Where can i use a 3d printer

3D Printing in 3 Steps (Yes, Only 3!)

3D Printing in 3 Steps (Yes, Only 3!) | Staples.comby Kevin Ackerman, Staples® Contributing Writer

Since it gives computer users the ability to produce tangible objects in a variety of materials and colors right from their desktop, 3D printing seems as if it would be technically complicated (or just magical). But in reality, it’s not all that different from printing in two dimensions on paper.

To produce a printed page, all computer users need is a document, a computer and access to a printer — and, of course, ink and paper. Likewise, printing in 3D only requires three similar things. Sure, the technologies differ, but that’s the basic gist, as these three steps explain.

Step 1: Develop a Concept

If you were to open a document file on your computer, hit some random keys on your keyboard and press Print, you’d have a paper printout — though it wouldn’t make much sense. With 3D printing, you can’t make a shape that easily, not even a poor one, so it’s worth beginning the process by putting some thought into your object.

Start by knowing what you’d like to print in three dimensions. If you don’t have an idea or concept, there are plenty of free suggestions online to get you started. Web sites like Thingiverse.com offer a library of pre-designed objects that you can print with any 3D printer to gain experience. Or you can be inspired by people who are already using 3D printing technology.

Phoenix-based sculptor Kevin Caron uses 3D printing to refine his artwork before making full-sized versions. "Mostly what I'm doing is proof of concept designs. You know, will it stand up, does it look right and are the proportions correct on it?” he says.

And Chris Considine, CEO and founder of Los Angeles–based CXC Simulations, uses 3D printing to prototype custom-designed parts for racing simulators that are so realistic, they are used by professional race car drivers. "We need 3D orienting to see if the part feels exactly how we want it to feel,” he says.” We went through about 30 versions before we found the one that was perfect for us. Other than 3D printing, there’s truly no way you could have done that without building it over and over again."

"We need 3D orienting to see if the part feels exactly how we want it to feel,” he says.” We went through about 30 versions before we found the one that was perfect for us. Other than 3D printing, there’s truly no way you could have done that without building it over and over again."

Step 2: Hop on a Computer

Once you know what you want to produce, it’s time to sit down at a computer and make it happen. 3D prints are most commonly generated from an STL or .stl file. Standing for “stereolithography” (what 3D printing was named when it was first invented), this file format is to 3D printing what the .doc file is to document output.

To open and manipulate an STL file, you’ll need computer-aided design (CAD) software. For decades, these programs have been used by everyone from architects to product designers, so there are many kinds of CAD software available.

SketchUp is a free modeling program designed to be straightforward and allow anyone to create three-dimensional renderings, whether simple or complicated. Likewise, Tinkercad keeps the design process easy by providing just three simple tools. It also runs in a Web browser and offers step-by-step design lessons to demonstrate how easy 3D printing can be.

Likewise, Tinkercad keeps the design process easy by providing just three simple tools. It also runs in a Web browser and offers step-by-step design lessons to demonstrate how easy 3D printing can be.

Meanwhile, programs like AutoCAD are favored by many experienced professionals, having been used in the design and prototyping of millions of products throughout the years.

To run these programs, you don’t need a particularly powerful computer. Caron uses an HP desktop machine to create his digital sculptures. "It's not a big screaming gaming computer by any means,” he says. "It's just a small office computer and it handles the CAD program just fine.”

Step 3: Get Access to a 3D Printer

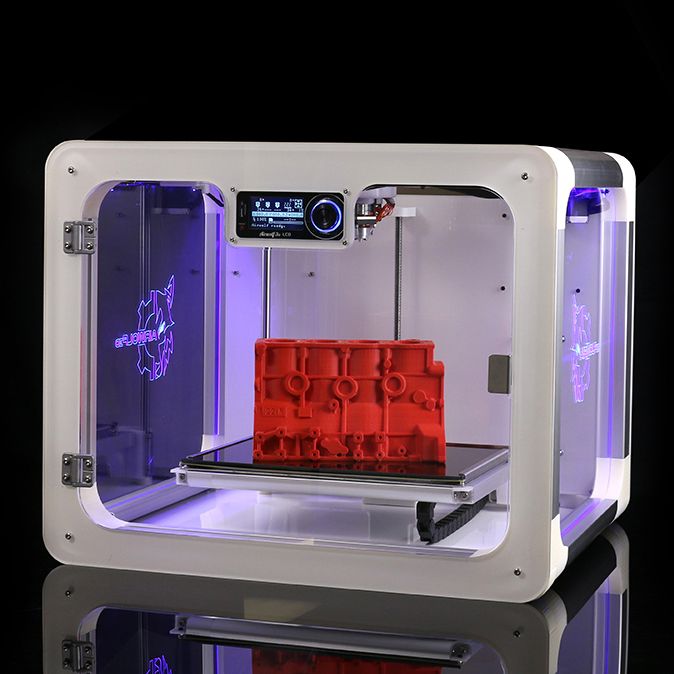

Most people assume they need to own a 3D printer to produce digitally rendered objects, but that isn’t true. Sure, owning a desktop 3D printer can put your designs within arm’s reach. But driving across town to pick up your objects at a Staples 3D printing service location or having them delivered by mail can be just as convenient for some businesses.

For example, Caron owns a CubeX™ commercial 3D printer. With the ability to print objects up to the size of a basketball, this device produces designs in plastic and in more than 4,000 different colors. He’s also used print-on-demand services to produce sculptures that he couldn’t make on his office’s machine.

