3D print slicer cura

Powerful, easy-to-use 3D printing software

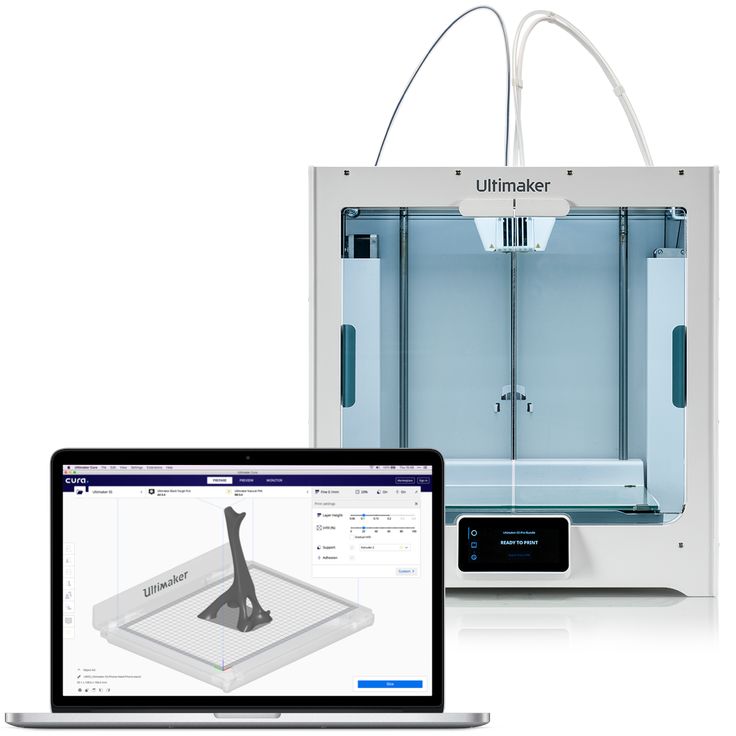

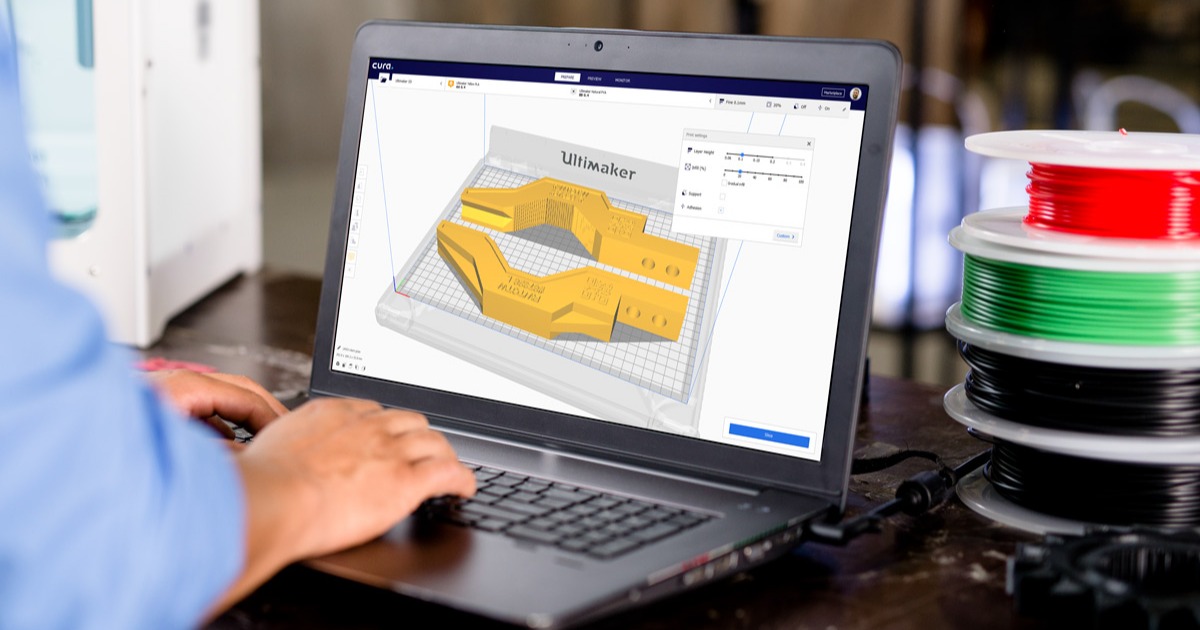

Trusted by millions of users, Ultimaker Cura is the world’s most popular 3D printing software. Prepare prints with a few clicks, integrate with CAD software for an easier workflow, or dive into custom settings for in-depth control.

Slicing features

At the heart of Ultimaker Cura is its powerful, open-source slicing engine, built through years of expert in-house development and user contributions.

Intent profiles print specific applications at the click of a button

Recommended profiles tested for thousands of hours ensure reliable results

‘Custom mode’ gives over 400 settings for granular control

Regular updates constantly improve features and printing experience

Integrated workflow

If you own a 3D printer, software matters. Get the most from your printer with software designed to suit your workflow.

Seamless integration with all Ultimaker products

CAD plugin integration with SolidWorks, Siemens NX, Autodesk Inventor, and more

Compatible file types: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

Easy to use

Manufacturing doesn’t need to be complicated. We design our software so anyone can use it – both experienced or rookie 3D printer users.

Prepare your 3D model for print in minutes with recommended settings

Simply choose speed and quality settings, and you can start printing

Ultimaker Cura is free and open source software

Ultimaker Marketplace

Being open and collaborating is in our DNA. Now we bring this to the professional 3D printing market with the Ultimaker Marketplace.

Download material profiles from leading brands for your application

Avoid manual setup when using third-party materials

Download useful plugins to customize the print preparation experience, star-rated by our community

An Ultimaker Cura experience that keeps your infrastructure rock-solid

Ultimaker Cura Enterprise delivers stability and security with features that are tailor-made for businesses.

Utimaker Cura Enterprise can be deployed, configured, and managed with cross-platform systems distribution

Ultimaker Cura Enterprise receives two updates a year.

These are thoroughly tested by our community and ensure the most stable desktop application. We support updates for 12 months after release (including security patches and bug fixes)

These are thoroughly tested by our community and ensure the most stable desktop application. We support updates for 12 months after release (including security patches and bug fixes)Each release of Ultimaker Cura Enterprise is independently scanned, tested, and analyzed for vulnerabilities. We publish a summary of that report and we commit to continuously improving security

Backup & sync your materials & plugins

Save projects to the Digital Library

Access 3D printing e-learning courses

Join a community of 40,000+ active users

3D printers that simply work

Our award-winning 3D printers are robust, reliable, and easy to use. They deliver quality parts time and again. Designed and tested to run 24/7, they allow you to achieve the results you need more quickly and easily.

Learn about our 3D printers

Software ready for Industry 4.0

Trusted by millions of users across 14 languages, Ultimaker Cura slices your model and integrates with any workflow through Marketplace plugins. Then scale production and digital distribution with Ultimaker Digital Factory.

Then scale production and digital distribution with Ultimaker Digital Factory.

Material choice like never before

Ultimaker offers the widest material choice on the market. Through our Material Alliance, choose the perfect filament for your application – from advanced polymers to carbon fiber composites.

Learn about our materials

Support dedicated to your success

Wherever you are in the world, Ultimaker support is close by. Our global network of service partners offer professional installation, training, and maintenance in your language and time zone.

Learn about our support

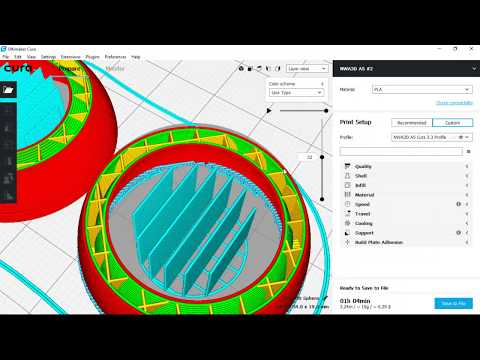

Easier collaboration and moderation with Ultimaker Cura 5.2!

Mariska Maas18 October 2022

News

The stable release of Ultimaker Cura 5.2 has arrived! In this release, there are a number of collaboration improvements for teams and classrooms using multiple Ultimaker printers.

Additionally, three new settings have been introduced that allow you to tune and improve your initial layer flow, allowing you to get better first-layer adhesion and reduce elephant’s foot.

We have also made it easier than ever to build and run Ultimaker Cura from source. Improvements to the way that Ultimaker Cura is built, and the associated documentation, will help open-source members of the community to contribute to the future of Ultimaker Cura more easily.

Abstract printer types allow you to match the printer you want to use, with the settings you’ve selected

Ultimaker 3D printers which are remotely connected to Ultimaker Cura can now be accessed using a new workflow. When working with multiple Ultimaker 3D printer, they are now automatically bundled by printer type.

You can select this abstract printer type when you start slicing your part. If you preferred the old workflow, that is still available. It’s now possible to see the loaded materials and print cores of all printers available to you via the Ultimaker Digital Factory, without selecting each individual printer. When you’ve finished finding the right print settings for your part, you are shown which printers are able to print that part for you. It is also possible to print the same print job on multiple printers without needing to switch between printers.

When you’ve finished finding the right print settings for your part, you are shown which printers are able to print that part for you. It is also possible to print the same print job on multiple printers without needing to switch between printers.

Your connected Ultimaker printers are now bundled in Abstract Printer Types for easier navigation

Print approval when using roles in Ultimaker Digital Factory

Organizations with a large number of users gain access to new moderation tools in Ultimaker Cura 5.2. When using an Ultimaker Professional, Excellence, or Education subscription, you can now assign ‘Guest’ roles. Colleagues or students in a Guest role can still prepare print jobs in Ultimaker Cura and send them to the printers via the Ultimaker Digital Factory like normal. However, print jobs sent using the Guest role will not start immediately, but will instead require approval from a user with the 'Member' or 'Admin' roles.

