3D printed dog bone

3d Printed Dog Bone - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 146 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

▷ dog bone stl file 3d models 【 STLFinder 】

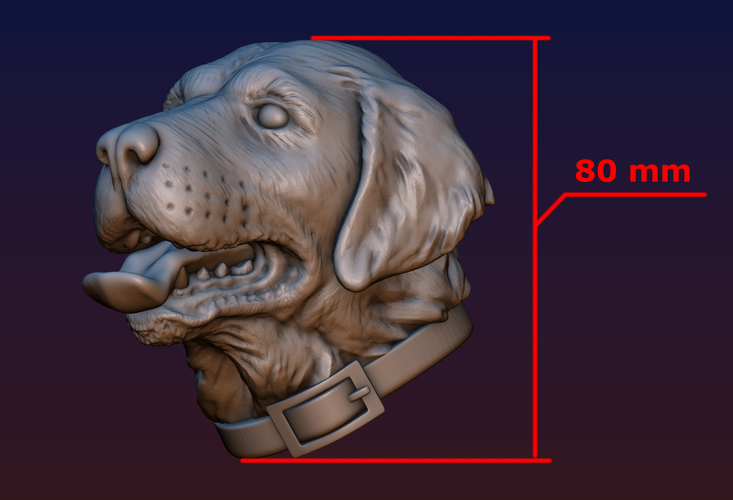

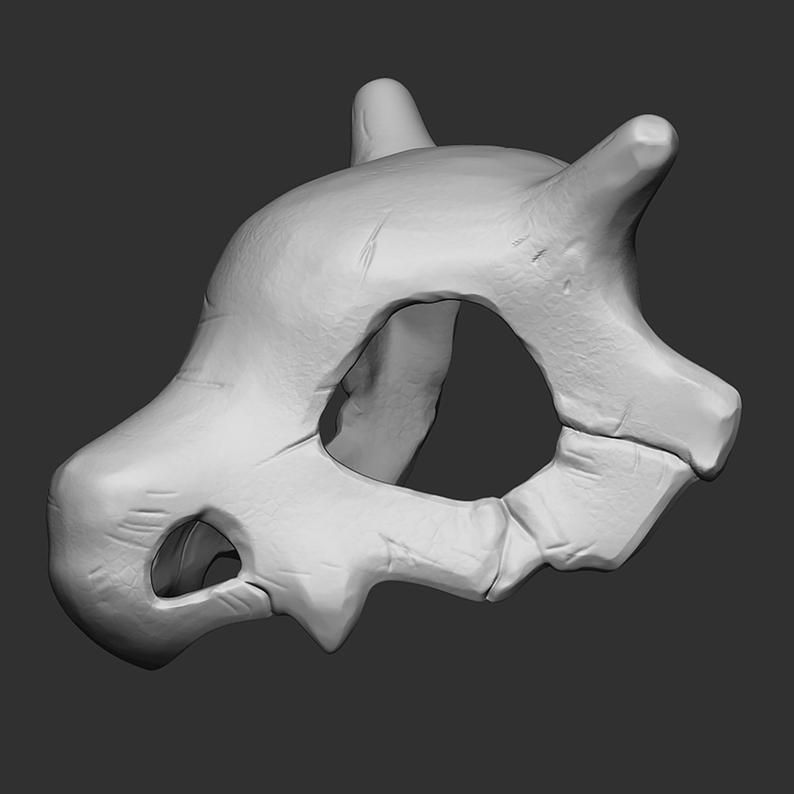

Dog Bone

thingiverse

Dog bone

Dog Bone

thingiverse

Just a Simple Dog Bone

Dog Bone

thingiverse

Emily designed a dog bone for her stuffed animal.

Dog Bone

grabcad

A Hi Def 3d scan of my dogs chewing bone. ...About 17" Long

dog bone

myminifactory

A sweet looking dog model with a bone, to offer to a friend or to print as a toy.

