3D printer troubleshooting cura

7 Common Cura Problems and Fixes – Printing It 3D

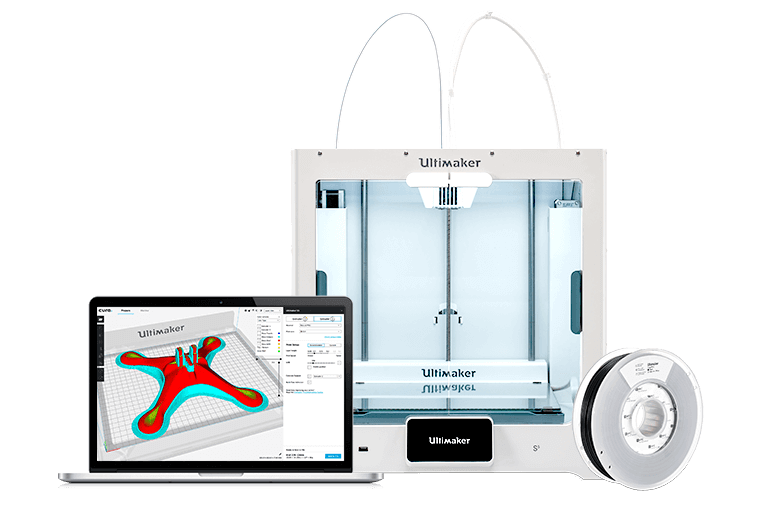

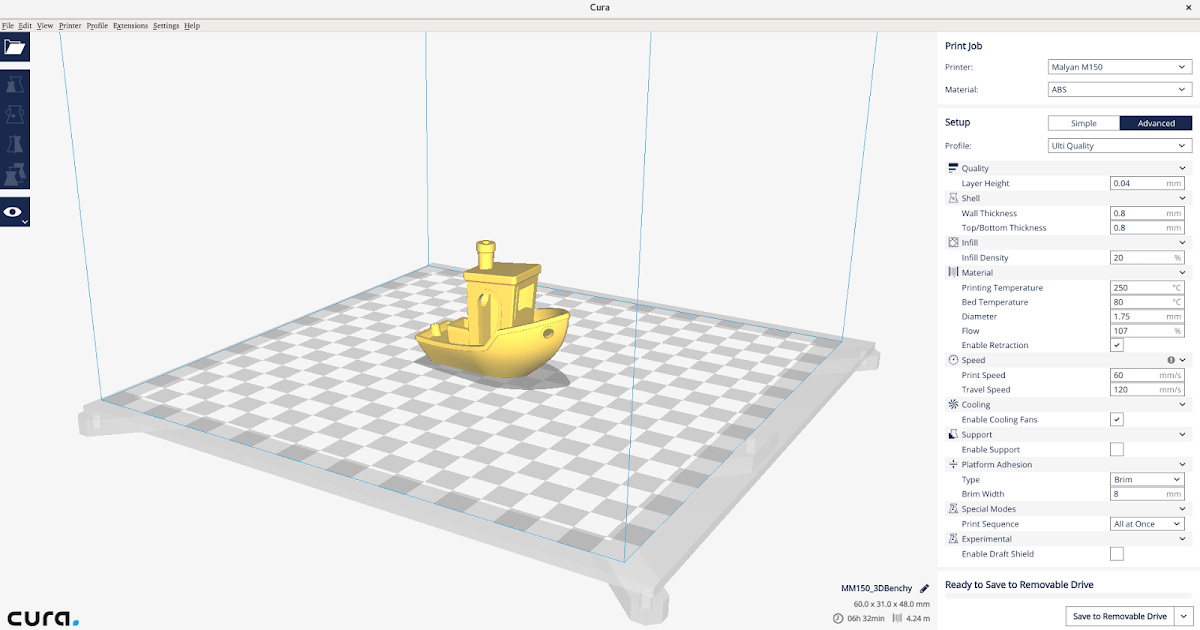

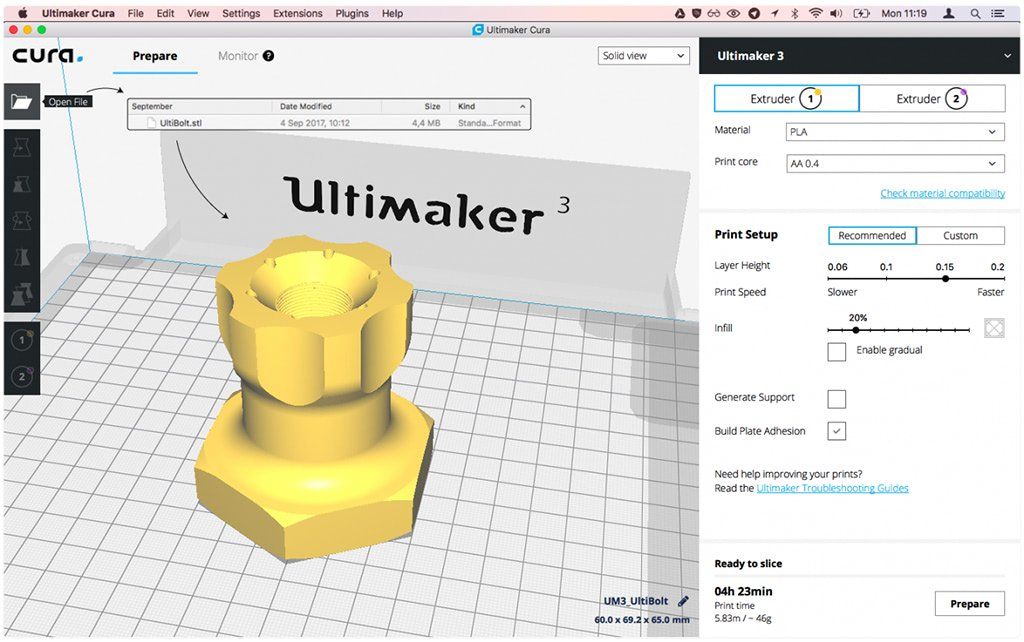

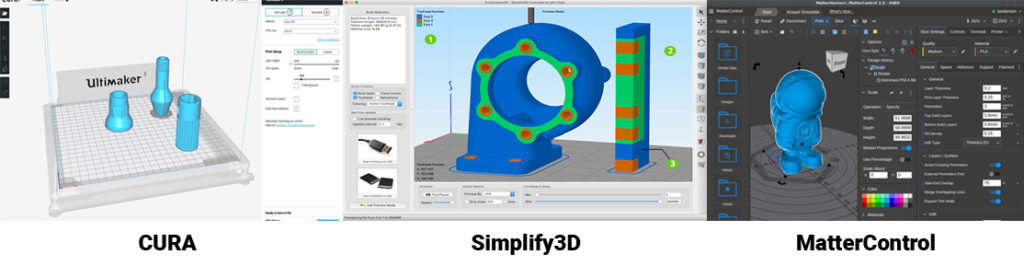

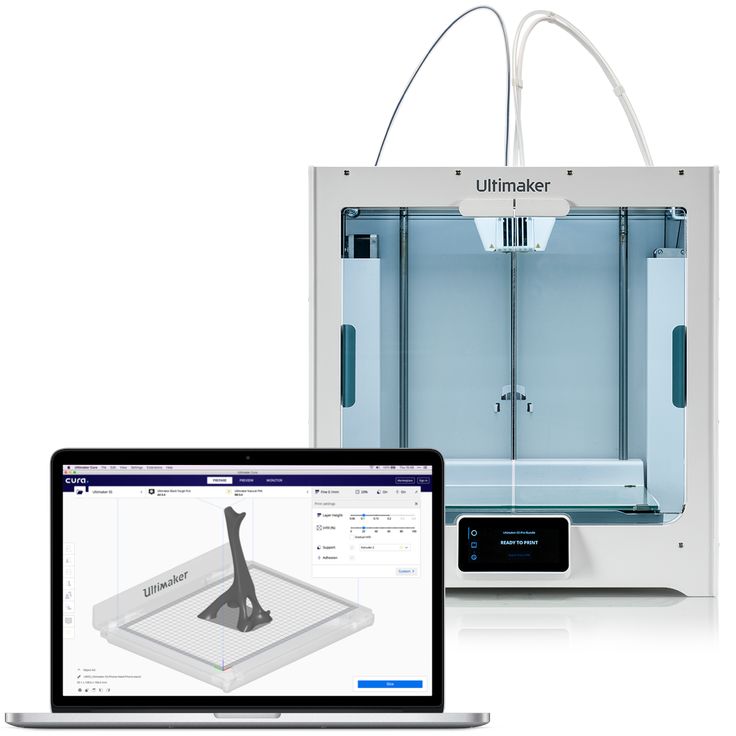

Ultimaker Cura is one of the most popular 3D printing software available on the market today. Notably, it’s a fantastic program to use for slicing 3D prints. Still, despite the program being one of the best slicers in demand, users occasionally run into a few problems.

Here are 7 common Ultimaker Cura problems:

- Cura Model Errors

- Manifold Error

- Overhang

- Zits and Blobs

- Cura Not Slicing

- Cura Not Detecting USB Printer

- Cura Not Generating Supports

While these aren’t the only Cura problems, they’re the most common and most troublesome. 3D software can be complicated, but you can easily and quickly get back to printing with a bit of know-how. Please keep reading to learn the common problems that occur with Cura and the best ways to fix them.