Print job approval helps organizations using Ultimaker Digital Factory with lots of users control what is printed, and when. Guests can attach notes to each print job which the moderator can use to determine if a print should be prioritized. Guests only have the rights to interact with their own print jobs and cannot interfere with other printers or print jobs.

Guests can attach notes to each print job which the moderator can use to determine if a print should be prioritized. Guests only have the rights to interact with their own print jobs and cannot interfere with other printers or print jobs.

Learn more about the available roles in an organization here.

Print jobs sent by users in a Guest role need approval before they are picked up by a printer. An approver can download the file in the Ultimaker Digital Factory.

If you sent a print job in a “Guest” role it needs to be approved in the Ultimaker Digital Factory before it is printed.

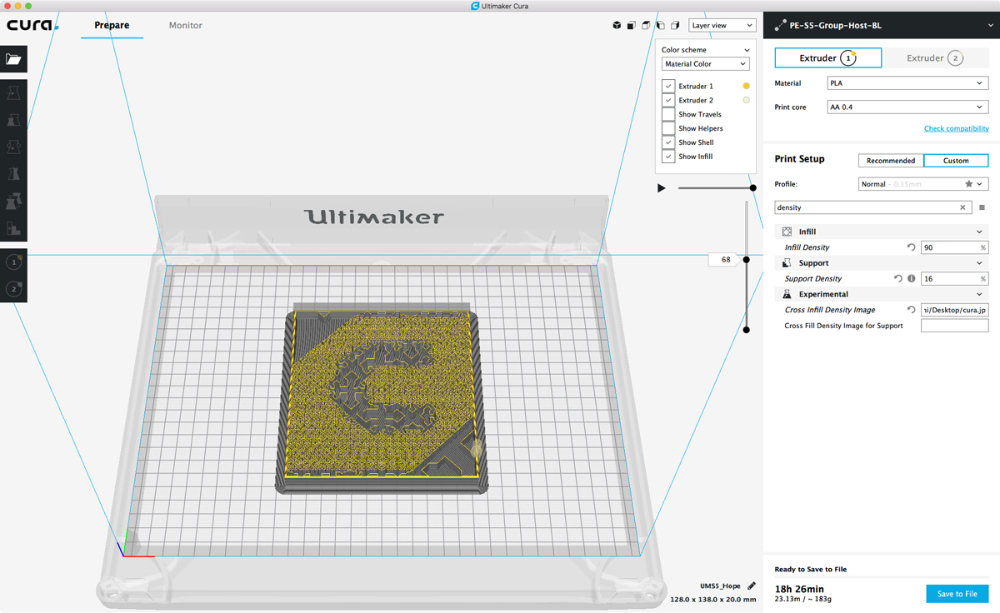

Better control over initial layer flow

We have introduced three new settings that will help you tune your initial layer. These are appropriate for when you are not able to use a brim or when using a flexible build plate that does not require a brim. These settings can be used to tune your first-layer adhesion and should enable you to decrease or eliminate elephant’s foot. The three new settings are:

Initial Layer Outer Wall Flow

Initial Layer Inner Wall Flow

Initial Layer Bottom Layer Flow

These three new settings can help you tune the flow in your initial layer. You can see their effect in the flow color scheme in your preview.

You can see their effect in the flow color scheme in your preview.

Additional improvements

The following improvements have also been implemented in Ultimaker Cura 5.2:

Building from source is now more accessible to Mac, Windows, and Linux users. If you want to contribute, it’s easier than ever to get started. Read more about it here.

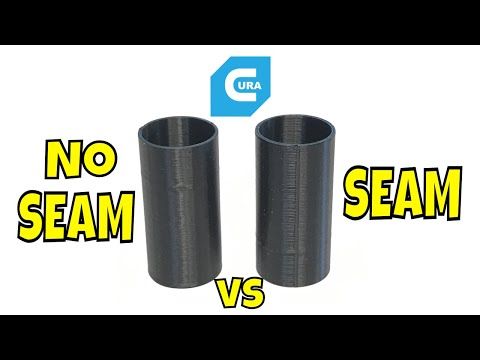

Fixed a bug so that the random Z-Seam setting is now more random

Fixed a bug where tree support had infill by default where it was supposed to be hollow

Fixed a bug where Windows users saw pointless notifications when they left Ultimaker Cura running in the background

Download now

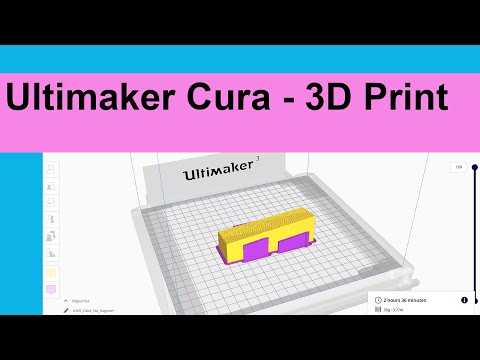

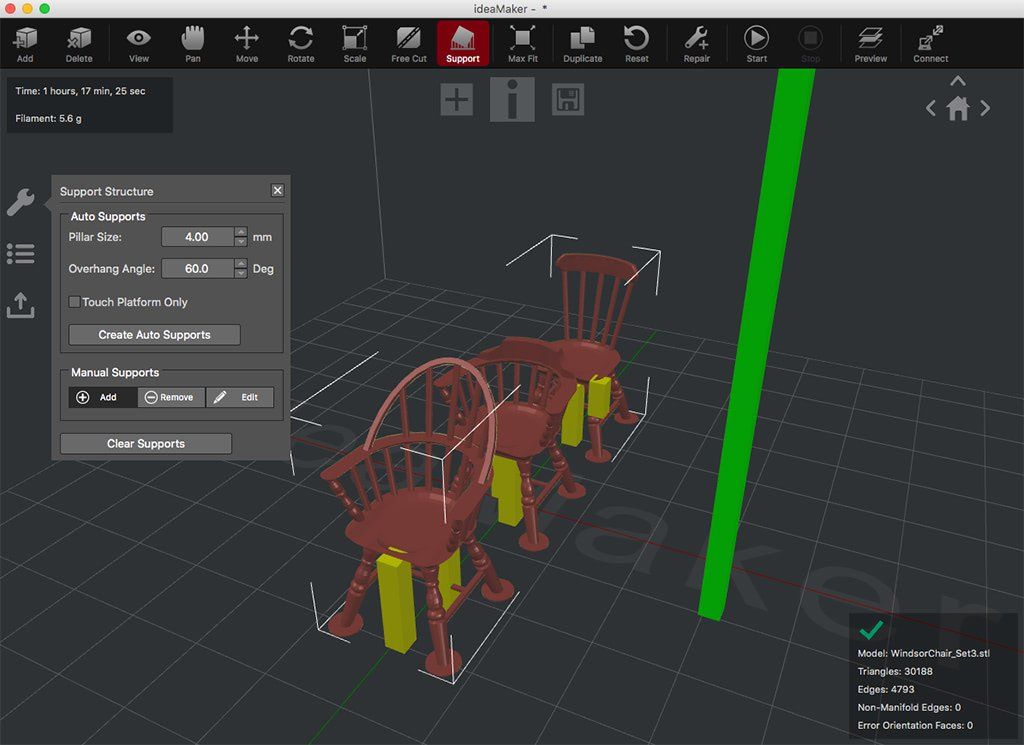

Cura 3D tutorial for beginners

3DPrintStory 3D printing process Cura 3D tutorial for beginners

Cura 3D is such a handy slicing program that many users don't even realize what they are doing. Simply upload your model, select the 3D print quality and start printing. It's as easy as printing with a regular 2D printer.

Simply upload your model, select the 3D print quality and start printing. It's as easy as printing with a regular 2D printer.

Intro

Basically, Cura 3D is a 3D printing program - a method of transferring a digital file from your personal computer to a 3D printer so that the latter can process the data and start printing.

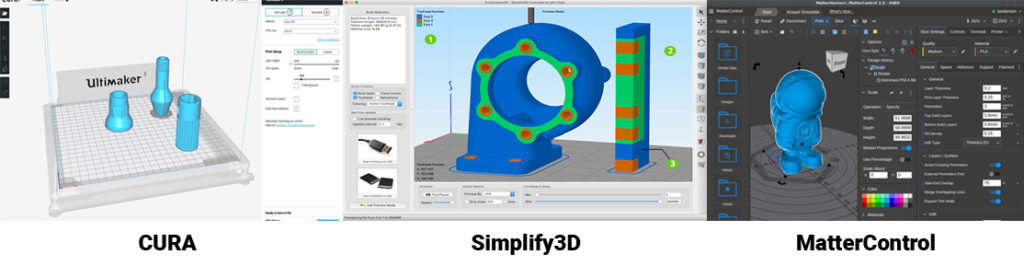

Compared to many other slicing programs, Cura 3D seems extremely simple. But if you need more flexible settings, they are also there. It's just that the user interface is implemented really competently and conveniently.

Cura 3D is developed and maintained by Ultimaker, a 3D printer manufacturer known for its perfectionism and strong support for the open source movement. There are a lot of manual settings, but they are hidden from the user (not really that deep), so if you are one of those who are interested in experimenting or need certain non-standard 3D printing settings, you can implement them.

For those who just want to print a part, just adjust the speed and quality.

This tutorial is aimed at those who are just getting started with their 3D printer. We assume that you have just turned on the printer and loaded the media. From now on, we will look at the necessary steps in Cura 3D to start 3D printing.

