3D printer fire alarm

Alright, lets talk 3D Printer fire prevention systems : 3Dprinting

I've been trying to find any good fire prevention systems for 3D Printers, and depending on the Region (USA/Europe), there seem to be few or none available.

This topic addresses all of us, since we can't sit in front of the Printer for 20 hours until the prints finish. Everyone risks life, house and home. Even expensive printers have a risk of burning down, with Thermal Runaway protection enabled or not.

An error in the software or a faulty thermal sensor can cause the heating cartridge to melt right through the aluminum heaterblock. Same goes for the heated bed.

So i think there are at least two things that need to be addressed here:

.

A case/enclosure for the 3D Printer is a must have for both scenarios, since both fire/power cutoff systems work much better if they are in a confined space. These won't do you any good if your Printer is sitting on your desk and you have an automatic firestopper mounted 2 meters above it. Smoke detection only kicks in if it's too late with that much headroom.

*On the enclosure side: it's a bit ironic with the rise of the IKEA Lack enclosures for printers, these things are mostly cardboard and a bit of pressed wood dust (coupled with plexiglass side panels), if you have a printer fire in an IKEA enclose it will be much worse than without one.

**also OctoPrint: OctoPrint does nothing for the nobody at home & fire scenario. Even if you check every 5 minutes for a failure, a fire hazard can break out in 2-3 minutes. And then you still got to drive home from work.

.

(sorry, i'm going to list some Amazon Germany for the examples here.)

Now these two things could be addressed with something like this:

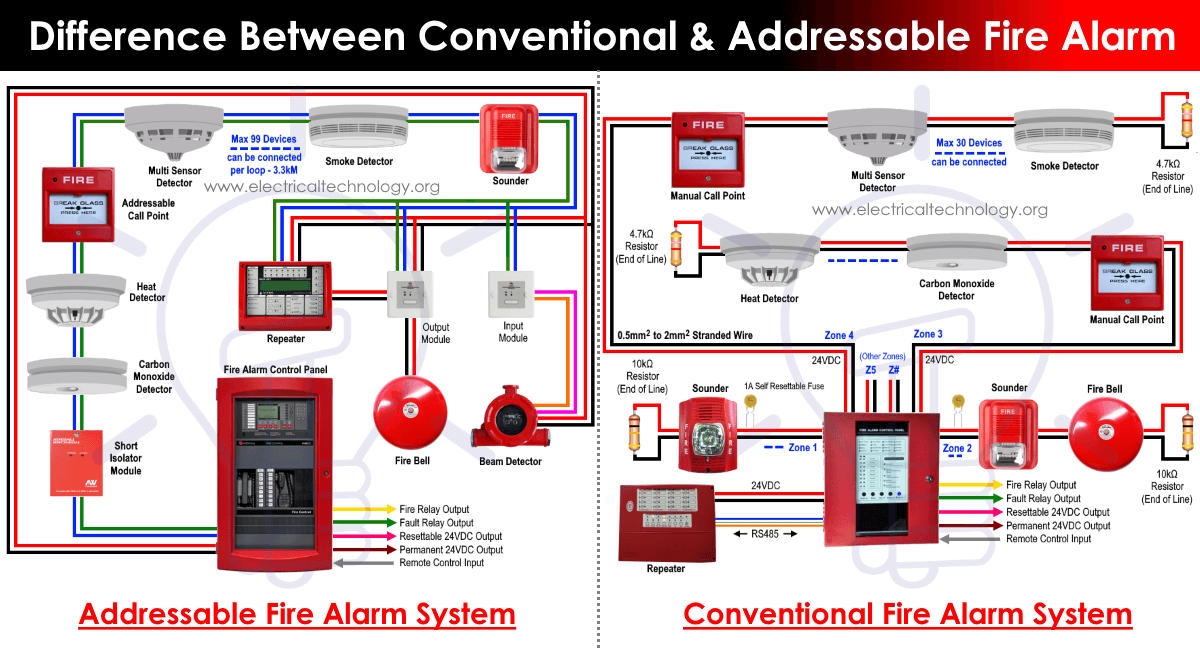

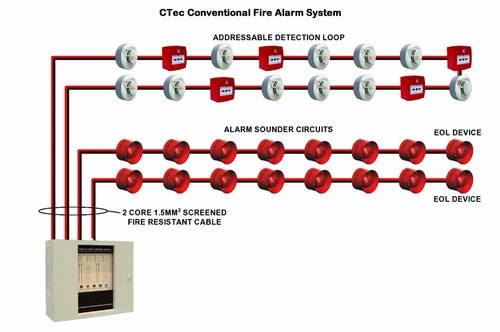

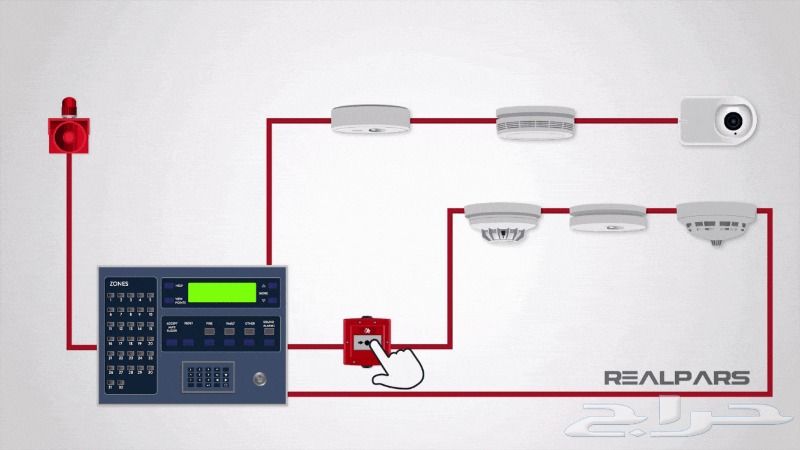

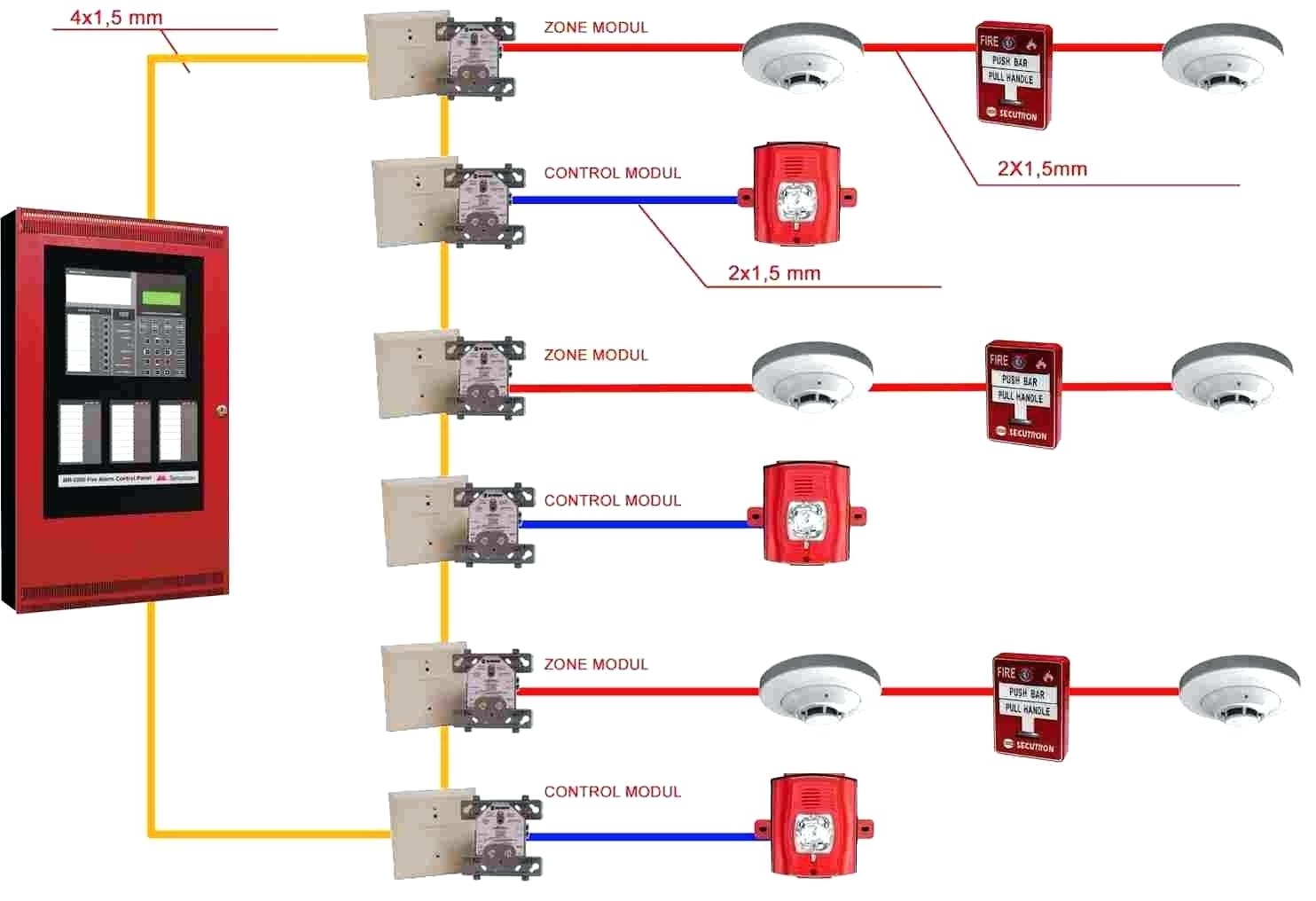

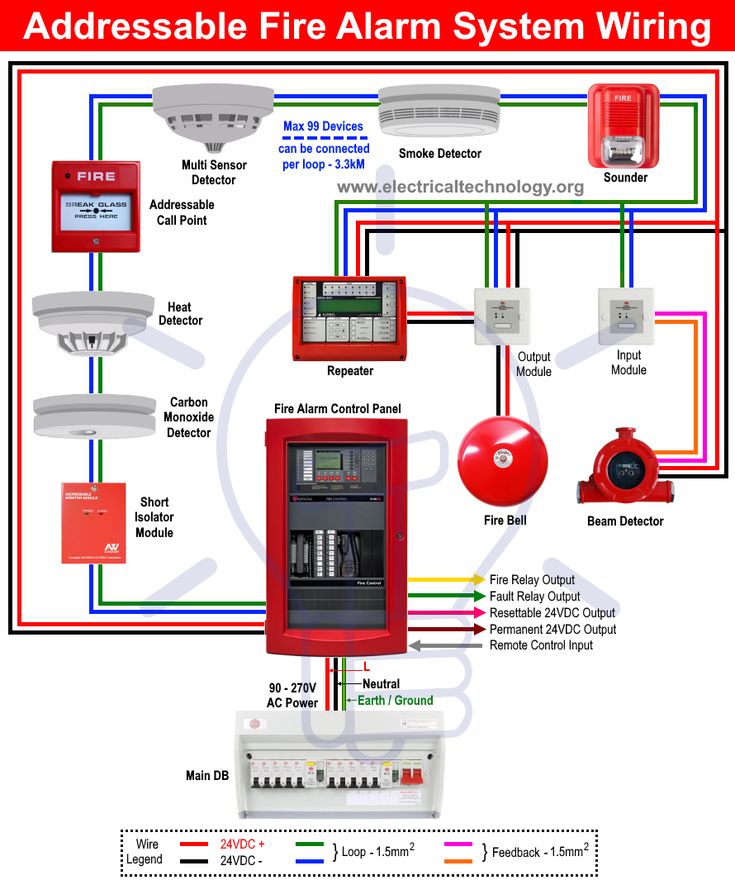

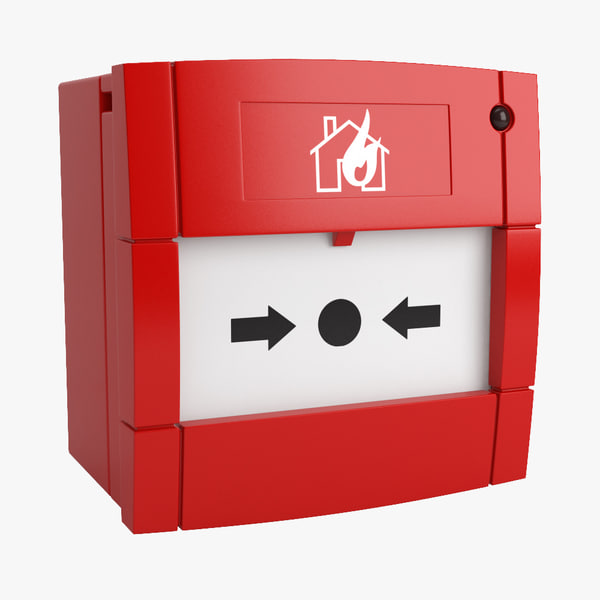

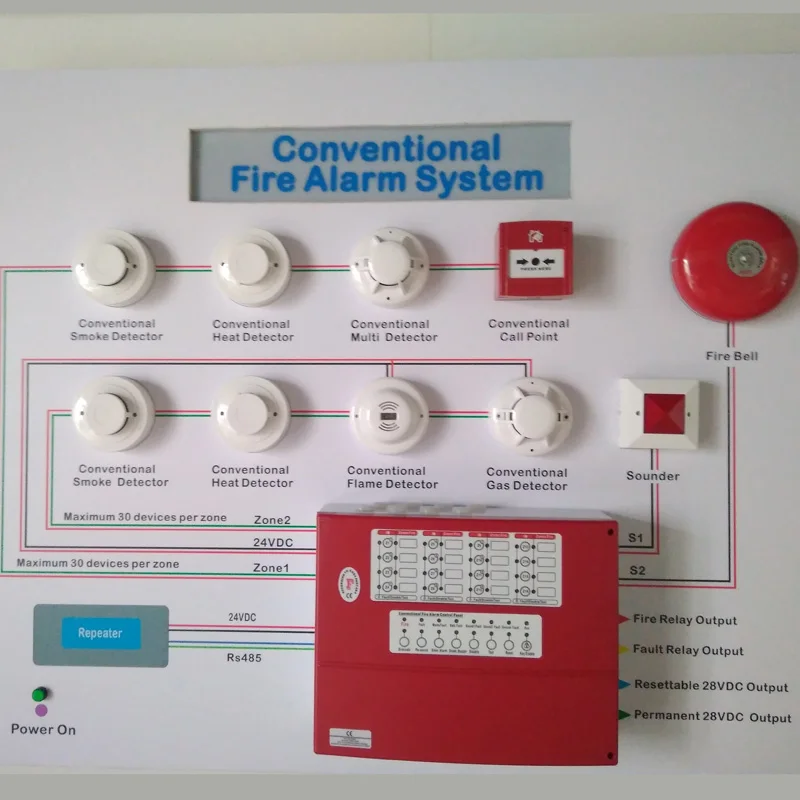

- A smoke detection sensor that powers down the power socket where the printer is plugged in.

Some people dabbled with this in the past with custom boards, but none of those are still made today or ship to more than one country in the world.

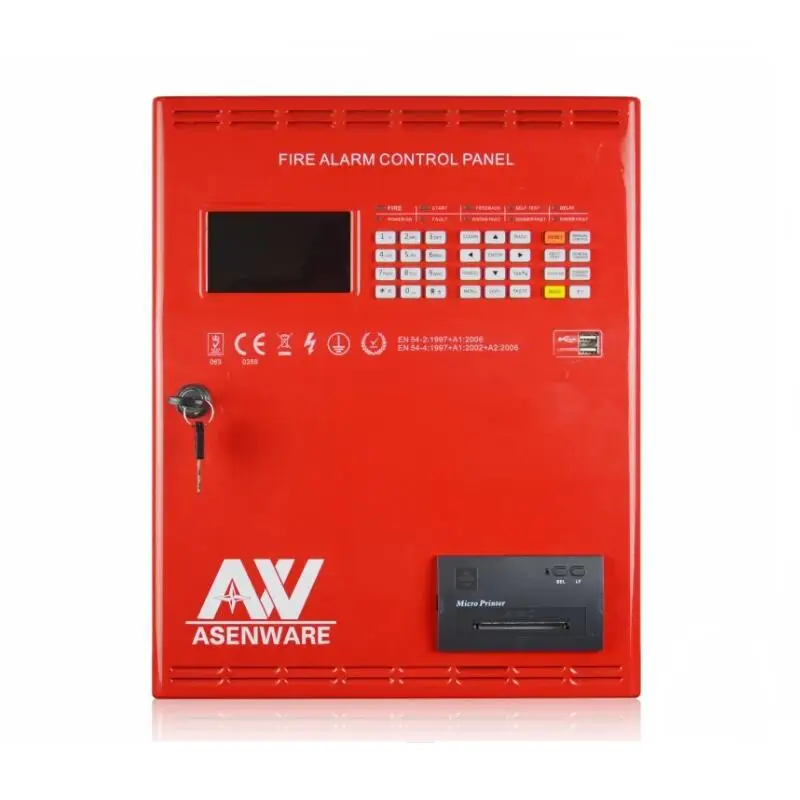

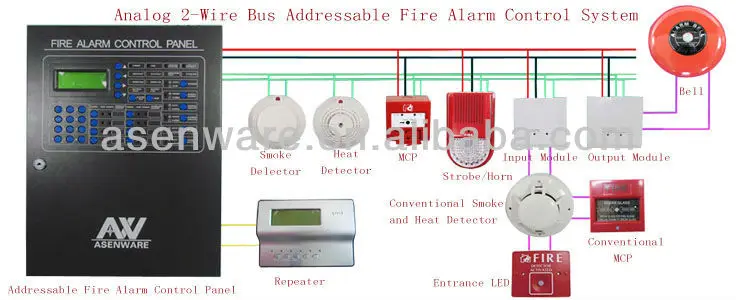

A good commercially and available (but expensive) solution would be a Z-Wave home control System.

Z-Wave Smoke detector + Z-Wave Power socket + Z-Wave control hub

Cost: about 250 - 300 euros for a good fire detection system

Alternative solution would be hacking a run of the mill smoke sensor, or using one that can control an external circuit with a high/low signal. Smoke detectors with the capability to switch something else are hard to find.

Hacking a run of the mill smoke detector is on my to do list, i will get one for this purpose and try to pair it with a circuit that switches off a power socket. Will post in the coming weeks.

.