Bone dog

cults3d

CAD Draughtsman FREELANCER Dog collar, name tag for safety. ... Contact: [email protected] CUSTOM JOBS STL file Ready to print

Dog Bone

3docean

Dog Bone 3d model in cartoon style. Preview images are rendered with Vray. ... Formats .max 2014 .obj .fbx No Texture No UVs 392 poly 370 vert In subdivision Level 0

Preview images are rendered with Vray. ... Formats .max 2014 .obj .fbx No Texture No UVs 392 poly 370 vert In subdivision Level 0

Dog bone

thingiverse

This is a dog bone, for dog toy. ...Print Settings Printer: A8 Anet Rafts: Doesn't Matter ...

Dog Bone

thingiverse

pet bone tag

Dog Bone

thingiverse

Bog Bone (Jessica)

Dog Ranger Spy Helmet Stl mask File 3D print model

cgtrader

. .. It is meant to be little over sized so you can put soft material inside to be comfortable for your dog . It can fit many dogs, if the sizing is made correctly . It works very well with glasses . You can put a camera on top secured with some glue.

.. It is meant to be little over sized so you can put soft material inside to be comfortable for your dog . It can fit many dogs, if the sizing is made correctly . It works very well with glasses . You can put a camera on top secured with some glue.

Dog Bone Dog Tag

thingiverse

This is a simple blank dog tag Instructions

STL file

prusaprinters

Be the first one on your block to prank people with the 3d printing equivalent of a rickroll! Print instructionsUnassociated tags: can you make an STL?, Do you have the STL?, Is there an STL?, STL file Category: Other Summary Has someone showed you...

Dog Tag Bone

grabcad

dog bone

STL file

thingiverse

Has someone showed you an insanely complicated 4000 hour plus IRL sculpture and asked if you have an STL file of it? How about classical architecture that took 80 years to build? Or someone elses patented invention? Well now you can give them the STL. ..

..

Bone dog cookie cutter

cults3d

Bone dog cookie cutter

Dog Bowl bone shape

thingiverse

Dog Bowl Bone shape

Dog Bone Cookie Cutter

thingiverse

Dog Bone Cookie Cutter

Dog Bone Cookie Cutter

thingiverse

Dog Bone cookie cutter

3D Dog Bone

grabcad

Maya 3D Dog bone, pretty sweet.![]()

Low Poly Dog bone

thingiverse

Low poly dog bone for dogs to play with.

Dog Tag Bone

thingiverse

This Is a Dog Bone Tag for your dogs collar

Dog Bone Cookie Cutter

thingiverse

A dog bone shaped cookie cutter for making dog treats

dog tag bone

thingiverse

. .. INSTRUCTIONS download openSCAD (http://www.openscad.org/downloads.html) download dog_bone_v2.scad (https://www.thingiverse.com/download:5129451) open dog_bone_v2.scad with openSCAD modify options --// MODIFY HERE !!! ...--line1_text = "CASEY"; //

.. INSTRUCTIONS download openSCAD (http://www.openscad.org/downloads.html) download dog_bone_v2.scad (https://www.thingiverse.com/download:5129451) open dog_bone_v2.scad with openSCAD modify options --// MODIFY HERE !!! ...--line1_text = "CASEY"; //

Dog bone fidget spinner

thingiverse

Dog bone fidget spinner. ...If you want the cap with two colors you'll need to pause it and swap colors around the 5th or 6th layer. Edit: changed bone stl to v2, made the circles smoother

Dog Bone Tag

thingiverse

Instructions Original File size is: 50 mm x 25mm x 5mm And I model it in Rhinoceros for Mac (btw it's free) 1) If you only download and print the . stl file, you can be creative and just print a label and put it on the dog tag. 2) You can download...

stl file, you can be creative and just print a label and put it on the dog tag. 2) You can download...

Dog Bone Cookie Cutter

thingiverse

Dog bone shaped cookie cutter for homemade doggie treats.

Dog Bone Key Holder

thingiverse

Dog Bone Key ring holder 1 with no words on it 1 with Bone Voyage added

Dog Bone 3D model

cgtrader

Dog Bone 3d model in cartoon style. Preview images are rendered with Vray. ... Formats .max 2014 .obj .fbx .stl No Texture No UVs 392 poly 370 vert In subdivision Level 0

Formats .max 2014 .obj .fbx .stl No Texture No UVs 392 poly 370 vert In subdivision Level 0

Dog bone fidget spinner

pinshape

... pause it and swap colors around the 5th or 6th layer. Edit: changed bone stl to v2, made the circles smoother Print Settings Printer: Monoprice Maker Select v2.1 Rafts: No Supports: No Resolution: .16 Infill: 50 Notes: May need to enlarge a percent.