What is Cura 3D?

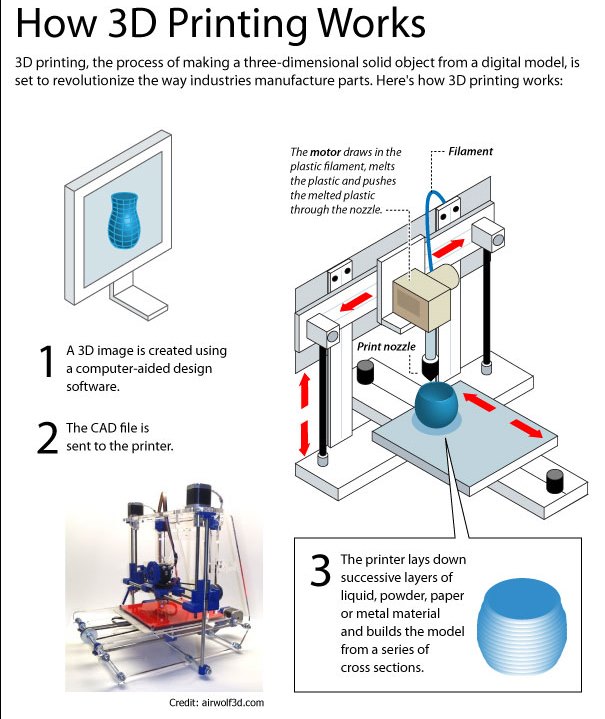

Cura 3D is a slicing software for 3D printers. Cura takes a 3D model as input and forms separate vertical layers to create a G-coded file that your 3D printer understands.

Before getting started with Cura, it's worth understanding the entire process of preparing a 3D model file. Even if you use ready-made 3D models, there should be a general understanding.

Three main steps in preparing files for 3D printing:

- Modeling. Modeling (formation of a virtual solid 3D model) is implemented in special applications like 123D Design or SketchUp, etc. These applications support their own specific file formats and allow you to open, edit, save, and export these files.

- Export 3D model file. After you have created your model, it must be exported to an STL or OBJ file. These formats are supported by Cura 3D. They differ from native 3D modeling application formats in that they only contain information about the final geometry, without separate nodes and editable content.

- Slicing file export. STL or OBJ file can be imported into Cura 3D, where it is processed and G-code is generated as output. G-code is just a text document, with commands that a 3D printer follows. For example, the temperature of the extruder, movement to the left, right, etc. are indicated.

The first step is to develop a solid model, but if you have no such experience, don't worry, on Thingiverse, Youmagine you will find a huge number of finished models. There are other sites where you can download models for free 3D printing. As a rule, in such repositories, models are already exported in STL format, so you can immediately import them into Cura 3D.

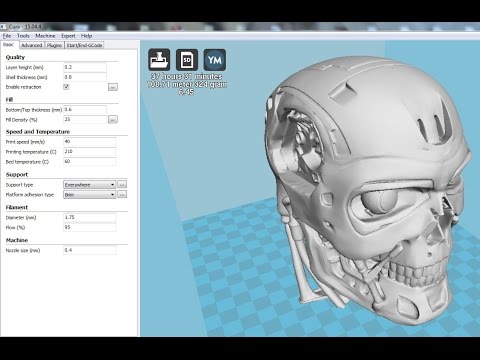

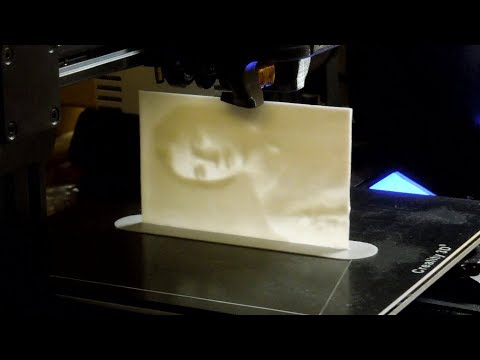

What exactly does Cura3D do?

Cura 3D converts a .stl or .obj file of a 3D model into a format that the 3D Printer can process. FFF 3D printers form each new layer on top of the previous one. Cura 3D takes a 3D model, cuts it into layers, and feeds those instructions to the 3D printer, layer by layer.

These instructions are transmitted as a G-code, a text document with a .gcode extension. If you open the file, you can view the code itself and even understand the commands.

For example, here is a small piece of code:

G0 F7200 X19.698 Y28.262 Z.36 G1 F1500 E0 G1 F1350 X22.467 Y26.175 E0.15654 G1 X23.338 Y25.568 E0.20447 G1 X24.246 Y25.027 E0.25218

Over time, as you become more familiar with 3D printing, you will be able to adjust the speed of the coolers, the height of the layers, the temperature of the extruder at different points. This is a very useful skill for troubleshooting some 3D printing issues.

Since each 3D printer has its own characteristics: print volume, table area and nozzle diameter, Cura 3D needs to know these parameters in order to correctly generate the G-code.

After you specify the design features of your 3D printer model, you can proceed to the settings for the height and layer thickness. Only then will Cura 3D be able to generate a valid G-code with motion path calculations.

The resulting G-code can be saved to an SD card or transferred to 3D printing via WiFi (depending on the interface that your 3D printer supports).

Getting Started with Cura 3D

In this part of the article, we will explain how to get started with Cura 3D. Namely - downloading and installing, optimizing your .stl and .obj files for further export to G-code.

Step 1: Install Cura 3D

Cura 3D is a multi-platform program that is available for Linux, Mac and Windows OS. All versions can be downloaded free of charge from the Ultimaker website.

You will download a file that will install Cura 3D. The installation procedure may differ slightly depending on your OS. In this tutorial, we used Cura 3D version 2.3.1.

- Launch Cura 3D.

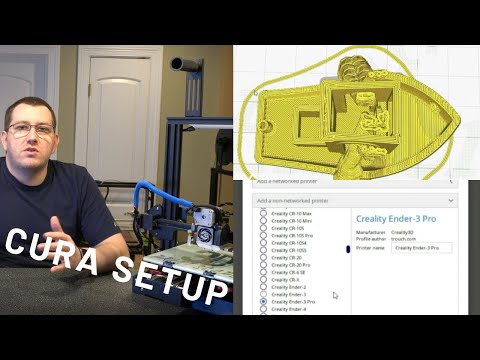

- Select your 3D printer model. The first time you launch Cura 3D, it will ask you to select your printer model. If you have Ultimaker or Lulzbot, then they come with a special version of Cura 3D with ready-made settings. If not, or if you want to set up a new 3D printer, then after loading the program select ' Select -> Printer '.

The 3D printer selection menu will load. If you downloaded the program from the link above, then all available printers will be Ultimaker. To select another model, press Other . If you're lucky, your 3D printer will be on the list.

If not, you can go to your printer manufacturer's website and look for a custom version of Cura 3D to download. If it is not there, then select Custom -> Add Printer .

A window will open with the option to add 3D printer settings. At this point, you will need information about your model. Again, you can probably find this information on the manufacturer's website. And if you assembled a 3D printer yourself, then you probably remember all the parameters!

And if you assembled a 3D printer yourself, then you probably remember all the parameters!

Enter all required parameters and click Finish .