Lets list the devices that stop feeding energy into the heating elements:

US based:

Z-Wave Set: Z-Wave Smoke detector + Z-Wave Power socket + Z-Wave control hub

Temp Controller

Safe T Sensor

Thermal Fuses

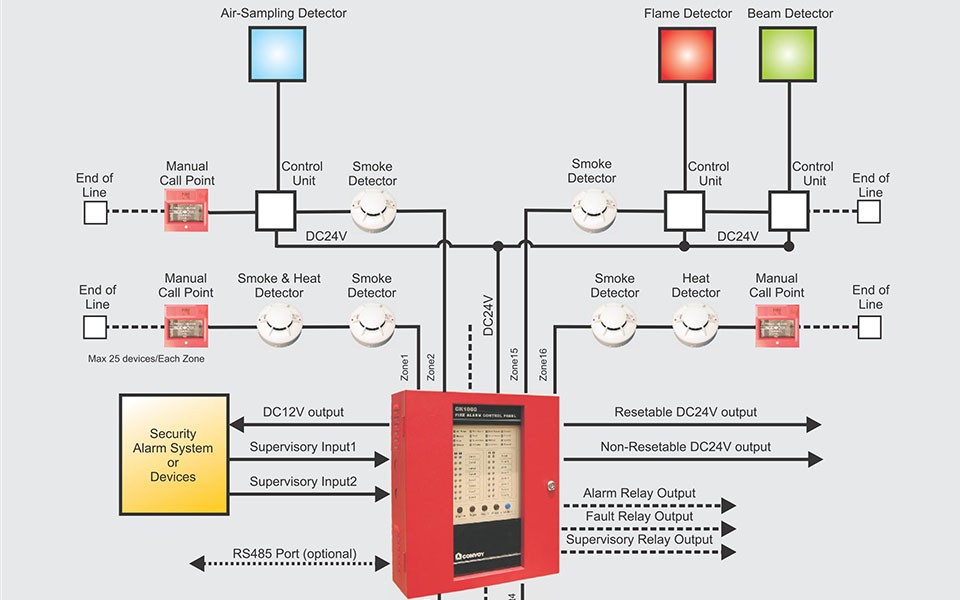

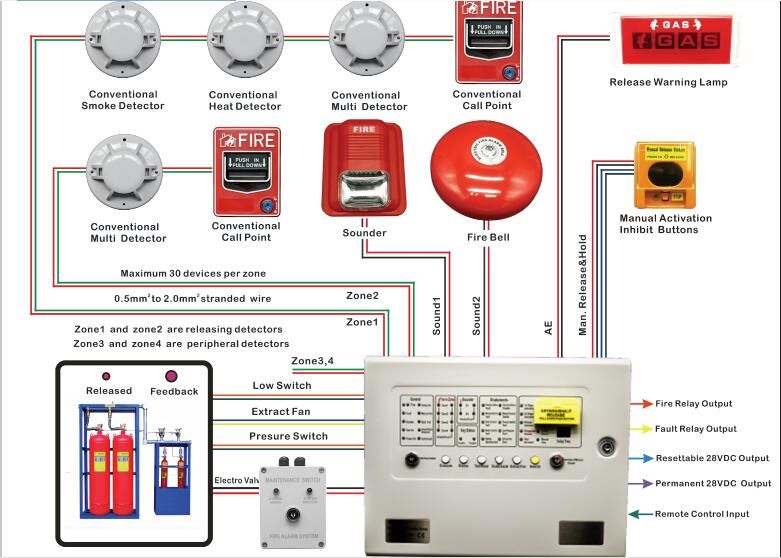

Smoke Alarm Relay Module

Europe based:

Z-Wave Set Z-Wave Smoke detector + Z-Wave Power socket + Z-Wave control hub

Temp Controller

.

- An automatic fire stopping device that puts out fires.

In America, there is a nifty little 'put above hot things fire extinguisher in a can' device called a FireStop, or Auto-Out . It's not as small as it seems, and you'll need to have a big case to put this in.

In Europe, there are only these giant fire stopping balls, these usually work well and quick, but next to impossible to fit into a case. Usually ships from china.

Also both of these devices (ball/can) need direct contact with the flame, since they have an igniter cord/fuse cord, like fireworks have.

.

Lets list fire stopping devices that we have so far:

US based:

Auto-Out

FireStop

BlazeCut

Europe based:

MABO, sold in Europe + How it works

Bonpet

Auto Fire Off Balls

.

edit 6, Bonus Round:

- Improving the electronics of your 3D Printer.

Yeah, i forgot this one, you guys are right.

Cheap electronics on cheap printers will do more harm than good, and these things often fail in the weirdest ways possible. Control boards going up in smoke. Power supplies shorting out or putting voltage on the metal frame of the printer. Cables get intermittent failures causing the weirdest problems that often take quite a bit to find out and fix.

What popular improvements/mods can be done to improve the often cheap hardware?

**side note, almost every 3D Printer manufacturer under 1000 dollar/euro uses cheap electronics. Hotend Clones, or bottom-barrel LED power supplies. Often the very cheap printers have underdimensioned MOSFETS on very old Ramps boards.

Popular improvements are listed here. (in this example, the Anet A8, including the MOSFET mod.

Also consider ATX power supplies. If your electronic skills are up to it, rewire an older ATX PSU to a workbench/3D Printer power supply. These are loads better than the cheap LED power supplies, with dozens of protection circuits hardwired even into the oldest models. ATX be praised.

ATX be praised.

Even cheap ATX PSUs have: Power Good Signal, No-Load Operation, Over-Current Protection, Over Voltage/Under Voltage Protection, Over Power Protection, Over Temperature Protection, Short Circuit Protection, Secondary Internal Power Supply (think 15Watt for RaPi/OctoPrint, LEDs), very low Ripple on the rails, controlled/slow ramp up voltage, Cooling Fans, Physical Off Switches, Haswell+ Generation doesn't need +5V loads anymore for stable +12V, much better power efficiency at lower and higher loads, and ATX PSU manufacturers go through certification hell to get it all validated at every country in the world.

Cheap LED PSUs... may have one or two of those.

These improvements are the quickest and easiest you can make to improve on the fire situation. (be careful with the ATX mod, you'll need some experience with electronics)

.

Lets do something about this, since you all know house fires from 3D Printers go well in the media.

So what can we do about preventing fires ourselves?

This wonderful hobby excludes one little tidbit, a potential to burn your house down and ruin your life.

Since most of our 3D Printers come from Open Source, lets put our heads together to create a fire suppressant/prevention system that perhaps everybody can can build at home, just like our printers.