1. Cura Model Errors

One of the most common problems that Cura users run into is model errors. A few reasons for this may include:

- Self-intersecting

- Separate objects

- Holes

- Inner faces

Self-intersecting is basically when your mesh has clipping, and it tends to happen with more complex models.

Cura doesn’t recognize the model in your software due to original design model errors. That can be frustrating when trying to print your model. It can be even more frustrating than getting a leaking nozzle because at least your model prints.

Inner faces happen when there’s a model within a model. If the mesh has problems in your chosen 3D modeling program, it should be fixed before printing. Luckily, there’s an easy fix to get your model up and working again.

How To Fix

A model error occurs when the model has an error in the mesh. The error is already causing problems before exportation, so the mesh problem must be located and fixed before you can print out your model using Cura.

Fix the model error using these steps:

- Go into your 3D Design Software settings

- Look for any models errors and export them into Cura

- Locate the problem and alter the design in your chosen 3D design software (such as Blender or Maya)

- Reload back to Ultimaker Cura by exporting another 3D model from your software

- Manifold Error

2. Manifold Error

Another common problem you may run into while attempting to slice your model is a manifold geometry error.

3D Models must have a manifold. Manifold is simply a way of saying that what supports a 3D model in a virtual sense does not support a model in the real world. If your model has a non-manifold mesh, it won’t print correctly in the real world.

Non-Manifold is when more than two faces share any model edge; Essentially, two identical edges are on top of each other. This can happen when the model’s edge is extruded but not moved.

Making your mesh watertight is essential when slicing. Cura won’t print if it recognizes your mesh having holes; it fails to read the file properly and displays an error message. Holes will cause problems when trying to print. It may seem silly, but Cura must ensure the mesh doesn’t have any openings before it marks the print as acceptable enough to slice.

Cura won’t print if it recognizes your mesh having holes; it fails to read the file properly and displays an error message. Holes will cause problems when trying to print. It may seem silly, but Cura must ensure the mesh doesn’t have any openings before it marks the print as acceptable enough to slice.

How To Fix

A 3D model mesh is manifold, which means it has holes within the shell. An object with a non-manifold will cause Cura to slice the model incorrectly.

To fix this, click on the “file” tab in the drop-down menu and locate the “Repair STL file” button. This method isn’t always successful for every model, but it’s worth a shot before attempting a more complex fix.

If this method fails, try redesigning your mesh with your chosen 3D modeling software.

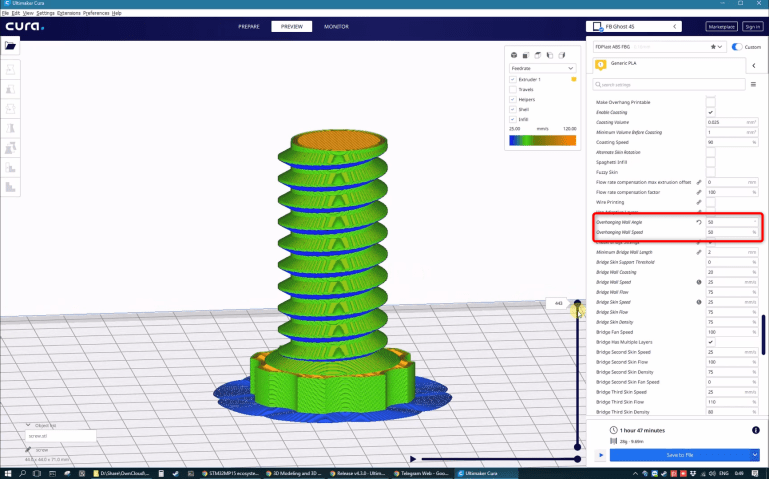

3. Overhang

You may come across a problem in your model called the overhang. The overhang angle is how much support material your model has. A slight angle leads to more support. This problem occurs when Cura thinks a vertical wall is present when it’s not. This usually is due to the mesh having the wrong normals.

This usually is due to the mesh having the wrong normals.

Any 3D model with more than 45 degrees horizontal edges is challenging to print. The material must be stable, and overhangs will cause curling, delamination, sagging, or even collapse during the printing process.

How To Fix

There are a couple of easy fixes you can try to fix your model from having an overhang:

- Check your settings in the section “mesh fixes.” If your model is acceptable, then Cura can fill the parts that need extra filling without you having to redesign.

- Click the gear and locate the fixes and make them all visible. If your “union overlapping volumes” are causing the overhang problem, this box must be unchecked.

Keep in mind that settings save. If you fix things to make all of the faces visible, it may be necessary to readjust for future prints.

4. Zits and Blobs

Throughout the printing process, the extruder usually maintains a steady extrusion. However, switching between on and off may cause problems. Notably, once a layer is finished printing, a quick blast of over-extrusion can occur if the print head’s filament remains pressurized. Such markings can also be seen at the extruder’s starting point. These are known as zits and blobs.

However, switching between on and off may cause problems. Notably, once a layer is finished printing, a quick blast of over-extrusion can occur if the print head’s filament remains pressurized. Such markings can also be seen at the extruder’s starting point. These are known as zits and blobs.

Here are some common reasons for zits and blobs to occur:

- Printing temperature is high

- Extruder pathing is incorrect

- Coasting is unsuitable

- Printhead is stuttering

- The extrusion system has built-up pressure

- Too much filament

- The mainboard is too slow

How To Fix

Here are the common solutions for avoiding zits and blobs:

- Retract and wipe all settings

- Verify the restart distance

- Relocate the starting point

- Lower the speed of printing

- Adjust the coasting

- Reduce extrusion multiplier

- Lower the print temperature

- Adjust Maximum Deviation and Resolution

5.

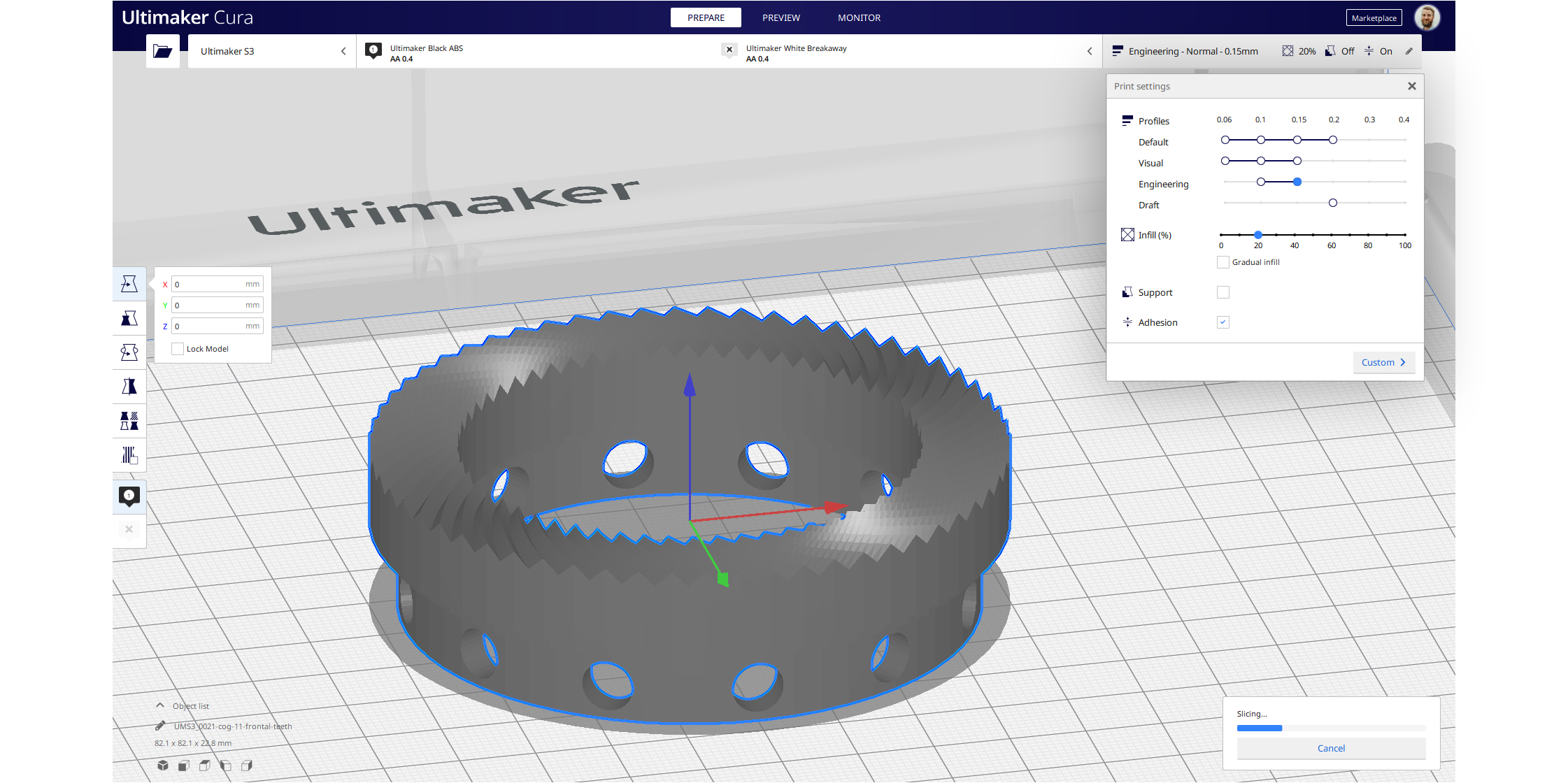

Cura Not Slicing

Cura Not SlicingCura sometimes fails to slice when required. There are many reasons why this may happen; however, it can sometimes occur for no apparent reason. You may click “Prepare,” but nothing happens after this.

