Fabricated 3d printing

9781118350638: Fabricated: The New World of 3D Printing - Lipson, Hod; Kurman, Melba: 1118350634

Voted one of the top 25 books of 2013 in China by Chinese readers! Fabricated tells the story of 3D printers, humble manufacturing machines that are bursting out of the factory and into homes, businesses, schools, kitchens, hospitals, even the fashion catwalk. The magic happens when you plug a 3D printer into today's mind-boggling digital technologies. Add to that the Internet, tiny, low cost electronic circuitry, radical advances in materials science and biotech and voila! The result is an explosion of technological and social innovation.

Fabricated provides readers with practical and imaginative insights to the question "how will 3D printing technologies change my life?" Based on hundreds of hours of research and dozens of interviews with experts from a broad range of industries, Fabricated offers readers an informative, engaging and fast-paced introduction to 3D printing now and in the future.

Chapters and contentsChapter 1: Everything is becoming science fiction. What would "just another regular day" look like in a future, 3D printable world?

Chapter 2: A machine that can make almost anything. Information morphed from analog form to digital. Will physical objects be next? Ten key principles explain 3D printing's disruptive power.

Chapter 3: Nimble manufacturing. Emerging business models lie somewhere between mass production and the local farmer's market. Small-batch manufacturing is becoming profitable, freeing entrepreneurs from the tyranny imposed by economies of scale.

Chapter 4: Tomorrow's economy of printable products. 3D printing, low-cost design and manufacturing technologies create new market opportunities as consumers increasingly crave on-demand, custom "experience" products.

Chapter 5: Printing in layers. For those of a technological bent, a deep dive into the inner workings of the 3D printing process.

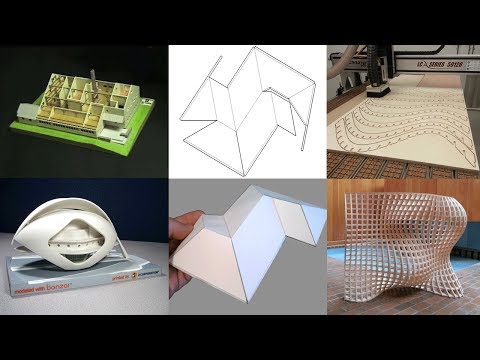

Chapter 6: Design software, the digital canvas. Without an attached computer, a 3D printer is just an elaborate paperweight. An overview of design software and "digital capture."

Chapter 7: Bioprinting in "living ink." Design software and 3D printers read medical scans to fabricate living tissue and custom artificial joints. How long before all of us can tap into this Fountain of Youth?

Chaper 8: Digital cuisine. Today you can 3D print "high resolution" and delicious shortbread, chocolate figurines and tortillas. In the future, Quantified Selfers and couch potatoes alike will balance their diets by streaming biometrics to a food printer.

Chapter 9: A factory in the classroom. Primary and middle school teachers teach "children's engineering" using vivid, hands-on lesson plans.Chapter 10: Unleashing a new aesthetic. 3D printers are the output device computer-savvy artists, designers and architects have been waiting for.

Chapter 11: Green, clean manufacturing. What's cleaner to make? A 3D printed plastic toy or a mass-produced plastic toy? 3D printers may introduce greener living... or help us drown in a rising tidal wave of plastic junk.

What's cleaner to make? A 3D printed plastic toy or a mass-produced plastic toy? 3D printers may introduce greener living... or help us drown in a rising tidal wave of plastic junk.

Chapter 12: Ownership, safety and legal frontiers. Technology evolves faster than the law. Consumer safety and intellectual property laws will stretch to deal with printed weapons, counterfeit products and unregulated custom-made products.

Chapter 13: Designing the future. Why was Star Trek's Replicator used only to make Earl Grey tea? Because once we shape our tools, then our tools shape us. Next-generation design software will unshackle our imaginations, giving us new ways to imagine and edit the physical world.

Chapter 14: The next episode of 3D printing. What lies ahead? Watercolor artists create infinite hues by blending primary colors. Regular people will design and blend standard materials -- or micro-scale electronic components -- and "print" them out in fine, meticulously patterned sprays. The result? Weird and wacky new materials. Robots that walk out of the 3D printer. Ready-made, responsive smart materials.

The result? Weird and wacky new materials. Robots that walk out of the 3D printer. Ready-made, responsive smart materials.

"synopsis" may belong to another edition of this title.

From the Author:

People frequently ask us "how can I predict how 3D printing technologies will affect me? My job? The things I care about or do for fun?" While interviewing experts for Fabricated, we discovered that diverse users had some things in common, a set of core reasons why 3D printing enabled them to expand the limits of what they do. We wrote up these recurring observations and called them the Ten Principles of 3D Printing.

The Ten Principles of 3D Printing give us a roadmap into the future and explain why 3D printing will disrupt manufacturing and product design. A disruptive technology shrinks key barriers of time, cost or skill. Each Principle represents one core (and disruptive) characteristic of 3D printing that removes or reduces a core barrier of time, cost or skill (or all three).

Ten Principles of 3D PrintingPrinciple one: Manufacturing complexity is free. On a 3D printer, it costs as much to make a simple cube as it does an elaborate and complex object of the same material. This is disruptive since in traditional mass manufacturing, complex geometries (elaborate shapes) cost more to produce in terms of time and skill. Free complexity will disrupt traditional pricing models and change how we calculate the cost of manufacturing things.

Principle two: Variety is free. Like a human artisan, a single 3D printer can fabricate many different shapes. The intelligence lies in the computer, not in a machinist who must re-tool the way the machine is set up. Free variety reduces the cost of customization and gives a single entrepreneur the ability to create many different types of 3D printed products on a single printer.

Principle three: No assembly required. A 3D printer can print a hinge, a bicycle chain or even a nested set of Russian Dolls in a single "print job," no assembly required. Traditional manufacturing machines make parts which must be assembled. The more parts a product contains, the longer it takes to put together, the longer the supply chain and the more expensive it becomes to make. Reduced part count saves on assembly, reduces inventory and shortens supply chains.

Traditional manufacturing machines make parts which must be assembled. The more parts a product contains, the longer it takes to put together, the longer the supply chain and the more expensive it becomes to make. Reduced part count saves on assembly, reduces inventory and shortens supply chains.

Principle four: Zero lead time. A 3D printer can print on demand, when an object is needed. Lead time, the time lapsed between a product's conception and its actual manufacture, is a core competitive differentiator. 3D printed, on-the-spot manufacturing will liberate companies from stockpiling physical inventory. Product design will accelerate; custom, on-demand products made in direct response to customer demand will become financially feasible.

