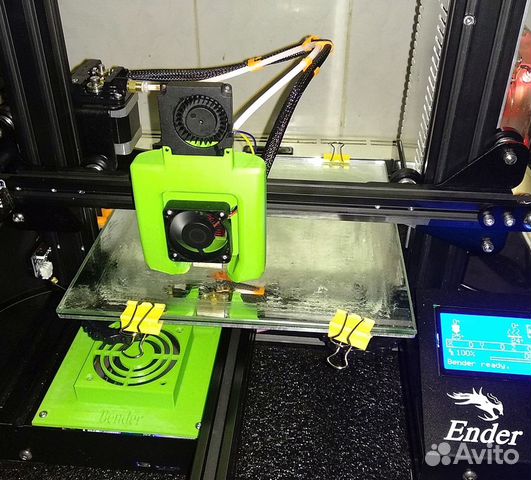

Crealty 3d printer

Official Website, Leading 3D Printer Supplier & Manufacturer

CREALITY - Official Website, Leading 3D Printer Supplier & ManufacturerView more

Ender Series CR Series Fully Enclosed Printers Resin 3D Printers Ecosystem

Ender-5 S1 3D Printer

$559.00 Learn More >

Ender-5 S1 3D Printer $559. 00

Ender-3 V2 Neo 3D Printer

$299.00 Learn More >

Ender-3 V2 Neo 3D Printer $299.00

Ender-3 Max Neo 3D Printer

$399.00 Learn More >

Ender-3 Max Neo 3D Printer $399.00

Ender-3 Neo 3D Printer

$219.00 Learn More >

Ender-3 Neo 3D Printer $219.00

Ender-3 S1 Plus 3D Printer

$529. 00 Learn More >

00 Learn More >

Ender-3 S1 Plus 3D Printer $529.00

tw-block tw-mt-12 tw-mb-5 tw-hidden "> Learn More >

tw-block tw-mt-12 tw-mb-5 tw-hidden ">

Application Fields

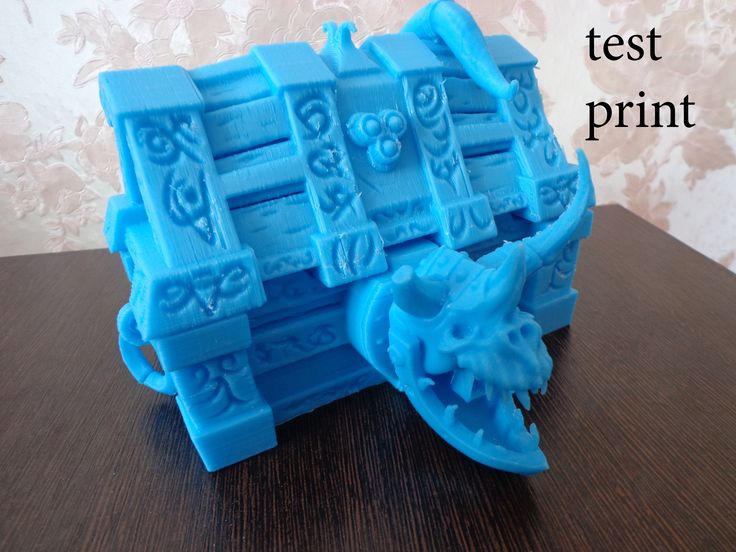

Consumer/Maker

Consumer/Maker

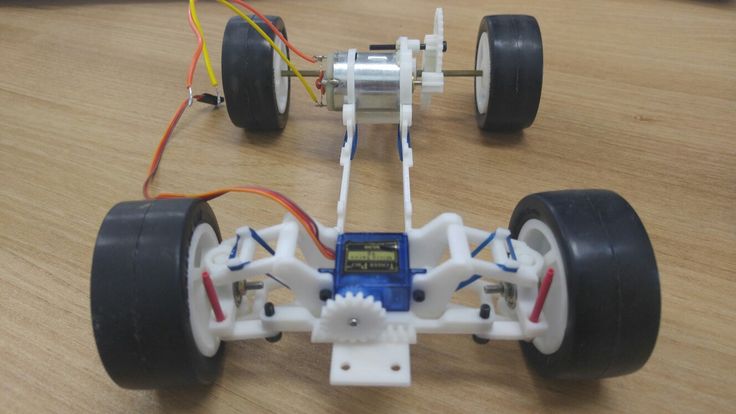

3D Printing To Realize Wonderful Ideas

3D Printing To Realize Wonderful Ideas

Education

Education

Solution For Demonstration, Research and Career Preparation

Solution For Demonstration, Research and Career Preparation

Dentistry

Dentistry

Solution for High-percision and Low-priced Dental Cast

Solution for High-percision and Low-priced Dental Cast

Anime

Anime

Solution For Carage Kits Production