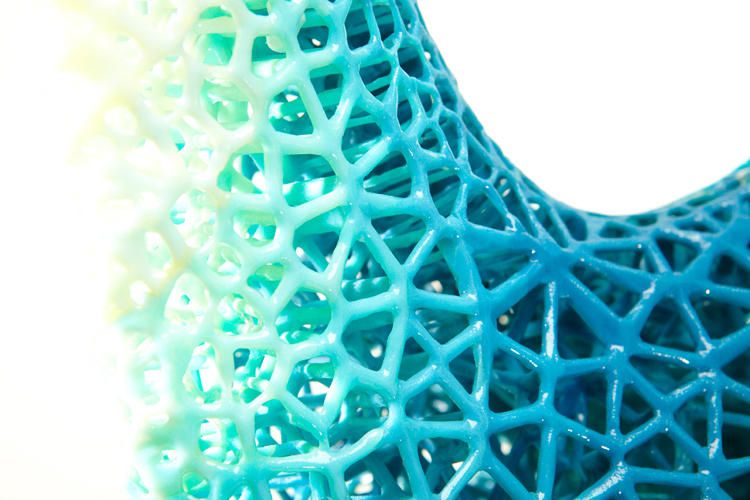

"They’re breathtaking when you see them,” he says of the two acrylic sculptures. "The detail that I could view on the computer came out in the print — it just blew me away.” Caron is planning to scale his designs down and turn them into jewelry to sell. "I've gotten one back in a polished glass and it's stunning. You can’t tell it from gold other than by the weight."

If you are interested in using 3D printing but need help with these steps, visit one of our stores that offers 3D printing services (currently in Los Angeles and New York City). There, we can help you with all the steps, from getting in touch with designers to actual 3D printing. You can even get in our 3D printing photo booth and have your face put on a figurine.

You can even get in our 3D printing photo booth and have your face put on a figurine.

Go from Concept to Reality

Some businesses would argue that 3D printing, whether it’s done in the office or at an outside service, is worth its weight in gold. "I can go from concept in my head to holding the part in sometimes as quickly as an hour,” says Considine. "It’s a very powerful thing for an engineer to have. It's liberating."

Related Articles

7 Things You Didn't Know About 3D Printing

In the ever-expanding universe of 3D printing, no one knows it all. Though the technology has been around since the 1980s, it’s only recently... Read more

8 Tips from MakerBot for Making Better 3D-Printed Objects for Your Small Business

Both an art and a science, 3D printing is actually easy to do, but difficult to master. The experts at MakerBot have seen... Read more

The experts at MakerBot have seen... Read more

Carrie Mae Rose

Does mankind’s destiny lie in the stars? Artist Carrie Mae Rose thinks so. Her show... Read more

3D PRINTING OPTIONS – Enabling The Future

There are many options for those that are interested in assembling their own 3D printed e-NABLE hand and arm designs for themselves or someone they know but do not have access to a 3D printer at home.