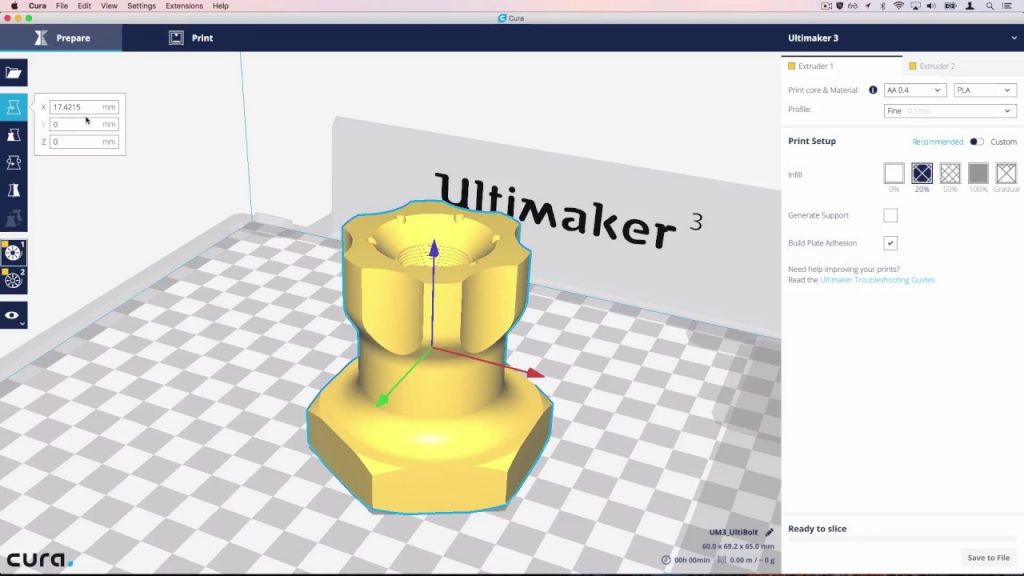

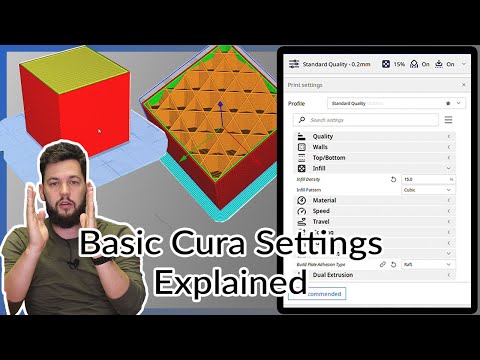

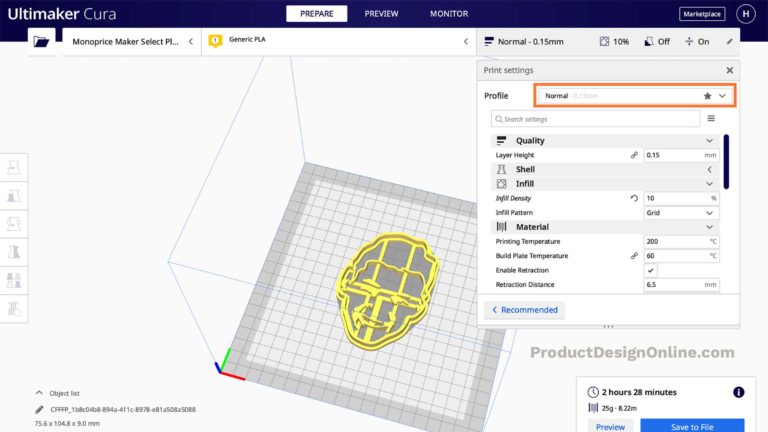

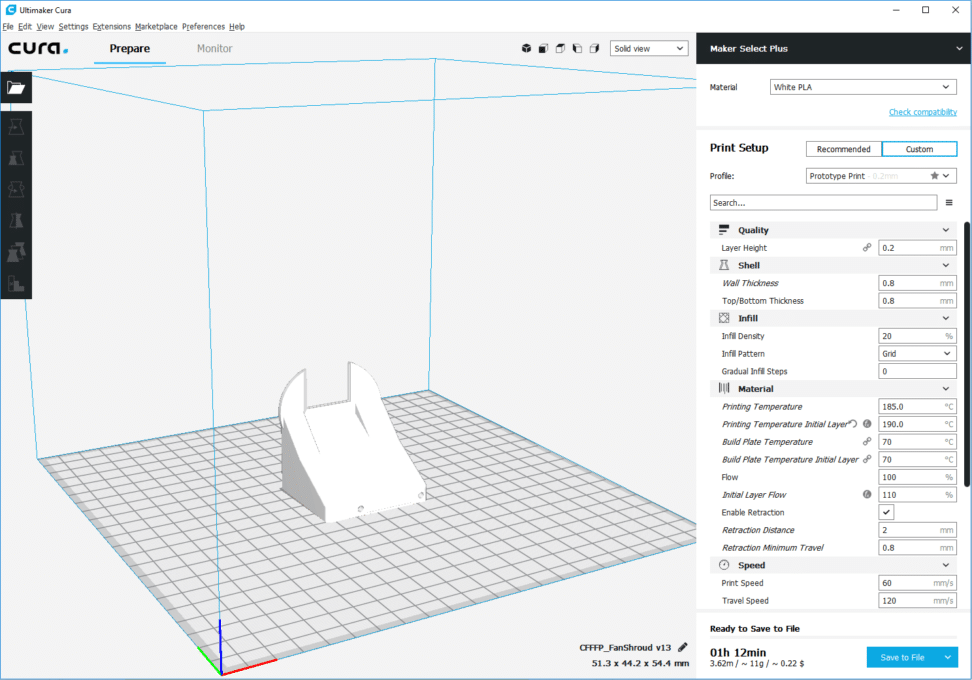

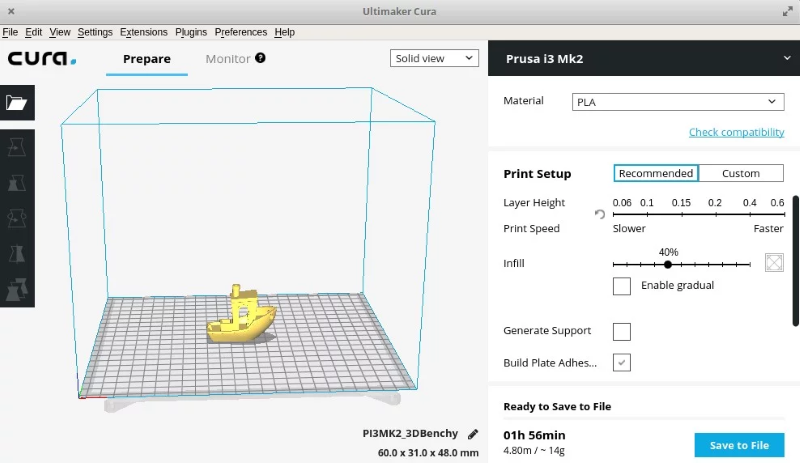

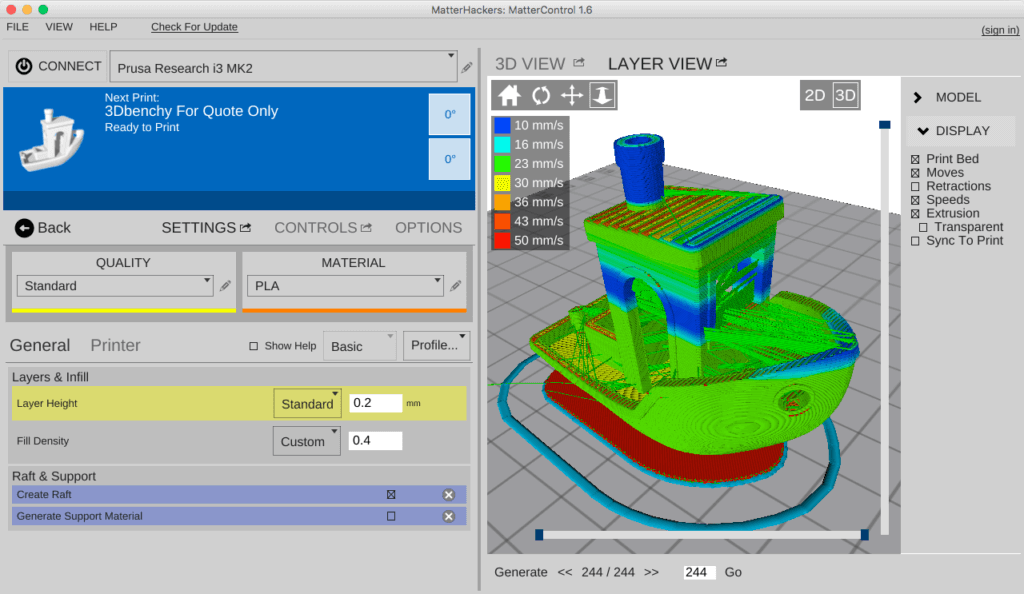

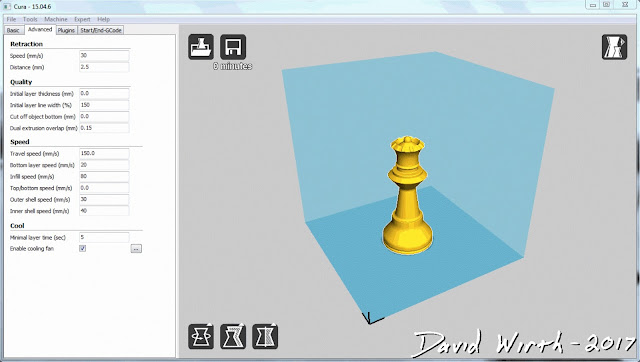

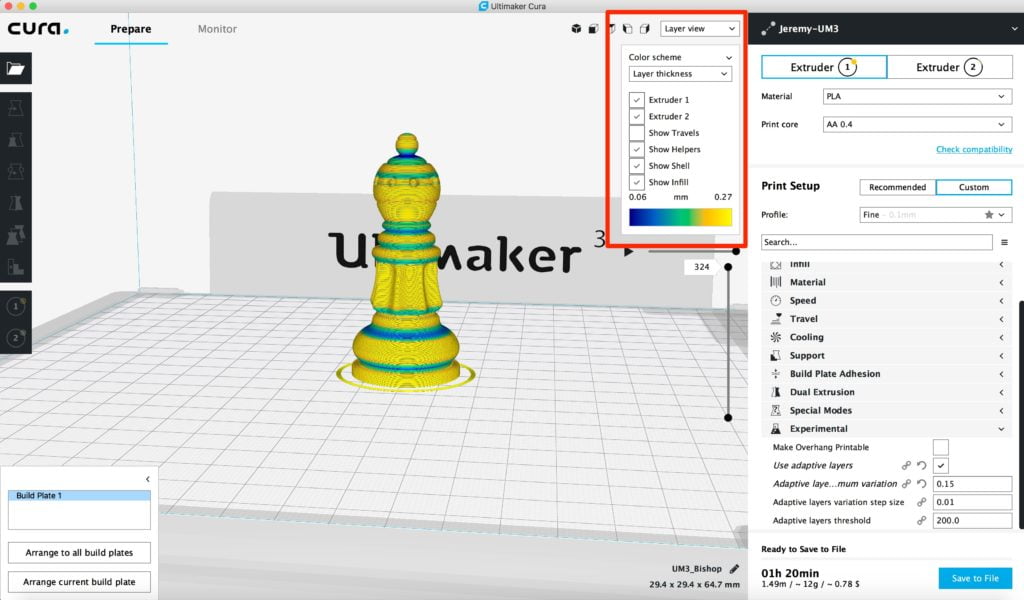

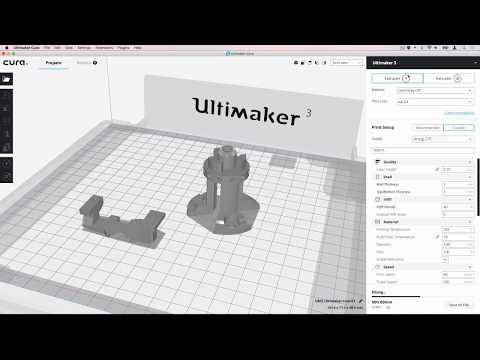

Step 2: Overview of the Cura 3D interface

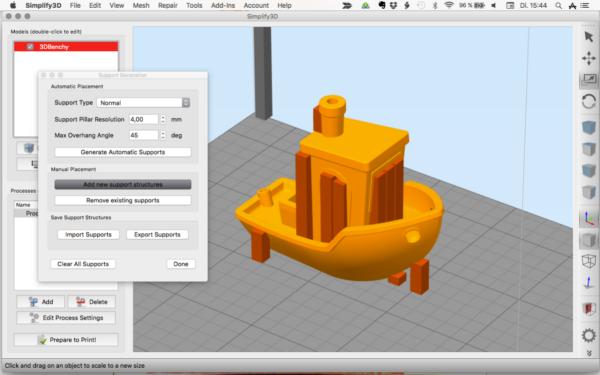

The screenshot below shows the main blocks of the Cura 3D interface.

