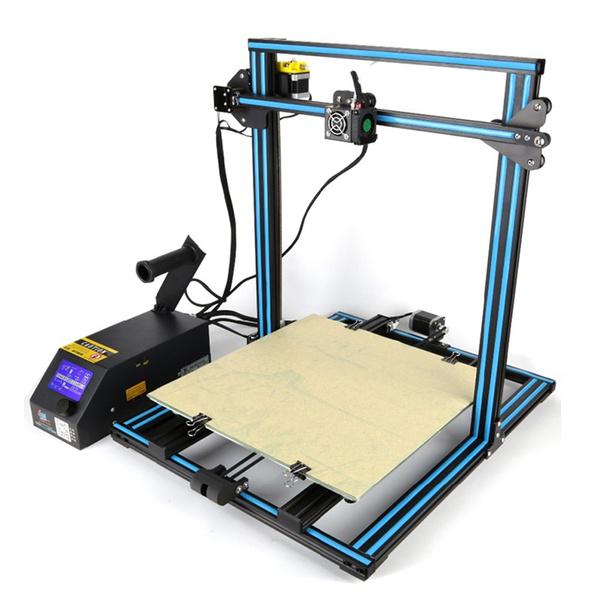

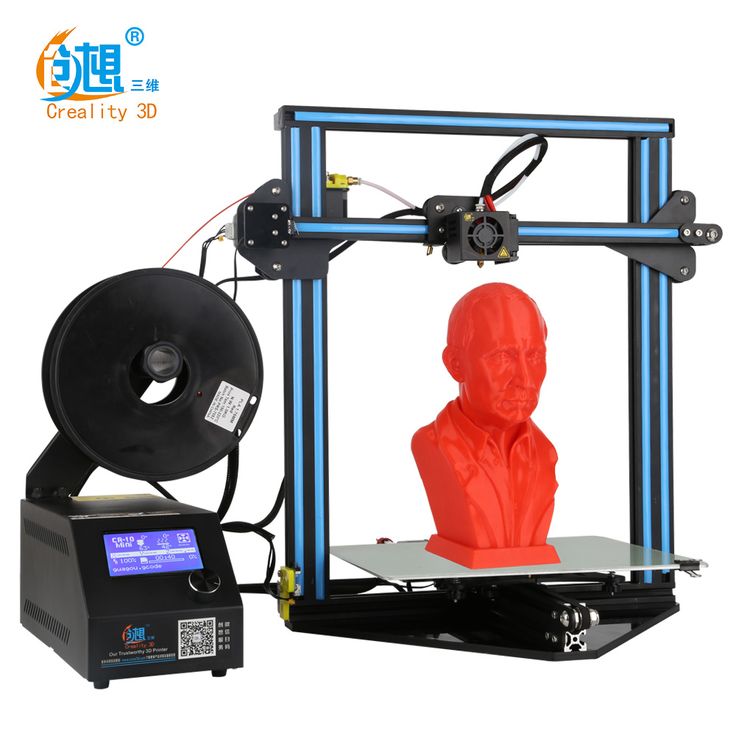

Large 3d printer heat bed

heat management - Heated Bed vs Heated enclosure for large scale printer

Asked

Modified 4 years, 5 months ago

Viewed 4k times

$\begingroup$

I'm /relatively/ new to 3d printing (I'm getting pretty good prints from my Wanhao di3 plus, but haven't done any DIY kits or anything) and materials engineering is probably the furthest thing from my area of expertise so I thought I would pose this to more experienced makers:

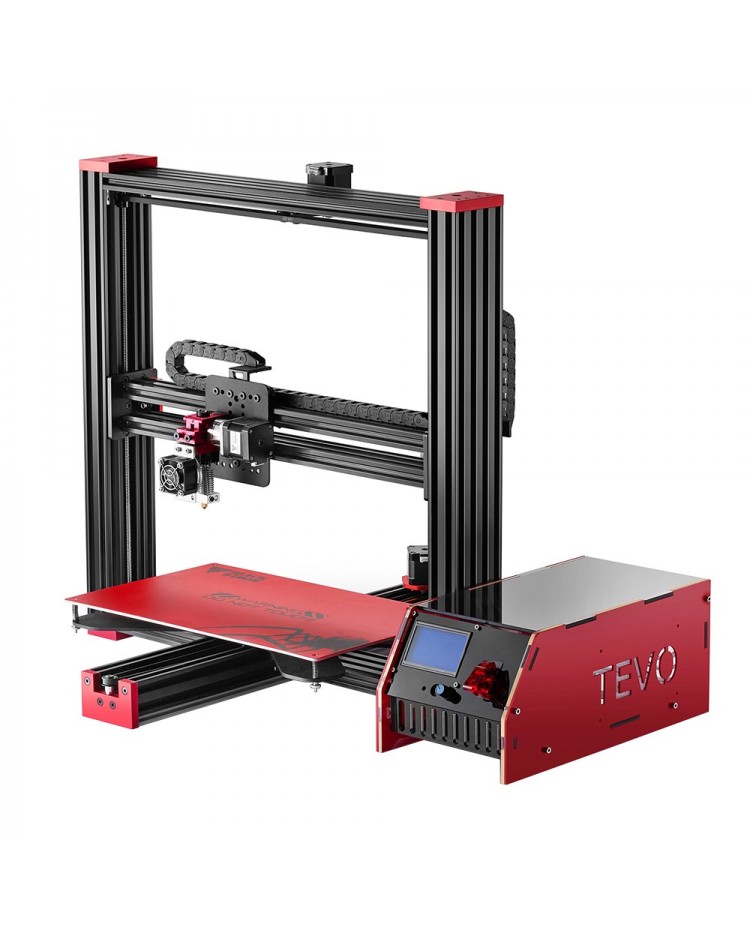

If I'm building a large scale printer (probably a similar size to substation33 - sub33D's 1200x1200 printer) that I'm only going to print in PLA and MAYBE ABS occasionally, can I substitute the heated bed for simply heating the entire enclosure? The idea would be to have a thermistor measuring the ambient air temp inside the enclosure with a heat gun or two to hear the entire enclosure as necessary. I want to do this to try and reduce the cost (significantly as far as I can tell) as it seems 400*400 silicone heat pads tend to go for about 80 bucks a pop. An alternate idea I had was to use two or three heat pads and space them evenly under a glass bed, although I feel that this won't work as well because the heating won't be homogenous...

Any input is appreciated :)

- heated-bed

- heat-management

$\endgroup$

$\begingroup$

I tend to agree with Davo, that you might want both. But I'd probably try the enclosure first. My printer is about 1200 by 400. I looked at options, and found some difficult trade-offs:

First, the big heatbed approach:

as you know, getting a single heatbed that big will be expensive (and if it ever breaks or fails, you have to replace it all).

a big heatbed also draws far more power than a RAMPS board can switch, so you'll have to use the on-board control to control a power relay (solid state or mechanical).

a big heatbed will also waste a great deal of power when you're doing small things.

Second, the heated enclosure approach:

more costly to heat up at the beginning, but if insulated it may be cheaper for long prints (with a bed that large, your prints might take really long, too) because it can retain the heat better.

if you keep the air circulating inside, you'll get much more uniform heat, rather than hot first layers and cooler higher layers.

consider the effect of the heat on all the other components: motors, electronics, pre-heating the fibers, thinning any lubricants,....

you could save some heating cost and time by providing a way to shrink the space to be heated: perhaps just a partition you can insert when doing smaller prints. It wouldn't have to be nearly airtight to make a big difference.

A third option is several small heatbeds:

this lets you turn on just the ones you need for any given print

still expensive, but cheaper than one big one, especially when any of them fails.

there will be uneven heat at the seams, but if you place the boards tight together I doubt it's enough to matter. You could also carefully trim the boards' edges to get the spacing closer to uniform.

temperature regulation will be tricky. If you want to support a temperature sensor for each board, you'll have to start hacking at the control software, because (as far as I can tell) there's no provision for multiple heaters. Probably easier to create a completely separate unit with a big power supply, and a simple thermostat for each of the beds, that you just set manually before starting a print.