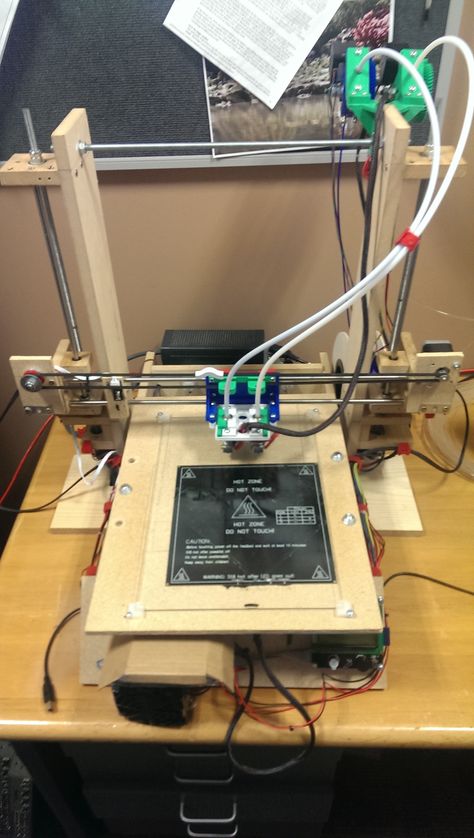

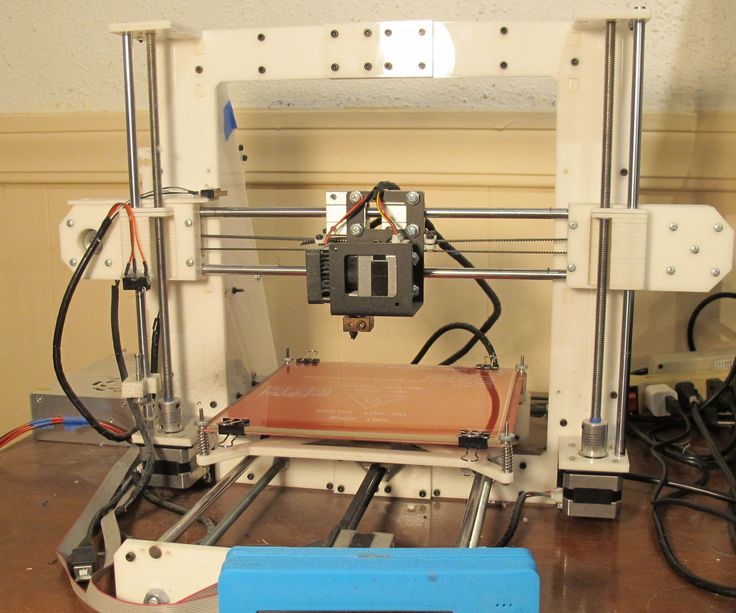

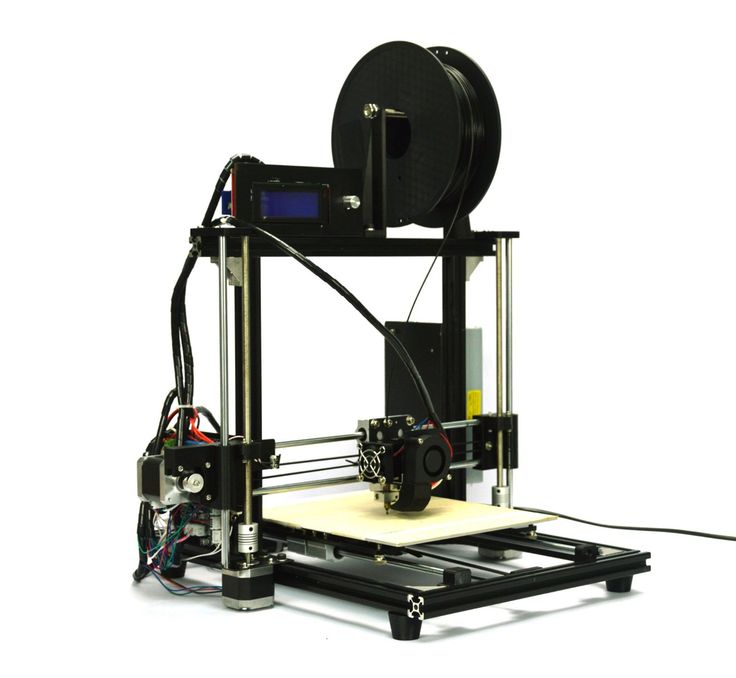

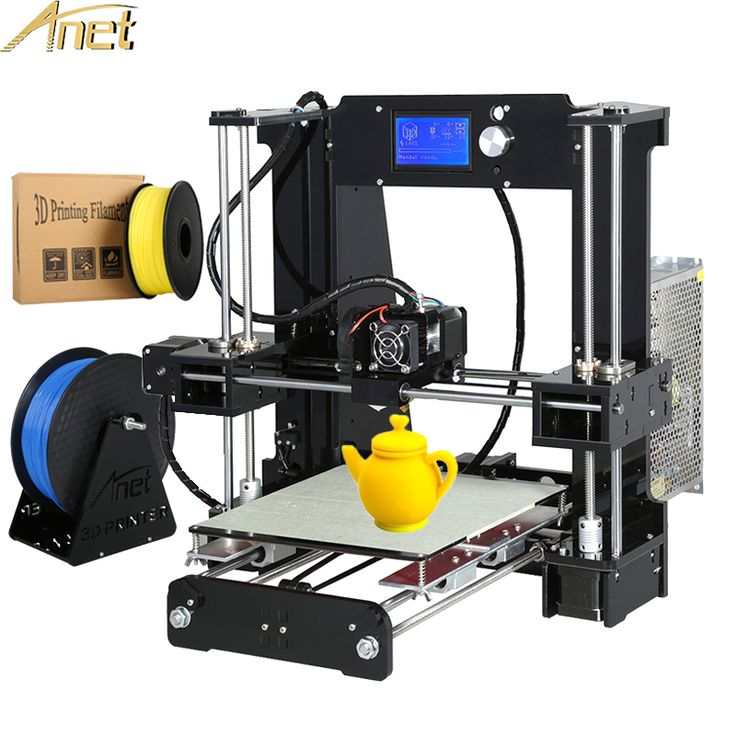

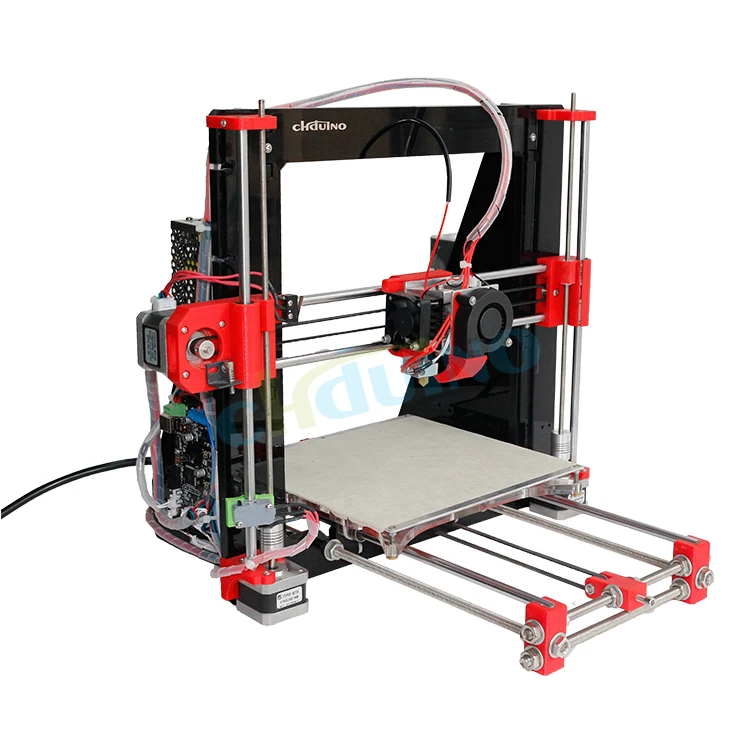

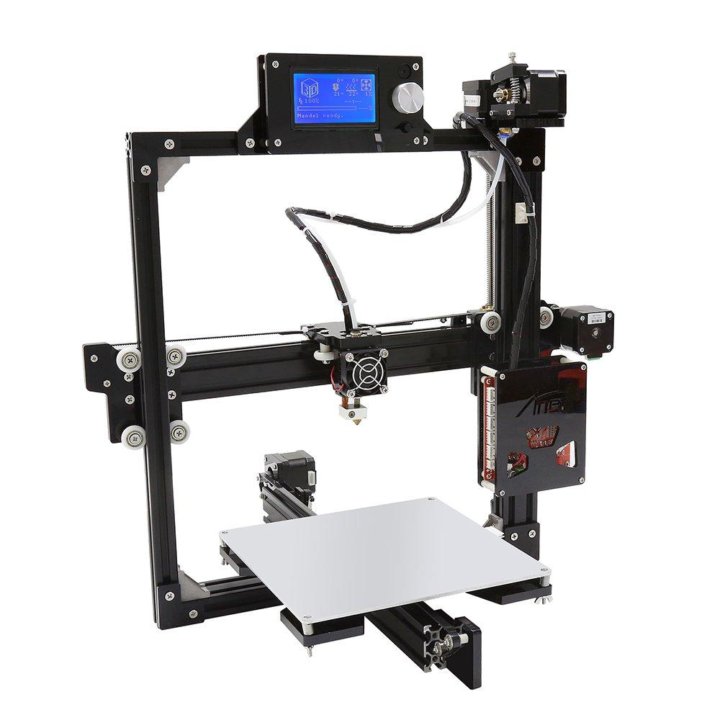

Many libraries, schools, universities, maker-spaces and community centers now offer public access to their machines and there are also many wonderful 3D printer companies who have affordable home desktop 3D printers available as well if you are interested in purchasing one of your own!

Step 1. Determine which design works best for your needs. Feel free to ask for guidance and help from our volunteer community!

Feel free to ask for guidance and help from our volunteer community!

Step 2: Check the maps below to see if there are any libraries, schools or makerspaces near to you that provide public access to 3D printers in your area and feel free to contact them directly to inquire if they are able to help create one of the e-NABLE Community 3D printed hand or arm designs for you or someone you know!

Step 3: Check out our Resources page for tutorials, hardware resources and other information that will help you in creating your own devices.

Step 4: Watch the Tutorial Video to learn how to take images that will help you get the measurements you need to create your device.

Once you have familiarized yourself with the Community and chosen the design that best works for your needs and are ready to find a 3D printer to create a device – please see the below suggestions and choose the option that works best for you!

Find an e-NABLE Chapter Near you: We have a growing map of e-NABLE Chapters who are willing and able to help print parts for you, assemble devices or invite you into their labs to teach you how to build your own device! If you are looking for a local chapter – please visit our Chapters page HERE!

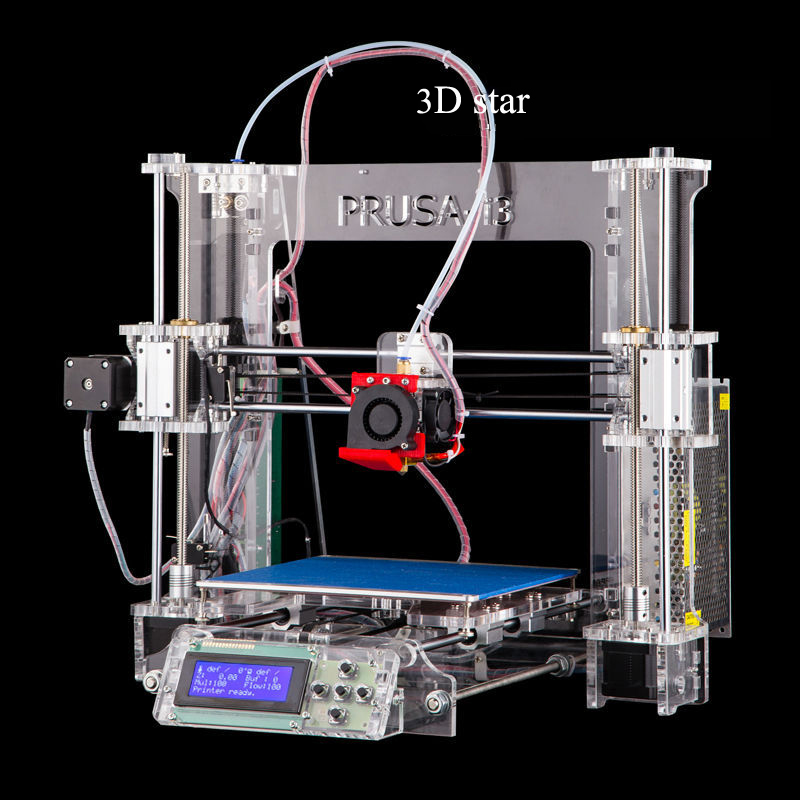

Purchase a home desktop 3D printer of your own: After having their first hand created for them by an e-NABLE Volunteer, many families have decided to purchase their own 3D printer so that they can print out replacement parts at home as well as participate in re-designing and printing parts for others! You can find our recommended 3D printers page HERE.