Cura can also sometimes stay stuck on the “Slicing” option without anything ever moving or happening. That can be a frustrating problem among Cura users. Cura is not perfect and is constantly being updated. It’s also a free program and only accepts donations, so updates are sometimes far and few in-between. You may need to fiddle with adjustments to get your Cura to work.

How To Fix

That can be a frustrating problem and happens randomly. You may have to try a few different solutions that can be time-consuming. Here are a few methods to fix a Cura not slicing issue:

- Uninstall and reinstall Cura

- Reset your settings to default

- Shut off a firewall if necessary

If none of these troubleshooting techniques work, Cura has a setting under quality called the “cutoff object bottom” in the advanced tab. Try setting this to a non-zero value.

Try setting this to a non-zero value.

If problems persist, force the settings into factory setting mode by following these steps:

- Go to the “Help” tab

- Find the “Show Configuration Folder” (This opens the folder that holds your settings for Cura)

- Close Cura and then remove everything from that folder

- Restart the program to put the settings back to factory default

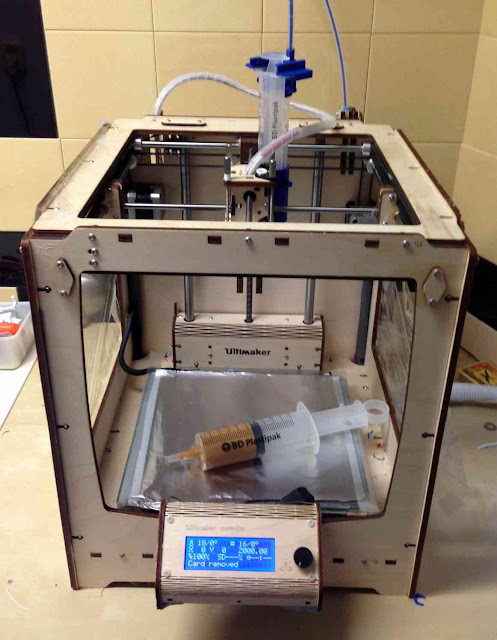

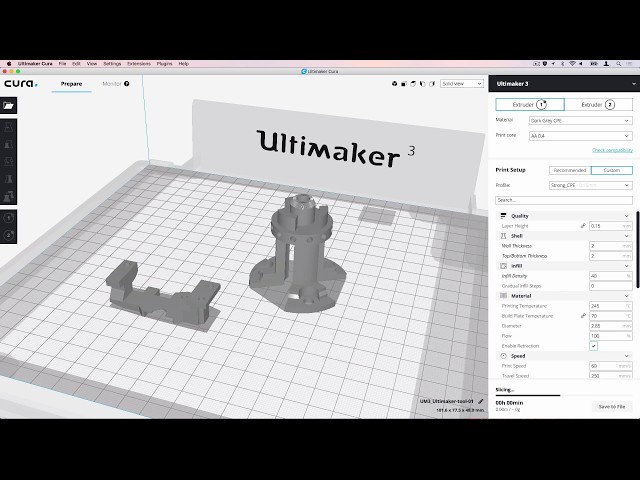

6. Cura Not Detecting USB Printer

A common issue with Cura Ultimate is Cura doesn’t detect your USB printer. This happens pretty often, and Cura users find it a frustrating problem among a few others.

You may decide that connecting a USB port to your computer and printing via USB is a great idea; however, users may experience problems with connectivity.

Here’s a great video that explains this issue further:

To get your USB printer detected without using a third-party program, use an SD card or Bluetooth connection, whichever is best for you.

How To Fix

A few easy ways to fix Cura not detecting a USB printer are:

- Check the port and baud rate in the device manager. Verify that this matches your machine settings in Cura, as this certainly causes your USB not to be detected.

- Check the USB cord itself. If you have tried the following methods with no luck, then replacing the cord may be the best bet. Many users who have trouble with USB ports usually have a faulty cable or port. You may try to replace the line before adjusting the settings within Cura itself.

- Use your SD card rather than a USB port. That can be a more straightforward fix than using a USB. Make sure your drivers are all up to date, as expired drivers can sometimes cause connection issues.

7. Cura Not Generating Support

If you need support on your overhang, the settings are marked as “Support Overhang Value,” and Cura still isn’t printing or showing support for your overhang, then your overhang may be too small for Cura to recognize.

If you are running Cura on Windows 10 or Windows 7, you may also experience problems. Cura software sometimes won’t open or opens incorrectly if your computer runs on outdated software. Remember to update your drivers and your computer before using Cura.

How To Fix

To fix the overhang, try changing your value to zero. This should force Cura to recognize your overhang, no matter how small. You may also load your model into a meshmixer to use their tree support, or you may add your own to your model in places you desire.

You may also need to check your settings. For instance, settings may be on “everywhere” and not “touching build plate.” Or it may be necessary to adjust the support distance setting until support shows up on the model.

Before redesigning your model or adjusting any settings, verify that you’re using the most updated version of Cura. Many users have reported this problem when using an older version.

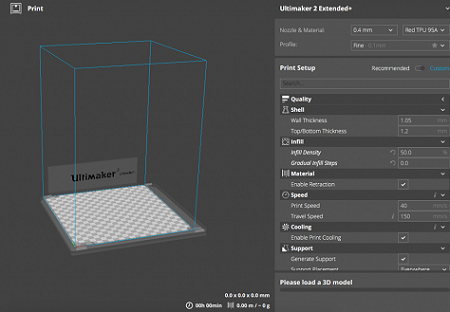

The Best Cura Settings

If you have problems with Cura, you may need to adjust some of your settings. The wrong settings can cause significant problems when 3D printing and modeling. Always check to ensure the appropriate settings are locked in before troubleshooting problems more in-depth.

The wrong settings can cause significant problems when 3D printing and modeling. Always check to ensure the appropriate settings are locked in before troubleshooting problems more in-depth.

Here are some appropriate basic settings for your Cura software:

- Layer Height Should be at 0.12 mm (0.005 in)

- Infill Should be at 20%

- Initial Fan Speed should be at 0

- The speed of the first layer should be 20 mm/s (0.8 in/s)

- Retraction should be at 6mm (0.24 in)

- The print temperature should be at 200°C (392°F)

- Printing bed temperature should be at 50°C (122°F)

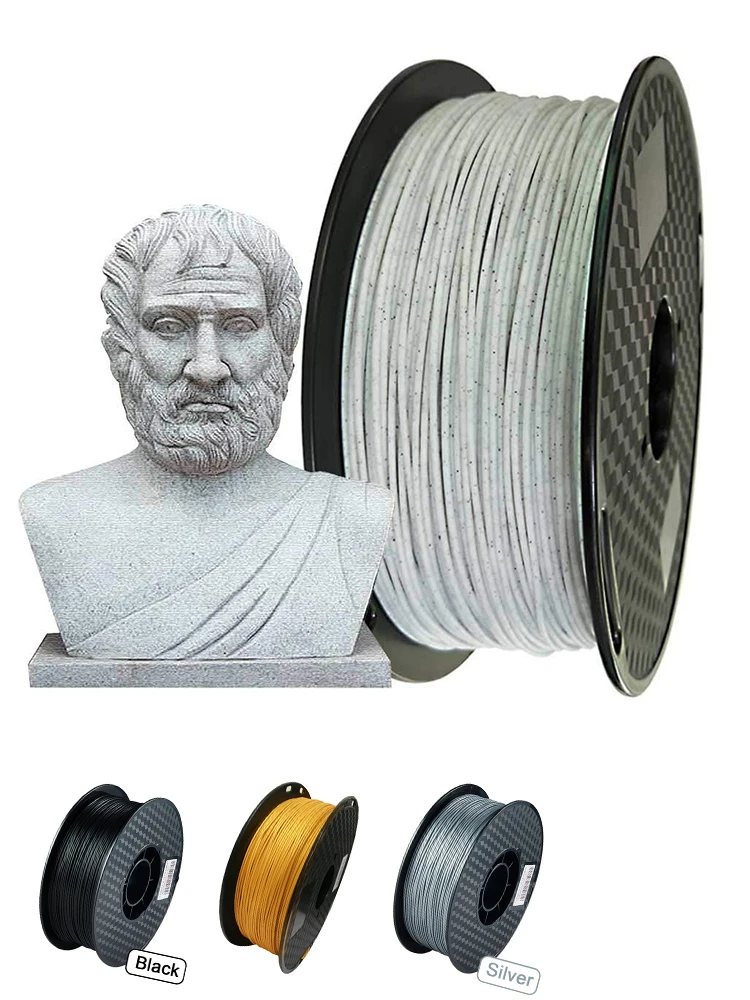

Keep in mind that settings also depend on what type of material is used to create the 3D models. Different filaments melt at different temperatures. However, these basic settings ensure your Cura settings are similar settings for your 3D printer.

It’s important to remember that bed and melt temperature is essential to printing the best 3D models. If you are using a material that melts too fast, you may experience many problems such as nozzle leaking or other issues.

Having the correct settings for your 3D printer and Cura is crucial for having the best-looking models. Remember that no model is ever perfect, and some imperfections are inevitable, but having the correct settings for your printer is vital to having great prints.