Block

Top Navigation- Open File : Use the button in the top left corner of the menu or the option File -> Open File to open your .stl or .obj file.

- Edit : Use to select all models, delete or merge 3D models. Standard, useful commands.

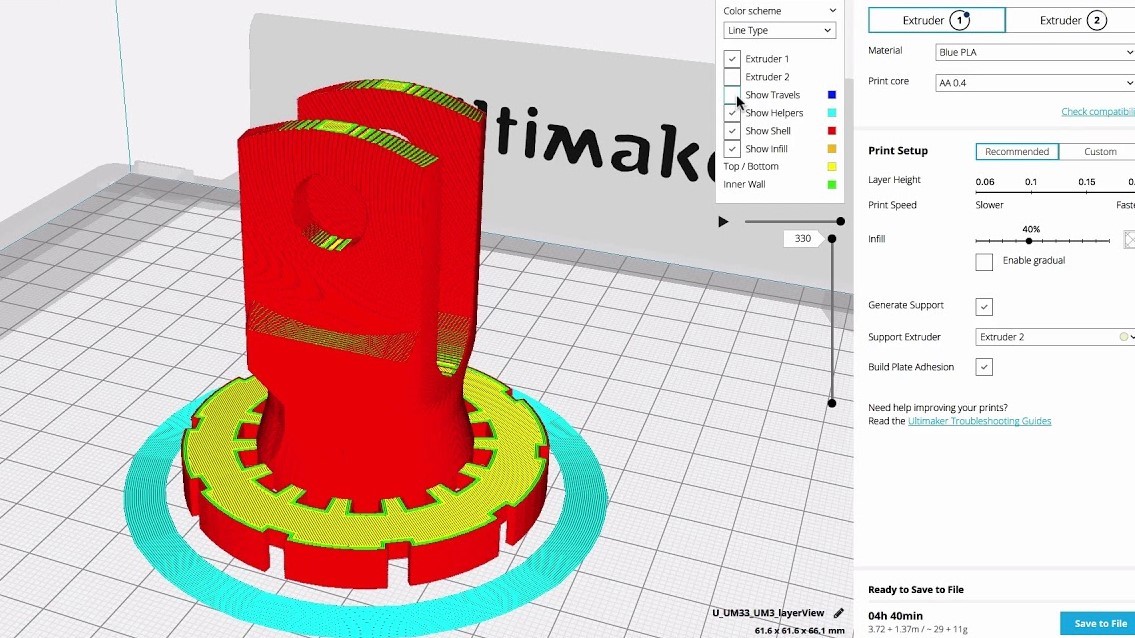

- View Mode : This button allows you to switch between Solid, X-Ray and Layers views of the model.

- Settings : Opens the media and 3D printer settings.

- Extensions : This is for more advanced users. Allows you to install Cura 3D Extensions, which, for example, activate the ability to manually edit the G-code.

- Help : If you have questions, you can't figure something out - this is a great place for

Block

Tool bar (left)- Open File : Allows you to open the .stl or .obj file you want to print.

- Move : When clicked, arrows will appear around the selected model. Using the arrows you can move the model on the desktop.

- Scale : Increase or decrease the size of your 3D model.

- Rotate : A handy tool for adjusting the orientation of the model, its rotation.

- Mirror : When clicked, arrows appear around the selected model. Click to mirror the position of your model.

- Select Settings : A handy feature for adding frequently used settings to the sidebar. For example, you can display the wall thickness ( wall thickness ), model infill ( infill ) and speed ( speed ).

Active only for loaded 3D model.

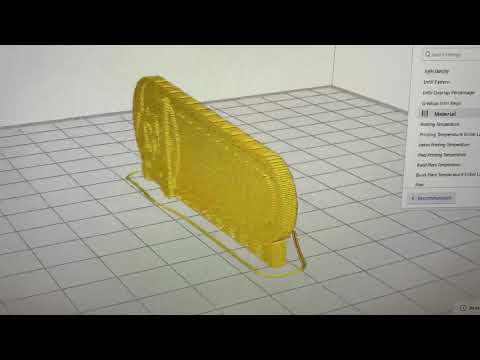

Active only for loaded 3D model. - View Mode . Solid X Ray and Layers . If Layers is selected, a slider will appear allowing you to "cut" the model into layers.

Settings Palette box (right)

In this box, you can adjust the print quality and select media.

Printer . This is the 3D printer you chose in the first step. If you have more than one 3D printer, they can be configured and selected from this list.

Material . Quick selection of the material that is used for 3D printing.

Profile . There are three available 3D print qualities: Low , Normal and High . Selected from dropdown. At the first stages, it is recommended to use the provided blanks. Over time, as you get comfortable with your 3D printer and printing, you can experiment and create your own profiles that suit you better.

Print Setup . There are two options - Simple (Recommended) and Advanced (Custom)

- Simple (Recommended) . Settings Simple (Recommended) ( Simple (Recommended) ) are pulled from the 3D printer settings you enter when you first start Cura 3D. This option is a great option for beginners or for the first launches of a new 3D printer model to see if the connection between the printer and the software is established. The number of settings is limited, but you can still quickly adjust the infill percentage of the 3D model, print table adhesion and add support material.

- Advanced (Custom) . This is where the main fan begins. With custom advanced settings, you can customize everything from quality to 3D print speed. We will explore this section and its capabilities later in the article.

Step 3: Processing the model in Cura 3D

Now that you are familiar with the Curs 3D interface, you can get to work. The first step is to upload the 3D model file. You can export your own model to STL or OBJ file or download from one of the sites with models for 3D printing.

The first step is to upload the 3D model file. You can export your own model to STL or OBJ file or download from one of the sites with models for 3D printing.

Loading a 3D file into Cura 3D:

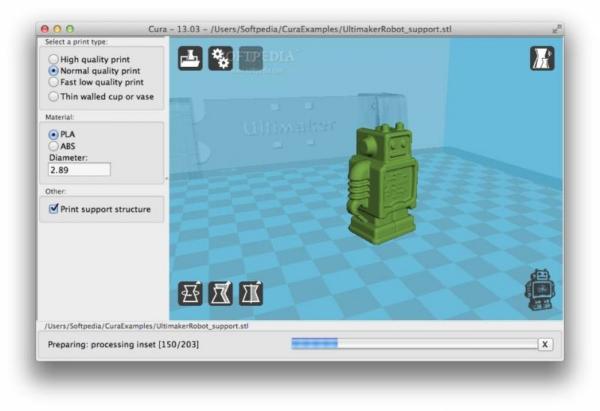

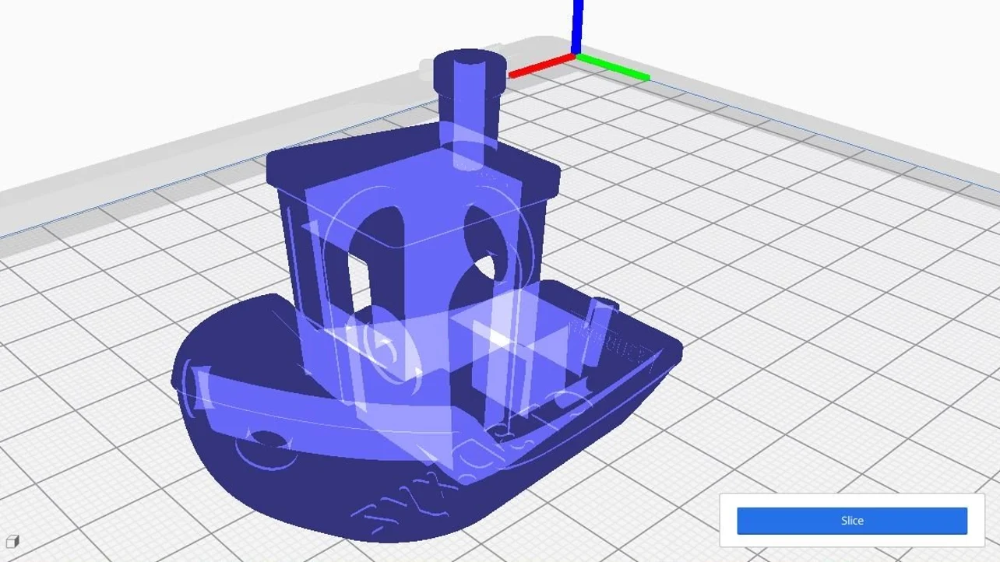

- Click on the "Open File" icon or use the menu File -> Open File and select the desired STL or OBJ file. For this tutorial, a 3DBenchy 3D model was used. This is a great model for testing new 3D printers or software.