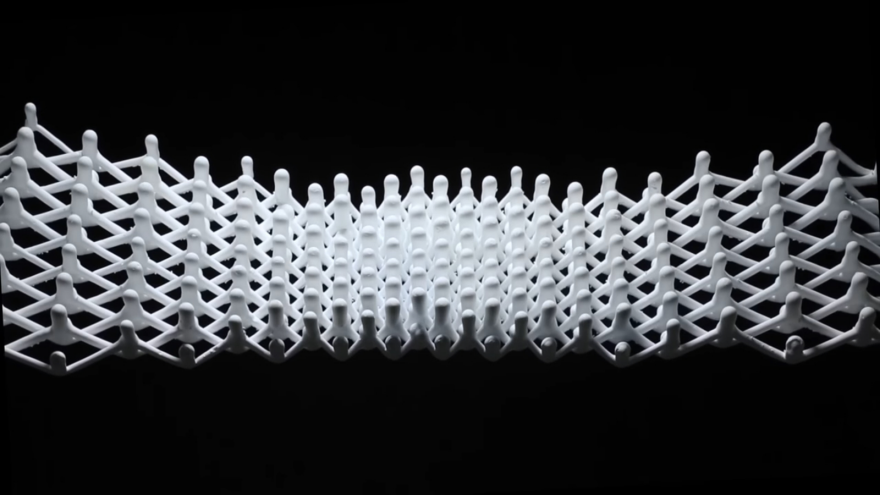

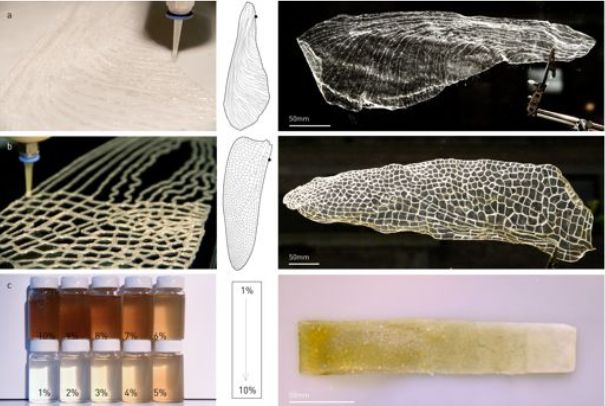

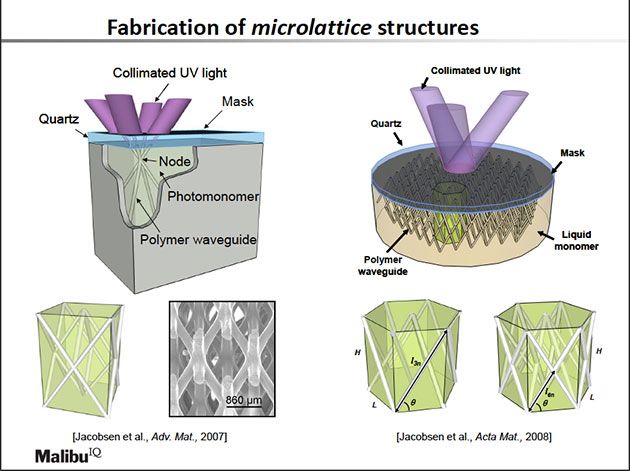

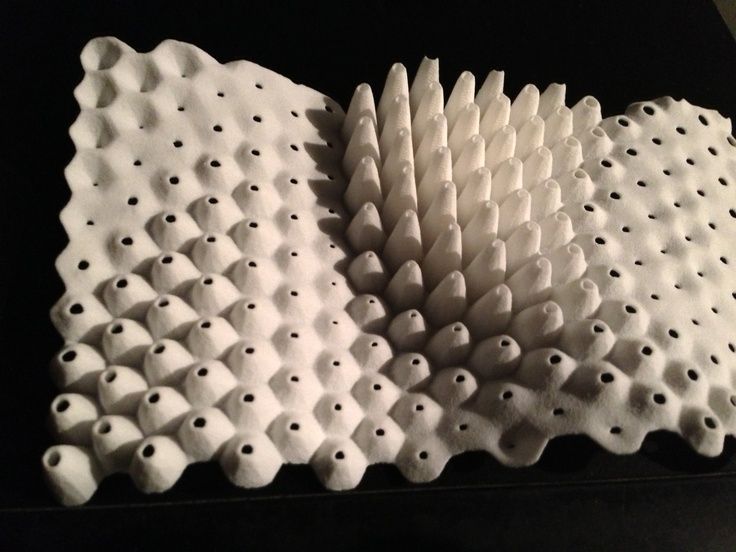

Principle five: Unlimited design space. The 3D printing process, since it builds objects layer by layer, is capable of making physical shapes that were once impossible to make. It's simple to 3D print hollow objects, interlocked objects, precise and complex internal structures. With a 3D printer, we can create objects that once only nature could make, opening up vast new design possibilities.

With a 3D printer, we can create objects that once only nature could make, opening up vast new design possibilities.

Principle six: Zero skill manufacturing. Traditional manufacturing machines still demand that a skilled expert to adjust and calibrate them. A 3D printer gets most of its guidance from the design file. Once the design file is created, the printer can swing into action immediately. Unskilled manufacturing opens up new business models and could offer new modes of production for people in remote environments.

Principle seven: Compact, portable manufacturing. A 3D printer has a small footprint. A 3D printer is also compact, as the size of the object being printed can be nearly as large as the printer. In contrast, an injection molding machine can only make objects significantly smaller than itself. Even better, a 3D printer, if the "print head" can swing freely, can fabricate objects even larger than itself such as structures or furniture.

Principle eight: Less waste by-product. 3D printing is a precise process since objects are created in layers, not by carving away raw material or molding molten material into solid shapes. Machining metal is highly wasteful as an estimated 90 percent of the original metal gets ground off and ends up on the factory floor. Molding is a precise, low-waste manufacturing process but can only make simple shapes.

3D printing is a precise process since objects are created in layers, not by carving away raw material or molding molten material into solid shapes. Machining metal is highly wasteful as an estimated 90 percent of the original metal gets ground off and ends up on the factory floor. Molding is a precise, low-waste manufacturing process but can only make simple shapes.

Principle nine: Infinite shades of materials. As 3D printers in the future gain the capacity to print with different types of raw materials in a single print job, we will witness the emergence of a new class of materials. Multi-material 3D printers can blend and combine different raw materials in precise blends. Digitally designed and precisely printed blends of materials will offer us a large and mostly unexplored palette of novel materials that have unusual properties or useful types of behaviors, for example wearable electronics or living tissue.

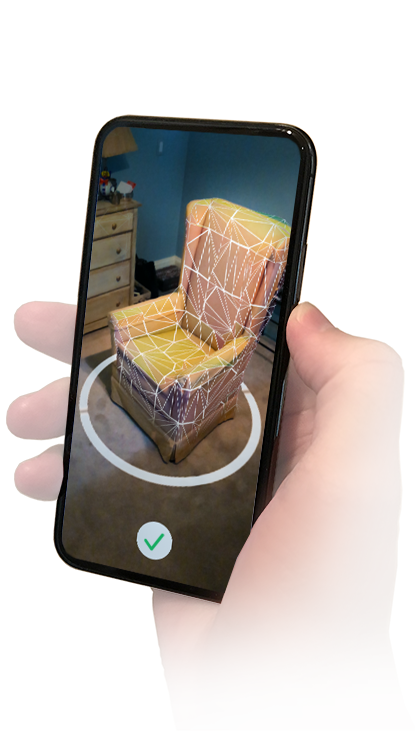

Principle ten: Precise physical replication. The 3D printing process relies on digital instructions. The ability of the 3D printer to precisely carry out digital instructions will bring the design freedom and malleability of the digital world to the physical world. Like digital music and media, physical objects will be scanned into digital form and then edited, copied or re-designed.

The ability of the 3D printer to precisely carry out digital instructions will bring the design freedom and malleability of the digital world to the physical world. Like digital music and media, physical objects will be scanned into digital form and then edited, copied or re-designed.

From the Back Cover:

What would you create if you had a machine that could make (almost) anything? Fabricated offers you practical and imaginative insight into the question, "How will 3D printing change my life?"