If you are interested in purchasing your own 3D printer, please note that there are an abundance of home desktop 3D printers available and while some of them may be very low cost, they may not provide the print quality that is needed to ensure that the 3D printed e-NABLE hands are printed at the quality needed to function properly.

Print at your local library: Many local public libraries now have 3D printers available to use for a small materials fee. Call around to your nearby libraries and see if they have any machines available for use in creating an e-NABLE device for you or someone you know.

PUBLIC, ACADEMIC AND SCHOOL LIBRARIES WITH 3D PRINTERS

There are usually time limits set on these machines so that everyone has an equal chance to use them, so hands may have to be created in pieces with short print times and spread out through out a week or two instead of printing all of the parts at the same time. Most devices require 10-15 hours of printing to complete but the device files can be split so that parts can be printed separately to reduce the amount of time per print.

Many public libraries will charge for materials used but you may be able to offer to provide your own materials or they may donate the plastic needed to produce the hand.

• See the story of 10 year old Colin, who 3D printed his own hand at his local library!

• Check out the hand-a-thon at the Toronto Reference Library!

IF YOU ARE A LIBRARY WHO WOULD LIKE TO BE LISTED ON THIS MAP – PLEASE VISIT THIS PAGE.

Print at your local school or university: Contact your local schools and universities to locate one near to you that may have a 3D printer. More and more teachers are getting involved with the e-NABLE Community and using this project as a classroom tool to teach Science, Technology, Engineering and Math (STEM) to their students. You may have a teacher near to you with access to a 3D printer who may be interested in helping to print your device as a service learning project for their classroom.