Solution For Carage Kits Production

About Creality

1. 6

6

Million+

Number of users

1

Million+

Annual shipments exceeded

Patented Technology

Featured On

Learn More >

Download

Learn MoreSupport

Learn More Learn MoreGo to the Store to Buy Now

Buy NowCreality Ender 3 3D Printer sale

Home Collections Ender 3 DIY 3D Printers Kit | 8.66x8.66x9.84inch | Resume Printing FunctionAn Ideal First 3D Printer. One of the most popular filament-based 3D Printers; AUGUEST SALE COLLECTION-3D Printer & Parts, Filament. BUY ANY 2, GET 10% OFF

$ USD

$ USD

35 Reviews 11·11-TOP PICKS Pricing Not Include Tax

Ship From

United StatesCzech RepublicChinaAustraliaUnited KingdomCanada

Model-1

Ender-3Ender-3 NEO

Ship to

It is expected to arrive within and will cost $ USD to ship

This item can't be shipped to this Country/Region

Bundles

Quantity

28 Available

Add To Cart Buy It Now

Continue To Shopping View Cart

People who bought this item also bought

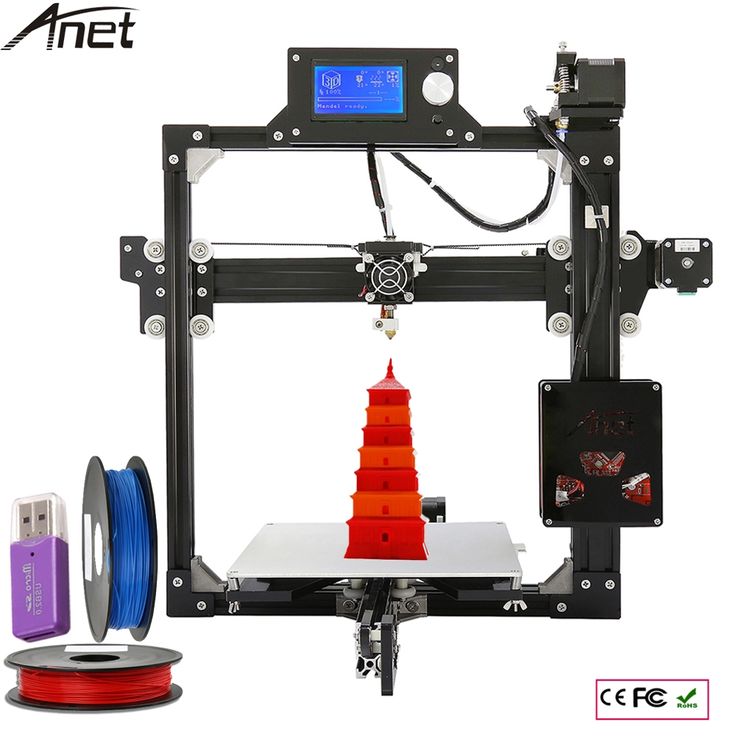

Official Creality Ender 3 3D Printer Fully Open Source with Resume Printing

- Easy and Quick Assembly: It comes with several assembled parts, you only need about 2 hours to assemble 20 nuts well.

- Advanced Extruder Technology: Upgraded extruder greatly reduces plugging risk and bad extrusion; V-Shape with POM wheels makes it move noiseless, smoothly, and durable.