- Businesses will be liberated from the tyrannies of economies of scale

- Factories and global supply chains will shrink, finding themselves closer to their customers

- The law, already reeling from digital media, will once again need to be redefined

- Our environment might breathe easier in a 3D printed economy, or it could choke on a rising tide of plastic

- 3D printed digital and intelligent, adaptive materials will change our relationship with the physical world

This book is an informative and fast-paced exploration of 3D printing technologies and the people who use them. Based on hundreds of hours of interviews, Fabricated explores the promise and peril of a 3D printed present and future.

Based on hundreds of hours of interviews, Fabricated explores the promise and peril of a 3D printed present and future.

"About this title" may belong to another edition of this title.

Fabricated: The New World of 3D Printing

Selected type: Paperback

Quantity:

Print on Demand

$27.95

Digital Evaluation Copy

Request Digital Evaluation CopyHod Lipson, Melba Kurman

ISBN: 978-1-118-35063-8 February 2013 320 Pages

-

E-Book

Starting at just $17.

00

00 -

Print

Starting at just $27.95

E-Book

$17.00

Paperback

$27.95

Download Product Flyer

Download Product Flyer

Download Product Flyer is to download PDF in new tab. This is a dummy description. Download Product Flyer is to download PDF in new tab. This is a dummy description. Download Product Flyer is to download PDF in new tab. This is a dummy description. Download Product Flyer is to download PDF in new tab. This is a dummy description.

This is a dummy description.

Description

Fabricated tells the story of 3D printers, humble manufacturing machines that are bursting out of the factory and into schools, kitchens, hospitals, even onto the fashion catwalk. Fabricated describes our emerging world of printable products, where people design and 3D print their own creations as easily as they edit an online document.

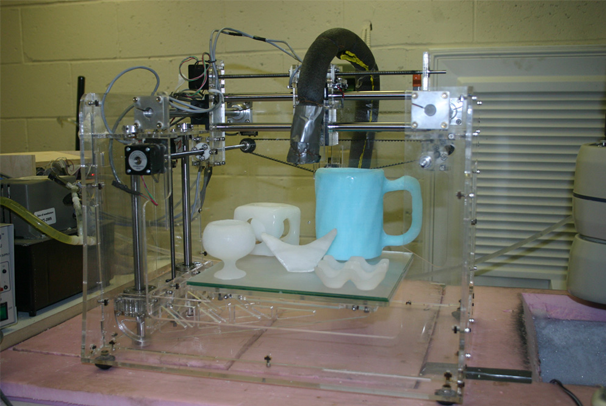

A 3D printer transforms digital information into a physical object by carrying out instructions from an electronic design file, or 'blueprint.' Guided by a design file, a 3D printer lays down layer after layer of a raw material to 'print' out an object. That's not the whole story, however. The magic happens when you plug a 3D printer into today’s mind-boggling digital technologies. Add to that the Internet, tiny, low cost electronic circuitry, radical advances in materials science and biotech and voila! The result is an explosion of technological and social innovation.

Fabricated takes the reader onto a rich and fulfilling journey that explores how 3D printing is poised to impact nearly every part of our lives.

Aimed at people who enjoy books on business strategy, popular science and novel technology, Fabricated will provide readers with practical and imaginative insights to the question 'how will this technology change my life?' Based on hundreds of hours of research and dozens of interviews with experts from a broad range of industries, Fabricated offers readers an informative, engaging and fast-paced introduction to 3D printing now and in the future.

Buy Both and Save 25%!

This item: Fabricated: The New World of 3D Printing

The Business Model Innovation Factory: How to Stay Relevant When The World is Changing (Hardcover $32.00)

Cannot be combined with any other offers.

Buy Both and Save 25%!

This item: Fabricated: The New World of 3D Printing

Trillions: Thriving in the Emerging Information Ecology (Hardcover $34.95)

Cannot be combined with any other offers.

Buy Both and Save 25%!

This item: Fabricated: The New World of 3D Printing

Make It In America: The Case for Re-Inventing the Economy, Updated Edition (Paperback $18.95)

Cannot be combined with any other offers.

About the Author

Hod Lipson and Melba Kurman put innovative technologies into context. Lipson is a leading researcher and speaker on 3D printing, digital materials, and the transformative power of intelligent machines. His lab at Cornell University has pioneered interdisciplinary research in 3D printing, product design, artificial intelligence, and smart materials. Kurman is an author and technology analyst who covers game-changing technologies in language that intelligent (and busy) non-experts can understand.

His lab at Cornell University has pioneered interdisciplinary research in 3D printing, product design, artificial intelligence, and smart materials. Kurman is an author and technology analyst who covers game-changing technologies in language that intelligent (and busy) non-experts can understand.