.

edit 1: found another automatic fire suppressant system called the Fire Knock-Out, sold in Europe. dimensions are 390 x 260 x 220 mm with a price of 130euro, type foam

edit 2: found another automatic fire extinguisher system called the MABO, sold in Europe + How it works dimensions are 278 x 64 x 61 mm with a price of 170 euro, type liquid that releases a fire suppressant gas

edit 3: another Europe based device similar to the MABO, the Bonpet. Price is 140 euros, dimensions are 60mm х 280mm, different colors available, type liquid that releases a fire suppressant gas

edit 4: and another automatic fire suppressant system called the Blaze Cut (thanks aciddj, Ihategeeks), information here seems to be made for larger vehicles or big fuse boxes. can't find any price or dimensions

edit 5: thanks for the mods for stickying this for a while

edit 6: added info about generally improving knows electrical shortcomings on cheap printers and ATX power supplies.

edit 7: added clarification for the ATX power supplies, on why these are generally better than LED PSUs.

edit 8: this can be a good idea as well: a temperature controller plug in the Printer into the temp.controller and set a high temp limit of lets say 60 degrees celsius. mount that probe somewhere in the case. Probe detects high temps from melting plastic parts and switches the printer off. drawback here is it switches on the ac plug again after a while when the temp drops, but heating elements on a 3d Printer do not power on again

edit 9: added the collective suggestions to the two main points above.

Smoke Alarm Shutdown - Graham Jessup

The smoke alarm shutdown in action – that’s a can of “test smoke”

Why the smoke alarms?

Chinese “clone” printers have made 3D printers accessible as hobbyist equipment by cutting costs. The downside of low-cost printers is that the manufacturers cut corners to lower the price point, especially where quality control and safety are concerned. Certain printers have poorer reputations than others (Anet A8 printers seem to be especially fire prone) but even my Creality CR-10S was shipped with a glaring firmware flaw – no thermal runaway protection. The fact of the matter is that all fused filament fabrication printers will have one or two powerful heating elements, and it’s a risk to leave such a device unattended. Thankfully, there are ways to mitigate some of the risk of unattended printing.

Certain printers have poorer reputations than others (Anet A8 printers seem to be especially fire prone) but even my Creality CR-10S was shipped with a glaring firmware flaw – no thermal runaway protection. The fact of the matter is that all fused filament fabrication printers will have one or two powerful heating elements, and it’s a risk to leave such a device unattended. Thankfully, there are ways to mitigate some of the risk of unattended printing.

For my enclosure, I chose to adapt Henry Arnold’s 3D Printer Safety Shutdown (Thingiverse). The basic concept is that when the enclosure detects smoke, it turns the printer off. It also beeps, a lot. Henry Arnold’s design uses an interconnect-style smoke alarm to trigger a relay, cutting power. Arnold’s design is clever because most 3D printer fires are caused by malfunctioning heating systems or poor electrical connections, and removing power to the printer de-energizes those potential fire sources. Additionally, I think the simplicity of the hard-wired smoke alarm relay system gives it a leg up over a “smart” system with wifi switches and wireless smoke alarms. Henry Arnold’s documentation of his system is pretty comprehensive, so I’ll leave most of the details of the system to his write-up and focus on my modifications here.

Henry Arnold’s documentation of his system is pretty comprehensive, so I’ll leave most of the details of the system to his write-up and focus on my modifications here.

Safety

This smoke alarm system won’t stop your printer from burning your house down. The smoke alarm shut down is just another layer of risk mitigation, not a guarantee. If your printer goes up in flames, removing the power from the system won’t make much of a difference if the fire is already self-sustaining. The DIY nature of this safety system means it has no certification, it’s a “better than nothing” type of system.

My “Realistic” Printer Safety Priority list:- Enable Thermal Runaway Protection in your printer’s firmware.

- Enclose your printer with non-flammable materials, remove/replace potential fuel sources (plastic printer frames, filament rolls)

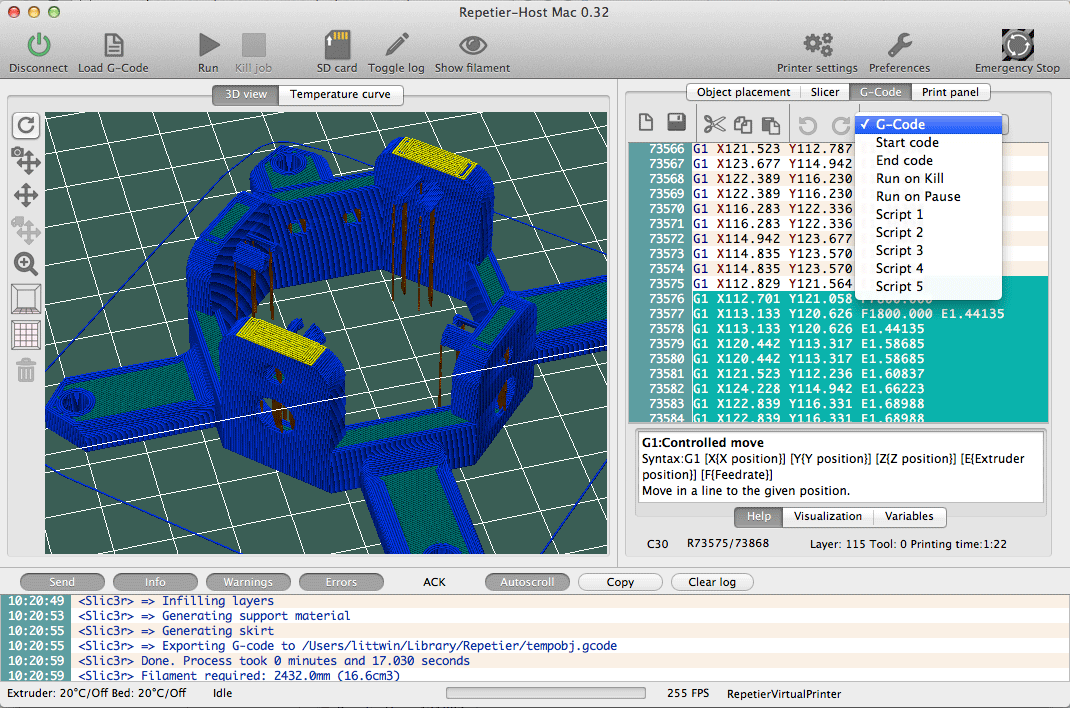

- Monitor your printer remotely (OctoPrint + webcam)

- Smoke Alarm Shutdown

- Automated fire suppression (eg.

engine room fire extinguishers).

engine room fire extinguishers).