3D printing is a complex hobby; it requires a lot of learning and understanding of complex programs such as Maya or Blender or other programs that design 3D prints. You may have to take the time to read through many manuals to troubleshoot your problems. It’s not an easy process, and it may be pretty time-consuming. You may also need to replace, redesign, or remake many of your models before being able to slice and print correctly.

It’s essential to take the time needed to learn about these different types of programs before diving into 3D printing. You may damage or break pieces of your printer that have delicate parts. Be sure to have your settings placed correctly before upgrading or replacing any parts inside your 3D printer.

Cura is a fantastic program, but with any program, there are bugs. If you have a problem that you don’t believe can be fixed with any of the above solutions, then you may need to report these bugs to the Cura developers. Many bugs are issues with the software itself and will be fixed with the next big update.

🔥 The definitive guide to solving 3D printing problems by Bitfab

🤬Having problems with your 3D printer? You’ve come to the right place.

In Bitfab we have prepared the definitive guide to solve all your 3D printing problems. Thousands of hours of professional 3D printing behind our back to help you with the setbacks you have with your printer.

And we not only give you the keys to diagnose your printing errors but also the best tips to prevent them from reappearing, fix your printer and calibrate. Pictures, videos and our best tips in a mega article.

👇 Enjoy the guide and use the index if you want to go to directly to the part that interests you.

📖 What do you want to read?

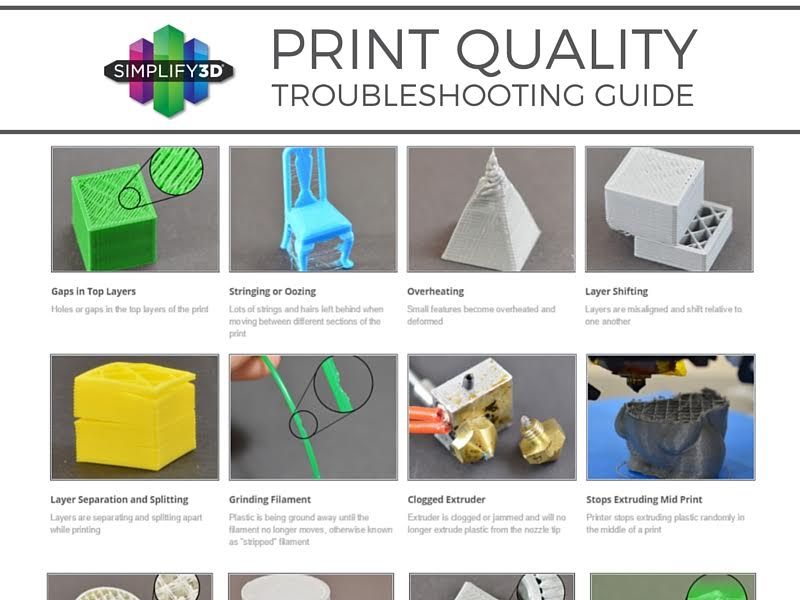

🤬 The most common defects and problems in 3D printing

We have put together a collection of the most common problems that arise when using our 3D printer. They are the same problems that we commonly encounter in our online 3D printing service, and so we have quite a bit of experience dealing with and solving them.

A well calibrated printer, correct lamination and an experienced operator are key to avoiding these problems. By having that you will be able to solve any printing problem.

If you experience any of these issues, follow the instructions we give you and if you still can’t solve them, you have the comment box at the end of the article to tell us your doubts.

❌ Warping, the first layer peels off and the parts bend

Warping is a decreasingly common problem, as the vast majority of modern printers have hot beds. In any case, warping can be caused by the following factors:

- Lack of adhesion to the bed: this can occur due to incorrect height of the nozzle in relation to the base, or poor leveling; but also lack of adhesion to the printing surface.

- Thermal contraction of the upper layers, which when “shrinking” pull on the lower layers. If this occurs, the print surface may even break if it is a BuildTak type, as the sticker will be torn off the bed. This can also happen with glass. This happens mostly with materials such as ABS or Nylon, and it is very difficult for it to happen when printing PLA.

Depending on our problem we can look for a solution accordingly:

For the lack of adhesion there are several solutions. If we are using a glass base, it is highly recommended to use some adhesive to increase the fixation of the part. Some known adhesives are the famous Nelly hairspray, or its more professional version 3Dlac. If we are using ABS we can apply a layer of the mixture known as ABS slurry which we can make ourselves by dissolving ABS in a container with acetone.

If your problem is related to thermal contraction, increasing the adhesion will not help you too much since, as we have said, the ABS when deformed can even break our printing base. To solve this problem we can simply cover the printer with whatever we have at home. A large box can work, as well as a more professional enclosure made in a closet.

To solve this problem we can simply cover the printer with whatever we have at home. A large box can work, as well as a more professional enclosure made in a closet.

The idea in this case is to enclose the heat generated by the bed, so that there is not much difference between the temperature of the first layers and the temperature of the upper layers, which are farther away from the heat of the bed.

Here’s an article that we made explaining this problem more in depth: How to avoid warping and cracking in my 3D prints.

❌ Cracking or delamination

Following on from the above problem is cracking or delamination. We talk about cracking when the layers of a part are not well joined, resulting in these layers being separated (hence the name delamination). This problem can be caused by two different reasons:

- Poor adhesion between the layers: the layers do not stick properly to each other.

- Thermal shrinkage: the layers stick together well, but a difference in temperature between different sections of the part causes it to deform, which can cause some layers to separate.

If the problem is lack of adhesion, it is usually due to low of temperature. Most filaments have a temperature range in which they can be printed.

Within this range, lower values will give us a better aesthetic appearance, since the deposition will be “cleaner”. Conversely, higher values will give us better layer adhesion. Printing materials such as ABS at less than the proper temperature often leads to cracking when trying to bond two layers without applying enough heat.

To check if our part is cracking due to lack of adhesion between the layers, we can try to raise the temperature and/or reduce the speed of the layer fan, as excessive cooling can also affect it negatively. Some materials, like ABS, will always be prone to cracking and will be more difficult to control; others like PLA are very easy to print without cracking.

On the other hand, if our problem is thermal contraction the solution is more complicated, as we must manage to create a warmer environment in our printing area. The optimal solution would be to cover our printer, as indicated in the previous point. This can result in some problems, since an excessive temperature can lead to failures in the electronics: missing steps or losing printing artifacts… it can also cause clogging, since there is not enough difference in temperature between the cold zone and the hot zone of the hotend.

The optimal solution would be to cover our printer, as indicated in the previous point. This can result in some problems, since an excessive temperature can lead to failures in the electronics: missing steps or losing printing artifacts… it can also cause clogging, since there is not enough difference in temperature between the cold zone and the hot zone of the hotend.

In general, avoiding draughts (and the consequent temperature variations) and covering our printer will help, but we must be careful to avoid the problems mentioned.

❌ Layer shift

Layer shifting is a problem that occurs in the form of a displacement on some axis at a certain height. It can occur in the X-axis, the Y-axis or even both simultaneously. The most common causes of layer shifting are:

- Excessive temperature in the motors, or drivers: the electronics in general are not designed to operate continuously at a very high temperature.

- Lack of power in the motors, usually caused by a very low voltage value in the drivers.

- Mechanical failure: it can happen that we have some of our belt’s teeth broken, or there is some debris on the shafts that can cause a jam in the movement of our printer. Sometimes a wrongly tightened component can also cause layer displacement defects when the whole shaft moves freely.

A general advice would be to put heatsinks, and if possible ventilation, to the drivers of our board. These components basically take care of sending all the necessary air flow to the motors, so they tend to heat up. Likewise, if our printer operates in very hot environments it would be appropriate to add some heatsink to the X and Y axis motors as well. If the drivers are very hot, you will usually hear a knock, knock, knock on the motors when the drivers are briefly disconnected to give them time to cool down.

Additionally, you can check if your printer has drivers with adjustable voltage, and if so, you can increase this voltage slightly by carefully turning the potentiometer on each driver. Be careful when doing this, and always do it with the printer turned off or using a ceramic screwdriver to avoid short-circuiting with a metal screwdriver. If you turn up the power on the motors too much you risk falling into the overheating problem again.

Be careful when doing this, and always do it with the printer turned off or using a ceramic screwdriver to avoid short-circuiting with a metal screwdriver. If you turn up the power on the motors too much you risk falling into the overheating problem again.

Finally, check that the shafts of your printer are clean and free from obstructions. Also check that the belts and bearings are not too tight (if the bearings are tightened with flanges or screws). Shafts that do not move well, over-tightened belts… cause motors to work harder and may lose steps.

❌ Z-wobble

This problem can be difficult to identify, as it is often not easy to distinguish it from a simple inconsistency in the extrusion. To identify it we must look at whether this inconsistency is repeated on a regular basis. If it seems random, or just noise in general, your problem is probably not z-wobble but an extrusion problem. Conversely, if there seems to be a pattern that repeats periodically such as waves on the surface, you may well have a problem with your Z-axis.

This problem is mostly due to structural failures in the construction of the machine, and is difficult to solve without making major modifications to our machine chassis. First of all check that all the parts are properly assembled, maintaining the perpendicularity and making sure that there are no loose screws.

Try to tighten all the screws on the couplers that connect the z-axis motors to the spindles. Also check that there is no wobble between the spindle and the trapezoid nut. It is complicated to give a correct solution, because the axis needs some freedom to move to compensate small errors in the chassis, such as corners that are not perfectly perpendicular.