Permissions

Request permission to reuse content from this site

Table of contents

Preface xiii

Chapter 1: Everything is becoming science fiction 1

Chapter 2: A machine that can make almost anything 7

Printing three-dimensional things 11

The ten principles of 3D printing 20

Chapter 3: Nimble manufacturing: Good, fast, and cheap 25

Somewhere between mass production and the local farmer’s market 27

The blank canvas of the 21st century 35

Chapter 4: Tomorrow’s economy of printable products 45

Like ants with factories 46

The experience economy 51

A future economy of printable products 56

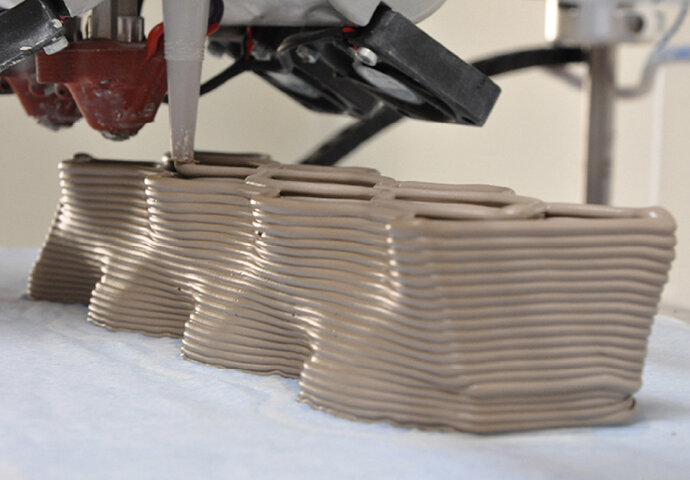

Chapter 5: Printing in layers 65

A manufacturing process at heart 65

Two families of printers 68

Cleaning up design files 77

The raw materials 81

Chapter 6: Design software, the digital canvas 85

A word processor for drawing 85

Today’s design software 91

What you design is not (necessarily) what you print 100

The next generation of design software: digital capture 102

Chapter 7: Bioprinting in "living ink" 105

The printer of youth 105

Tissue engineering 111

CAD for the body 120

The future 124

Chapter 8: Digital cuisine 129

Digital gastronomy 130

Feeding the quantified self 142

Processed food 144

Chapter 9: A factory in the classroom 153

Make to learn: Children's engineering 154

Not a national crisis. . . but learning should be enjoyable 161

. . but learning should be enjoyable 161

Now let's see you draw that abstract equation on a graph 166

Barriers to classroom adoption 171

The road ahead 173

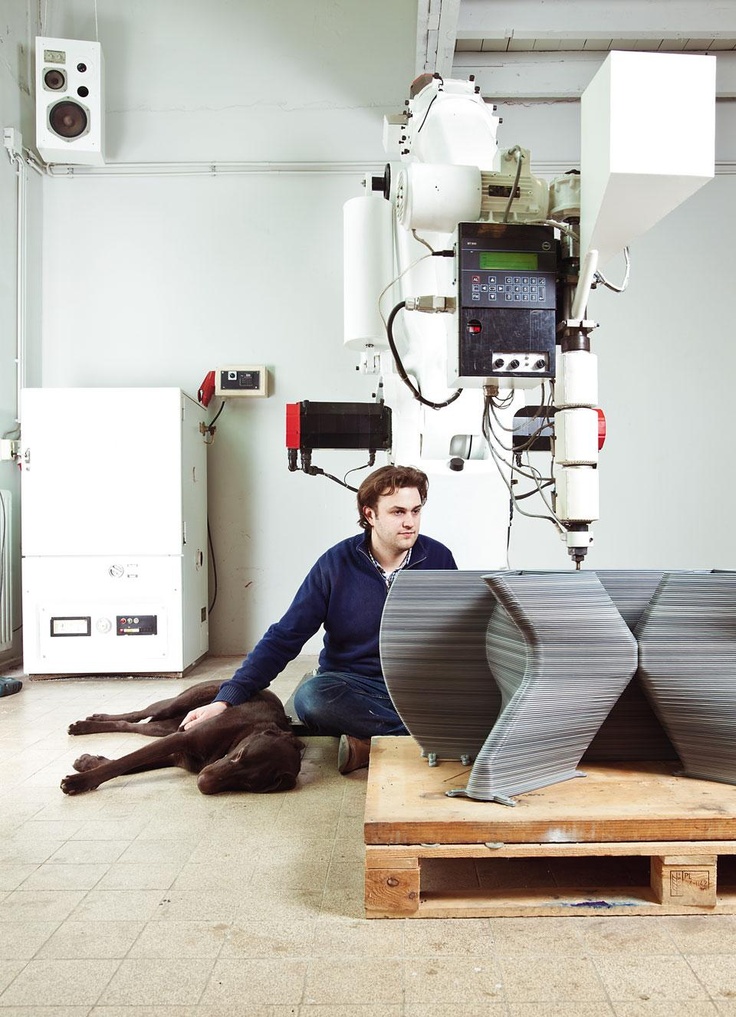

Chapter 10: Unleashing a new aesthetic 175

Computers that act like nature 176

Printing wavy walls and custom gargoyles 191

Chapter 11: Green, clean manufacturing 197

A tale of two plastic toys 200

Greener manufacturing 202

3D printing a more beautiful landfi ll 206

Chapter 12: Ownership, safety, and new legal frontiers 217

Printing weapons, drugs, and shoddy products 218

Rip, mix, and burn physical things 224

Exclusivity vs. the freedom to innovate 230

Chapter 13: Designing the future 241

Tea. Earl Grey. Hot. 241

A bicycle for our imagination 243

The language of shapes 252

Changing the shape of design tools 260

Chapter 14: The next episode of 3D printing 263

The three episodes of 3D printing 265

Cofabrication of multiple materials 266

Moving from printing passive parts to active systems 271

The final episode—from analog to digital 275

Machines making machines 280

References 283

Index 291

Steel 3D Printing - A Quick Guide / Sudo Null IT News

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts? nine0003

This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts? nine0003

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts. nine0009 Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)

The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0003

It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0003

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D) A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts. nine0003