- Safety Protected Power Supply: Only needs 5 minutes for the hotbed to reach 110℃.

- It is a great project for middle school and high school-aged students. The perfect gift to spark a lifelong love for science and engineering, and provide a deeper understanding of machinery and robotics.

Creality Ender 3:Complete beginner's guide to 3D printing - Assembly, tour, slicing, levelling and first prints

CR Touch Install Guide - From 3D Printscape

Why Most People Choose Ender 3 3D Printer

From 2018 till now, the Ender-3 model has remained in the "Best Selling". Although we are launching new Ender-3V2, Ender-3S1. So why do many choose Ender 3?

Although we are launching new Ender-3V2, Ender-3S1. So why do many choose Ender 3?

1. In terms of price: the price is lower than 200, stable printing quality and 220*220 printing size, supports different filament materials

2. In terms of performance: support resume printing, 5mins rapid heating, reliable power supply

3. Upgrade convenience: ender 3 direct drive, cr touch auto leveling kit, touch screen , tempered glass bed and more. There's do much you can do with it

4. Who chose him: News for 3d printing, 3d printing enthusiast; for DIY makers, for education... Customer

Ender 3' S FAQ:

Filament did not stick on the hotbed?

For newcomers, this is the most common problem. Do not worry, you can solve it easily. Generally,the distance between the nozzle and platform is too far or near. So rotary the knob under the platform to adjust the distance between the nozzle and platform again,at a piece of A4 paper distance or less).

Creality Ender 3 Bed Leveling – All You Need to Know

Any structure needs a strong foundation. The same is true for 3D-printed objects. Leveling the bed on your Creality Ender 3 will ensure that that all-important first layer is solid...

How to level Creality Creality Ender 3?

Move the nozzle so that it’s positioned over the left corner of the bed. A half-inch or so from both sides is a good location.

Slide the paper between the nozzle and the bed. If it doesn’t fit, drop the corner until it does.

Once the paper is able to slide under the nozzle, very slowly raise the corner with the adjuster. Remember: Clockwise moves the bed up. As you do this, gently slide the paper back and forth. The moment you feel even the slightest resistance to your moving the paper, stop turning the knob. That corner is (almost) ready to go.

Do the same for the other three corners of the build plate. Always advance the hot end to a new corner slowly. This will prevent damage to the build plate in case the nozzle starts to drag. If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

After you’ve adjusted each corner once, go back and check the four corners again. You may have to do further adjustments to get all four correct.

Article: Creality Ender 3 Bed Leveling – All You Need to Know.

Download

Download

Download

Download

Download

Download

Download

Download

Download

Customer Reviews

Based on 35 reviews

77%

(27)

17%

(6)

Write A Review

Ask A Question

Reviews (35) Questions (5)$ USD

$ USD

11·11-TOP PICKS

ADD TO CART BUY IT NOW

Write a review

Ask a Question

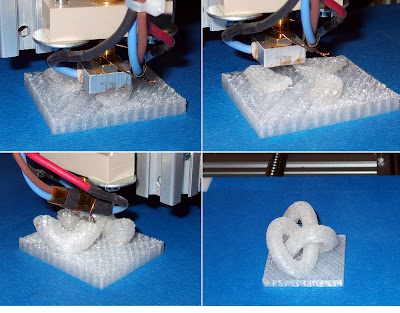

"The first real 3D printer" prints the entire object at once

Alexander Noskov Photo: University of Michigan

The University of Michigan figured out how to create three-dimensional objects not layer by layer, but entirely. And it's not just fast. Objects cured with two beams of light are much stronger than “puff” ones.

And it's not just fast. Objects cured with two beams of light are much stronger than “puff” ones.

The technology created by American specialists brings the mass adoption of industrial 3D printers closer. Because until now, despite some successes, printing has not been fast enough to serve the needs of most modern industries. Speed is especially important for small producers that adapt to the needs of customers. Additive technologies are most effective when it comes to small-scale production. But they are not efficient enough when it comes to medium-scale production.