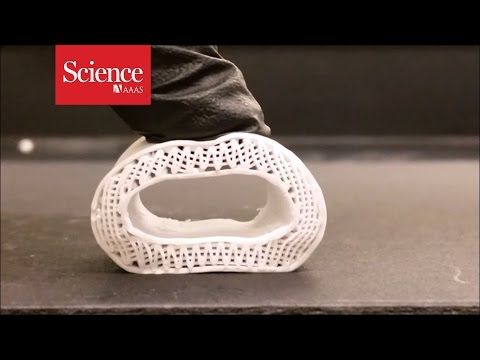

How bones, vessels and organs are printed using 3D printers / Habr

In the early days of rapid prototyping, it was widely believed that 3D printing would transform all manufacturing, spurring a consumer revolution that would bring a printer into every home. This has not yet happened, however, as has happened with many of the latest technologies, rapid prototyping has found its application in a completely different area - in medicine.

Article from the Gizmodo website.

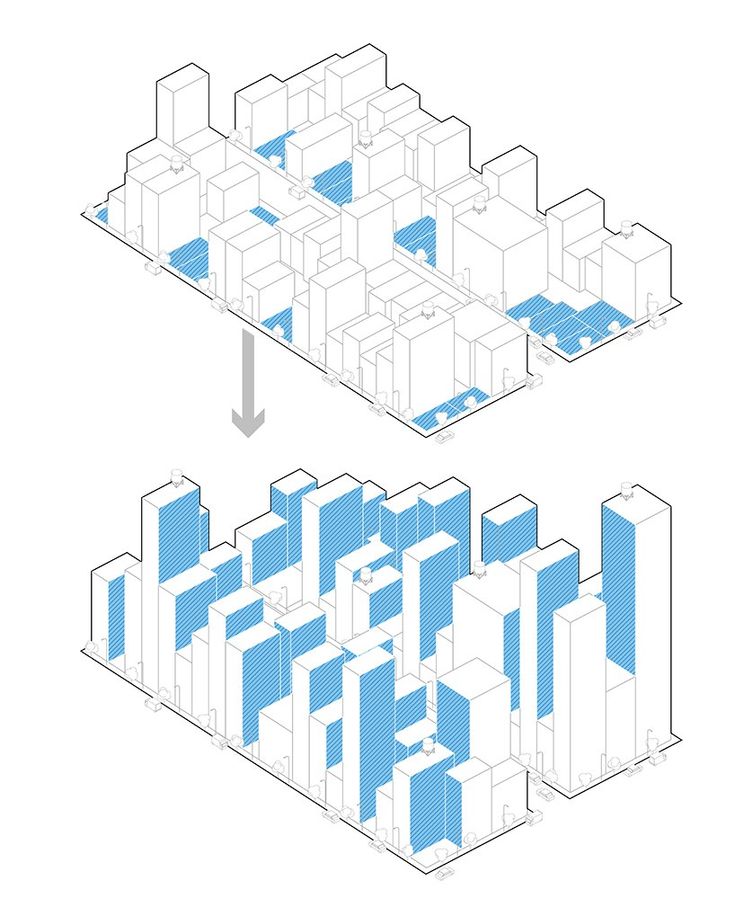

The research and projects below are some of the most interesting examples of the use of bioprinting and the use of computer-controlled machines to assemble biological matter using organic inks and ultra-strong thermoplastics. The range of application of bioprinting is very wide - from the reconstruction of the main parts of the human skull to the printing of scaffolds - scaffolds on which stem cells can develop into new bones. Read the details below.

Skulls

Osteofab is a product of the company

Oxford Performance Materials . Initially, OPM entered the market by selling in its raw form a high-performance polymer often used in the manufacture of medical implants - a thermoplastic called polyetherketone ketone (PEKK), but over the past few years the company has become the first to master the use of this material, primarily in additive manufacturing . So, in February 2013, an American patient

So, in February 2013, an American patient

FDA approved 3D skull implant. The casting and printing was carefully crafted to match the unique geometry of the patient's skull, of which 75% is now an implant.