nine0003

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture. nine0003

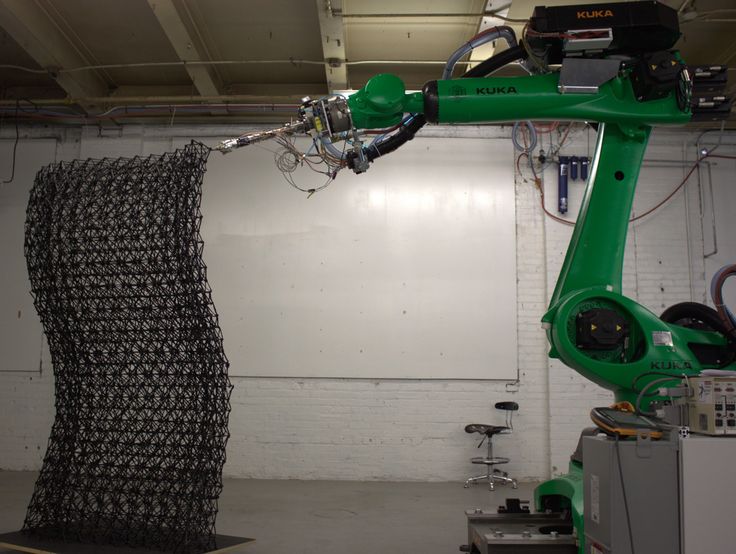

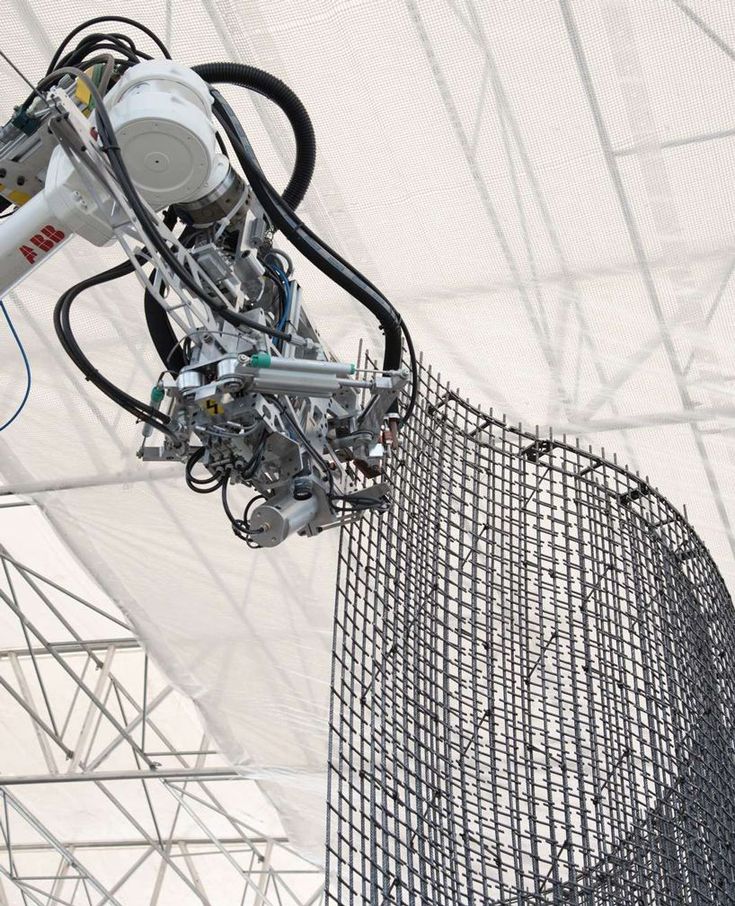

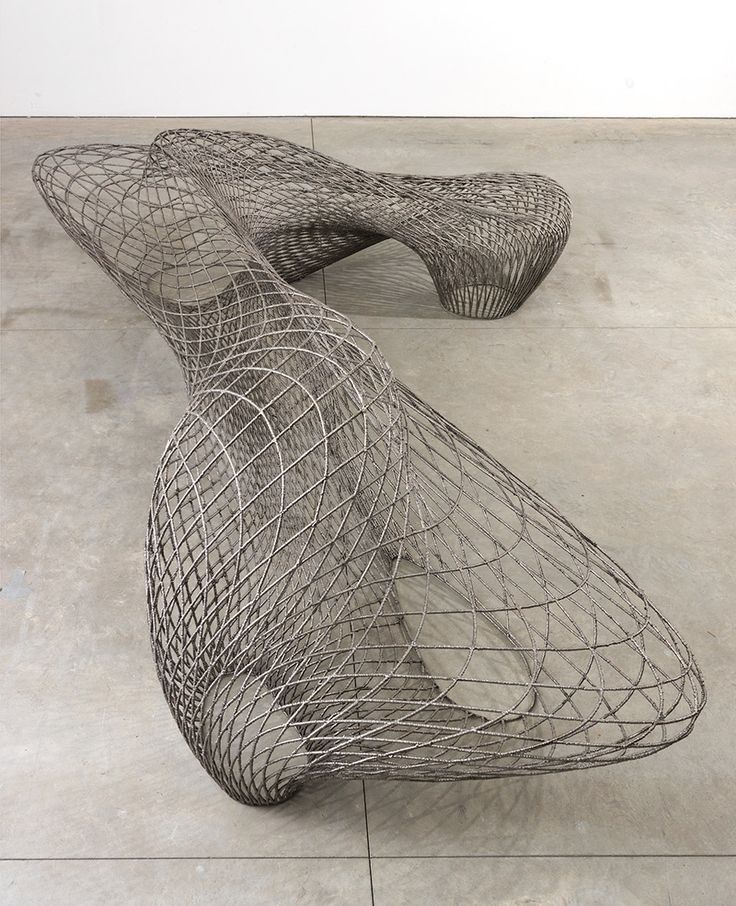

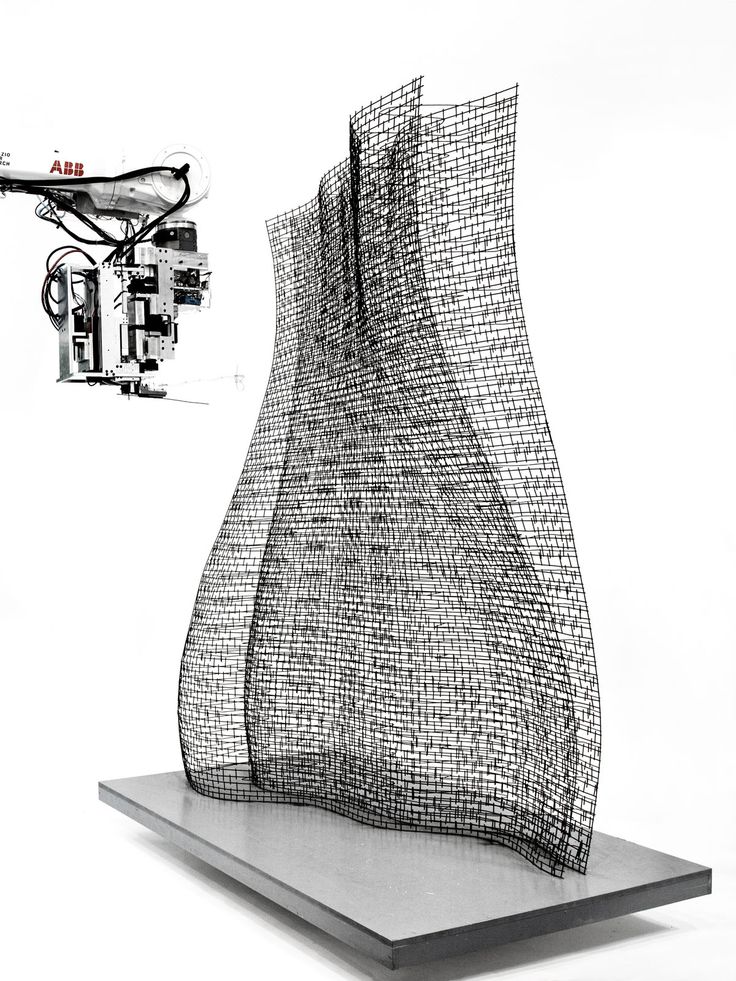

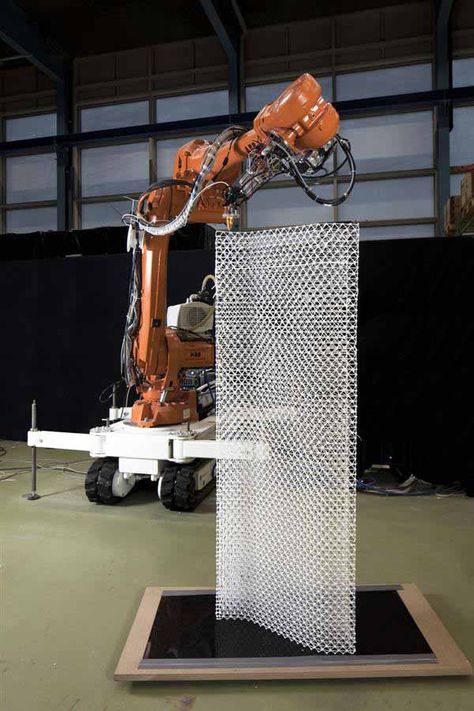

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength. nine0003 MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D)

nine0003 MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D)

Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product. nine0003

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants. nine0003

nine0003

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods. nine0003

nine0003

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish. nine0003

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast. nine0003

Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast. nine0003

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. nine0003 FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts. nine0003

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts. nine0003 (Source: BCN3D)

While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology. nine0003

nine0003

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal)Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0003