Finally, it should be noted that this system uses daisy-chained power strips. Generally, daisy-chained power strips are a no-no, because they allow too many devices to be plugged into a single outlet or extension cord. Too many devices creates too much current draw, and then cords start melting. In this setup, the printer is the only high-power device plugged into the system, the electrical area is covered by the enclosure door, so I’m not concerned. However, if someone is looking to run a space heater and uses your printer’s power strips, you may find the smoke alarms coming in handy.

Smoke Alarm System Function

Smoke alarm shutdown systemThe relay used to shut off printer power has three types of outlets: “Normally On,” “Always On,” and “Normally Off.” I expanded the capacity of the “Normally On” and “Always On” outlets with power strips, labeled in the above diagram.

Electrical panel with labelsFor normal operation, the “Normally On” outlets are used to power the printer and upper and lower vent fans. When the smoke alarms are triggered, the “Normally On” outlets turn off, removing power from the printer and fans. The vent fans are switched with the printer minimize the flow of air to avoid fanning the flames. The “Always On” outlets power the items that I want to continue to function after the smoke alarms are triggered: Lights, smoke alarm power, and the raspberry pi. The “Normally Off” switch supplies the “latching” power to to the relay, keeping the relay in the triggered state until power to the entire system is reset. The relay latch is one of multiple possible inputs to the relay, so an “OR” logic is necessary.

When the smoke alarms are triggered, the “Normally On” outlets turn off, removing power from the printer and fans. The vent fans are switched with the printer minimize the flow of air to avoid fanning the flames. The “Always On” outlets power the items that I want to continue to function after the smoke alarms are triggered: Lights, smoke alarm power, and the raspberry pi. The “Normally Off” switch supplies the “latching” power to to the relay, keeping the relay in the triggered state until power to the entire system is reset. The relay latch is one of multiple possible inputs to the relay, so an “OR” logic is necessary.

PCB and Enclosure

KiCAD PCB SchematicBecause my printer enclosure is designed to isolate the control box from the printer itself, the upper and lower enclosures both need to be monitored with a smoke detector. Henry Arnold’s system uses two diodes soldered together to create the “OR” logic that triggers the relays, but I needed at least three inputs, so I created a simple printed circuit board (PCB) that expands the “OR” gate functions with the convenience of wire terminals. A protoboard would have worked fine for this application, but with the cost per PCB of about $5 each, I “skipped a step” and went straight to the PCB. I used KiCAD to design the PCB. This is the first PCB that I’ve designed and made, and I was happily surprised at the ease of manufacturing (I used OSH Park). On the next revision I would round the corners of the PCB, and maybe skip a couple of fasteners.

A protoboard would have worked fine for this application, but with the cost per PCB of about $5 each, I “skipped a step” and went straight to the PCB. I used KiCAD to design the PCB. This is the first PCB that I’ve designed and made, and I was happily surprised at the ease of manufacturing (I used OSH Park). On the next revision I would round the corners of the PCB, and maybe skip a couple of fasteners.

The component list of the PCB is pretty simple, basically just the diodes and terminal blocks. Here’s the BOM:

- DO41 Diodes – Qty 8 (ex 641-1310-1-ND from Digi-Key)

- Two Position 0.10″ Terminal Block – Qty 1 (ED10561-ND from Digi-Key)

- Eight Position 0.10″ Terminal Block – Qty 2 (ED10566-ND from Digi-Key)

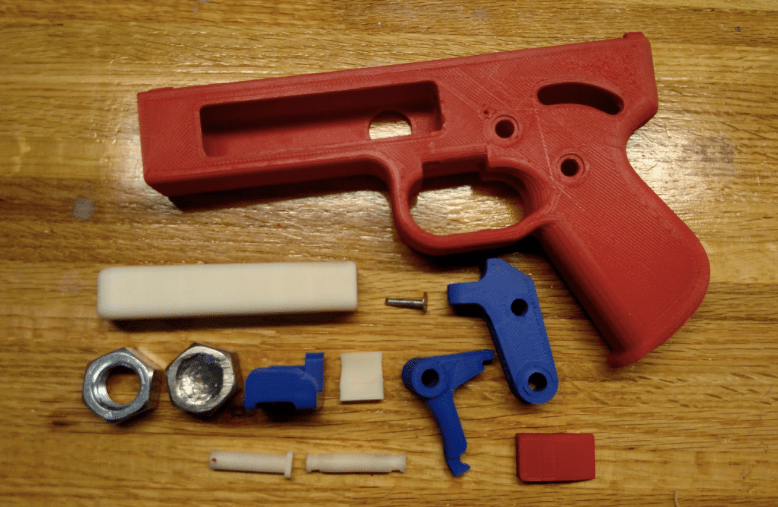

The PCB enclosure was fun to design, this is one of the first practical designs I printed with my 3D printer. The cable tie mounts would be terrible to manufacture traditionally, but I wanted to “cheat” and use the capabilities that are unique to 3D printers. I used M3 heat-set inserts for the enclosure lid fasteners, I like the reliability of machine screws rather than plastic thread-forming screws. The enclosure was modeled in Fusion 360.

The cable tie mounts would be terrible to manufacture traditionally, but I wanted to “cheat” and use the capabilities that are unique to 3D printers. I used M3 heat-set inserts for the enclosure lid fasteners, I like the reliability of machine screws rather than plastic thread-forming screws. The enclosure was modeled in Fusion 360.

You can find the KiCAD file for the PCB and the STL for the PCB enclosure on my Thingiverse Remix of Henry Arnold’s design.

"Or" gate PCB and relay input PCB enclosure with coverSmoke Alarm Mount and Wiring

Upper smoke alarm and mountInterconnect-style smoke alarms are designed to be mounted on the ceiling, and they have a connector on the back of each alarm. That connector is designed to send the 9V alarm signal to the other smoke detectors in the system, allowing all alarms to sound at once if smoke is detected. For the printer shutoff, that 9V signal is used to trigger the relay. In my enclosure, it wasn’t practical to cut a recess behind each detector for the 9V signal wires, so I designed and printed a simple spacer bracket. There isn’t much extra space between the detector and the printer, but if it fits, it fits!

In my enclosure, it wasn’t practical to cut a recess behind each detector for the 9V signal wires, so I designed and printed a simple spacer bracket. There isn’t much extra space between the detector and the printer, but if it fits, it fits!

