleneSulfidePolypropele-GF-30PolypropylenePrecise PLAPrintaMent PURE (matt)Raptor PLAResinRigid 10K ResinRigid 4000 ResinRigid Polyurethane (RPU)Rigid opaque ResinRigurRiziumSTRubber-like (TPU)Rubber-like ResinSBSST-130Silicon NitrideSilicone ResinSilicoreSomos 201Somos EvoLVe 128Somos NeXtSomos WaterShed XC 11122Stainless Steel 17-4 PHStainless Steel 316LStainless Steel 420 Bronze InfusedStandard acrylic ResinSteel PETGStoneFil PLAStrong ResinTPCTPE SEBS 95ATPU 60DTPU 70DTPU 95ATPU Shore 45-56 ATPU Shore 79ATPU powderTR250 ResinTango (Rubber-like material)Titanium (Ti6Al4V)Titanium Ti64Tough3000Tough PLATough ResinTranslucent RigidTricalcium PhosphateTungsten Fill PLAULTEM(PEI) 1010 CGULTEM(PEI) 9085 CGUV Color Сhanging PLAUltem (PEI) 1010Ultem (PEI) 9085Urethane Methacrylate (UMA)VeroVisiJet CE-BKVisiJet CE ElastomericVisiJet CR-CLVisiJet CR-WTVisiJet FTX CastVisiJet FTX resinVisiJet M2 ElastomericVisiJet M2 RigidVisiJet M3VisiJet M3 DentcastVisiJet M5VisiJet SL ClearVisiJet SL e-StoneVisiJet® EX200VisiJet® HR200VisiJet® SR200Visijet CE-NTVisijet CF-BKWaterClear ResinWax-like ResinWax Filament (MoldLay)Wood PLAZ-ABSZ-ASA ProZ-ESDZ-GLASSZ-HIPSZ-PCABSZ-PETGZ-PLAZ-PLA ProZ-ULTRATZirconia 3YZirconia 8YZortrax Basic ResinZortrax Resin PRObronzeFill - PLA/PHA + fine bronze colorFabb-XT (Amphora AM1800)copperFill - PLA/PHA + fine copper corkFill - PLA/PHA + fine cork fibrecoPLAiglidur I180nGen-CFnGen Amphora AM3300 (PET-G)nGen FLEXwoodFill - PLA/PHA + fine pinewood zp130 Powder

Sort by

AnyDistanceLowest PriceBest Rating

Upload files to compare instant quotes from local 3D printing services

Upload filesor contact us directly to get a volume discount.

If you’re looking to get something 3D printed and delivered to Newtown, New South Wales, Australia, you’re in the right place. All companies that provide prototyping and printing near you are listed above.

How much does it cost to 3D print my parts?

To check out the pricing instantly, choose a vendor and hit the “Instant order” button. From a 3D model file such as STL, PLY, OBJ or 3MF we are able to calculate the price automatically. If you aren’t sure which vendor to choose, you can “Get instant quote” at the very bottom of the page with the list of all available 3D printing bureaus.

What if I don’t have a 3D file?

3D printing starts from a model, so it is necessary to have a file. Fortunately, many companies that provide additive manufacturing can help you design the parts. For more complex modeling tasks, consider hiring a professional 3D designer.

How do I choose a vendor?

Treatstock aims for transparent workflow between 3D printing companies and customers for great results. To make sure you have all the information needed to choose your manufacturing partner, we include a list of vendor’s machines and customer ratings for each service provider. The full list of their capabilities is included on their business page as well.

To make sure you have all the information needed to choose your manufacturing partner, we include a list of vendor’s machines and customer ratings for each service provider. The full list of their capabilities is included on their business page as well.

How does it work?

- Upload a 3D file to instant order;

- Select specifications and fill in the delivery details;

- Finalize the order process;

- Monitor progress in your Purchases;

- Get your custom parts delivered to your door.

Our support team is always available for assistance. To learn more about 3D printing technologies, visit our manufacturing guide. And the material guides will help you find out more about all available manufacturing mediums.

Printing locations

- Melbourne

- Brisbane

- Perth

- Adelaide

- Sydney

Product Application

- Prototype

- HD Prototype

- Jewelry

- Dental

- Multi-color

- Metal

- Miniatures

Materials

- PLA

- ABS

- Nylon

- Wood PLA

- ASA

- Resin

- Rubber-like (TPU)

- PA12 Nylon

- PETG

Technology

- FDM (Fused Deposition Modeling)

- DMLS (Direct Metal Laser Sintering)

- SLS (Selective Laser Sintering)

- PolyJet and PolyJetMatrix

- SLA (Stereolithography)

- CJP (ColorJet Printing)

- DLP (Digital Light Processing)

- DUP (LCD-based Direct UV Printing)

Our site uses cookies. By continuing to use our site you are agreeing to our Privacy Policy

By continuing to use our site you are agreeing to our Privacy Policy

or

Forgot password?

Remember Me

By using this Service, you agree to our Terms and that you have read our Privacy Policy, including our Cookie use.