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel. nine0003

Desktop Metal and Markforged offer four types of steel. nine0003

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal instruments. nine0003

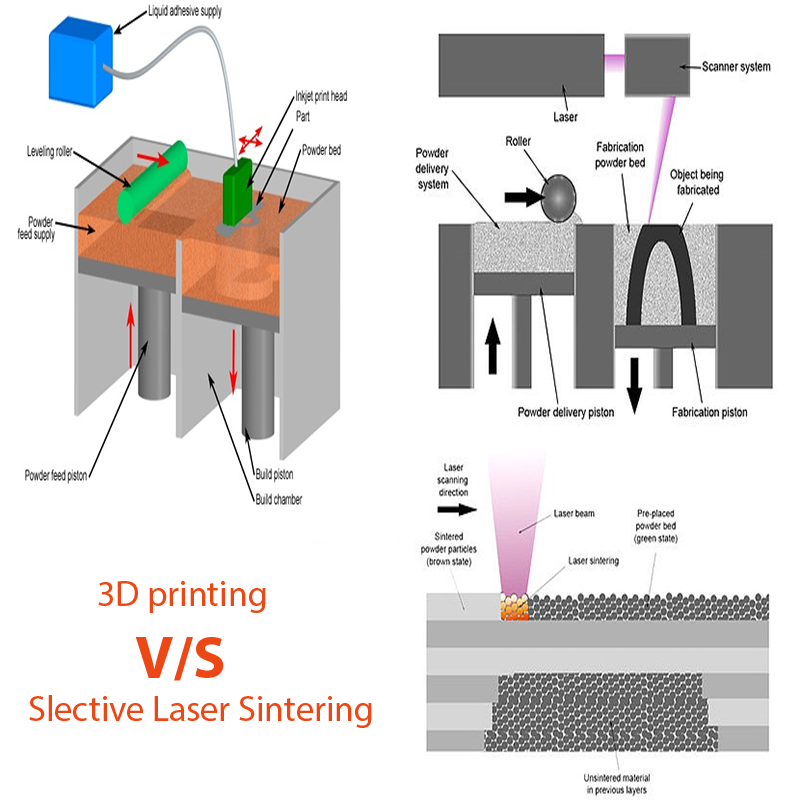

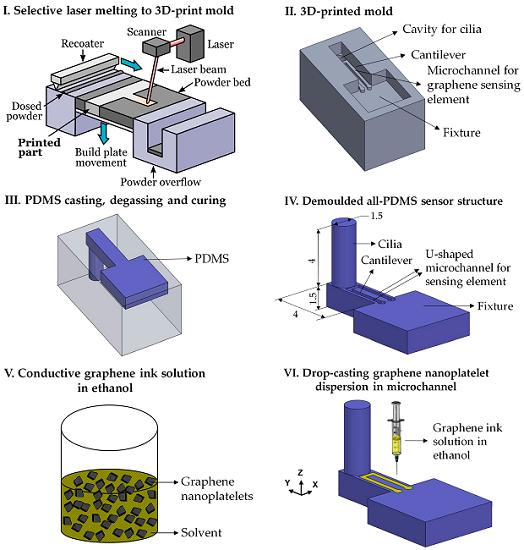

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer. nine0003

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments. nine0003

Binder Jetting

Binder 3D printing technology uses metal powder and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding. nine0003

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels. nine0003

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer. nine0003

nine0003

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries. nine0003

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation. nine0003

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding. nine0003

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0003

DED can get such parts much closer to finished than traditional CNC machining. nine0003

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

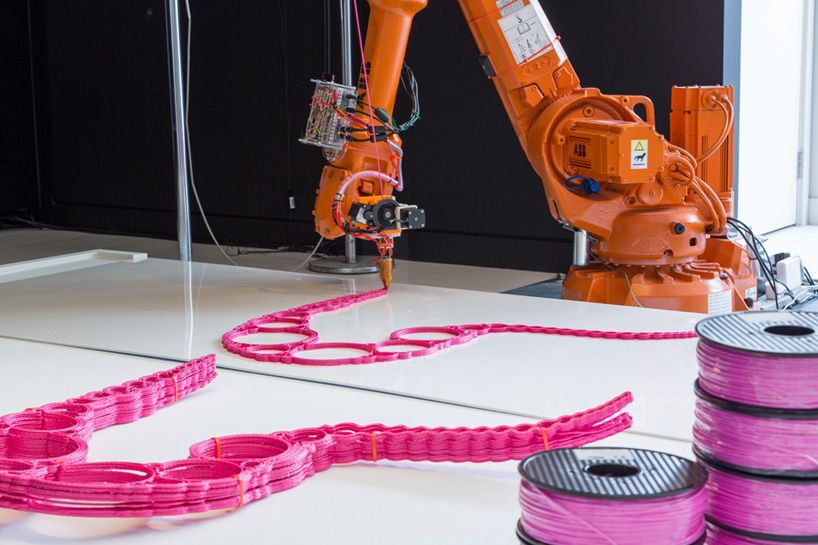

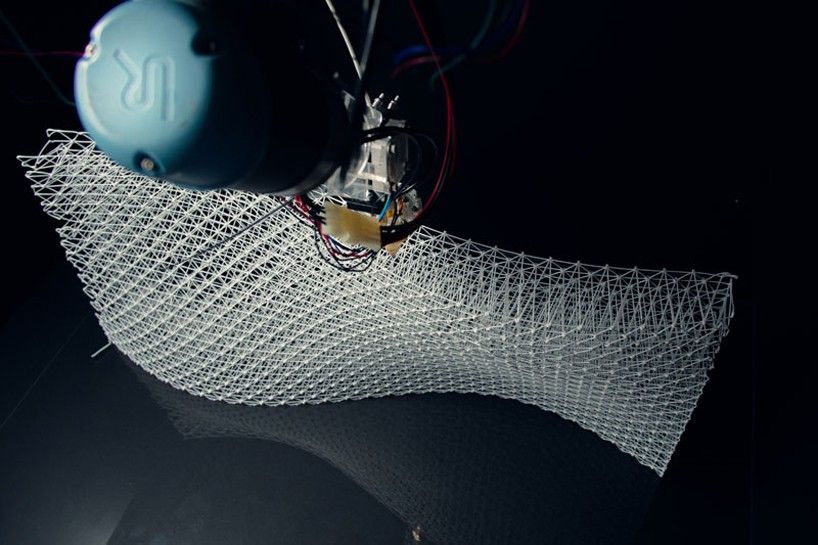

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field. nine0003

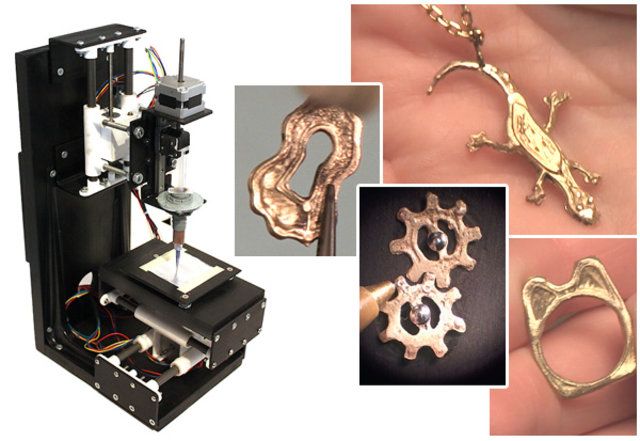

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint) Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts. nine0003

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.

A third micrometal 3D printing method is microselective laser sintering, in which a layer of metal nanoparticle ink is applied to a substrate, then dried to produce a uniform layer of nanoparticles.

German researchers have successfully tested micro SLS printing of hollow microneedles using 316L stainless steel. nine0003 Metal parts from 3D Systems, Desktop Metal, MX3D and Materalise. 90,000 manufacturing miniatures 28mm, dioram, gaming locations using 3D printer

09. 03.2022

03.2022

Content

-

- How to choose a 3D printer for miniature

- Advantage of 3D printing for miniatures

- FDM 900 LCD/ DLP

- Advantage of 3D printing for miniatures

- Printing Examples

- Best Printer Ranking

- FDM

- LCD

- Totals

- How to choose a 3D printer for miniature

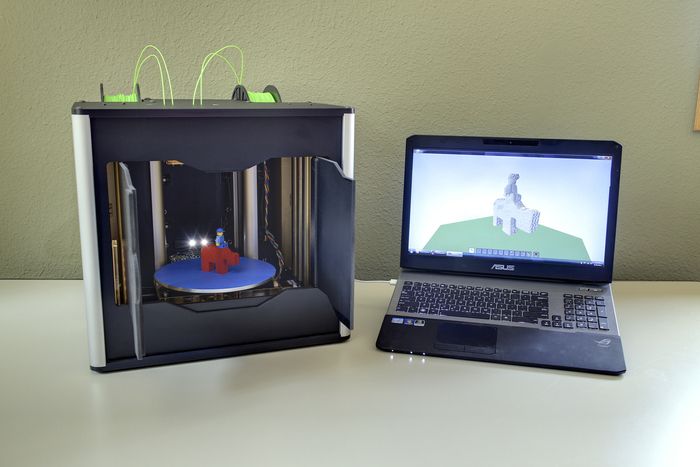

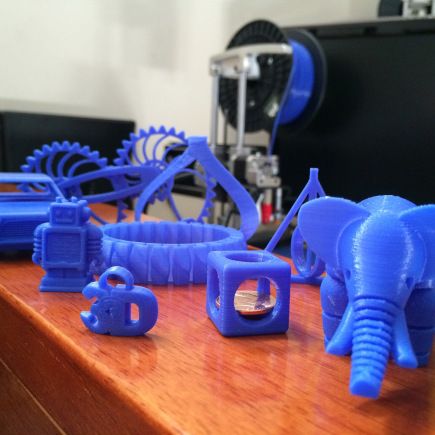

3D printing finds its application in various fields, not only as a production machine, but also as a reliable hobby assistant.