The printed mounting spacer allows the 9V signal wires to be routed sideways from the base of the smoke alarm. The orange and white wires picture above are the signal wires. I used crimp-style butt splices (Digi-Key) to connect the wires to a two conductor 18 AWG cable (Also from Digi-Key). The jacket of the cable I used is not very flexible, I would consider using a nicer quality cable next time.

Smoke alarm power wiringI removed the battery trays from the smoke alarms and soldered barrel connector pigtails onto the battery leads. I think the smoke alarms would be OK with batteries, but because I was running signal wires regardless, I decided to hard-wire the power as well. When installing this system, I was worried about potential false alarms, and wanted a way to easily disable the smoke alarms. In retrospect, false alarms have not been an issue. The smoke alarms are connected to the 3.3V supply with barrel connectors, I used a barrel connector Y-splitter to split the power (Digi-Key). If I were to do this again, I’d consider just using the AA batteries to save some assembly time.

When installing this system, I was worried about potential false alarms, and wanted a way to easily disable the smoke alarms. In retrospect, false alarms have not been an issue. The smoke alarms are connected to the 3.3V supply with barrel connectors, I used a barrel connector Y-splitter to split the power (Digi-Key). If I were to do this again, I’d consider just using the AA batteries to save some assembly time.

Connectivity and Future Improvements

Raspberry Pi running Octoprint - Printer and Webcam USB cables attachedI use a raspberry pi running OctoPrint to control and monitor my printer. Using a VPN running on my home router, I can access the webcam and control the printer remotely, which is valuable for checking in on long prints. In addition, I use Fabian Schlenz’s Telegram Plugin for OctoPrint that sends printer status updates to the telegram app on my phone. The telegram plugin notifies me whenever there’s an issue with the printer. If the printer shuts off and OctoPrint loses connection, I’ll receive a notification on my phone with an error message and a webcam image of the printing area. If the smoke alarm system has triggered, I’ll at least be notified that the printer has shut down, and theoretically the webcam image could tell the rest of the story. This is an indirect notification system, and in the future I’d like to more directly integrate the raspberry pi with the smoke alarm signal.

If the printer shuts off and OctoPrint loses connection, I’ll receive a notification on my phone with an error message and a webcam image of the printing area. If the smoke alarm system has triggered, I’ll at least be notified that the printer has shut down, and theoretically the webcam image could tell the rest of the story. This is an indirect notification system, and in the future I’d like to more directly integrate the raspberry pi with the smoke alarm signal.

In the future, I’d like to use the Raspberry Pi’s GPIO to do two things: Trigger the shutdown relay, and read the smoke alarm signal directly. The “OR” gate PCB has extra inputs available, and will accept the Pi’s 3.3V logic signal, so triggering the shutdown relay with GPIO shouldn’t be too hard to implement. I see the shutdown ability being useful as a print control “nuclear option,” or if the printer is printing in standalone (SD Card) mode and something’s gone awry. Running the 9V alarm signal logic to the Pi would provide direct feedback of the smoke alarm condition. Direct feedback would be valuable because it would remove any doubt about the cause of a print shutdown, and would allow me to set up a custom “Printer is one fire” alert that would be harder to overlook.

Direct feedback would be valuable because it would remove any doubt about the cause of a print shutdown, and would allow me to set up a custom “Printer is one fire” alert that would be harder to overlook.

3D File Smoke Alarm 3D Model・3D printer design to download・Cults

Vaseline 3D model

13.63 €

CRT TV 3D model

17.04 €

PBR texture

11.36 €

Vintage door handle 3D model

11.36 €

Blood Texture PBR

9.08 €

Teapot 3D model

22.73 €

Ring 3D model

11.36 €

Harmonica 3D model

11. 36 €

36 €

Best 3D Printer Files in Architecture Category

nine0003 Sand castle build with math functionFree

NYC Times Square

Free

Jaen Cathedral

Free

Taj Mahal

Free

Trullo from Alberobello, Puglia, Italy

Free

nine0003 NEW YORK - CITY OF MANHATTAN3.99 €

Color Test Pyramid

Free

Winterfell tree Game of thrones

Free

Bestsellers in the category Architecture

Orthanc Tower - Isengard - Lord of the Rings 3D print model

1 €

nine0003 Garage equipment and furniture1 €

Space Launch System (SLS): NASA Artemis I Lunar Rocket with Platform.

STL-OBJ file for 3D printer

STL-OBJ file for 3D printer 2.95 €

[Japanese capsule toy car] EduColon (rich design set)

4.67 €

EIFFEL TOWER - PARIS

4.99 €

nine0003 GRAIN HOPPER WITH SMOOTH WALLS1,75 €

NEW YORK - CITY OF MANHATTAN

3.99 €

WEDNESDAY Addams, Merlina

11.32 €

Tower of Terror Disneyland Paris

3.50 €

1/64 Generic Showroom

1 €

nine0003 Cessna 172 Skyhawk 1:722 €

1-75 scale furniture Architecture

0,73 €

House Toretto v2

4. 98 €

98 €

Cinderella Castle

5 €

1-100th scale furniture Architecture

0,73 €

nine0003 Seletti - Bird Lamp Looking - Lampara de pajaro9.49 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE YOUR FRIENDS: * Invite your friends, discover the platform and the great 3D files shared by the community! nine0006

Potential hazards of the 3D printer. Part 1

In early February, a great tragedy occurred in the United States - a young family and pets died in their house under unclear circumstances. And the first suspect was a 3D printer. Allegedly, carbon monoxide released during 3D printing could cause poisoning for people and their pets. While the police cannot reliably establish the source of the gas leak and the causes of the tragedy, however, we decided to remind once again what potential dangers lie in wait for the owners of home printing devices and how to protect yourself and your loved ones from their impact. nine0006

1. Getting burned

It must be remembered that the principle of operation of the FDM printer is based on the melting of a plastic filament. Thus, the heating elements of the device present a great danger when touched. As a rule, the temperature of the extruder of a working device can vary from 170 to 300ºС. The specific figure depends on the type of material and appearance of the product you choose.

As a rule, the temperature of the extruder of a working device can vary from 170 to 300ºС. The specific figure depends on the type of material and appearance of the product you choose.

The melting temperature of the filament used in printers is sufficient to cause burns. For ABS plastic, it is about 210-270ºС, for PLA - 180-190ºС. This is enough to get painful damage in contact with both the material itself and the heating elements of the printer: the table and the extruder nozzle.