METAL 3D PRINTING. Characteristics and features of materials.

One of the important advantages of metal 3D printing is the ability to create a product from almost any alloy. In addition to standard metals, there is a wide range of special alloys - unique high-tech materials that are produced for specific customer tasks.

The 3D metal printing process consists in sequential layer-by-layer fusion of metal powders using powerful ytterbium laser radiation. The industry uses several different names for the same process, including selective laser melting (SLM).

Main advantages of 3D metal printing:

High density: 1. 5 times higher than casting;

5 times higher than casting;

· the ability to create miniature and geometrically complex objects and other unique forms in the form of closed bionic structures;

Wide range of metal alloys, both standard and special;

· Shortening production cycles and speeding up the output of finished products.

Applications:

aerospace industry;

mechanical engineering;

automotive industry;

oil and gas industry;

electronics;

medicine;

food industry;

· research and experimental work in design bureaus, scientific and educational centers.

Types of metals used in additive manufacturing

Modern additive technologies involve the use of about 20 tested and ready-to-use materials, including tool, stainless, heat-resistant alloys, aluminum and titanium alloys, medical cobalt-chromium and titanium.

Since there are a lot of metals, and each of them has certain properties, one metal can be replaced by another based on technological tasks. For example, if it is necessary to use a titanium alloy in the technological chain, then the technologist will be able to choose one of the many titanium alloys with the properties that are needed for the production of a particular product.

For example, if it is necessary to use a titanium alloy in the technological chain, then the technologist will be able to choose one of the many titanium alloys with the properties that are needed for the production of a particular product.

The following materials are the most common and in demand:

Material Ti 6 Al 4 V (Titanium alloy)

Ti6Al4V is the most common titanium alloy with excellent mechanical properties. Considered the strongest and toughest titanium alloy, it is particularly difficult to process. It has a density of 4500 kg/m³ and a tensile strength of more than 900 MPa. The Ti6Al4V alloy offers undeniable weight saving benefits in industries such as aerospace, automotive and shipbuilding. These metals are used, in particular, in the manufacture of inserts in molds, turbine blades, combustion chambers, as well as products designed to operate at high temperatures (up to +1100°C).

The main technical parameters of titanium alloy 3D printing are as follows:

Material IN 718 (Nickel Alloy)

Nickel has the ability to dissolve many other metals in itself while maintaining ductility, so there are many nickel alloys. For example, in combination with chromium, they are widely used in aircraft engines, they are used to make working and nozzle blades, turbine rotor disks, combustion chamber parts, etc. The most high-temperature resistant are nickel-based complex alloys that can withstand temperatures up to +1100°C for hundreds and thousands of hours under high static and dynamic loads. The minimum wall thickness and roughness can be attributed to the titanium alloy material. Its main mechanical properties are as follows:

For example, in combination with chromium, they are widely used in aircraft engines, they are used to make working and nozzle blades, turbine rotor disks, combustion chamber parts, etc. The most high-temperature resistant are nickel-based complex alloys that can withstand temperatures up to +1100°C for hundreds and thousands of hours under high static and dynamic loads. The minimum wall thickness and roughness can be attributed to the titanium alloy material. Its main mechanical properties are as follows:

Material AlSi 10 Mg (Aluminum Alloy)

These are the cheapest casting alloys. Their advantages include high corrosion resistance, fluidity, electrical and thermal conductivity. In industry, they are used, as a rule, for the manufacture of large-sized thin-walled castings of complex shape.

Main technical parameters of aluminum alloy:

Material 316 L (Stainless steel)

This category includes complex alloy steels with a chromium content (not less than 12%). Chromium oxide forms a corrosion-resistant film on the metal surface, which can be destroyed under the influence of mechanical damage or chemical environments, but is restored as a result of reaction with oxygen. Stainless alloys are used in the production of valves for hydraulic presses, fittings for cracking units, springs, welded equipment operating in aggressive environments, and products used at high temperatures (+550…800°C). Currently, it is the leader in demand among metal materials in the 3D printing industry.

Chromium oxide forms a corrosion-resistant film on the metal surface, which can be destroyed under the influence of mechanical damage or chemical environments, but is restored as a result of reaction with oxygen. Stainless alloys are used in the production of valves for hydraulic presses, fittings for cracking units, springs, welded equipment operating in aggressive environments, and products used at high temperatures (+550…800°C). Currently, it is the leader in demand among metal materials in the 3D printing industry.

The main technical parameters of stainless steel 3D printing:

The potential of metal 3D printing

Modern technologies make it possible to obtain powder for metal 3D printing with certain properties to solve specific production problems. And since almost any metal can be sprayed, the range of metal materials for 3D printers is extremely extensive.

Achievements in metallurgy are fully realized in additive manufacturing, allowing the use of unique alloys for the manufacture of geometrically complex products of increased accuracy, density and repeatability. At the same time, the introduction of metal additive installations also has limiting factors, the main of which is the relatively high cost of powders.

At the same time, the introduction of metal additive installations also has limiting factors, the main of which is the relatively high cost of powders.