Invite a school to participate in the growing number of schools that are helping to create and share e-NABLE based curriculum and encourage our youth to learn how to use technology to help make a difference in the world and change lives!

• Visit the website from a school who has not only created hands for kids who need them but has also created video tutorials to help others assemble the devices!

• Visit the story of Chicago Christian High School’s engineering class who have made 8 hands so far and shipped them to places like Vietnam, Ukraine, Syria and China!

Print at your local Maker-space or find a local Makerfaire: More and more maker-spaces are forming in cities and towns all across the world. These spaces provide the tools and staff to help you build your own projects and many have 3D printers and are donating the materials to 3D print e-NABLE devices for those that need a “Helping Hand.”

These spaces provide the tools and staff to help you build your own projects and many have 3D printers and are donating the materials to 3D print e-NABLE devices for those that need a “Helping Hand.”

LIST OF FABLABS AROUND THE WORLD!

PLEASE CLICK THE IMAGE TO VISIT THE FAB FOUNDATION’S BEAUTIFUL MAP AND FIND A FABLAB NEAR YOU!

LIST OF MAKERSPACES AROUND THE WORLD!

PLEASE CLICK THE IMAGE AND SCROLL DOWN THEIR PAGE!

Makerspaces and Fablabs are amazing! If you have one near you, give them a call! Most of them have heard about the e-NABLE project and would welcome the chance to help you create a device for you or someone you know! Many will have membership fees or materials fees but many of them will waive the fees for an e-NABLE recipient. There is a growing list of makerspaces and Fablabs – but if you do not see one near you, try contacting the one as near to you as possible and you may be pleasantly surprised!

• Find a Makerfaire near you! Chances are, there will be a booth with e-NABLE Volunteers or 3D printer companies who can assist you in creating your own devices!

• Check our community events calendar to see where we might have some volunteers giving presentations or holding booths! We would love to connect with you!

Print through a 3D printing service: There are many 3D printing service shops available all over the world who are able to print your files for you for a fee. Many of them are now e-NABLE Volunteers and are willing to donate the materials to print but some will charge a fee for the service. Find a shop near you or send your files to one of the many 3D printing services online.

Many of them are now e-NABLE Volunteers and are willing to donate the materials to print but some will charge a fee for the service. Find a shop near you or send your files to one of the many 3D printing services online.

If you are interested in printing an e-NABLE hand to assemble at home, school or as team building projects, if you do not want to wait for the matching system through the Enable Community Foundation, if you are a student who would like to assemble a device for a science fair project, if you are a volunteer who wants to make hands for our recipients but lacks a 3D printer of your own or if you just want to print out a hand for fun – you can send your files to a print shop and pay to have the device printed for you.

Join the Google+ Community and ask for assistance from our many volunteers who are eager to assist you!

** Please note: Enablingthefuture.org is not part of the matching system of volunteers and recipients. Enablingthefuture. org does not guarantee that you or your child will be matched with a volunteer by going through the matching system set up by the Enable Community Foundation. We highly encourage you to research into your own communities to locate 3D printers in your areas to get assistance from libraries, schools, fablabs, print shops and makerspaces to help print your own devices and seek guidance from the e-NABLE Community Volunteers through the forums!

org does not guarantee that you or your child will be matched with a volunteer by going through the matching system set up by the Enable Community Foundation. We highly encourage you to research into your own communities to locate 3D printers in your areas to get assistance from libraries, schools, fablabs, print shops and makerspaces to help print your own devices and seek guidance from the e-NABLE Community Volunteers through the forums!

Please let us know if there is anything else we can help you with!

Like this:

Like Loading...

20 Use Cases for 3D Printing

3D printing has progressed so rapidly in recent years that we will soon stop talking about what can be created using additive manufacturing. It will be easier to mention what cannot be done. Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

Fruit

A gift for impatient parents

Young parents often experience an irresistible desire to acquire all sorts of items, one way or another related to their child, even if not yet born. The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figure made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, the company 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level.

Although the desire to get such a model may seem a bit strange, there is a perfectly logical explanation. As it turns out, the idea was originally aimed at giving blind parents the opportunity to "look" at the ultrasound of the unborn child.

Weapons

Functional 3D printed receiver from AR-15 without any numbers

The possibility of 3D printing of weapons has seriously alarmed law enforcement agencies around the world. After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

Clothes

One of Snezhana Gross' designs

Some consumables for 3D printing, especially soft photopolymers, are quite suitable for making clothes and even underwear. The bra in the illustration was laser sintered from nylon. This design from Continuum Fashion aims to showcase the possibilities that 3D printing opens up for couturiers. However, don't think this is an experimental model: the company offers finished products for sale on the Shapeways website.

Russian designers did not bypass the new technology either: Snezhana Gross demonstrated casual wear designs integrating functional 3D printed components.

Art

Easy to print. Take a picture - as lucky

Take a picture - as lucky

Would you like a replica of the Venus de Milo? No problem, just choose the material and printing method. True, marble is not yet on the menu, but sandstone imitators are already available. Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre.

Although, if you are too lazy to make digital models yourself, you can always download them.

Products

What's for breakfast?

Although giant hot dogs are still far away, 3D printers have already learned how to print minced meat. An example of this is the Foodini culinary printer, a simple and practical device using syringe extrusion. Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Characters

Parts of models used to animate ParaNorman's protagonist

Whether it's a miniature version of a giant robot from a favorite manga, a creepy alien creature from Alien, or a Keanu Reeves action figure (as in a black cape and sunglasses, and with a beard and a sandwich sitting on a bench), 3D printing allows you to create replicas of game and movie characters for the delight of fans. And the fact that such souvenirs can be printed even on household 3D printers opens up great opportunities for those who like to collect such models - after all, not all of them are available for sale. Do you want a model of a rare aircraft? Print it.