For PLA printing, this risk is lower because a heating bed is not needed, but if you are working with ABS, be extremely careful not to touch the hot elements. The risk of injury is directly proportional to the area of the heating surfaces. Remember that the temperature should be checked only by the readings of the sensors that are displayed in the printing program or on the display of the device, and not by hand or improvised means. nine0006

In situations where direct contact with hot surfaces is required, such as when cleaning the nozzle, special tools and personal protective equipment must be used, and extreme care and discretion must be exercised.

Also, keep children and pets away from the printer and never leave them alone with the printer. It is always easier to prevent danger than to deal with its consequences. nine0006

2. Electrical injury

Like any mains powered device, a 3D printer can cause electrical injury to a person. Naturally, with proper operation of the device this will not happen. Even in the event of a ground fault, the voltage in the exposed parts of the 3D printer will usually not exceed 12-24 V, which is considered safe and will only cause a slight shock.

However, when disassembling the device for repair, replacement of a part, or removal of plastic, the possibility of receiving a 220 V electric shock increases many times over. nine0006

It must be remembered that any electrical appliance must be disconnected from the mains before servicing. Some printers have an external rather than an internal transformer, but this should not be a reason to forget about safety and leave the plug in the outlet.

Not to mention the risk of short circuits. The probability of such an event in a 3D printer, as in any other household appliance, is small. But if you are assembling a set according to the drawings, be careful when connecting the wires. In the best case, the printer simply will not turn on or the fuse will burn out, but in the worst case, everything can end in an electrical injury or fire. nine0006

Evgenia Kurochkina, Development Director at ZENIT 3D, comments:

“There is no more danger from using a 3D printer than from any other electrical device used in everyday life or in professional activities. But, nevertheless, they are presented on the market as 3D printers with a high degree of security and, let's say, ordinary ones. What you should pay attention to when choosing a 3D printer using FDM technology and when working with it.

Such devices, as a rule, have two heating elements: an extruder and a heated platform or simply a table. The temperature of these nodes can reach up to 310ºС (extruder) and 110ºС at the table. To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment. nine0006

The temperature of these nodes can reach up to 310ºС (extruder) and 110ºС at the table. To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment. nine0006

Many manufacturers save money at the expense of safety. One of the options for such savings is to "power" the heating table directly from 220 V. In our opinion, this is wrong and unsafe. For example, when working with a 3D printer, many people use a spatula to remove a part, it is quite sharp, and any inaccurate action with a spatula when the table is on can lead to a short circuit and a 220 V current shock. Realizing this, we went the other way, and instead of 220 All ZENIT 3D printers supply only 24V to the table.

The extruder is the hottest part and must be handled with the utmost care. To remove the remaining plastic from the extruder, it is imperative to use a special tool.

To remove the remaining plastic from the extruder, it is imperative to use a special tool.

As for the electrical part, there is also something to look for when choosing a 3D printer. All wires and connections must be insulated, and best of all, hidden in the printer case. Any open connections, contacts, wires, boards in the event of an accidental short circuit can at least damage the equipment, at worst - harm health

Our company, developing 3D printers, considers the safety of its devices to be one of the important tasks. In particular, when developing the new ZENIT 3D model, which will be launched on the market in 2017, we paid a lot of attention to the safety aspect.”

3. Fire hazard

While we're on the subject of fires, let's talk about fire hazards that are not related to electricity. In point 1, we already wrote about high temperatures of heating surfaces in the context of burns, but an open printer case can also ignite materials lying around the printer. Paper and flammable liquids that have a low flash point should be kept away from a working printer, especially if it is an open type. nine0006

Paper and flammable liquids that have a low flash point should be kept away from a working printer, especially if it is an open type. nine0006

Another problem could be overheating of the extruder. For example, the ignition temperature of PLA plastic is about 388ºC. Purely theoretically, it may happen that a broken printer temperature sensor will cause spontaneous combustion of the material. If your printer also has a plywood or plastic case, this automatically turns it into fuel for the resulting fire.

For this reason, it is recommended that you install a fire alarm in areas where you print, and keep a fire extinguisher handy at all times. Also, you can not leave a working device alone for a long time. It is clear that it is impossible to constantly monitor the printing for several hours, but it is better to monitor the operation of the printer from time to time. nine0006

A compromise would be to purchase a compact camera installed in the print room and broadcast to a smartphone or tablet.

4. Moving parts

3D printers have a lot of moving parts. These are motors, pulleys, threaded rods, carriage and fans. All this can easily grab you by the protruding part of the body and cause a lot of trouble. Avoid contact with moving parts of the printer while it is in operation! Do not reach in or attempt to correct a sliding object or push the carriage by hand. nine0006

If your 3D printer is an open type, wear tight-fitting clothing and keep an eye on your hair to minimize the risk of cloth and hair getting caught in moving parts. It is also worth worrying about the placement of the spool with consumables in advance, so that in the future the thread does not catch on foreign objects and knock the printer to the floor.

If the device does grab your clothing or hair, turn off the printer immediately and manually move the carriage until the pinched part of your body is completely free. nine0006

Irina Solomnikova, Commercial Director of IMPRINTA comments:

“If we talk about the possibility of carbon monoxide poisoning, then yes, such tragedies as in the USA are possible and, unfortunately, common. If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc. nine0006

If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc. nine0006

But it is definitely worth remembering that when using a 3D printer, you should follow safety precautions and use it for its intended purpose. Misuse of any appliance, such as a game console, microwave oven, telephone, iron, etc., can lead to unpleasant consequences.

The rules for using the 3D printer are very simple:

- The 3D printer must be installed in a ventilated area.

- The 3D printer must be placed on a level, stable surface. nine0159

- Before connecting to the network, it is worth checking the reliability of the power supply.

- Some parts of the printer get very hot. Do not touch them while the printer is in operation to avoid burns.

- The printer has moving parts. During the operation of the 3D printer, it is necessary to avoid getting foreign objects into the moving mechanisms of the printer, this can lead to injury and damage to the equipment.

- Do not place anything on the 3D printer. nine0159

- Please note that some media may be toxic. When choosing a material, you must carefully read the description, temperature conditions and use only trusted manufacturers of printing materials.

- Do not leave young children unsupervised while the printer is in operation.

- Do not leave a working printer when you leave home.

By following these simple rules, as well as following the instructions, the use of a 3D printer will be safe both in the office and at home. nine0006

In conclusion, we add that a 3D printer, like any device, can harm a person.