Leather

The main problem with creating new skin using printing is the difficulty of recreating a specific shade from the entire possible spectrum. Given that our skin is unique, thin and subject to change, it is quite difficult to create an exact copy of it. There is a huge amount of interesting research on this topic, the essence of which cannot be put into a short story.

However, here are two of the most interesting: Scientist James Yoo of Wyke Forest University, with a grant funded by the US Department of Defense, is working on a machine that can print skin directly on burn victims. Another study is being carried out by scientists at the University of Liverpool, who are using carefully calibrated 3D scanners to obtain skin samples containing all of its finest nuances, which will allow more realistic implants to be printed later.![]()

The research is still ongoing and the team plans to create a "skin sample database" of scanned samples that can be accessed from remote hospitals that do not have the cameras needed to scan a particular patient's skin. [ Gizmodo ; PhysOrg ]

Noses and ears

The creation of prosthetic ears, noses and chins is often a painful, expensive and time-consuming process for both the patient and the doctor himself. British industrial designer Tom Fripp has worked with scientists at the University of Sheffield over the past 5 years to develop a cheaper and easier-to-make 3D printed facial prosthesis. The process of creating such a prosthesis includes 3D scanning the patient's face (which is much less painful than casting it), modeling the replacement part and printing it, which uses pigment, starch and medical silicone.

These prostheses have the added bonus that when they wear out (which they eventually will), they can be reprinted at a very low financial cost. [

[

]

Prosthetic eyes

Fripp and a team at the University of Sheffield published the results of testing a similar process for making prosthetic eyes. Prosthetic eyes are expensive and, because they are hand-painted, can take months to make. Fripp Designs printers can produce 150 prosthetic eyes in an hour, and details such as iris color, size and number of blood vessels can be easily changed to suit the needs of the patient. [

PhysOrg]

Functional implants

As electronic devices – from drones to medical implants – get smaller, scientists are struggling to create batteries for them that are small enough, but with those could provide the necessary charge. However, a team of engineers from Harvard University is already printing microbatteries the size of a grain of sand using a 3D printer. Here's what the press release says:

“…researchers created an anode ink using nanoparticles of one lithium oxide compound, as well as a cathode ink made from nanoparticles of another kind of this compound. The printer applied ink to the teeth of two gold combs, thus creating a tightly connected structure of anodes and cathodes. The scientists then placed the electrodes in a tiny container and filled it with an electrolyte solution to make a battery."

The printer applied ink to the teeth of two gold combs, thus creating a tightly connected structure of anodes and cathodes. The scientists then placed the electrodes in a tiny container and filled it with an electrolyte solution to make a battery."

Over time, they will be able to charge medical implants, which are held back due to charging problems. [ Harvard ]

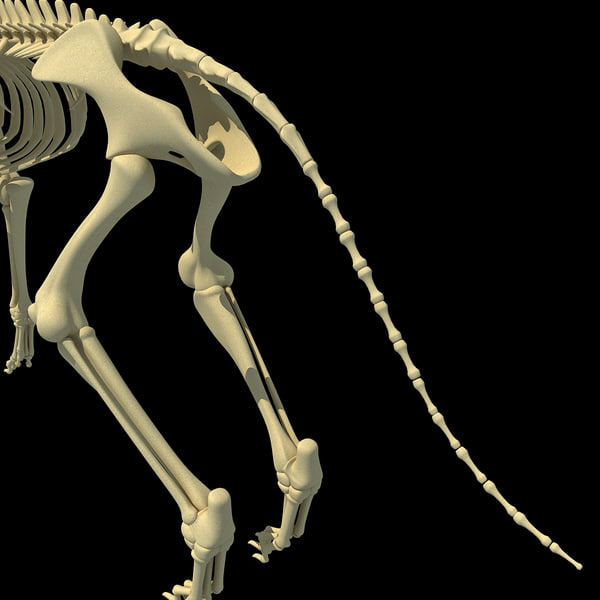

Bones

3D printed implants such as the jaw have been around for several years. However, a small group of researchers is conducting an experiment whose goal is to print real bones. For example, scientist Kevin Scheiksheff of the University of Nottingham invented a bioprinter that creates matrices from polylactic acid and gelatin alginate, which are then coated with stem cells.