- When the model has loaded, you can check if it is positioned correctly. If everything is OK, then the model will be highlighted in yellow. If there is a problem, it will turn gray and Cura 3D will tell you exactly why it is not possible to start printing.

It is also useful to learn the navigation options in the Cura 3D workspace.

Travel . Hold Shift and the left mouse button to move the workspace along the coordinate axes. This is a useful option when you are zooming in to check small details of a model.

Rotation . Hold Ctrl and left mouse button to rotate around the workspace. This is useful for checking the model from different angles.

Zoom (zoom) . If your mouse has a wheel on the middle key, use it to zoom. If not, then we recommend to buy :).

Different 3D model display options

Cura 3D has three basic model display options. Each option is useful in its own way, and if you're having trouble with 3D printing, one or the other option can help you sort it out.

Solid . This display is used by default and makes it possible to evaluate how the model will look after 3D printing. The dimensions and shape of the model are shown relative to your print table. As a general rule, if you have looked at the model from all angles and it looks good, 3D printing will be successful.

X-Ray . If you encounter problems during 3D printing, this display option will help you evaluate the internal structure of the model. Perhaps you will see what exactly needs to be reworked into details (for example, intersecting planes may appear inside).

Perhaps you will see what exactly needs to be reworked into details (for example, intersecting planes may appear inside).

Layers (Layers) . If you have a problem with 3D printing at the same point, or you just want to see a specific cut across a layer, you can use this option. The most accurate way to move between layers is to use the up/down buttons on the keyboard. There is a second option - to use the slider for a quick view. Over time, as you gain experience with 3D printing, this display option will help you to change settings in the G-code (for example, increase the speed of the cooler, adjust the height of the layer or the amount of material fed to the extruder) at the level of certain layers.

3D model setup for Cura 3D . If you need to tweak the model, all you have to do is click on it to highlight it and select one of the options from the toolbar on the left. Here you can quickly move, rotate and scale the model.

When you click on one of the options provided, arrows will appear around the model. Just grab the arrow or ring to apply changes in the direction you want. If you make a mistake right click and select R eset .

If you need to print more than one model, right-click on the base surface and select Duplicate . Cura 3D will automatically try to place the models as well as possible. If there is enough space to print two or more models, the platform will be yellow. If there is not enough space, the print space will be highlighted in gray.

Step 4: Simple (Recommended) 3D printing settings

The easiest 3D printing option is to let Cura 3D apply settings Simple (Recommended) . Although most of the settings will already be specified, you will be able to select the 3D print quality and specify the support material settings.

- Printer . Make sure your 3D printer is selected.

- Material . Make sure the 3D printing material is up to date.

- Profile . Select the 3D print quality.

- Infill . Hollow - printing will be as fast as possible, but inside the model will not be filled with material. Solid (Full filling) - the model will be with maximum rigidity due to full filling, but printing will take a lot of time and material. For starters, it is better to use the most versatile setting Light (Low filling) .

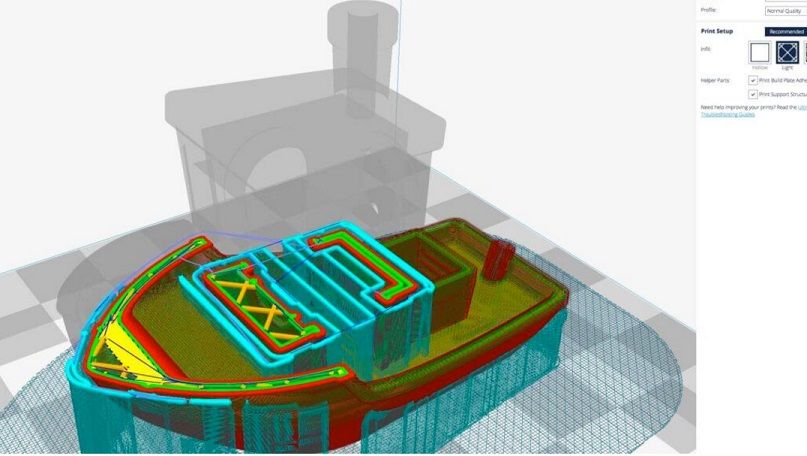

- Helper Parts These are the settings for the support material and adhesion. If you are typing for the first time, it is best to enable both options. If the contact area of your model with the print table is large, then you can disable option Print Build Paste Adhesion . If the model does not have sharp changes in angles and peculiar "overhangs" (for example, arms placed at 90 degrees in the human model), then you can disable the option Print Support Structure .

Step 5. G-code Generation

At this point your model is ready to be 3D printed and all you have to do is export the file from Cura 3D to an SD card or send it directly to your 3D printer. Cura 3D will take care of all the necessary steps to convert an STL or OBJ file into a G-code that your 3D printer will understand.

- Save the 3D model file . In Cura, press Save to file , Save to SD or Send to Printer .

- Estimate 3D printing time . Cura 3D will provide you with an estimate of the time it will take to print your model.

- Start 3D printing . If you transmitted the G-code directly, sit back and relax while your printer prints. If you are using an SD card, install it in your 3D printer and start printing.

Cura 3D Settings

Using Simple (Recommended) settings is just the beginning. Over time, you will want to implement more flexible settings. You can find these settings in the Advanced tab . We will review them below.

Over time, you will want to implement more flexible settings. You can find these settings in the Advanced tab . We will review them below.

Select Advanced (Custom) from the print preferences panel on the right.

- Quality . This is related to Layer Height (Layer height) . This setting depends on the capabilities of your 3D printer. The lower the layer height, the better the quality, and increasing the layer height will increase the print speed. By default, the layer height is set to 0.1mm for Ultimaker 2 Extended.

- Shell . This parameter controls the thickness of the walls of your model, as well as the thickness of the bottom and top layers. This parameter must be proportional (1x, 2x, 3x, etc.) to the nozzle diameter. For example, a wall thickness of 0.8, if you are printing on an Ultimaker 2 3D printer, will mean that the wall will consist of two lines, since this model has a nozzle diameter of 0.

4 mm.

4 mm. - Speed . Generally speaking, the lower the speed, the better the 3D printing.

- Cooling . An important component of any 3D printer and you definitely need to activate this option. As a rule, coolers do not operate at full capacity until the end of the 5th layer.

- Support . Allows you to add support structures.

- Build Plate Adhesion . Not all models have sufficient footprint to make good contact with the print bed. If so, this setting will help you make good contact with the substrate.

- Special Modes . If you are printing more than one model, this option will allow you to specify that they will be printed one by one.

3D Print Quality Settings

- Quality . Every 3D printer has a maximum and minimum material layer height. In this window, you can specify the desired layer height. 0.02 mm is high quality and slow 3D printing speed, and 0.

6 mm is the opposite, low quality and high printing speed.

6 mm is the opposite, low quality and high printing speed. - Shell . Choice of wall thickness. Thicker walls will allow you to print a more rigid model with a better surface. If a nozzle with a diameter of 0.4 mm is used, then the wall thickness must be set proportionally: 0.4, 0.8, 1.2 mm, etc.

- Top/Bottom Thickness . Again, as a rule, it is set in proportion to the size of the nozzle. One recommended practice is to start with twice the size of the nozzle diameter.

Material settings

- Material . Each material for 3D printing has its own characteristics. In most cases, the ability to use a particular material is determined by the structural components of a 3D printer, and not by software. So this setting is unlikely to be useful to you.

- Enable Retraction . It is recommended to always enable this option. Thanks to it, the material is fed in the opposite direction during the idle movements of the extruder.

Speed settings

- Print Speed . This is the overall speed of 3D printing during direct feed. Generally speaking, the lower the speed, the better the print quality. The recommended 3D printing speed is 60mm/s. If you want to increase this speed, it is recommended to increase the printing temperature at the same time ( Printing Temperature ).

- Travel Speed . This is the speed at which the print head moves when no media is being fed. On the Ultimaker 2, this speed is set to 120 mm/s by default. This speed is recommended to be set depending on the speed of direct printing. And to be more precise, it is 2 times more. In this case, acceleration and deceleration will occur smoothly enough to provide high-quality and at the same time fast printing.

Infill settings

Infill Density . This is the amount of material that is fed to the inside of the model. The higher the filling, the greater the rigidity of the model. As a rule, this parameter is set to 20%.

The higher the filling, the greater the rigidity of the model. As a rule, this parameter is set to 20%.

Cooling

Enable Fan Cooling . Disabling this option is not recommended. As a rule, no matter what material you use, cooling is necessary for high-quality 3D printing.

Support Material Settings

- Option Enable Support is best left unchecked unless you are 100% sure you don't have knots with sudden angle changes.

- Option Placement allows you to choose where exactly the supports will be located: Touching Build Plate means that the supports will be located only on the print table. Everywhere means that support structures can also be based on the part.

Bed adhesion settings

One of the most common 3D printing problems is when the model comes off the print bed. Buil Plate Adhision are the settings that help improve model-to-bed contact. There are three options for improved contact - Skirt , Brim or Raft .

There are three options for improved contact - Skirt , Brim or Raft .

Skirt . This is the setting that is best used at all times. This is the line around the 3D model during the first layer printing that helps clear the nozzle when the 3D print starts.

Brim . These are a few additional lines that are printed before the first layer of the model and provide better adhesion of the bottom layer of the model and the table.

Raft . Grid under the first layer of the 3D model, thanks to which the contact between the model and the table is significantly improved.

Each of the listed settings has additional options that will allow you to more flexibly adjust the quality of the contact between the 3D model and the print table.