Miniature figurines with amazing detail attract the eye. A little grotesqueness and slightly wrong proportions (otherwise it would be inconvenient to play or transport such a “little one”) are more than compensated by detailed elaboration and an abundance of small, at first glance, insignificant details. These are no longer just small table soldiers, but heroes with their own unique history. nine0003

Warhammer 40k miniature soldier

Miniatures come in different sizes: from 6mm and more. The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

A 3D printer will help not only in the production of miniatures, but also in related areas, such as the creation of figurines, details of game locations, or, for example, elements of dioramas. To understand the advantages of 3D printing over classical manufacturing methods, it is worth remembering how such models are usually made at home. nine0003

Advantage of 3D printing for miniatures

Not everyone was ready to shell out a substantial amount for the purchase of a set of table soldiers, and sometimes the necessary heroes simply were not on sale. Then baked and self-hardening plastics for modeling were used.

First you need to make a wire frame, so the finished figure will turn out to be more durable, and it will be much easier to keep all the proportions. The wire frame can be attached to the stand, which will make the miniature statue more stable, and it can be easily fixed in any position without fear of smearing small parts with your fingers. nine0003

nine0003

Wire frame for miniature

Gradually, layer by layer, the volume of plastic increases on the frame. Each layer must be baked or dried well, depending on which plastic is used - self-hardening or baked.

Gradually, we begin to add small details and work out the details. In fact, this is a very painstaking process that requires perseverance and some sculpting abilities. For a convenient study of small details, you may need special stacks for modeling, but they can be successfully replaced with improvised tools. nine0003

Sculpting tool kit

The result is such a miniature statue.

Miniature 28mm baked plastic

By the same principle, large table figures, or some elements of dioramas, can be made.

Sometimes a sculptor is more accustomed to working with plasticine. Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army. nine0003

Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army. nine0003

But it is necessary to properly prepare the figurine for casting. The finished "warrior", most likely, will have to be divided into several parts, so that it would be more convenient for the caster to remove the molds and make castings. During the cutting process, it is worth adding a few locks so that the finished castings can be easily assembled, like pieces of a puzzle.

Molded figurine against silicone mold

Some craftsmen have learned to cast metal copies. Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold. nine0003

Metal soldier casting

In addition to making figurines from scratch, some craftsmen remake ready-made miniatures. This is called conversion.

This is called conversion.

Conversion in miniatures is a refinement, stylization or alteration of a finished figure. Unfortunately, not every hobbyist has good sculpting skills, and this alteration helps to achieve good results regardless of artistic skills. The main thing is to act very carefully. nine0200

Conversion helps enthusiasts achieve amazing figurine detail, add some detail, change the pose, or create a new character that is not yet on sale.

Lord of the Astral Claws turned to Chaos

In addition to making the figures themselves, modelers create colorful locations to immerse themselves in the world of their favorite game. This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting. nine0003

Game location for board game Warhammer40k

The creation of such locations is painstaking work, and both improvised and special equipment are used as material.

Role play location

A 3D printer allows you to produce miniature figures and game locations much faster. On the Internet you can find many paid and free models of 28mm figures from different universes or various elements of locations - houses, fences, mechanisms, etc. Adapting or slightly changing the finished 3D model for yourself is much easier than cutting and gluing a finished figure. And creative people with modeling skills are unlikely to have difficulties with the transition to “digital clay”. nine0003

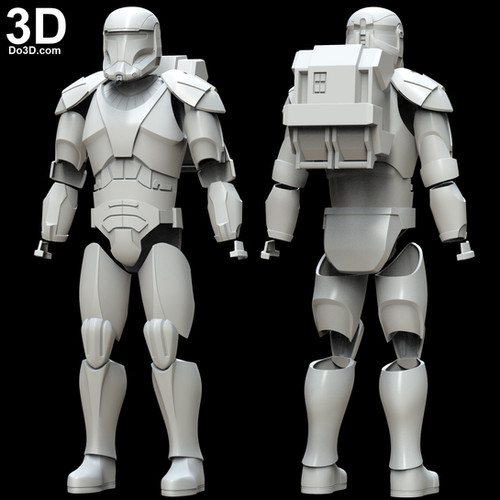

Warhammer40k universe 3D model

And of course, dioramas are worth noting. This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

Diorama based on the game STALKER

nine0003

Each diorama is unique, so the craftsmen use improvised materials to make it. Everything is limited only by the imagination and ingenuity of the artist.

Everything is limited only by the imagination and ingenuity of the artist.

Diorama “Desert Hero”

The main advantage of 3D printing is high detail and repeatability. If you need to make a small batch of miniatures, it will be much easier to print them than to cast, for example. Casting small items is a painstaking process that requires some skill and equipment. It is very difficult to achieve good pourability of small products the first time. nine0003

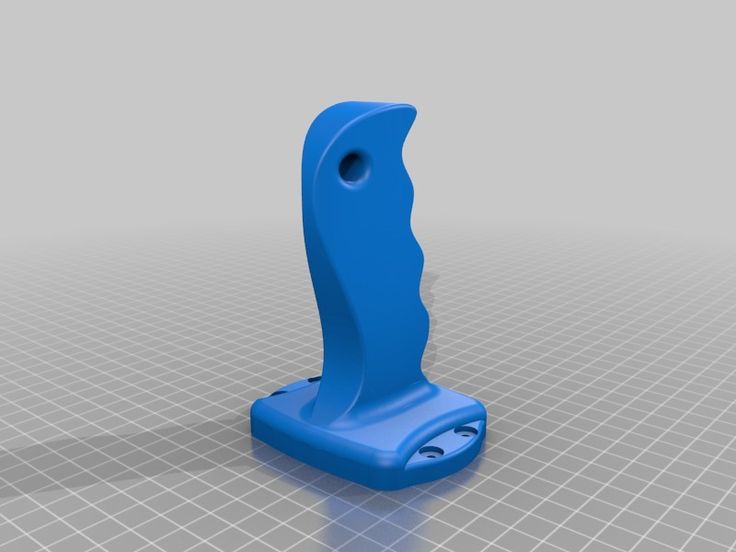

From model to finished figure

And for the manufacture of piece products, such as a diorama element, a 3D printer can replace many materials and tools for modeling. In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass. nine0003

Which technology to choose

To begin with, it is important to determine the requirements for the printer - will it be used only for the manufacture of 28mm personal army or should it be a universal printing machine? It is important to understand what size the finished model will be, how detailed it should be, and how much time can be spent on post-processing.