The implanted matrices will gradually dissolve and be replaced by new growing bone: it will take approximately three months for the bone to completely transform. [ Forbes ]

Blood vessels and cells

We can already print

organs , but there is a serious problem in creating a functioning circulatory system.

German scientist Günther Tovar, head of the Fraunhofer Institute for Interfacial Engineering and Biotechnology, is working on a project called BioRap. His task is to use a 3D printer to print blood vessels, which uses a mixture of synthetic polymers and biomolecules. The printed circulatory systems are being tested on animals - they are not yet ready for introduction into the human body. However, they will eventually make organ transplants possible. [ Fraunhofer Institute ]

How do you see the future of 3D printing with living and substitute artificial materials for use in the human body? Will we soon be able to grow and replace full-fledged organs, such as the liver? Share your opinion in the comments.

How 3D printing is used in domestic medicine: successful examples and developments

How do additive technologies help doctors and hospitals work? For what areas are 3D printing technologies used in our country? Consider the example of successful cases of their use in Russian medicine.

Application of 3D printing in world practice

For the first time, additive technologies in medicine were officially used in 1999, when employees of the American Wake Forest Institute of Regenerative Medicine implanted an organ made using computed tomography and a 3D printer into a human.

Now 3D printing in medicine is a rather extensive list of directions and possibilities. Among them are:

- creation of implants;

- bone printing;

- modeling of human internal organs;

- creation of medical instruments for doctors.

3D printing in medicine makes it possible to model and create dental implants, prostheses, and organ prototypes with high accuracy. Also, 3D printing helps already working specialists and doctors to study and improve their skills more effectively, practice and make accurate plans for surgical operations.

With the advent of new, more and more advanced printing devices and the expansion of the list of materials, additive technologies in medicine are developing more and more rapidly. The most active 3D printing is used in the USA.

The most active 3D printing is used in the USA.

For example, in 2019, a 3D-printed finger bone was transplanted to a Florida patient for the first time. And University of Kentucky radiology and cardiology professor Michael Winkler has created a 3D printed model of the heart that doctors can work with. Such organ prototypes help surgeons plan operations more accurately and increase the chances of a patient's quick recovery.

How are medical 3D technologies developing in Russia?

There are a number of successful companies in Russia that produce devices and materials for 3D printing, develop additive technologies in various industries (among them are PICASO 3D, Imprinta, Anisoprint, Tsvetnoy Mir and many others). Domestic medicine has also achieved considerable success in terms of the use of 3D technologies.

For example, back in 2016 in Nizhny Novgorod, specialists from the Federal State Budgetary Institution “PFMIC” of the Ministry of Health of Russia performed two successful surgical interventions, during which they implanted prostheses for the hip joints printed on a 3D printer.

Since 2015, the hospital at the St. Petersburg State Pediatric Medical University has been carrying out heart surgeries, which are planned on 3D printed organ prototypes. An important characteristic of such objects is that they are modeled taking into account all the anatomical features of a person and help surgeons perform the necessary procedures more quickly and accurately. In the treatment of heart defects, this reduces the time of the operation and reduces the risk of complications.

More information about how additive technologies are used in modern Russian medicine can be found in the report of Roman Gorbatov, head of the PIMU Laboratory of Additive Technologies, who will speak at the seventh 3D Print Expo on October 4th.

Russian "bone cement" for the treatment of fractures

Scientists from around the world are working on the invention of the optimal material for 3D printing of bones. So, researchers from the US Northwestern University in 2016 came up with an elastic and at the same time durable material for this. Russian specialists have developed a fabric that can become an alternative to titanium implants.

Russian specialists have developed a fabric that can become an alternative to titanium implants.

Researchers at the National Nuclear Research University have created a biocompatible material for printing bones. It is based on the composition of animal bones, so it is not rejected when implanted. The material is quite plastic, but quickly hardens, and then gradually dissolves: the body manages to heal the damage quickly and without side inflammatory processes.