Overall, I think the heated enclosure may be best. I like the hair dryer idea or heat gun idea, of course you'll need a little extra circuitry to switch it, but you can use the usual software for temperature regulation by installing thermistor or thermocouple in the case (just be careful about circulating the air well enough to avoid "hot spots").

You may want to add an extra cutoff to protect against runaway heating -- I had that happen once when a thermistor literally fell out of the mounting hole in the hotend. Something like https://www.grainger.com/product/SUPCO-Thermostat-407L11.

Let us know how it turns out.

$\endgroup$

1

$\begingroup$

With a well-insulated and well distributed (or perhaps well-mixed is a better term - even heating) enclosure you should have a veritable heated bed by dint of heating the enclosure (with the bed in it), unless the bed needs to be hotter than the enclosure. I think that would be bit more elaborate than "a couple of heat guns" and involve several fans to distribute and mix air continuously.

But - heated enclosures are not a freebie - everything inside the heated enclosure needs to be happy running at the sort of temperatures the enclosure is running at, and that can be hard on some electronic parts, shortening their lifetimes at least. Likewise, your calibration needs to be done on the hot enclosure - mechanical parts (particularly on a large scale printer) will change size due to the temperature.

Likewise, your calibration needs to be done on the hot enclosure - mechanical parts (particularly on a large scale printer) will change size due to the temperature.

Insulation will both reduce your running cost (the more heat you keep, the less you have to add) and help keep the temperatures even, by slowing the cooling at the edges of the enclosure.

$\endgroup$

$\begingroup$

If you want to print ABS at even one third of that scale, you will want a heated bed and a heated enclosure. Posts here (and my personal experience) support this; unfortunately, I can't find an impartial, non-anecdotal source to cite.

$\endgroup$

1

$\begingroup$

The point of using a heated bed it's to keep the part within a certain range of temperature while printing. 2 is good enough.

2 is good enough.

From my experience:

I used 500W silicon heater with SSR (AC mains) and it heats as fast as hotend (on DC 12V).

I also recommend tooling plate (CNC machined Aluminum plate), it is better for heat transmission (Al) and it is more flat (machined to +-50um).

You might consider thermal insulation under the silicone heater and also some foil on build plate itself - to minimize thermal losses. Cork might be useful for bottom. For top I use blue foil (in which it was originally wrapped).

Enclosure I think it is also necessary, combined with heater, but then you must also have tubes for cooling of printed part, motors, fridge on hot end, etc.

Word of caution: You must realize that you will be probably using 1.0mm nozzle or even more, since on 1200x1200mm you will just wait for weeks for part to complete. For reference: I print on 340mm diameter (delta) with 0.3mm nozzle and works just fine. But if I use just 0. 1mm instead of 0.2mm layers it takes more time, but at the end it looks fantastic. So in your case even layer height must be big to reduce printing time. So you can increase speed, but then there could emerge some artifacts on printed object and also consider heater on hot end, which might be lagging behind.

1mm instead of 0.2mm layers it takes more time, but at the end it looks fantastic. So in your case even layer height must be big to reduce printing time. So you can increase speed, but then there could emerge some artifacts on printed object and also consider heater on hot end, which might be lagging behind.

There are a lot of problems when you go this big and all are not even closely to be considered solved, but if you have time..

$\endgroup$

1

Heated bed - what are the benefits? Why use one?

Heatbeds have two purposes:

- Increase surface energy of the print bed to improve bonding strength of the first layer (particularly important when using surfaces like PEI or Kapton)

- Keep the bottom few millimeters of the print hot enough to provide a warp-free foundation for the rest of the print.

The bit about surface energy is straightforward. Most materials are stickier when hot than cold. In comparison, pure mechanical-bonding bed surfaces like fibrous painter's tape and perfboard don't particularly benefit from bed heat.

Most materials are stickier when hot than cold. In comparison, pure mechanical-bonding bed surfaces like fibrous painter's tape and perfboard don't particularly benefit from bed heat.

Warping is a bit more complicated. The basic cause of warping is when the previous layer is allowed to cool and thermally contract before the next layer is deposited. When you stick hot, expanded material on top of cold, contracted material, large shear stresses are generated when the fresh material cools and contracts. Those inter-layer shear stresses then accumulate over many layers into large-scale bending stresses that try to lift the edges of the print off the bed.