G-code file generation

Once you have these settings, the model will be ready to print. All that's left is to export the file from Cura 3D to a card or directly to a printer. Cura 3D will convert the OBJ or STL file into a G-code that your 3D printer understands, just like when exporting in Simple (Recommended) mode.

Cura 3D will convert the OBJ or STL file into a G-code that your 3D printer understands, just like when exporting in Simple (Recommended) mode.

- In Cura 3D press Save to SD or Send to Printer .

- Cura 3D will give you an estimate of the time it will take to print your 3D model.

- Start printing and wait for your part to print!

We hope you found this Cura 3D beginner's tutorial helpful. Leave feedback, share your success in the comment form below. The discussion often generates new ideas and answers to questions that have not been covered in this manual.

Cura 3D Tutorial - How to use Cura Slicer

The Cura Beginner's Guide shows you step by step how to use Cura and choose the right settings for 3D printing.

Cura 3D is a slicing software with a user-friendly interface so user-friendly that many people don't know what it does. They simply load the model, select the quality and press the button. It's as easy as 2D printing.

It's as easy as 2D printing.

An Introduction to Cura 3D

Basically, all Cura 3D printing software is is a tool to produce a digital file for a 3D printer on a computer in a format that the 3D printing hardware understands.

Compared to other slicing software, Cura 3D seems to be very simple, with limited features and settings. However, more complex settings, if you need them, are available - they are just very cleverly hidden.

Cura 3D is backed by 3D printer developer Ultimaker, a company renowned for its hardware perfectionism. The program hides (but not too deeply) almost all the settings and options that can be found in most similar applications. So if you're the type who likes to fiddle around with settings, you might as well do it.

If you just need to print, change quality and speed, Cura 3D has these settings neatly exposed and you're good to go.

This tutorial is for anyone just getting started with 3D printing. Let's assume that you have just turned on the printer and loaded the filament. From now on, we will help you get started with Cura 3D and start 3D printing.

From now on, we will help you get started with Cura 3D and start 3D printing.

Great overview of 3D printer software - Cura comes first

What is Cura 3D?

Cura 3D is a 3D printer slicer that takes a 3D model and slices it into layers to produce a file known as G-Code, which contains codes that the 3D printer understands.

Before we look at Cura 3D, let's take a look at the printing process in terms of 3D files and how they are prepared. It's about converting a computer file into a 3D object, which can be confusing. So it's helpful to get an idea of what's going on, even if you don't have to take that first step.

There are three main steps in preparing files for 3D printing.

- Simulation. It's done in 3D modeling software like 123D Design or SketchUp, just two of the many examples out there. These applications have their own file formats, these programs allow you to open, edit, save and export data.

- Export 3D files.

After you have created a model, you must export it either to an STL or an OBJ file. These formats are understood by Cura 3D. They differ from 3D modeling application formats in that they describe only the final geometry, without individual parameters and editable content.

After you have created a model, you must export it either to an STL or an OBJ file. These formats are understood by Cura 3D. They differ from 3D modeling application formats in that they describe only the final geometry, without individual parameters and editable content. - Export sliced files. The STL or OBJ file can then be imported into Cura 3D, where it is sliced and converted into a layered structure called G-Code, which is essentially just a text document containing a list of commands for the 3D printer that the printer reads and executes: this hot end temperature, such and such movement to the left, such and such movement to the right, etc.

This step of the process involves 3D modeling, but if you don't know much about it, you can go to sites like Thingiverse or Youmagine and download one of the millions of printable models already available. They are usually offered in STL format and are ready for direct import into Cura 3D.

10 catalogs of 3D printer models - a selection of quality models

What does Cura do?

Cura 3D slices 3D models. It translates 3D STL or OBJ files into a format that the printer understands. Fused filament fabrication (Fused filament fabrication) 3D printers create 3D objects by printing them layer by layer. Cura 3D takes a 3D model, converts it into layers that will be laid out on the desktop, and creates a set of instructions for the printer - how it should work, layer by layer.

These instructions are G-Code, a text document with a .gcode extension. If you open such a file and see what is in it, you can see quite a lot of code and even figure out exactly what instructions are being sent to the printer.

Here is a piece:

G0 F7200 X19.698 Y28.262 Z.36

G1 F1500 E0

G1 F1350 X22.46.175 E0522 9057.3. .20447

G1 X24.246 Y25.027 E0.25218

As you get more comfortable with 3D printing, you can learn how to edit this code by manually changing the cooling fan speeds, layer thicknesses, and hot end temperature at different points in the model. This may come in handy in order to solve some problems that may arise with 3D printing.

This may come in handy in order to solve some problems that may arise with 3D printing.

Since each printer has its own setup system, work area, desktop, and nozzle size, Cura 3D needs to know these hardware parameters that make up the device profile in order to calculate the exact set of instructions to correctly print on your printer.

Once these fundamental parameters have been set and the filament type has been specified, the layer thickness and filament thickness can be specified. Next, it calculates the contours and path of the nozzle to print your model and calculates a set of instructions that Cura 3D saves in a G-Code file.

G-Code can be saved to an SD card or sent to a printer, either wirelessly or via cable.

Main problems and defects in 3D printing and how to deal with them

The Basics

In the first lesson, you'll learn the basics of working with Cura 3D, from downloading and installing it, to optimizing your STL or OBJ files to prepare them for export to print-ready G-code files.

Installation

Cura 3D is a multi-platform program with installers for Linux, Mac and PC. All versions can be downloaded for free from the Ultimaker website.

Download the file for your operating system and start the installation. In this Cura 3D tutorial, we are working with version 2.3.1.

- Launch Cura 3D.

- Select your printer model. The first time you launch Cura 3D, you will be asked to select a printer. If you have an Ultimaker or Lulzbot, they come with a special version of Cura 3D. If not, or if you want to configure a new printer, select Settings > Printer after launching the application.

Now you have to select a printer. If you downloaded the program from the link above, then all printers offered will be Ultimaker. For any other printer, select Other, and with any luck, your machine will be listed as well.

If you're unlucky - as, for example, in the case of the Lulzbot printer, go to the printer manufacturer's website, where you can find and download a special version of the program. If it’s past here too, choose Custom and Add Printer.

If it’s past here too, choose Custom and Add Printer.

You now have the Add Printer screen, and here you will need details about your specific device. These details can be found on the manufacturer's website, or if you built the printer yourself, you should know them by heart.

Just enter these details and click Finish.

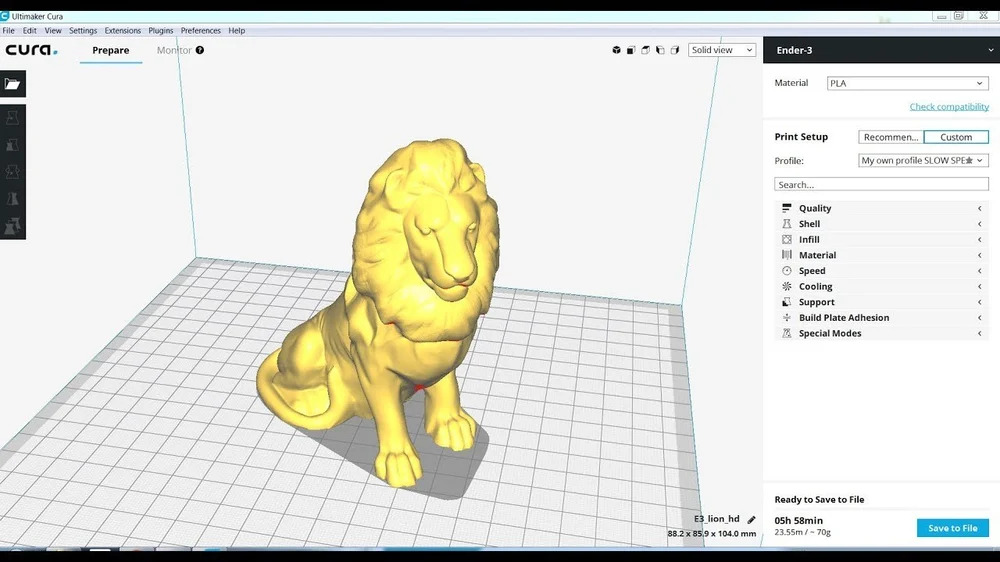

Cura 3D interface at a glance

This screenshot shows the main parameters of the Cura 3D interface.

Cura 3D top navigation

- Open file. You can open an STL or OBJ file by selecting File > Open File at the top left.

- Edit. This is for editing models on the desktop, removing them from it, for merging models. Basic but useful commands.

- View Mode. This menu item allows you to switch between viewing modes: Solid, X-Ray, Layers.

- Settings. Printer settings and media settings live here.

- Extensions. This is for advanced users who need to install Cura 3D extensions that allow manual G-code editing and more.

- Help. Help, of course.

Cura 3D Left Toolbar

- Open File. Loading STL or OBJ to prepare them for printing.

- Move. If you click here, arrows will appear around the selected model, allowing you to move it around the desktop.

- Scale. Increase or decrease the size of your 3D model.

- Rotate. Rotation.

- Mirror. If clicked, arrows will appear around the selected model, when clicked, the model is mirrored along the corresponding axis.

- Select Settings. Select frequently used settings to display in the sidebar (wall thickness, infill, speed). Tied to the loaded model.

- View Mode: Solid, X-Ray and Layers.

If you select Layers, a slider will appear that allows you to quickly scroll through the layers of the model.

If you select Layers, a slider will appear that allows you to quickly scroll through the layers of the model.

Cura 3D right toolbar

It is divided into two sections, labeled at the top with the icons of material (Printing settings) and printer (Printer settings).