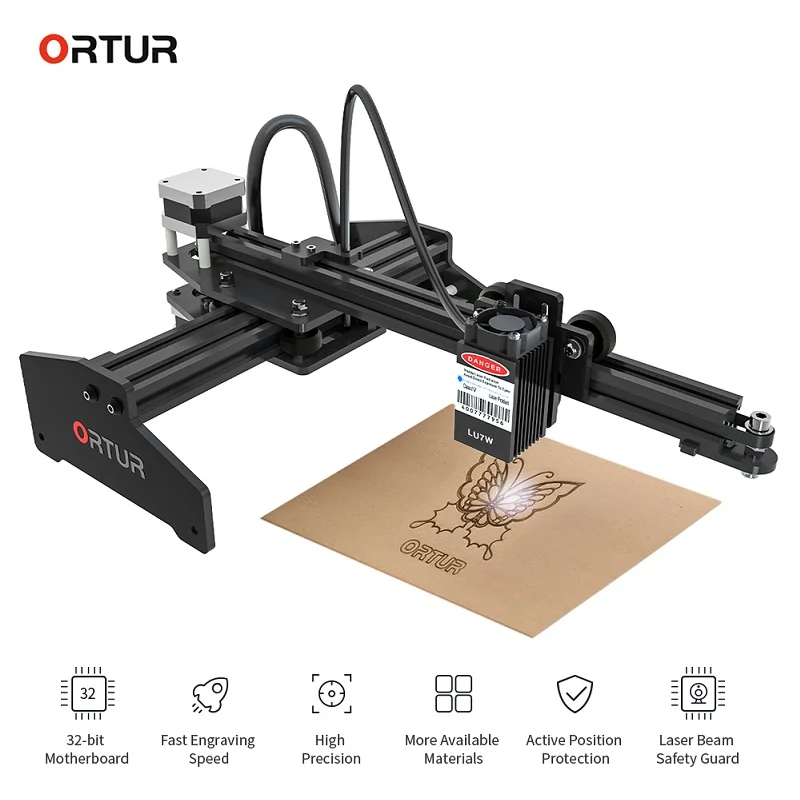

Depending on this, it is worth deciding on the technology by which the 3D printer will work. You can choose one of two technologies - FDM or photopolymer printing (there are several technologies, but DLP and LCD printers are currently popular). nine0003

FDM

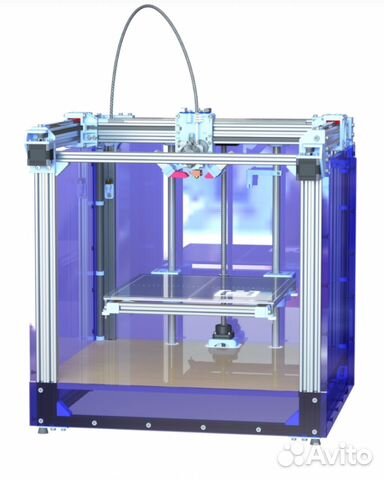

FDM 3D printers use a plastic filament as a material. In a heated extruder, the filament is melted and extruded through a thin nozzle, so layer by layer, a three-dimensional model is grown.

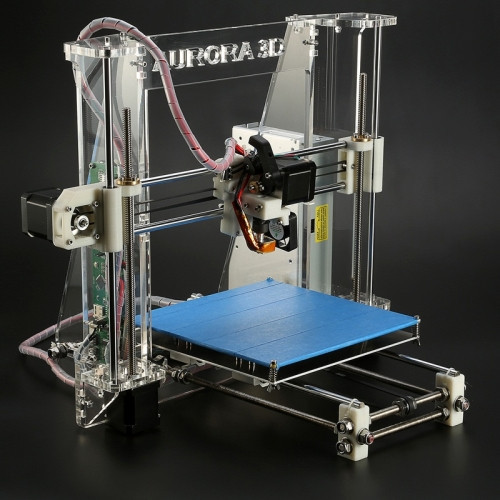

How the FDM 3D Printer Works

Layer thickness and nozzle diameter can be changed in some printer models. The minimum layer is usually 0.1 mm. In some models of 3D printers, a layer of 0.05 is available, but for printing with such a layer, it is important to choose the right many settings and the print speed will be quite slow. nine0200

Pros:

-

Large print area

-

Many different materials are available for every “taste and budget”

-

Inexpensive Consumables

Cons:

Of course, FDM printers are hardly suitable for making miniature figures, but they can be successfully used to print large souvenir figures, create game locations and some parts of dioramas. nine0003

nine0003

LCD/DLP

The principles of operation of LCD and DLP printers are very similar. The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

Working principle of photopolymer 3D printer

Pros:

- nine0002 The ideal surface of the finished figure

-

Many different materials available

-

High print accuracy even for the smallest items

Cons:

Photopolymer 3D printers are able to create miniature products that cannot be made using FDM technology. This technology will be an ideal choice for creating miniatures, small poster models, etc. nine0003

Printing examples

Robot printed on Asiga Pro 4k

Phrozen Sonic Mini 4k Figurine

28mm miniatures printed on photopolymer 3D printer

3D Printed Halloween Miniature

3D Printed Game Models

FDM Cube Thrower

Figure making process from 3D model to painting

Best Printer Ranking

FDM

Creality3D Ender 3 (Build Kit)

nine0366 Features:

Print technology: FDM/FFF

Working area size: 220x220x250 mm

Number of extruders: 1

Max. extruder temperature: max. 255℃

extruder temperature: max. 255℃

Closed Camera: No

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

A popular and unpretentious 3D printer that many makers liked. Creality3D Ender 3 is sold as a kit (assembly kit), but thanks to the detailed instructions, there should be no problems with assembly. nine0003

Wanhao Duplicator 6 Plus

Features:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: max. 260°C

Closed Camera: Optional

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others nine0003

Wanhao Duplicator 6 Plus is an updated version of the Duplicator 6. The new modification adds automatic calibration, printing resume after a power outage, and others. You can immediately purchase a printer with a closed case, this will allow you to easily print with composites. Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers. nine0003

Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers. nine0003

FlashForge Creator Pro 2

Features:

Print technology: FDM/FFF

Working area size: 200x148x150 mm

Number of extruders: 2

Max. extruder temperature: max. 240°C

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others nine0003

FlashForge Creator Pro 2 is an almost professional dual extruder 3D printer. Thanks to the closed body, Creator Pro 2 has no problem even with composite materials, and two extruders allow the use of soluble support for complex models. Moreover, FlashForge extruders are independent, this allows you to print 2 mirror or identical models at the same time. This allows you to speed up the production of the same type of models. FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production. nine0003

FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production. nine0003

LCD

Anycubic Photon Mono 4K

Features:

LCD display resolution: 3840x2400 (4K)

UV wavelength: 405 nm

Working area size: 132x80x165 mm

Layer thickness: 0.01-0.15mm

Inexpensive, but fairly modern 3D printer with a 4K monochrome display. Anycubic Photon Mono 4K will be a good tool for printing miniature models. nine0003

Phrozen Sonic Mini 4K

Features:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x130 mm

Layer thickness: 0.01-0.30mm

The Phrozen Sonic Mini 4K is a compact high resolution 3D printer. It allows you to get accurate models even with an abundance of small details. Sonic Mini 4K is a good choice for those who need to print quickly and accurately. nine0003

nine0003

Phrozen Sonic Mighty 4K

Features:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

With a larger work area, the Phrozen Sonic Mighty 4K allows you to quickly produce large models or small batches of small items. Such a 3D printer will be a good help for a small workshop or a hobby circle. nine0003

Phrozen Sonic Mini 8K

Features:

LCD resolution: 7.1" 8K Mono LCD

XY Positioning Accuracy: 22 µm

UV wavelength: 405 nm

Working area size: 165x72x180 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mini 8K is one of the representatives of 8K photopolymer printers, which can still be counted on the fingers of one hand. The high resolution LCD-matrix allows you to print figures with amazing surface quality and amazing detail.