A good solution that is not too expensive is to replace the motor-coupler-spindle assembly with a motor with a built-in spindle. We can also add reinforcements to our printer so that the frame of the printer does not wobble at the top.

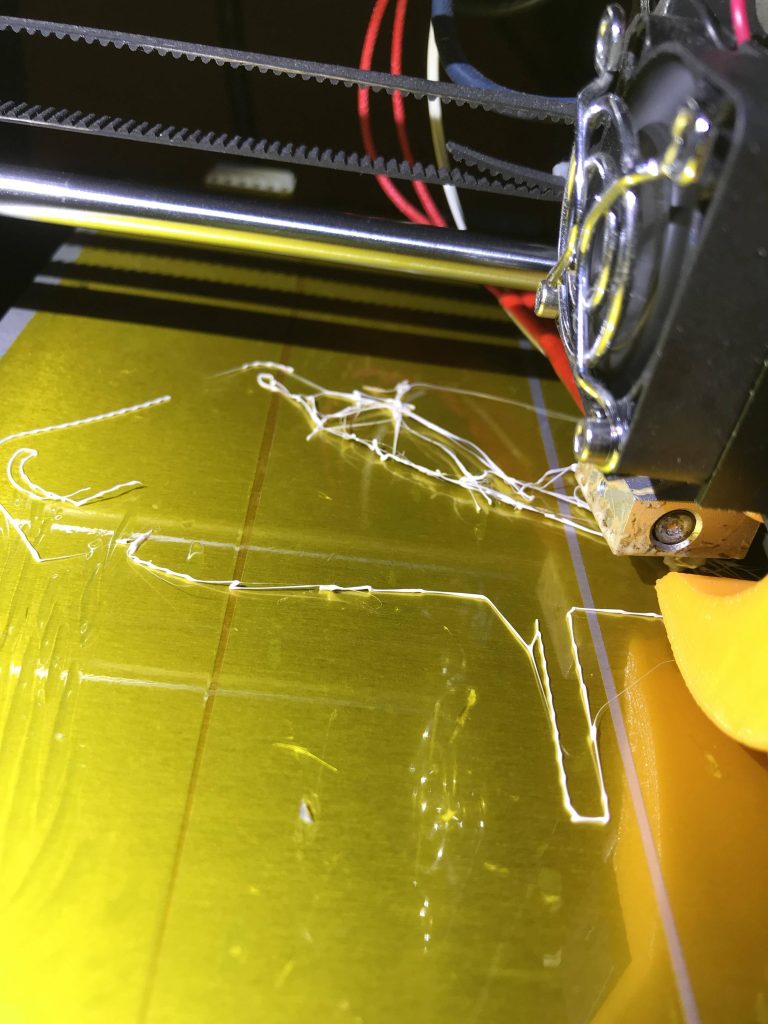

❌ Stringing

Stringing is one of the most common problems in novice parts in the world of 3D printing, so if your parts have a lot of strings don’t worry, it’s totally normal and quite easy to solve.

Stringing appears when, as the hotend moves between two sections of our print, a small amount of plastic drips off and sticks to both sections, leaving a small thread in between.

This problem can be caused by the use of a bad quality hotend, but usually the machines have a hotendsn of sufficient quality, so the problem almost always comes from bad lamination in the slicer.

The most important parameters you should check in your slicer to minimize the stringing are the following:

- Temperature

- Retraction distance

- Retraction speed

Temperature is a vital factor and probably one of the 5 most important settings in your profile. If you have a lot of stringing you are almost certainly melting at too high a temperature. Remember that all materials have a range of temperatures in which they can be printed, so try lowering the temperature and bringing it closer to the lower limit recommended by the manufacturer. If you are already using a very low temperature and still have stringing, check the following points.

While it is not possible to “suck” plastic out of the nozzle, as no negative pressure can be created, it is possible to minimize the pressure on the nozzle by pulling the filament out of the hot zone of our hotend. The shrinkage distance is very dependent on our printer, as both the melter and extruder and the type of extrusion (direct or bowden) must be considered. Most bowden printers perform well with a shrinkage value between 3mm and 6mm, and direct extrusion printers between 0.5mm and 2mm.

The speed of retraction is another important factor, as the higher the speed the lower the stringing. This speed will depend on the motor of our extruder and also on the type of extrusion (1:1 vs 3:1 like the Titan extruder). Generally values between 40 mm/s and 60 mm/s usually work, but if you have any doubt, please ask in a forum or group dedicated to your specific printer.

Additionally, almost all slicers or laminators have different more advanced settings that can help reduce the stringing, but these will only be of importance if the three previous ones are well adjusted. This is a very broad topic and we could make an exclusive guide about this problem, so if you want to see it, leave us a comment!

This is a very broad topic and we could make an exclusive guide about this problem, so if you want to see it, leave us a comment!

❌ Overheating, curling

One of the easiest problems to diagnose is overheating.

As we can see in the image, melting our plastic at an excessive temperature will cause the parts to look deformed, with the center of the layer sunken. This is because when melted at too high a temperature, the material does not have time to cool down, and that is why the layers can collapse or sag.

These deformations will be much more pronounced in small areas, such as small peaks of our part, where instead of a clean figure, a deformed churro will remain.

The solution to this problem is simple: lower the temperature. We must also play with the values of the layer fan, since a high temperature can favor a more fluid extrusion and we can compensate this temperature with a good cooling. In this way the material will be cooled down quickly and we will be able to obtain optimal results.

❌ Elephant’s foot

The elephant foot is a defect consisting of the expansion in the horizontal plane of the first layers of our part. It can occur due to two things or, normally, a combination of both: the nozzle is too close to the bed or the temperature of the bed is too high.

If the nozzle is too close to the bed, it is obvious that the first layers will be more flattened and therefore expand in the XY plane. To solve this problem we must correctly level our first layer, as indicated in a previous section of this article.

An excessive bed temperature (say, 90 or 100 degrees for PLA) can cause the newly deposited plastic to expand and deform, causing this very characteristic effect.

❌ Ghosting, ringing

The best article on this topic on the internet is the 3D Campy post by 3DSpana about ghosting, because he dedicated himself to try different combinations and components, taking pictures of the results, so you can see how decreasing the weight of the axes affects ghosting. If you prefer it on video, here’s the summary:

If you prefer it on video, here’s the summary:

😍 Keys to print correctly with your printer

You’ve seen the list of problems we’ve collected. Now you have to know how to DO things.

Knowing your printer and laminator is the key to error and defect-free printing, so here are some tips to avoid problems and help you diagnose and fix them:

✅ Printing speeds

One of the most common mistakes we find on beginners is wanting to print too quickly on their first parts.

The printing speed is one of the most important printing parameters to obtain the best printing quality and an excess of speed affects the part very negatively for many reasons: vibration, extrusion problems, overheating, loss of steps…

One of the first things you have to do when you encounter a problem is to reduce the printing speed to see if it is solved. We usually print almost all parts between 40 and 60mm/s, no more is needed for most cases. In a printing service the most important thing is reliability and when you are looking for reliability it is best to print at reasonable speeds so you don’t have to throw the parts away.

We usually print almost all parts between 40 and 60mm/s, no more is needed for most cases. In a printing service the most important thing is reliability and when you are looking for reliability it is best to print at reasonable speeds so you don’t have to throw the parts away.

It is not necessary to print your parts at 100mm/s, especially the first ones. Yes, we all know someone who does it and gets it done, but it’s not the best way to make sure they come out right.

✅ Bed adjustment and leveling

Learning to set the bed correctly level and the extruder at the right height is one of the first steps we take with a new 3D printer.

Here’s what a properly adjusted bed looks like: the height of the first layer has to be correct across the entire surface of the bed.

First layer too close

If your first layer is too close to the printing surface, you can cause jams, scratches on the bed, parts with the wrong dimensions, elephant foot…

Correct first layer

When the first layer is correct, the threads deposited by the extruder touch each other and are not too flat against the bed.

First layer too separate

A very separate first layer can be noticed by the separate threads.

Parts printed in this way are usually detached from the bed or warp.

And how do you properly level a hot bed? Our preferred technique is paper in the corners. It is not necessary to have a printer with self-leveling, the best thing is to have a reliable and well calibrated printer to print with quality.