Metal 3D printing has great potential to improve production efficiency in many industries and is being used by a growing number of companies and research organizations. An example for the global industry is shown by such industrial leaders as General Electric, Airbus, Boeing, Michelin, who have already moved from the manufacture of single metal products to serial additive manufacturing.

Metal 3D printing is constantly evolving and every year it becomes one step closer and more accessible. This technology is not so accessible for personal use and most likely will not become so, but nevertheless it has become more accessible and, in addition to large companies, entrepreneurs of medium and possibly even small businesses can use it.

We carry out 3D printing with any metal. If you need metal printing, then to find out the details (terms, cost, etc. ), write to Us at [email protected] or call +7 (995) 009-16-60

), write to Us at [email protected] or call +7 (995) 009-16-60

Our contacts :

Phone: +7 (995) 009-16-60

Post: [email protected]

Our site: https://rkadget.ru

Facebook: 3D university | 3D printers | Rkgadget ( https://vk.com/3dlxy )

Create a cat master of a cat using Raise3D N2

Application

Sign up for

Subscribe

Sharing an unusual case 3 D of the print of the master model provided by our customers. The guys are engaged in the design of new forms, the production of prototypes, master models, the manufacture of products from reinforced polyethylene and much, much more. We can’t name the company, the guys are very modest and don’t want attention yet =)

Our first steps in 3D printing

At the beginning, we thought for a long time which method would be more suitable for making master models, but settled on FDM printing. This method is cheaper than, for example, printing with photopolymer resins, and we don’t need super precision. If necessary, you can manually modify the printed models. And if you choose a thickness of 0.1 when printing on Raise3D, you can get just super-accurate results and very high quality results.

This method is cheaper than, for example, printing with photopolymer resins, and we don’t need super precision. If necessary, you can manually modify the printed models. And if you choose a thickness of 0.1 when printing on Raise3D, you can get just super-accurate results and very high quality results.

There was no doubt that 3D printing is one of the best ways to produce prototypes. Renders alone are not enough for visualization. And it’s easier for the eye to perceive a real model, because renders always look great, but only in a tangible model you can see all the jambs and problems that are easy to fix and as a result get something perfect. True, our first 3D printer almost killed the desire to print =) It was a manual Chinese device with a small area of 10x10x15. He typed, of course, disgusting. But then Raise appeared and instilled faith in 3D printing =)

Studied the market 3D printers in search of an ideal commercial and not exorbitantly expensive. No bad reviews were found for Raise3D, while there were reservations for other printers, and in all respects it was completely suitable. The N2 has a large camera, print resume function, omnivorousness on plastic, and most importantly, stable, accurate printing, which was confirmed after purchase. Of course, there are problems, without them nowhere. But everything is solved.

The N2 has a large camera, print resume function, omnivorousness on plastic, and most importantly, stable, accurate printing, which was confirmed after purchase. Of course, there are problems, without them nowhere. But everything is solved.

At the beginning, we encountered the problem of thread 'biting', as a result of which the gear pushing the thread was clogged with small crumbs from the thread itself. As a result, the supply of plastic was stopped, and at the point of bite, the thickness of the thread was reduced by half. This problem arose several times, I solved them with the help of cleaning plastic - I disassembled it completely and cleaned the nozzle.

There were also problems with setting the correct table temperature. After a series of experiments, he deduced his ideal temperature for sticking plastic - about 65 degrees.

On our N2 we mainly print models in 1:4 or 1:6 scale. If you need a full-size prototype, we make it from polystyrene foam on a CNC machine. But sometimes master models in 1:1 scale.

But sometimes master models in 1:1 scale.

Operation Sleeping Cat

One of our latest projects is the creation of a cat sculpture in metal from scratch. This is not a commercial story - a friend's cat died, and we decided to make a monument. The Raise3D N2 printer purchased from Tsvetnoy Mir was chosen as a tool for making the master model.

Of course, this is not our only project involving a 3D printer, we will definitely share the rest of the results after the release of the products. No one canceled the trade secret =)

Let's get back to the cat...

We didn't want to use models from free access, and we created a model in 3DMAX based on the photo of the cat.

A couple of small scale samples were printed from the modeled figurine to see if any corrections needed to be made to the file. The goal was to print a life-size cat in several parts, and it was important to understand how the model would look when finished.

The goal was to print a life-size cat in several parts, and it was important to understand how the model would look when finished.

The model was cut into 4 pieces of approximately equal size, given the same length and width, it seemed the most convenient. White Esun PLA was used for printing.

The result was a cat sized 40x40x25 cm.

Printing time was 12-14 hours for each of the four parts.

Layer thickness: 0.2 mm

Infill: 5%

The printed cat was glued, puttied and sanded…

Then we made a silicone mold, with its help we got a wax copy, then a burnt-out model and the last step was the casting of our cat!

9

More interesting articles

K54115

Loading

11/12/2022

1101

17

Subscribe to the author

Subscribe

Don't want to

I have a bike and he once had the protection of the leading star so that she, the star, does not chew her pants .