So, to prevent warping, we should minimize the amount that the previous layer is allowed to cool before the next layer goes down. But we DO need it to cool solid so the print doesn't sag in a mushy mess. This is a balancing act: cooling the plastic solid without over-cooling it. The optimal temperature for the print is right around the glass point of the plastic: this is the temperature at which the plastic becomes fully solid and thermal contraction stresses start to accumulate.

The extruder pumps more heat into the print as it deposits molten plastic and radiates a little bit of heat. So we want to set the heatbed temp a little bit below the glass point to ensure the print is able to cool solid. Now, this gets a bit difficult, because everyone's print bed temperature sensor is different. What matters is bed surface temp. Many people have to set their bed temp quite a bit higher than the actual surface temp. It's just something you have to calibrate via print results. The exact filament glass point (Tg) also depends on the blend.

- ABS: Tg is around 105C, optimal bed temp 95C in a warm, low-airflow environment

- PLA: Tg is around 55C, optimal bed temp is 55C in a cool, high-airflow environment because PLA holds heat and is slow to cool compared to other filaments

- PETG: Tg is around 70C, optimal bed temp is 60-70C with mild airflow

- Nylon doesn't really work with these rules because it's semi-crystalline, meaning it "freezes" far above its Tg and thus starts accumulating warping stress at fairly high temps.

.. advice varies wildly, from printing cold to 120C bed

.. advice varies wildly, from printing cold to 120C bed - PC: Tg is around 150C, optimal bed temp is 130C

There are other schools of thought, for example printing the first layer onto a surface much hotter than Tg for good adhesion, and then dropping the bed temp to a value somewhat below Tg to allow the print to solidify. That works fine too.

But, with all that said, it's important to understand that the heatbed only keeps the bottom of the print warm. A centimeter up from the build plate, the print is typically much closer to ambient temp than it is to the bed temp. Heated build chambers are thus much more effective for large prints. But heatbeds are still quite effective, because they allow building a strong, warp-free foundation that resists warping stresses induced by the cooler zones higher up in the print.

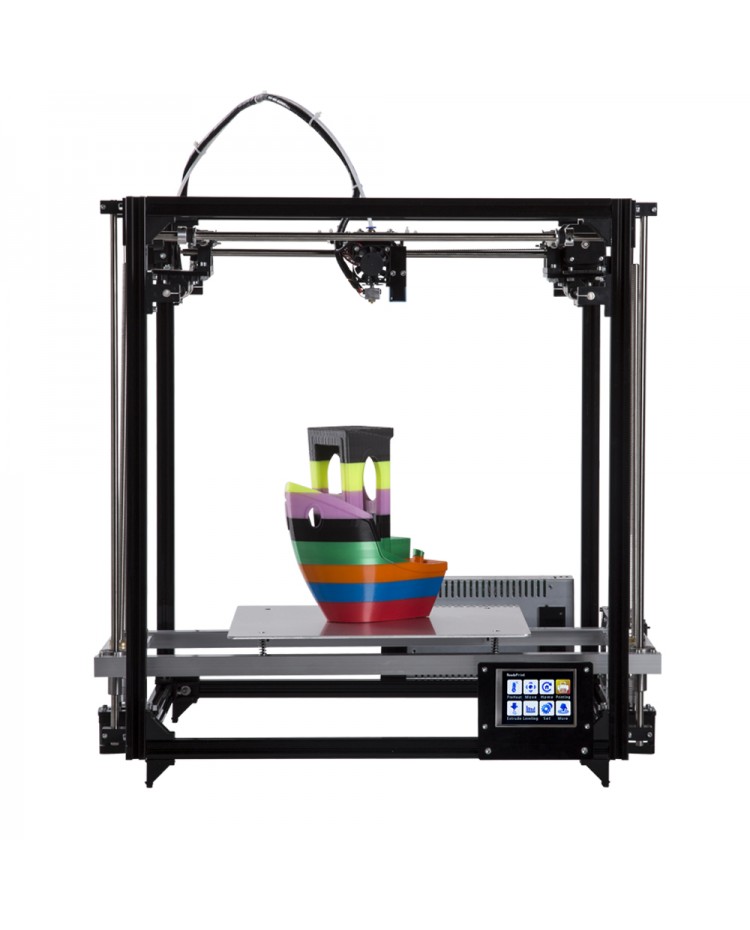

Types of tables for 3D printer

Contents

-

- Print platform materials

- Heated table

- Non-heated table.