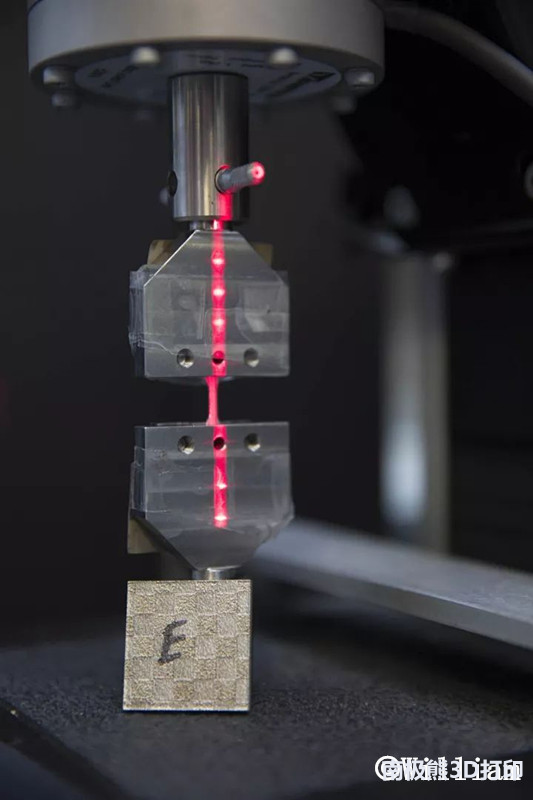

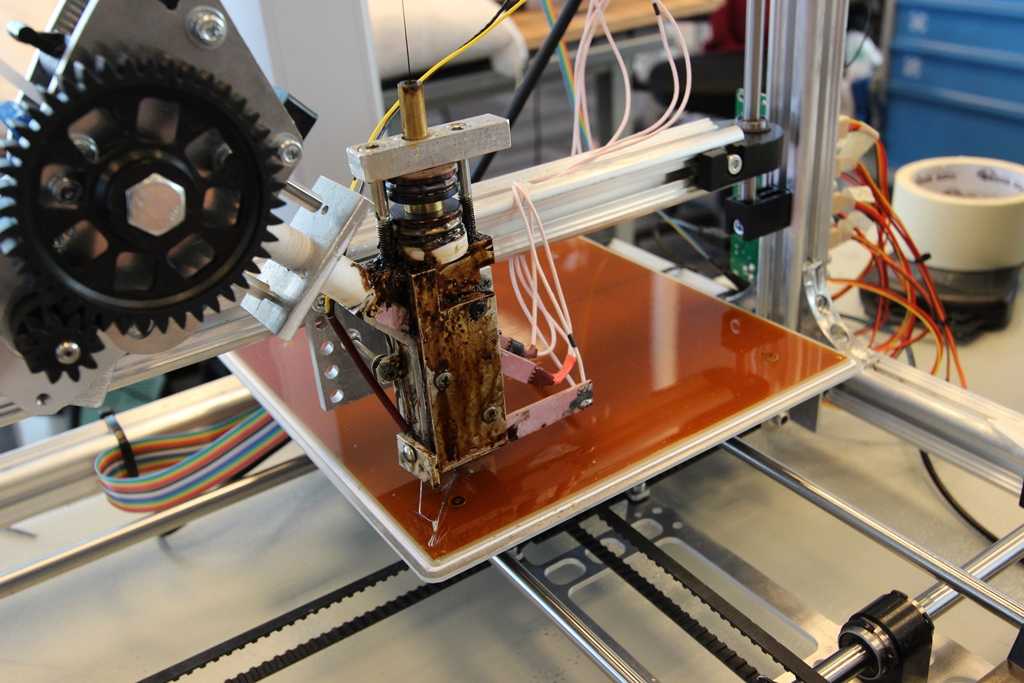

✅ How to prevent and fix extruder clogging

Extrusion jams are the number one cause of failure on a farm like ours. You may have mastered your printer but the jams are always going to be there, so it’s critical to understand them and be able to prevent and fix them.

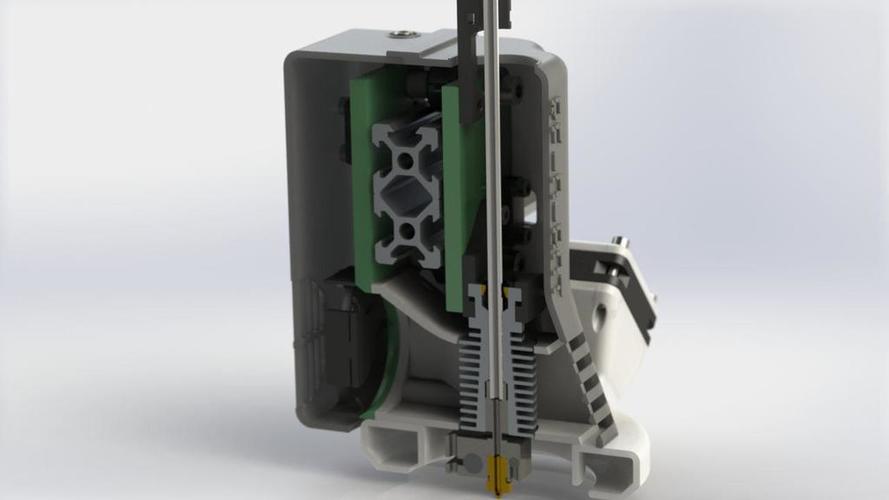

If you don’t yet understand how a 3D printer extrusion works and what the common terms for referring to them are, you can first check out our guide to 3D extruders.

Causes for clogging

Clogs arise from many different causes, sometimes in conjunction with each other. I believe the best way to solve them is to first understand all those causes and then try a series of techniques that can help fix them.

- Contamination at the tip and print canal. Impurities that are deposited in the print canal or at the tip of the nozzle and hinder or completely block the flow of the filament.

- PTFE/teflon degraded. Teflon hotends in the hot zone require maintenance of the Teflon, which when degraded clogs the filament flow.

- Extruder problems. Maybe your extruder is not working properly:

- Too much tension or too little tension in the dock

- Low voltage in the driver that does not give enough power to the motor

- Dirty thrust wheel, with teeth covered with filament debris

- Any loose or broken parts

- Scratching the filament. This is very, very important to understand.

When we see the scratched filament, nibbled by the extruder wheel, it is not always the cause of the clogging. All printing clogs, whatever the cause, end up scratching of the filament. And only those clogs that are due to spring tension and excessive shrinkage are the root cause of the clog itself.

When we see the scratched filament, nibbled by the extruder wheel, it is not always the cause of the clogging. All printing clogs, whatever the cause, end up scratching of the filament. And only those clogs that are due to spring tension and excessive shrinkage are the root cause of the clog itself. - Tip scratching the base. If the first layer is too low, it can interrupt the flow of the melted plastic and quickly cause a clog in the extrusion system.

- Watch out for shrinkage. A part with a lot of very fast retractions can end up scratching the filament. And long, slow retractions can overheat the cold zone of the extruder and cause clogging as well. In general, retractions won’t cause your clogs, but you should always keep an eye on them.

- Poor cooling. Cooling is a fundamental variable in all-metal hotends. If your extruder is 100% metal like the E3D V6 you have to be very careful with this and with excessive shrinkage.

Unclog the nozzle with acupuncture needles

The technique of passing an acupuncture needle through the printhead is most useful if the real cause of your clog is an impurity. The nozzles themselves last many hundreds or even thousands of hours of use, so you will almost never have to change them.

Most likely a particle has been deposited in the nozzle and you should be able to get it out with the needle. We heat the head and stick the needle while hot, and then pull out the filament with the particles that might be causing the clogging embedded in the molten filament.

Repeat this process until the plastic comes out of the nozzle again easily.

Hot and cold pulling

The pulling takes a little longer to do than using the acupuncture needle, but it cleans the impurities better and also takes away the filth not only from the tip, but from the whole interior of the hotend.

They are easier to explain with a video like the one below:

Teflon switching

In hotends with Teflon liner it is necessary to change this component, in general, every several hundred hours. The Teflon or PTFE liner is a small tube that goes in the hot zone of your hotend to guide the filament in the last centimeters of run, and that is degraded due to the temperature it reaches. Changing it is a job that you will have to learn to do to properly maintain your printer.

Before the tube degrades completely, you will notice that your printer is having more and more trouble printing, the filament thread that comes out is thinner and it’s harder for it to deposit material on the parts that you print faster.

In every printer the change of Teflon is different, but here is the example of the Hephestos 2 from BQ to help you understand it better.

Adjusting the printing parameters

There are clogs that can occur because our laminate is not well adapted to the type of part and printer we are going to use.

To allow your printer to extrude more easily you can try:

- Printing slower

- Printing at a higher temperature

- Printing thinner layers

- Reducing the flow rate if you have more than 100%

These are all tricks that reduce the requirements on the extruder and melter because they require less flow through the hotend and heat the plastic to make it more fluid.

Retractions can also influence extrusion problems:

- Too many or too fast retractions can result in scratching of the filament in the extruder.

- Too long or too slow retractions can cause cooling problems in your melter (especially if it is all-metal) or end up clogging the plastic in the cold zone of the melter.

If you don’t know how to fix it, dissasemble the extruder and hotend

The best way to attack a mechanical problem that you don’t know how to solve is to proceed to disassemble what you want to fix. Taking apart a hotend and an extruder is quite simple and will allow you to see inside what is happening and reflect on the problem.

When you dismantle your extruder you will notice that there are some broken parts, dirt somewhere, some loose screws…

If you disassemble the hotend you will be able to see the state of the Teflon, the tension of the hotend threads and if there is print residue deposited in the filament canal.

In either case, take the opportunity to clean the parts to prevent errors in the future.

👋 That’s it for the 3D printing troubleshooting guide by Bitfab

Thank you so much for getting this far.

If you have any doubt or a different problem just put it in the comments and we will help you solve it, or maybe even add it to the rest of the problems 😁

👋 Greetings and thanks again!