This significantly speeds up the treatment process, reduces the risk of complications and eliminates the need for a second operation, as with titanium implants, which must be removed after a while.

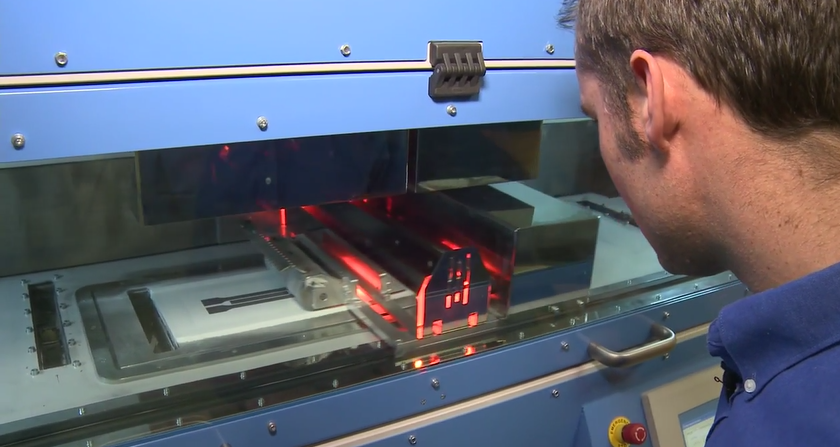

This technology is implemented as follows: biocement is loaded into a 3D printer, and the damaged bone is scanned. Based on the information received, a three-dimensional model of the fragment to be printed is designed. The implant is made according to an exact design from bone cement loaded into the printer, and the material solidifies right during manufacturing, becoming strong and hard.

Prospects for 3D printing technologies in Russian medicine

Rusatom – Additive Technologies, which is the main industry integrator uniting several enterprises, specializes in the development of the additive direction in Russia. In 2020, RusAT plans to start producing 3D printed medical implants. Aleksey Dub, CEO of the company, claims that, in addition, the corresponding software will be created.

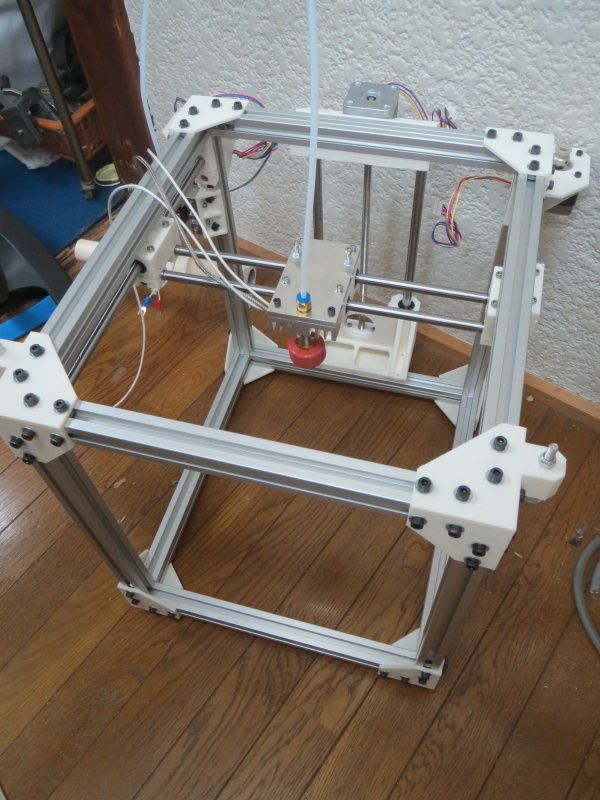

The project is currently being developed at the State Scientific Center of the Russian Federation TsNIITMASH, one of the institutes of Rosatom. The final product is an SLM printer with a three-axis optical system that will print objects using metal powder smelting technology. According to representatives of Rosatom, the printed products are anatomically accurate and ready to use. It is important that the objects are tested in the relevant authorities and are officially suitable for use.

With this SLM printing device, medical professionals can quickly create individual implants for any person (based on the data of his tomography and other studies).