- Table surface

- Types of calibration

- Automatic calibration

- manual calibration

- Calibration of a 3D printer table with Cartesian kinematics

- Calibration of the Delta printer 9000 9000

- Print platform materials

The correct calibration of the 3D printer bed, or as it is also called Hot Bed, is very important. The first layer is like a foundation for a house, if the foundation is fragile, then the house will not stand for a long time.

If the plane of the printed surface is uneven, then the model may be partially peeled off or deformed. The first layer may not stick to the printing platform at all, and the result of many hours of printing will not be a neat 3D model, but plastic noodles.

nine0039

Print failure example

Therefore, it is very important to properly calibrate the table. Printing platforms can be conditionally divided into two types - adjustable and not.

The adjustable table is attached to the printer with spring-loaded screws. It is not rigidly fixed in height and with the help of screws it is possible to calibrate the plane and the gap between the 3D printer table and the nozzle.

Adjusting screw

Unregulated is a printing platform that is rigidly fixed to the printer body. This solution is used in delta printers. Calibrate them only programmatically.

Non-adjustable delta printer table

Print platform materials

The material from which the table is made may vary depending on whether the table is heated or not. nine0003

Heated table

There are several types of heating elements for the 3D printer platform - aluminum, textolite, silicone and kapton. Each of them has its pros and cons.

Textolite heater - inexpensive, but fragile and can be strongly bent when heated.

Silicone heater - can not be used alone. Usually used in conjunction with a metal base. nine0003

An aluminum table is expensive, but it heats up more evenly and is less subject to thermal deformation than other platforms.

The Kapton heater is very expensive and cannot be used on its own. Usually glued to a metal base. Can be heated up to 200 degrees.

Types of heated printing surfaces

Most often, an aluminum heating table or a silicone heating pad is used in conjunction with an aluminum plate. Low price, ease of processing and high thermal conductivity make aluminum the most popular material for the manufacture of heated printing tables. nine0003

The main advantage of heating the printed surface is to increase the adhesion (adhesion) of the first layer of plastic. If the printer is with a closed case and a heated platform, a “passive thermal chamber” is created inside. Due to this, plastics with high shrinkage do not crack in layers during printing, the adhesion of layers (interlayer adhesion) increases, and internal stress is more evenly distributed during cooling.

But there are also disadvantages - when heated, the metal table expands a little, and since it has nowhere to expand, it begins to bend. For a printing platform up to 200x200 in size, deformation will not be very critical, but for larger tables this becomes a tangible problem. nine0003

Each manufacturer of 3D printers with a large printable area solves the problem of deformation of the metal table in its own way. For example, in Raise 3D, the table is fixed along the entire plane with pins at 13 points.

Heated table fixing Raise 3D

Table without heating.

An unheated printable surface is often used in 3D printers designed to work only with PLA and other low temperature plastics. For example - printers for children or large printers with an open case. nine0003

An unheated printable surface is often used in 3D printers designed to work only with PLA and other low temperature plastics. For example - printers for children or large printers with an open case.

For example - printers for children or large printers with an open case.

Children's printer with acrylic print bed

Tables without heating are made of aluminum or acrylic. If the table is aluminum, then glass or any other coating should be used on top. Aluminum is a soft metal and even a brass nozzle can scratch or damage it if not properly adjusted. nine0039

Heating table with aluminum base and mirror

Acrylic tables are often used in inexpensive 3D printers designed for kids. Acrylic is difficult to damage or break. You can print on an acrylic table without glass or other coating.