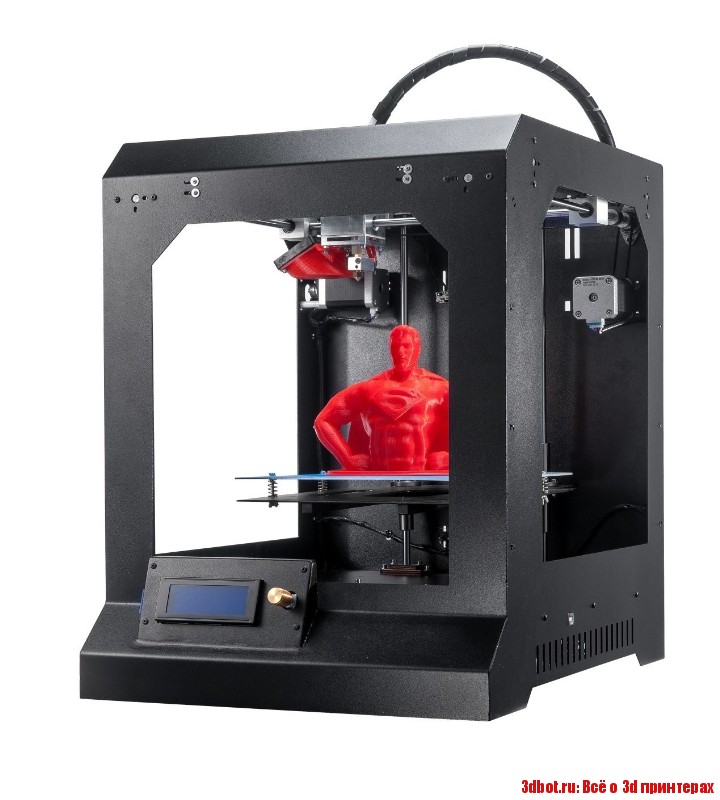

Problems, defects, 3D printing errors and solutions

Often during the operation of a 3D printer, problems may arise due to which defects appear on the finished model. Or instead of a neat product, plastic noodles suddenly appear on the table.

Or instead of a neat product, plastic noodles suddenly appear on the table.

In fact, the causes of defects can be conditionally divided into 2 types - these are physical and software.

Physical ones are those that arise due to problems with the mechanics or any other causes that can be eliminated physically. These include problems with printer mechanisms (belt tension, backlash), clogged or deformed nozzle, incorrect table geometry, etc.

Software - these are defects that occur due to incorrect slicer settings or, less often, errors in the printer firmware. For example, incorrectly selected print speed, retract settings, incorrectly selected temperature for plastic, etc.

Very rarely, the problem may lie in the wrong or “flying” printer firmware (although usually the printer simply will not start then), overheating of some boards during printing, etc. These are rather special cases, so we will not consider them.

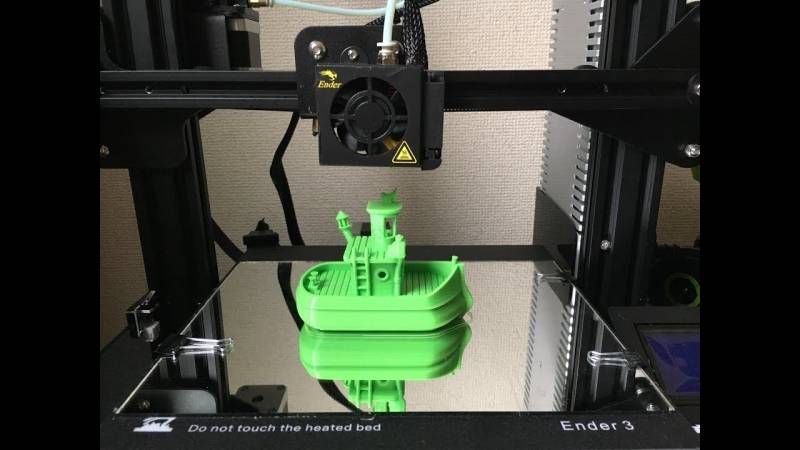

Model peels off or does not stick to the build plate

This is the most common 3D printing problem. Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Gap between table and nozzle 9 too large0023

This is the most common reason. You just need to set the correct gap between the table and the nozzle.

Modern printers often use an auto-calibration (auto-leveling) table system or an auxiliary table leveling program. To calibrate such printers, use the instructions. If there is no manual, it can be downloaded from the manufacturer's website.

If you have a simple printer without auto-calibration, a self-assembly or KIT kit, use a probe or a piece of paper folded in half to calibrate. The probe should be slightly pressed against the table by the nozzle. Before calibration, the table and extruder must be heated. Align the table surface over each adjustment screw (there may be 3 or 4) in turn, and only then check the center point.

If you're having trouble getting your table surface perfectly level, try raft printing. Raft is a thick substrate in several layers that is printed under the model. It will help smooth out the slight curvature of the table.

A small cheat sheet to determine the correct gap on the first layer

Plastic with poor adhesion

Some types of plastic, due to various reasons, such as large shrinkage, do not adhere well to the surface of the printing platform. In this case, try using stickers or special 3D adhesives to improve adhesion between the table and the first layer of plastic.

In the early days of 3D printing, there were experiments with different homemade 3D adhesive recipes. ABS diluted in acetone, BF glue, sugar syrup and even beer. Some experiments have been successful. Until now, some enthusiasts use some types of hairspray or glue sticks as 3D glue. But still they are inferior in their properties to industrial 3D adhesives.

Some types of high temperature plastics with a high percentage of shrinkage (ABS, Nylon, etc.) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case.

Plastic temperature too low

The hotter the plastic is when it exits the nozzle, the better it will adhere to the print bed. It is better to print the first 5-10 layers at a higher temperature (+ 5-10 degrees) and turn off the blower fan.

Wrong first layer settings (speed and thickness)

A thicker layer sticks easier, so the standard first layer is 0.3mm thick. With an increase in print speed, the heating block may simply not have time to heat the plastic to the desired temperature and it will stick to the table worse. Before printing, check the speed and thickness settings of the first layer in the slicer.

A lot depends on how the 3D printer prints the first layer. Try to control the printing of the first layer and only then leave the printer to work alone.

Plastic does not choke from nozzle

The printer has already begun to print, but the print table remains empty. Or part of the model did not print.

Clogged nozzle

In 3D printing, a nozzle is a consumable. The nozzles are clogged or worn out (frequency depends on the type of plastic). The simplest thing is to replace the nozzle. But if there was no spare at hand, you can try to clean the old one. To do this, there is a whole set of thin needles. Or you can heat a clogged nozzle above the melting point of the plastic and “burn out” the blockage. But later it is still better to replace the nozzle.

Low temperature nozzle

You need to increase the temperature of the extruder in the slicer settings or check the thermistor and heating block. Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

If the problem occurs after replacing the thermistor - contact the manufacturer or read articles about PID tuning.

Empty extruder

As the extruder heats up, plastic begins to ooze out of the nozzle. Because of this, the extruder may start printing half empty. Because of this, part of the first layer is not printed. You can push the plastic manually by simply pushing the bar into the nozzle. Or solve this problem programmatically - in the slicer, add a contour print around the model (one line).

Some manufacturers and 3D enthusiasts add a line print on the edge of the table at the beginning of each GCode. This is done so that there is plastic in the nozzle by the time the model is printed.

Feed mechanism does not push through plastic

The plastic pushes the feed mechanism to the extruder - a motor with a special pulley put on the shaft. If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

Elephant foot

The first layers of the model are wider and protrude beyond the boundaries of the model. This is due to the fact that the upper layers put pressure on the first ones that have not yet cooled down and flatten them.

High table temperature

Due to the too high temperature of the table, the lower layers remain soft for a long time. Try lowering the table temperature. It is better to reduce gradually (in increments of 5 degrees). You can try to turn on the blower when printing the first layers.

Small gap between nozzle and platen

If, when printing the first layer, the nozzle is too close to the table, then excess plastic will be forced out. After a few coats, this will not be as noticeable, but can lead to the effect of an “elephant's foot”.

Plastic re-extrusion

When too much material is squeezed out of the nozzle, the walls of the model are not smooth, but bumpy, with sagging.

The solution is software - in the settings of the slicer, you need to set the material feed rate (fluidity) to a lower value. The average value is 95-98%.

It is worth checking the diameter of the rod. If its size is greater than 1.75, then the plastic will be squeezed out more than necessary.

Plastic underextrusion

The plastic is squeezed out too little, because of this, gaps may appear between the layer. The finished model will be fragile and fragile.

Wrong thread diameter

Check the filament diameter in the slicer settings. Sometimes, instead of the popular 1.75, the default is 2.85.

Incorrect feed factor settings

Check the fluidity settings in the slicer. The average should be 95-98%.

Clogged nozzle

Something could get into the nozzle and partially block the exit of the plastic. Visually, the plastic will choke from the nozzle, but in a smaller amount than necessary for printing.

Hairiness or cobwebs on finished model

Thin threads of plastic protrude from the outer wall of the model (most often on one side). The defect appears due to the flow of plastic from the nozzle during idle movement.

Insufficient retract

A retract is a slight pull of a plastic filament from an extruder. Due to the retract when the extruder is idle (from layer to layer or from model to model), heated plastic does not drip from the nozzle. For some flowable plastics (eg PETG) the speed and amount of retraction must be increased.

"Hairiness" can be easily removed by grinding or cutting off the threads with a sharp scalpel.

High temperature extruder

The higher the extruder temperature, the more liquid the plastic becomes. It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

In the selection of the optimal extruder temperature, a test model - a tower - helps a lot. It clearly shows how plastic behaves when printed at different temperatures.

.

Temperature test

Top "perforated" or uneven

The top of the model is bumpy or with holes. The problem may arise if the top of the model is flat. For example, like a cube.

Insufficient airflow

When printing the top plane (cover), the plastic does not have time to cool down and remains too liquid. Because of this, the threads are torn and holes are formed. Increase the fan speed on the last layers.

Few top layers

The top of the print may be too thin and deform as a result. Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Low percentage of filling

If the infill percentage is too low, then the top layer will simply have nothing to rely on. Increase the fill percentage in the slicer settings.