Do you want a model of a rare aircraft? Print it.

And what is most interesting, this application has already had the opposite effect. ParaNorman cartoon characters were still printed. Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Home Robots

Early Terminator Prototype

The advent of inexpensive Arduino boards made it possible to design a wide variety of electronic devices at home. Here are your own 3D printed robots. You printed the case, inserted the servos and the board, and you have a new au pair. But what about people who do not understand programming or elementary soldering? Scientists from the Massachusetts Institute of Technology are developing a project aimed at automating the design and construction of domestic robots. Ideally, the user will only have to set the necessary functions for the future device, after which the system will compile the required design and send it to print. A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

Aviation

3D printed part used in Chinese fifth generation fighter aircraft prototypes

The toy airplanes we have already mentioned. What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons.

Space

Dragon v2 is Space's latest creation

The space industry is not far behind the aviation industry in its interest in 3D printing. NASA has successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

NASA has successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

Bioprinting

Biopens can help treat fractures

Vessels, tissues, whole organs - several companies are simultaneously developing the production of organic imitators that are completely similar to natural tissues. Although transplantation of 3D printed organs is still far away, work in this direction is underway. In parallel with the production of organic tissues from scratch, methods are also being developed to restore damaged tissues - for example, cartilage or bone. Devices called "biopens" are able to apply living cells to damaged areas, promoting their healing.

Prostheses

Titanium orthopedic prostheses with a porous structure for improved osseointegration

What if the tissues cannot be restored? 3D printing can help with prosthetics. Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Not only that, 3D printed limbs can compete with high-tech designs with one difference - their cost cannot be compared. How many people can afford a tens of thousands of dollars of prosthetic hands? How about a $50 fully functional prosthesis? And it's possible.

An even more common application of additive manufacturing is in dental prosthetics. If you have recently had a crown or bridge placed, it is possible that they were cast from models created with a stereolithography printer that prints with photopolymer resins.

Musical instruments

3D printed musical instruments

Guitars? Flutes? Drums? Easy. Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not seriously. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not seriously. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

Shoes

Luc Fusaro's stylish trainers

Eight-time world sprint champion Usain Bolt is famous for his love of gold. This includes not only medals, but also cars and even shoes. During his contract with renowned manufacturer Puma, Bolt wore signature gold-plated sneakers. And more recently, engineer and designer Luke Fusaro has taken on the development of sports shoes that Usain would like. Its distinctive feature is its golden color. Oh yes - and it's also designed for 3D printing. The use of additive manufacturing has one important bonus, namely the ability to produce shoes that are precisely tailored to the size and contours of the athlete's foot. Such shoes are produced by laser sintering, although this technology has already had a competitor.

Such shoes are produced by laser sintering, although this technology has already had a competitor.

Drugs

3D printing can facilitate the production of mixed drugs and help with drug testing on living tissues often in combination with tissue engineering. Thus, the Organovo company directs its efforts to create artificial human liver tissues to test new drugs for toxicity without risk to human health. But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient.

Cars

Doc Brown is introduced to 3D printing. That's about the reaction you'd expect.

Most automotive components can be printed, but it's not economically viable when it comes to mass production. But for prototyping new cars, 3D printing is great. As, however, for the production of unique machines or components. For example, you can print replacement parts for low-volume, discontinued models. Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Customization

Maximum glamor at minimum cost

Why not take a finished product and add decorative elements? Turn your bike into a work of art for everyone to envy. Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Furniture

One of Joris Laarman's clever designs

Toy furniture? No, not only. The advent of composite materials for FDM printing makes it possible to print "wooden" furniture, almost indistinguishable from the real thing. Actually, the material Laywoo-D3 could not do without real wood in the form of micro-sawdust. This stuff even smells like wood! Finished products are easily machined and varnished.

This stuff even smells like wood! Finished products are easily machined and varnished.

Or do you prefer metal furniture? Dutch designer Joris Laarman has created his own machine for metal 3D printing, without the use of expensive powders, vacuum chambers and lasers. The device draws with metal in the air, allowing you to create elegant interlaced designs.

Jewelry

Beautiful and functional

A clear demonstration of the precision of 3D printing is its application in jewelry. It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process.

But there is also an option for direct additive manufacturing of jewelry: laser sintering and melting technologies make it possible to create finished products from metal powder, including precious metal powders. True, the cost of such installations and materials is often too high for widespread use even by jewelers.

Construction

3D printing of buildings will help solve housing problems experimenting with the construction of concrete "boxes". True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Which method will be the most practical, time will tell. But in case of success of any of them, the construction industry can make a qualitative breakthrough, expressed in increased savings, safety and speed of building construction.