Free Shipping

Add to compare

Product added to compare Go nine0003

| Manufacturer | Raise3D |

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Flash Forge |

Table top

In order for the first layer to adhere to the table tightly, different surfaces are used that increase adhesion. It is more convenient to remove the model from the removable surface. If you need to immediately start printing another model, you can simply quickly change from one removable surface to another. nine0003

It is more convenient to remove the model from the removable surface. If you need to immediately start printing another model, you can simply quickly change from one removable surface to another. nine0003

The most popular table surface is the regular tempered glass or mirror. It is not expensive and available. It is believed that the accuracy class of the mirror is higher, but for small working areas (up to 200x200 mm), ordinary tempered glass is enough.

Glass itself does not hold the first layer well, so various adhesives or stickers are used to increase adhesion.

Ordinary glass can burst from a temperature difference or “crumble”, then the model comes off along with pieces of glass. Good thing it's easy to replace. nine0061

A piece of glass came off with model

Sitall glass - in fact, it is ordinary glass with the addition of boron oxide. This makes it stronger than ordinary glass and resistant to temperature changes.

But the cost of such glass is much higher than ordinary or tempered glass.

Sitall glass

Perforated table - mainly used for printing ABS plastic. Thanks to the perforation, the plastic adheres firmly to the print platform. In order for the bottom of the model to turn out to be even in the slicer settings, you need to enable printing on a raft (substrate). nine0003

Perforated table used in UP printers!

Stickers - There is a huge variety of stickers for printing platforms. It can be either ordinary masking tape or a specialized surface (rough with an adhesive surface).

The finished model is easier to remove from a flexible substrate than, for example, from glass. With some substrates, the model can be easily removed after the printing platform has cooled down. For some, you need to heat the table and only then tear off the model.

nine0003

Separately, you can select a variety of compositions that are applied to the surface of the printing platform to increase the adhesion of the first layers. 3D varnishes, 3D adhesives, etc. Probably every 3D maker has his own special recipe for the same composition that almost everything sticks to. It can be BF glue mixed with a solvent or alcohol, ABS diluted in acetone, kvass with sugar, glue stick, etc.

Do not spray varnish or other sprays inside the printer. Glue particles can settle on mechanisms, fans, and even get on electronics. This can lead to damage to the 3D printer. Simply remove the platen surface from the printer and apply the adhesive. nine0003

Add to compare

Product added to compare Go

Manufacturer Raise3D Add to compare

Product added to compare Go

Manufacturer Flash Forge Add to Compare

Product added to comparison Go

Manufacturer Flash Forge Calibrations

In addition to choosing the surface of the print platform, it is important to correctly level the plane of the table and set the correct gap between the table and the nozzle.

Calibration can be automatic or manual.

Printers with large print surfaces, such as the Raise 3D Pro 2 and Pro 2 Plus, are calibrated at the factory. The user only needs to check the gap between the table and the nozzle, because it may go astray during transportation. nine0003

Automatic calibration

Automatic calibration is performed using a sensor (optical or contact), which is mounted next to the extruder. The printer checks several points on the print platform one by one and remembers the values. The first layer will be printed correct for the curvature of the table.

You can meet the calibration using a conductive substrate that is placed instead of the printed surface. This method is rare, but still has a place to be. It is commonly used to calibrate 3D printers with delta or delta robot kinematics. nine0003

Automatic calibration allows you to quickly and effortlessly level the table. It becomes especially indispensable for printers with delta or delta robot kinematics.

Optical sensors "do not see" glass, so for printers with an optical sensor, it is better to use other surfaces of the print platform.

Some printer models have a menu with hints to help you properly set the platform plane and gap. It is enough to launch the “assistant” and follow the instructions on the screen. This is not exactly automatic calibration, but with such help it becomes much easier for a beginner to correctly calibrate the table. nine0003

An example of a 3D printer with automatic calibration is Raise E2. The Raise E2 extruder has a contact sensor to determine the distance between the nozzle and the printed surface. The resulting values help to correct the print height of the first layer. You can calibrate not the entire table, but only the area on which the model will be located.

Manual calibration

Manual calibration is when the user sets the plane of the table and the gap between the table and the nozzle himself.