But soon printing will be not only affordable, but also fast - about 100 times faster than modern "layered" printers.

In particular, this means that a factory does not need to order a hundred printers - one is enough. And saving is one of the main factors in the introduction of any new technology.

“[Our machine] is one of the first true 3D printers,” says one of its creators, Professor Mark Burns.

His printer does not print layer after layer of solution from the nozzle, as it does now. Burns and colleagues came up with a series of know-how that allows them to create solid shapes in a vat of special resin using two beams of light.

There have been attempts to create a printer working on the same principle before. However, they tried to cure the resin with one beam - like a dentist's photographic filling. This means that the resin also hardens in "beams" - along the entire illuminated line. And hardens instantly. To avoid this, you need to leave the possibility of oxygen access. However, the narrow "oxygen channel" that allows liquid to remain around the finished product and can be removed from the mold means that the resin itself must be sufficiently fluid. And such a liquid resin was very fragile - like objects made from it.

It is this limitation that allows you to bypass the use of two beams from different sources. They are aimed at any point of the solution in 3D, solidifying it, but not the surrounding space.

Creating 3D objects with a new method, according to Science Daily, resembles a photograph. To demonstrate the possibilities, Burns' team printed three complex structures in a vat: a grid, a toy boat, and the letter "M".

Speed is just one advantage. The creators claim that "irradiated" objects are much stronger than those created in layers, in which structurally weakened areas appear between the layers. And by adding special additives to the resin, you can make it even stronger.

An article based on the results of the work was published in the journal Science Advances. The University of Michigan has patented three know-hows that underlie the new approach. And Burns and his colleagues are creating a startup to commercialize the technology.

3D printers, if they really get fast, will transform a whole range of industries. So far, their use is rarely profitable outside of laboratories, where potential is demonstrated by creating incredible solutions and designs: for example, a steel bridge without a single straight line, masks indistinguishable from real faces, or an oven-printer for chefs of the future

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

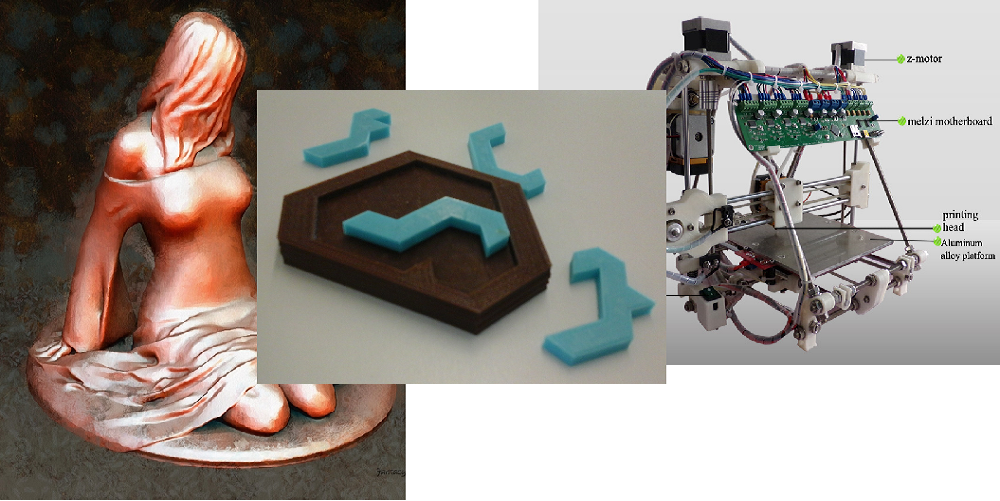

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc. ), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