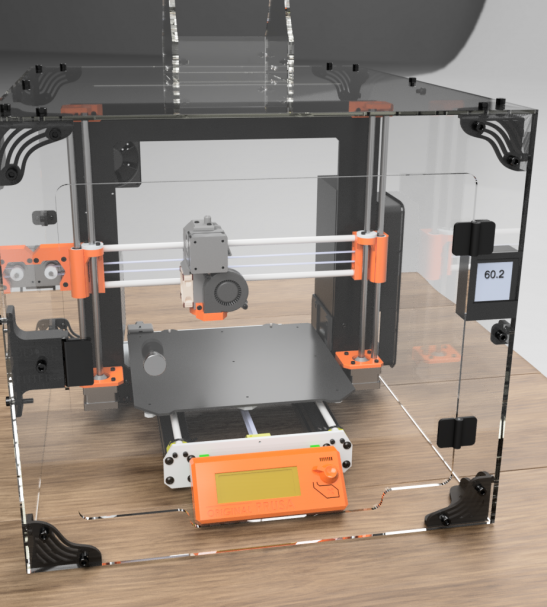

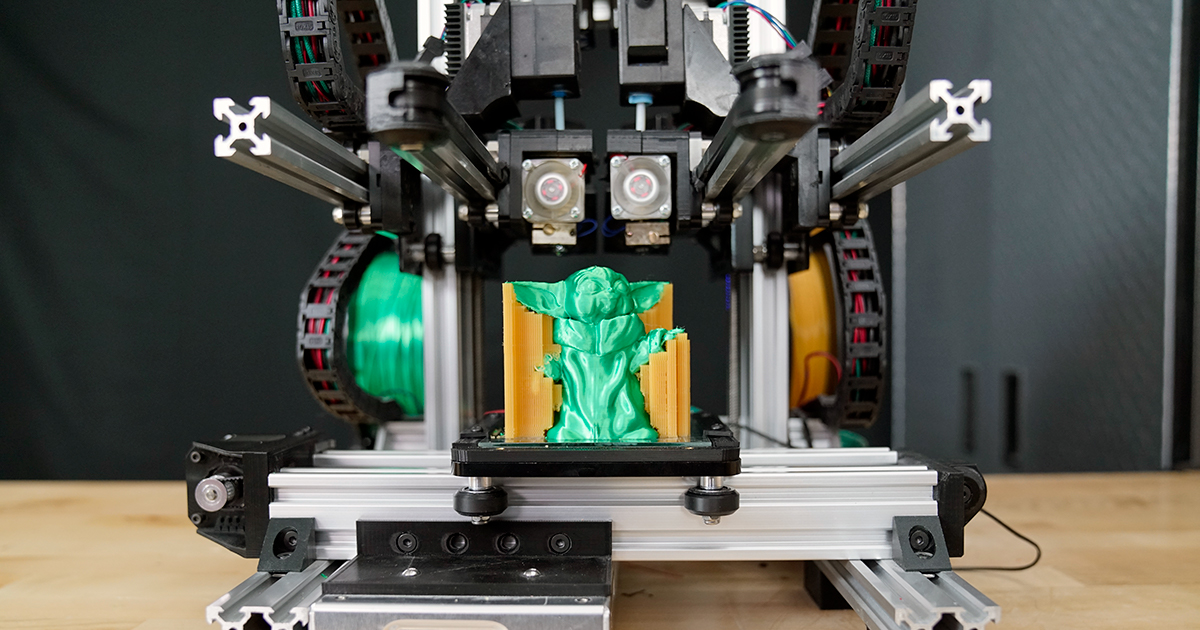

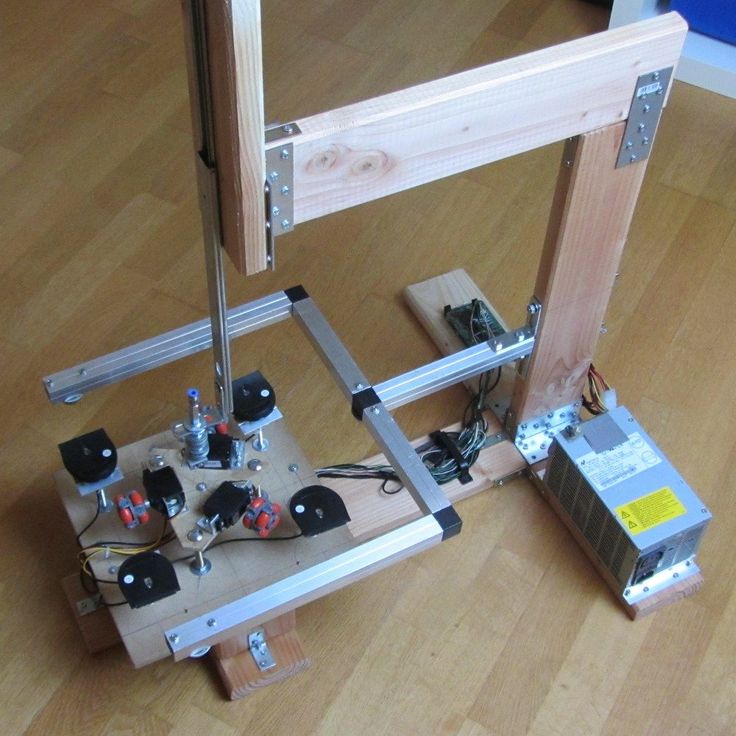

3D printers

What else can I print with a 3D printer? Another 3D printer! Even if not entirely yet: the necessary electronic and electromechanical components are not yet subject to printing, but this is only a matter of time. Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion.

Article prepared for 3DToday.ru

what a 3D printer can do

Possibilities of 3D printing

Unfortunately, the current level of awareness in 3D technologies leaves much to be desired. It happens that even with a basic knowledge of 3D printers, the actual application of 3D printing remains incomprehensible to a number of users. To avoid such situations, we have prepared this article and will consider in detail all the possibilities of 3D printing.

3D printing application

When talking about the use of 3D printing, it is worth considering not only the existing possibilities, but also the prospects. Already today, the application of 3D printing technology is extremely extensive and does not stop expanding. Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers.

Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers.