To do this, under the printing platform there are screws or winglets with which you can adjust the height of the printing platform. nine0003

Calibration screws

The standard gap between the platform and the nozzle, for most printers, should be 0.1-0.2mm. If there is no set of probes at hand, a standard A4 sheet folded in half can replace it. Before calibration, the print surface (if it is heated) and the nozzle must be heated.

Sometimes manufacturers of 3D printers recommend a gap between the table and the nozzle - 0. Therefore, read the instructions before calibrating. nine0003

We will consider the calibration of the two most common kinematics - Cartesian and delta.

Cartesian kinematics is based on the Cartesian coordinate system and the movement of the 3D printer's head along the x, y, z axes.

Printer example with Cartesian kinematics

In deltas, the extruder moves along 3 identical axes using carriages moving along vertical guides.

The delta printer can be called a simplified delta robot, but these are still two different kinematics. nine0003

Example of a printer with delta kinematics

3D printer table calibration with Cartesian kinematics

Different manufacturers may have slightly different calibration instructions. We will consider here the calibration of the printer with standard kinematics.

Heat up the table and nozzle. When heated, the metal expands slightly, so the gap between the printing platform and the nozzle may differ between the “hot” and “cold” ones. nine0003

Through the printer menu, send the table and extruder to the "home" or zero position in all axes. Usually the zero point is the near left corner of the extruder and the top position of the print platform. Be sure to make sure that the 3D printer does not rest the nozzle on the table and does not damage it. If this is the first calibration, use the nuts to lower the table as low as possible.

Through the printer menu or manually (for this you need to turn off the motors through the menu), move the extruder so that the nozzle is above the adjusting screw. nine0003

Use a feeler gauge and adjusting screw to set the gap between the print bed and the nozzle.

Repeat all steps for all calibration screws. Usually there are 3 or 4 screws.

After aligning the plane above the screws, move the extruder to the center and check the gap. If the gap matches the feeler gauge, then the table plane and platform distance are correctly calibrated. nine0003

Delta printer table calibration

Calibrating a delta printer is a very large topic, so here we will only describe the general principles.

The delta printer does not have the x, y and z axes we are used to. Instead, the delta printer has 3 towers - A, B, C, on which the carriages move.

Since the delta table is static, it is calibrated programmatically.

The gap is calibrated by 3 points (at the columns) and the lens (center) of the table. The lens can be concave or convex. nine0003

Before calibration, check the mechanics of the printer - the belts must be tensioned evenly, there must be no play in the carriages and the effector (the plate to which the extruder is attached). If the belts are loose or uneven, it will be problematic to calibrate the printer.

Some 3D makers check belt tension with a tuner. Evenly tensioned belts will sound the same, but the correct “note” is found empirically. nine0003

There are a huge number of programs for delta calibration, but one of two is usually used - Pronterface or Repetier-Host. Using them, you can directly access the printer using special commands and change the values in the firmware.

As auxiliary programs, you can use a virtual calculator and from there transfer the values \u200b\u200binto the firmware or download the finished GCode.

They need to specify the parameters of your printer - firmware (usually Marlin or Repetier), diagonal length, circumference, etc. These parameters can be taken from the firmware or measured with a caliper. It is important to specify all the parameters as accurately as possible, otherwise the printer will not be able to calibrate. nine0003

First, 3 points are aligned at towers A, B, C, and only then the lens in the center of the table is corrected.

Manual delta calibration is tricky, but it doesn't have to be repeated often. Typically, the printer only needs to be recalibrated after some mechanical parts, belts, or print bed cover have been replaced.

Totals

The calibration process may seem tedious and complicated, but in fact, once you do it yourself, the process will no longer seem so intimidating. In addition, most manufacturers try to help novice users and equip their printers with auto-calibration sensors or try to simplify this process as much as possible with detailed menu prompts.

nine0003

And a variety of coatings for a printed table will help you find exactly the surface that suits your needs. As practice shows, every 3D maker, novice or experienced, has his own proven way to make the first layer stick tightly.

Don't be afraid to experiment and let every 3D print be successful.