Increase the fill percentage in the slicer settings.

Model deformation

Some parts of the model seem to have melted in some places or on one side. The problem most often occurs when printing with PLA plastic. The defect appears due to the fact that the plastic does not have time to cool and deforms.

Insufficient airflow model

Turn the fans on to maximum. If their power is not enough (in some printers, the fan is located only on one side), you can put a regular desktop fan and direct it to the 3D printer table.

Small model

Small models are difficult to blow well. Try to print small items alongside larger ones, or place several identical models in different corners of the table. So the plastic will have more time to cool.

Layer offset

Layers shift along the x or y axis during printing.

Print head jam

Turn off the printer and try to move the extruder along the x and y axes with your hands. The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

Electronics overheating

Sometimes electronics problems can be to blame for misaligned layers. The most common cause is overheating of the drivers or too low current exposed to them.

Table top is loose

This is most often seen in 3D printers with glass. During printing, the nozzle may hit the model and move the glass slightly. Before printing, check if the glass or other printing surface is well fixed on the heating table.

Skip layers

Small holes are visible on the print, or the shell of the model is not continuous.

Teflon tube deformed

There are 2 types of thermal barriers - all-metal and with a Teflon tube. If overheated, the Teflon tube may deform. Plastic will pass through it, but in a smaller amount.

Low extruder temperature or high print speed

If the extruder is not heated enough, then the plastic will not be liquid enough and simply will not have time to be forced through the nozzle. The higher the print speed, the higher the extruder temperature should be.

Sometimes the outer walls print well, but the infill is “torn”. In this case, slow down the infill print speed in the slicer.

Model bundle

Cracks form on the surface of the printout during or after printing. Cracks can be large or very small. Most often, this problem occurs with plastics with a high percentage of shrinkage - ABS or Nylon.

Sudden temperature difference (if model delaminates during printing)

With a sharp temperature difference (for example, a draft), part of the model cools down faster. This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

But if the shrinkage percentage is more than a few percent, the model may burst in layers.

For printing with such plastics, it is recommended to use a printer with a closed housing. If this is not possible, try to avoid drafts and sudden temperature changes in the room where the 3D printer prints as much as possible.

Print temperature

Due to too low printing temperatures, the layers may not “stick” well to each other. Raise the print temperature in the slicer settings.

Hardening (if the model cracks after printing)

Sometimes cracks appear on the model a few days after printing. This is due to uneven distribution of internal stress after cooling. You can try to “harden” the finished product.

For hardening, the model is placed, for example, in an oven, and heated to the softening temperature of the plastic. After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Ringing

In places where the extruder changed direction, ripples are visible. Most often it looks like a shadow around the “sharp” protruding elements of the model.

Mechanical problems

Sometimes the problem occurs due to extruder play. Check if the extruder mount to the rails is loose. Be sure to check the tension of all belts.

High print speed or high accelerations

Moving the extruder too fast can cause vibrations that cause ripples on the wall of the model. The lighter the weight of the extruder, the less noticeable the ripples will be. To get rid of ringing, simply reduce the print speed in the slicer settings.

Slits for thin-walled models (not solid shell)

The thin wall of the model is not solid, but consists of two thin walls with a narrow gap between them. This problem is often faced by fans of printing "cutting" for baking.

This problem is often faced by fans of printing "cutting" for baking.

Left model with wall defect, right without

Wall thickness and nozzle diameter mismatch

If the wall thickness is 1 mm, and the nozzle diameter is 0.4, it turns out that for a solid wall, 2 nozzle passes are few, and 3 are already many. The result will depend on the slicer algorithm, but most often you will get 2 walls with a thin slot in the middle (the slicer cannot change the wall thickness). The solution to the problem may be a slight refinement of the 3D model or the use of a different slicer.

Algorithms for calculating 3D models are constantly being improved and refined, and now this problem is less common.

When modeling, take into account not only the thickness of the nozzle, but also the percentage of “overlapping” of lines on each other. If you have a nozzle with a diameter of 0.4 - make the wall in your model not 0.

8, but 0.7 - 0.75.

Wrong model geometry

When instead of a circle you get an oval, and instead of a square you get a semblance of a rhombus.

The main reason is malfunctions in the mechanics of the printer. Be sure to check:

Belts

Check belt tension in x and y. Belts stretch over time and may need to be tightened or replaced. Each 3D printer has its own way of tightening the belt. If the belts are slightly stretched, you can tighten them with the help of a "spring".

Loose pulleys, etc.

Check if all bolts and nuts are tight. Are there backlashes. Pay special attention to tightening the pulleys located on the motors along the x and y axes.

Sagging of some parts of the model

Some parts are not printed, broken, or instead of a neat surface, a swollen plastic snot is obtained.

No support for overhangs

A 3D printer cannot print in the air, so if there are overhanging elements in the model, you need to set supports - supports. The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

When printing with soluble support, you can set the gap between the model and support - 0. This will make the surface smoother. If the support material and the model are the same, you need to add a small gap. Otherwise, it will be difficult to separate the support from the model.

Split model

Sometimes the supports can take more plastic than the model. In this case, to save material and time, it will be more convenient to cut the model. If you have more than one 3D printer, then the model will print several times faster.

When cutting the model, you can leave grooves or mortgages so that the pieces of the model are connected without displacement.

Totals

In this article, we talked about the most popular 3D printing defects and how to solve them. Don't be intimidated by such a long list. Some problems are rare and you are unlikely to encounter them.

Some problems are rare and you are unlikely to encounter them.

There is a list of problems that arise due to the design features of a 3D printer, so try to choose a printer that suits your needs. To do this, you need to understand what products and what material you need.

Problems associated with printing algorithms are quickly eliminated by software developers.

Do not be afraid of possible difficulties and each print will be successful.

A small guide to fixing inconsistent extrusion in your 3D printer.

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.00 UAH

-

Thermal mat for 3D printing 200 x 200 mm

3D printing thermal pad

150.

00 UAH

00 UAH -

Buy epo3d+ 3D printer

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00

-

ABS granules

ABS granules for extrusion

400.00 UAH

-

PLA

PLA environmental plastic from Plexiwire. 100% advance payment....

UAH 375.00

-

Buy ABS plastic (ABS)

ABS plastic from Plexiwire.

100% prepayment. Free shipping...

100% prepayment. Free shipping... UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size is...

150.00 UAH

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends

Nozzle for 3D printer 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

-

PETG plastic for 3D printer

PETG plastic from Plexiwire. 100% prepayment. Free...

UAH 360.00

-

SHF-20 shaft support

SHF-20 Shaft support used for CNC

60.

00 UAH

00 UAH -

A4988 stepper motor driver

35.00 UAH

-

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00

All best sellers

Information

A small guide to fixing inconsistent extrusion in your 3D printer.

Inconsistent Extrusion Troubleshooting Guide

In order for your 3D printer to create accurate parts, it must be able to extrude a very constant amount of plastic. If this embossing is different in different parts of your print, it will affect the final print quality. Inconsistent embossing can usually be determined by observing the printer closely as it prints. .

Inconsistent embossing can usually be determined by observing the printer closely as it prints. .

The causes of inconsistent extrusion in 3D printing are many and can be related to various mechanical, electrical, thermal problems. The purpose of this article is to help narrow down the causes based on tests and observations.

How to determine if you have problems with inconsistent extrusion or shifted layers when stripes are displayed on a vertical surface.

Separately print two single-layer objects: a circle and a square, at least 30 mm across.

• Don't print an object that is too small or you will experience overheating problems.

• When using PLA, the fan must blow on the print.

• In your slicer: set perimeters to 1, no top layers, no padding.

• Alternatively, use the spiral vase mode so that there are no abrupt layer changes.

• If necessary, use the layer height on the higher side so you can see the layers more clearly. A layer height of . 20 mm or more is more noticeable.

20 mm or more is more noticeable.

• Mark the side facing out for reference.

Now take a close look at the inside and outside of the printed object where the streak or artifact is, and see where the streaks or artifacts start on the layer. Take a clear photo and zoom in to see more details.

If the perimeter moves sideways, you will see it pushing inward in places and outward in others. Look in which directions it is shifted and you will know:

• If it is only in the X or Y direction, then the problem is with that axis.

• If it oscillates in a regular sinusoidal waveform, then the Z-Axis may be causing it with a bent screw or loose rails, or something else loose.

• If shifting is random, it could be a problem with the drivers or there is friction (wedging) or loose mounting causing play.

• If the layer height is not consistent, it may be due to the Z-axis, drivers, or other mechanical issues.

To resolve these issues: see Layer shifting (shifting) for possible causes and solutions.

Otherwise, if the perimeters just get wider and narrower and don't move laterally, this is caused by an inconsistent extrusion.

Reasons for inconsistent extrusion

(This will be a mesh, not yet sorted)

• Extrusion temperature too low. Choosing the best temperature depends on your thermistor and where it senses temperature, heater and filament configuration.

• Clogged extruder mechanism with filament chips.

• Extruder skips steps due to low drive current - extruder may also stall or kick.

• Extruder is skipping steps due to thermal shutdown caused by high driver current or poor cooling.

• Insufficient pressure on compression bearing

• Too much pressure on bearing - flattened thread.

• Variable hotend temperature possible:

o PID settings;

Head heater block loose;

Thermistor incorrectly installed in heater block, or contaminated with burnt plastic

o Thermistor connection problem while moving (bad contact, broken wire)

o Thermistor is too far from the measuring point.