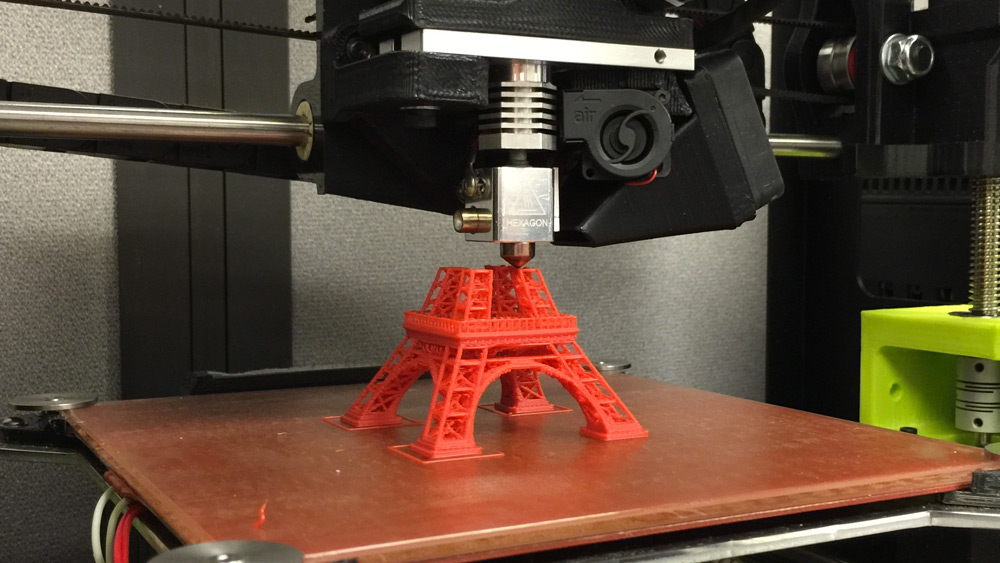

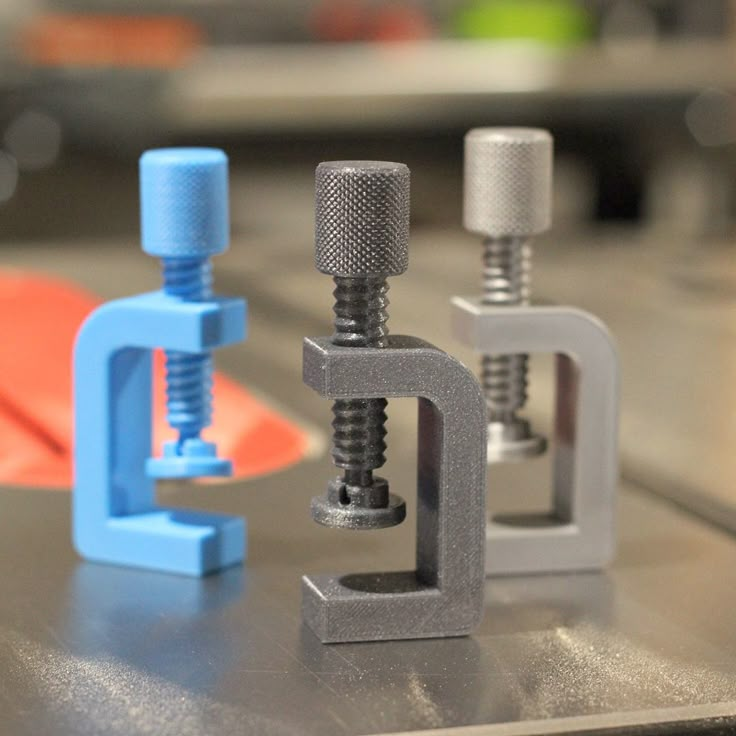

1. Prototyping

The best way to use 3D printing is for its intended purpose. Rapid prototyping is not only the second name of the technique, but also the original goal of its development. Creating prototypes using 3D printing significantly reduces production time and costs. And thanks to the possibilities of 3D modeling, the range of designed parts is practically unlimited. Prototyping allows you to visually assess the possible shortcomings of the product at the design stage and make significant changes to the design of the part even before its final approval.

2. Small-scale production

For small-scale production, 3D printing is a godsend. The properties of many materials allow the production of finished components at minimal cost. Compared to traditional production methods, small-scale production using 3D printing is very profitable from a financial point of view. The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts.

The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts.

3. Repair and restoration

Another application of 3D printing is the repair and restoration of damaged parts. For these purposes, 3D printing is ideal. You can carry out such a procedure both independently, with the appropriate skills and equipment, and in specialized 3D printing services, such as 3DDevice. First, a correct 3D model is built on the basis of the damaged product. 3D scanning can also be used to simplify design. Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows it to be reprinted at any time.

4. Production of functional models and finished components

One of the industrial applications of 3D printing is the production of functional models and finished components. Making products on a 3D printer from a transparent material allows you to see the work of a functional part “from the inside”, which is very useful when developing various engineering samples. In addition, a wide range of different materials for 3D printing turns it into a full-fledged production tool. Industrial 3D printers are gradually becoming a part of every industry, allowing the production of durable metal components.

Other questions and answers about 3D printers and 3D printing:

- Opportunities What is the future of 3D printing?

- Finance How to choose the right 3D printer?

5. Household items

Need an office organizer? Or a knife holder? Any household items can be printed on a 3D printer. The advantage of this application of 3D printing is that there are no restrictions when developing 3D models. That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively.

That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively.

6. Toys and souvenirs

Having a 3D printer makes it very easy to make a child happy – just make cute 3D toys. There are already some pretty interesting projects of collective 3D printed games, and in the future this list will only expand. This application of 3D printing will please not only children, but also enthusiastic collectors, because on a 3D printer you can print figures of any characters and attributes of computer games and films. And color 3D printing will make it possible to produce exclusive full-color souvenirs - miniature figurines of real people. To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual.

7. Design products

For creative people, there is another use for 3D printing. 3D technology in general is a unique opportunity to show your talent in the most unusual way. Artists, sculptors, fashion designers and designers from all over the world use 3D printing to create exclusive pieces of art that would be impossible to produce with standard methods. Such designer pieces impress with their beauty and originality, often fusing digital and traditional art. In addition, 3D printing techniques for clothing and footwear are being actively developed. Some models have even gone on sale, but it's too early to talk about mass production.

8. Capabilities of a 3D printer

We have listed the main capabilities of a 3D printer, but they do not end there. 3D printing finds application in a wide variety of industries. With its help, electronics, various components, food and even living tissues are printed. Of course, this list will be replenished in the future, but already now it impresses with its scale.