Printer Settings

This section provides detailed information on media and print quality settings.

Printer. This is the printer selected in the first step. If you have more than one printer, then the desired one is selected from the drop-down menu.

Material. Quick selection of media used by the printer. This option is for printers that have media linked to them and is not available if this feature is not available.

Profile. The Ultimaker comes with three print quality profiles: Low, Normal and High. They can be quickly selected from the drop-down menu. As you become more familiar with the program, printer, and printing process, you will be able to create profiles yourself that are better tailored to the type of object and model being printed.

Print Setup. Two options for setting up the print process: Simple (Recommended (Mac)) and Advanced (Custom (Mac))

Simple (Recommended)

The Simple (Recommended) mode is calculated based on the Cura 3D settings you previously entered for your printer. This is a great choice not only for beginners, but even for more advanced users who are just getting started with a new printer and want to see how software and machine interact. The number of settings here is limited: you can quickly change the infill, grip with the table and the main structures of the supports.

Advanced (Custom)

This is where the real fun begins! You can change a lot of printer settings - from print quality to speed. We will look at these possibilities a little later.

Working with the model in Cura 3D

Now that you've become familiar with the Cura 3D interface, it's time to start loading your 3D file. You can choose either a self-created model and an STL- or OBJ-file exported from it, or download it.

You can choose either a self-created model and an STL- or OBJ-file exported from it, or download it.

Loading a 3D file into Cura 3D

- Open the desired STL or OBJ file by selecting File > Open File at the top left. In this case, we are working with 3DBenchy - a great model for testing a new printer or program.

- The model is loaded and let's look at its location, if it needs to be moved. If everything is in order, the model will be highlighted in yellow. If there is a problem, the highlight will be gray and Cura 3D will tell you why the model cannot be printed.

The first thing to do is to check the printed object and make sure it fits on the desktop, ie. on the print platform. Here it will be useful to get acquainted with the model view modes and navigation in the Cura 3D window.

Moving the Cura 3D desktop. To move the desktop around the screen, hold Shift and the left mouse button. This is often useful to take a closer look at the model and check for some small details - just to make sure everything is in order and in the part of the object that, due to scaling, does not fit on the screen.

Rotation around the Cura 3D desktop. Hold down Ctrl and the left mouse button. So you can look at the model from different angles.

Enlarge or reduce the desktop. This is done with the mouse wheel. If you have a mouse without a wheel, it is highly recommended to purchase one with a wheel.

Different Model Views

Cura 3D has three main model views, each of which is useful in different situations, especially if you are having printing problems.

Solid. This is the (solid) default mode, which allows you to see the model as it will appear in the end. Here you can understand the relationship between the size and shape of the model and the desktop. Usually, if everything is fine, and you just looked at the model from all sides and perspectives, everything should print fine.

X-Ray. This option is useful when there are some problems with printing and you need to quickly look at the internal structure of the object. This mode is especially useful if your object has intersecting edges. X-Ray (i.e. "X-ray") will allow you to see problem areas.

This mode is especially useful if your object has intersecting edges. X-Ray (i.e. "X-ray") will allow you to see problem areas.

Layers (Layers). If the print is constantly interrupted in the same place, or if you have some tricky detail and you want to make sure everything goes as it should, switch to this (layered) mode. Fine movement through the layers is carried out by arrows; you can also use the slider. As you get more comfortable with the program and printing process, this option will come in handy to accurately select layers that require a G-code change to, for example, increase fan speed, layer thickness, or filament.

Operations with the model in Cura 3D. If the model needs to be moved or rotated relative to the platform, scaled or reproduced, simply click on the object to highlight it, and then select one of the functions in the left panel. So: move, rotate, scale.

When you click on any Cura 3D tool, arrows and circles appear around the model. You just need to hook one of the arrows or circles and pull in the right direction. If something went wrong, right click and click Reset.

You just need to hook one of the arrows or circles and pull in the right direction. If something went wrong, right click and click Reset.

But what if you want to print multiple copies of the model? Right clicking on the selected model offers the Duplicate option. Cura 3D will automatically redistribute the copies on your desktop. If there is enough space on the platform to print two or more objects, all models will be yellow. If there is not enough space, the emerging models will be highlighted in gray.

Print Settings Simple (Recommended)

The easiest way to print something is to set Cura 3D to Simple (Recommended). Although almost everything has already been done for you here, you can still change the quality and parameters of the props.

- Printer. Make sure the correct printer is selected.

- material. If the printer has media defined for it, select.

- Profile. Select the desired print quality.

- Infill. Hollow mode prints fast but without internal supports. Solid (solid) will produce the most durable model, but it will also print the longest, and the material will require a lot. For starters, Light is better.

- Helper Parts. These "auxiliary points" describe the props and platform grip. If you are printing for the first time, enable both. If your model has a lot of touch points on the desktop, it's best to turn off Print Build Paste Adhesion. If the model does not have overhangs (like balconies), turn off Print Support Structure.

Generating the G-code file

The model is now ready to be printed and all you have to do is either export the file from Cura 3D to an SD card or send it directly to the printer. Cura 3D will automatically convert STL or OBJ files into printer-friendly G-code.

- Save the 3D print file. Select Save to file or Save to SD or Send to Printer.

- Estimate of time for 3D print. Cura 3D will give you an estimate of how long it will take to print your object.

- Start the 3D print. If enabled, sit back and wait for the printer to warm up and start printing. If you saved the file to SD, remove the SD from the computer and insert it into the printer. Click Print, select a file and go ahead.

Cura settings

Using Cura 3D's Simple (Recommended) profile is just the beginning, but you can still get great prints. Over time, you will need a little more flexibility in the settings. The most advanced options are under the Advanced (Custom) tab. Here is a brief overview of what you can see there.

In the right settings panel, select Advanced (Custom).

- Quality. This is about the layer thickness. The value depends on your printer, but thinner layers provide better quality, larger layers provide faster speed. Layer Height (height, it is the same layer thickness) for the Ultimaker 2 Extended is set to 0.

1 mm by default.

1 mm by default. - Shell. This refers to the thickness of any of the walls in your model, as well as the thickness of the bottom and top layers. The Shell value is a multiple of the nozzle diameter. A thickness of 0.8mm means the walls will be two lines wide (because our Ultimaker 2 printer has a 0.4mm nozzle).

- Infill. Infill - the force structure of your model. The higher the density, the stronger, the more will be printed inside.

- material. Not all materials are the same, sometimes a little customization is required, which is exactly what is done here. As a rule, the only thing that needs to be changed is Retraction (retraction) in order to avoid excessive tension on the plastic thread. To avoid the most common problems, it is recommended to use a proprietary filament.

- Speed. This is about the speed of the print head. Generally, the slower the better the print.

- Cooling.

Cooling is an important thing for any printer, it must be turned on. Fans are usually fully turned on from the 5th layer.

Cooling is an important thing for any printer, it must be turned on. Fans are usually fully turned on from the 5th layer. - Support. If your model has overhanging elements, this option should be active, and then with a simple click you can choose where to put the support.

- Build plate Adhesion. Not all models have a footprint large enough to securely grip the desktop surface. In this case, this setting will help the adhesion of the model to the substrate.

- Special Modes. If you are printing more than one model, this option lets the printer know whether to print them at the same time or whether they will be installed one after the other.

Quality settings

- Quality. Each printer has its own minimum and maximum layer thickness. Enter the desired layer thickness here. 0.02 mm is high quality, but also a long print; 0.6 mm - the quality is low, but the process is relatively fast.

- Shell. Wall thickness selection. Thicker walls are a stronger object that can usually be machined well. With a nozzle thickness of 0.4 mm, the proposed wall thickness will be a multiple of: 0.4 mm, 0.8 mm, 1.2 mm, etc.

- Top/Bottom Thickness. The thickness of the upper and lower layers is also a multiple of the nozzle diameter. For starters, you can choose a double diameter. This will help to avoid the most common problems - like "bloat".

Material settings

- Material. Each material has its own specifications and requirements, which, as a rule, are associated with the hardware of the printer, and not with the program. The only situation where you might need to change something here is if the print is underextruded.

- Enable Retraction. In Cura 3D, this option should almost always be enabled. It is about drawing the filament back into the nozzle so that when the print head moves, no webs appear.

Speed settings

- Print Speed. This is the overall print speed as the filament is extruded. The slower, the usually better quality. The speed can be increased (recommended value is 60 mm/s). If you increase the speed, it is useful to increase the print temperature as well.

- Travel Speed. This is the print head movement speed. On the Ultimaker 2 it is set to 120mm/s. The movement speed is related to the previous parameter and must be a multiple of it. In such a case, accelerations and decelerations occur more smoothly, for example when changing from infill printing to wall printing.

Infill settings

Infill Density. The infill density is the amount of material that is consumed by the support structure within the model. The higher the density, the higher the strength. Usually 20% is set here.

Cooling

Enable fan Cooling. It is not recommended to turn off cooling, as this will lead to distortion of the part and other unpleasant effects.

Support settings

- It's usually useful to enable supports (Enable Support) unless you're sure nothing is hanging or floating anywhere.

- The Placement option determines the location of the supports: Touching Build plate means that the supports have only a build plate base; Everywhere means that they can be anywhere, incl. on the model and inside it.

Plate Adhesion Settings

The situation where the printed object does not adhere enough to the substrate is very common, and the Build Plate Adhesion option is just provided in order to increase this adhesion by adding "skirts", "edges" and "rafts" ".

Skirt. It's good to have at least a "skirt" - a line around the first layer of the object, which simply helps to position the extruder.

Brim. "Edge" is just an edge, a couple of extra lines directly on the bottom of the object to increase its area, as well as to minimize distortions.