Making a heated table for the MC2 3D printer with your own hands

Making a heated table for the MC2 3D printer with your own hands

We make a heated table for the MC2 3D printer with our own hands

In one of the previous articles, the technology for printing with ABS plastic on the cold table of the MC2 3D printer from Master Kit was presented. And what if we make this table heated and adjustable, eliminating the AUTO_BED_LEVELING function?

https://masterkit.ru/blog/articles/delaem-podogrevaemyj-stol-dlya-3d-printera-mc2-svoimi-rukami

With pleasure experimenting with the MC2 printer and refining it, I came to the conclusion that it was time I wish I had a heated table.

There's more that the printer's electronics support this feature. And at the same time try to make this table adjustable by eliminating the AUTO_BED_LEVELING function. In principle, the function works well, I wrote about this in this article, but I wanted to try this option as well. nine0003

Actually, for this you need to purchase only the heater itself, the thermistor and springs for adjustment - this can be done on the website 3d.masterkit.ru. And figure out how to thermally untie the plastic parts of the printer, designed to mount the table, and the heater.

After rummaging through the cupboards, I found a piece of fiberglass. Good, smooth, 2 mm thick. I sawed off a square 220x220 mm from it. (Heater size - 214x214 mm) And, without thinking twice, I drilled 4 holes in it for M3x10 screws with a sunk head for fastening the textolite to standard glass holders and 4 holes for mounting the heater. I drilled holes of 2.5 mm in the details for fastening the glass and screwed the textolite with screws like self-tapping screws.

nine0003

Now you need to attach the heater to the textolite through the springs. For a while I thought about how to make sure that the nuts of the adjusting screws were fixed, but then I decided to do without nuts at all. I cut the M3 thread directly in the fiberglass, it turned out somewhere around 4 turns. I tried several times to screw in and unscrew the spring-loaded screw. If you do this carefully, the thread holds well, does not deform. Let's see how the solution will behave during long-term operation; if the thread deteriorates, I will stick a metal nut-washer with an M3 thread on the textolite, you can print a retainer from ABS, or something like that. nine0003

Next, glue the thermistor into the central hole in the heater with heat-resistant tape or paper tape. It connects to the control board at connector T1. Also in the Marlin firmware, you must allow reading data from this sensor. To do this, in the Configuration.h tab, you need to change 0 to 1 in the line #define TEMP_SENSOR_BED 1

After that, in the RepetierHost program, you can see and set the table temperature value.

Printing glass - how could it be without it - it is convenient to fix it with stationery paper clips. You can find them in any stationery department. This is how the sandwich turned out. Pretty hefty, I must say. I decided that it would be necessary to reduce in connection with this acceleration along the Y axis, and at the same time X. We climb into the firmware again. And we halve the following parameters in Configuration.h (new values are indicated):

#define DEFAULT_MAX_ACCELERATION {4500,4500,100,9000}

#define DEFAULT_ACCELERATION 1000Probably a little slower typing, oh well, we're not in a hurry.

In order to eliminate the influence of the extruder mounting on positioning accuracy and to fully realize the possibility of adjusting the table, I decided to rigidly fix the extruder in its holder, for which I drilled through the details of its fastening and tightened it with screws. In this regard, I had to rearrange the Z-axis limit switch under the platform on which the X-axis is implemented.

I printed a part with two slots for adjusting the limit switch and simply glued it with dichloroethane to the base connecting the three stepper motors from the bottom of the printer. Just in case, I also tightened it with a screw. Now the limit switch is triggered when the platform is lowered to the desired level. nine0003

As a power supply, taking into account the current consumption increased by 10A (!) I used an ownerless power supply from an old computer with a power of 350W. It gives 15A current on the 12V yellow wire. The heater is connected to the terminals D8 of the control board. I checked the voltage at full load, it stays at the level of 11.5-11.6V. The block does not heat up. Good!

Now let's try to print something with ABS. Test cube 30x30mm, for example. We see in RepetierHost: 100 degrees on the table, 250 on the extruder. 200 µm layer, blowing off. nine0003

Smells a little, but with the window open it's quite bearable. For me, let it smell like that, even nice!

It turned out quite a decent cube, agree! By the way, when printing, the part was not blown, because it cools the extruder by 10 degrees.

Learn more