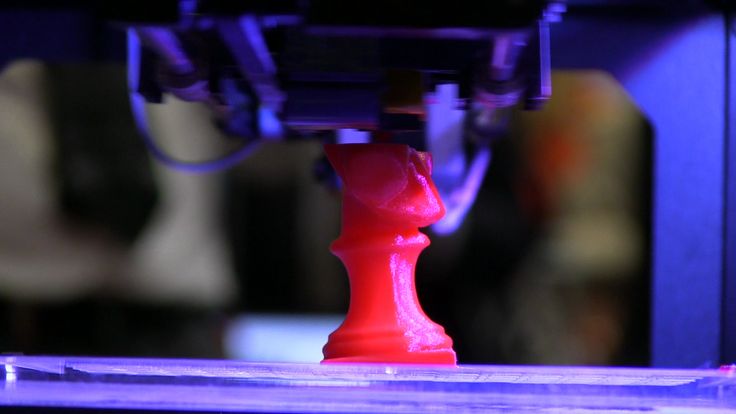

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

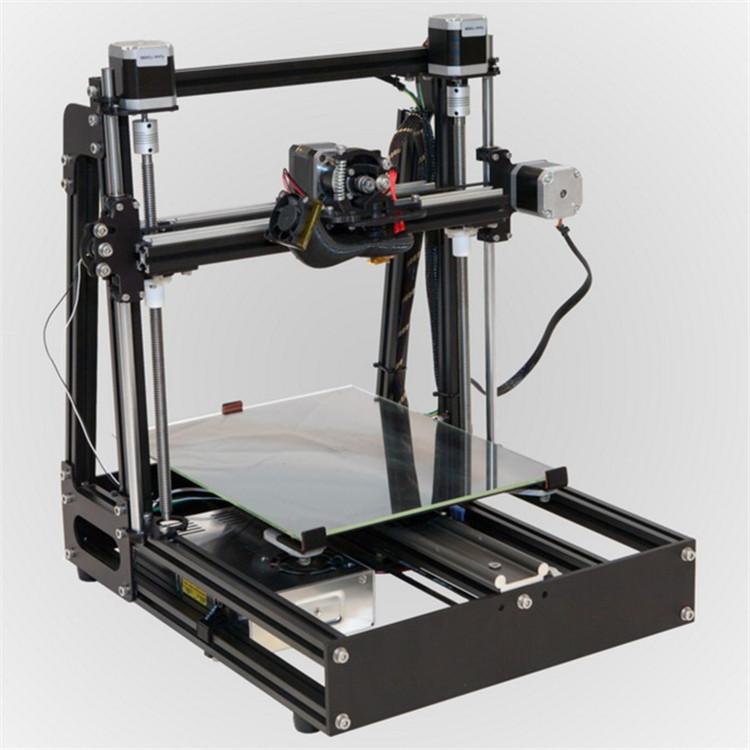

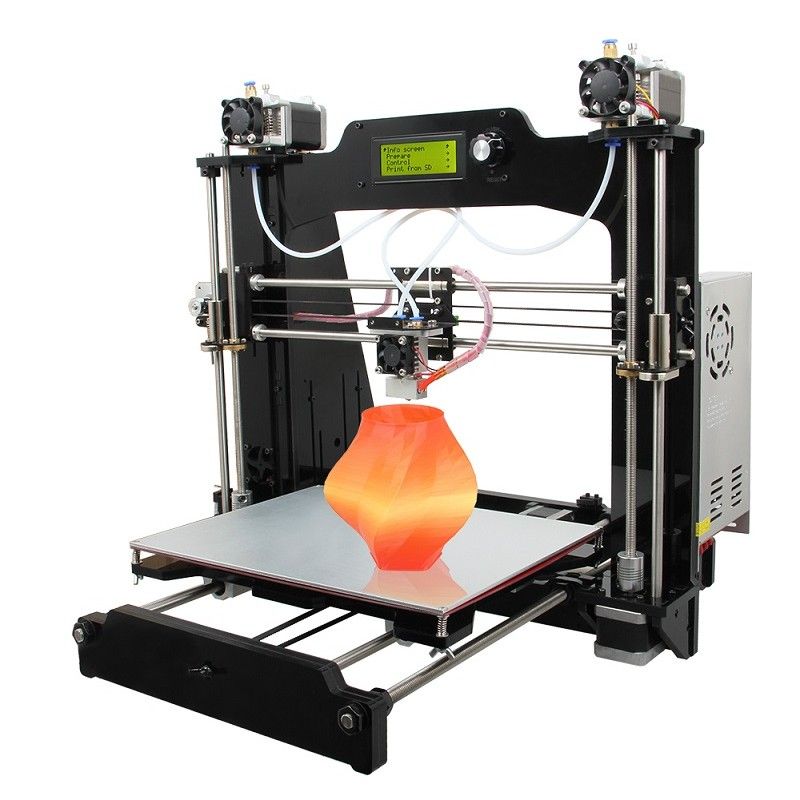

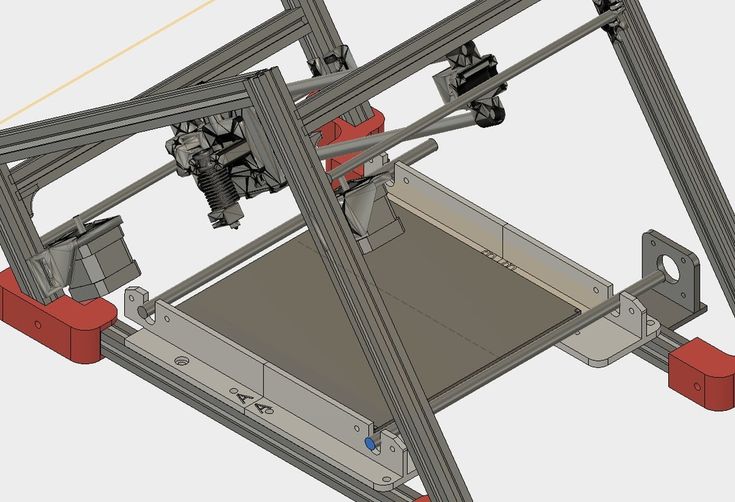

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

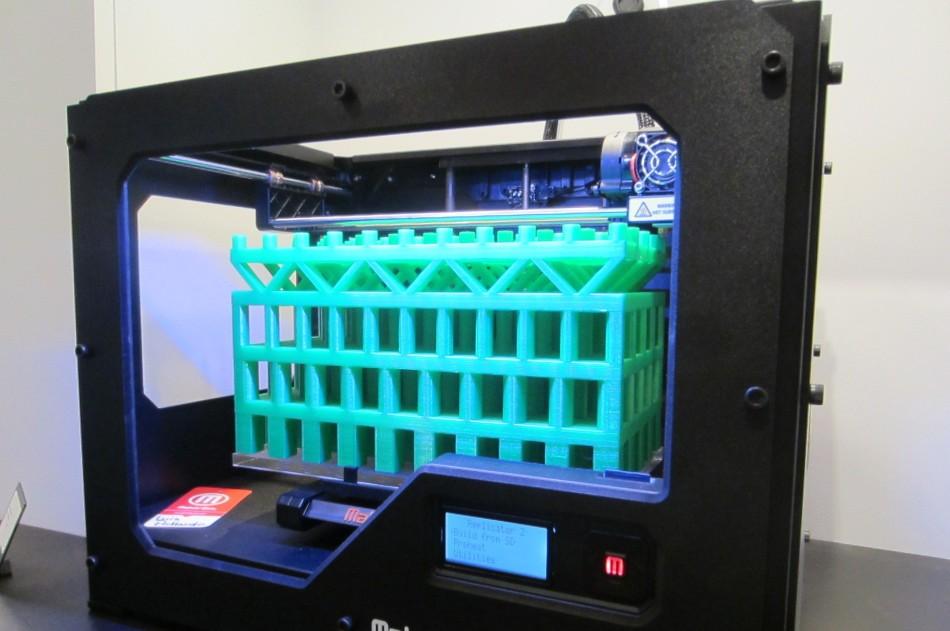

First of all, it is worth mentioning the company MakerBot, which started as a startup, based on the ideas of RepRap and little by little turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend.

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer using SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

Personal 3d printers of today are very close to professional devices, the development of which also continues. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

In addition to the "classic" scope of 3D printing, today more and more often you can see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells.

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).